Flange nut-washer assembly

A technology of flange nuts and assemblies, which is applied in the direction of nuts, threaded fasteners, screws, etc., which can solve the problems of inconvenient operation of flange nuts and washers, improve the anti-loosening effect of the base, improve the locking effect, and eliminate the thread pitch The effect of half-angle error of sum tooth profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

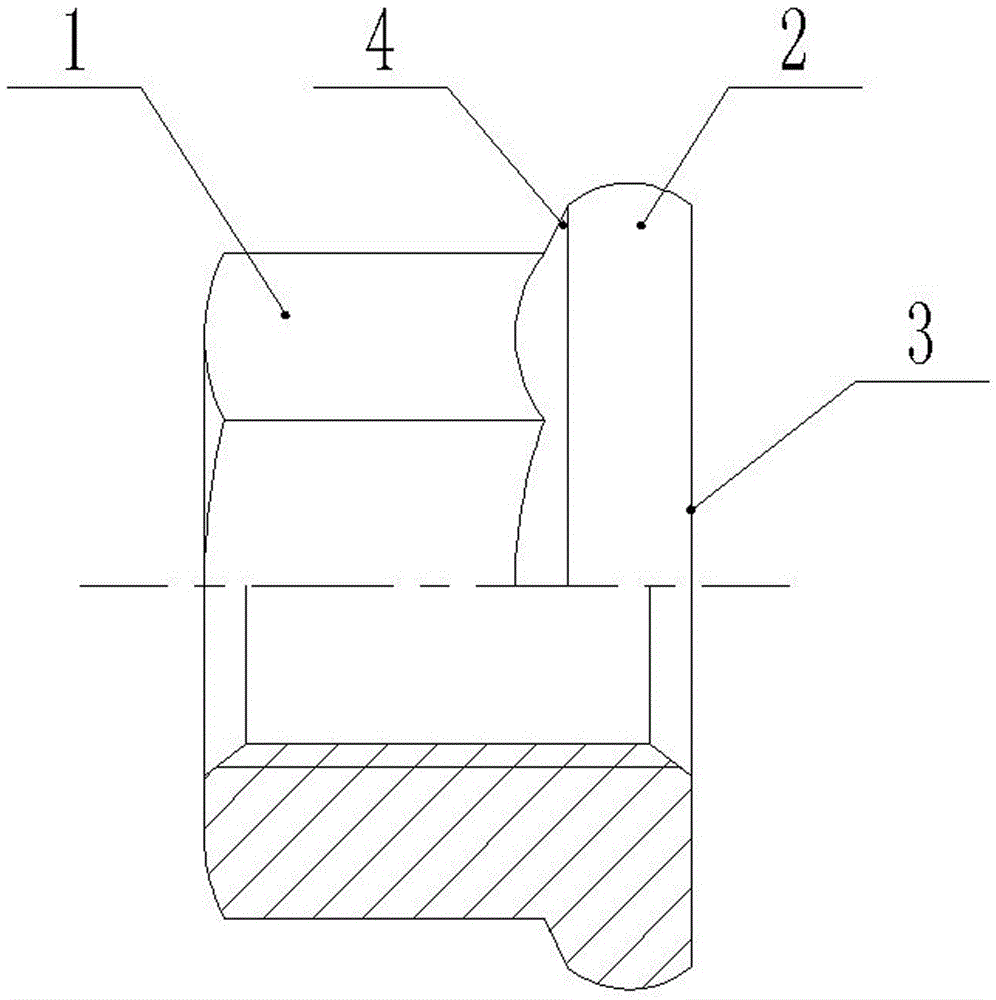

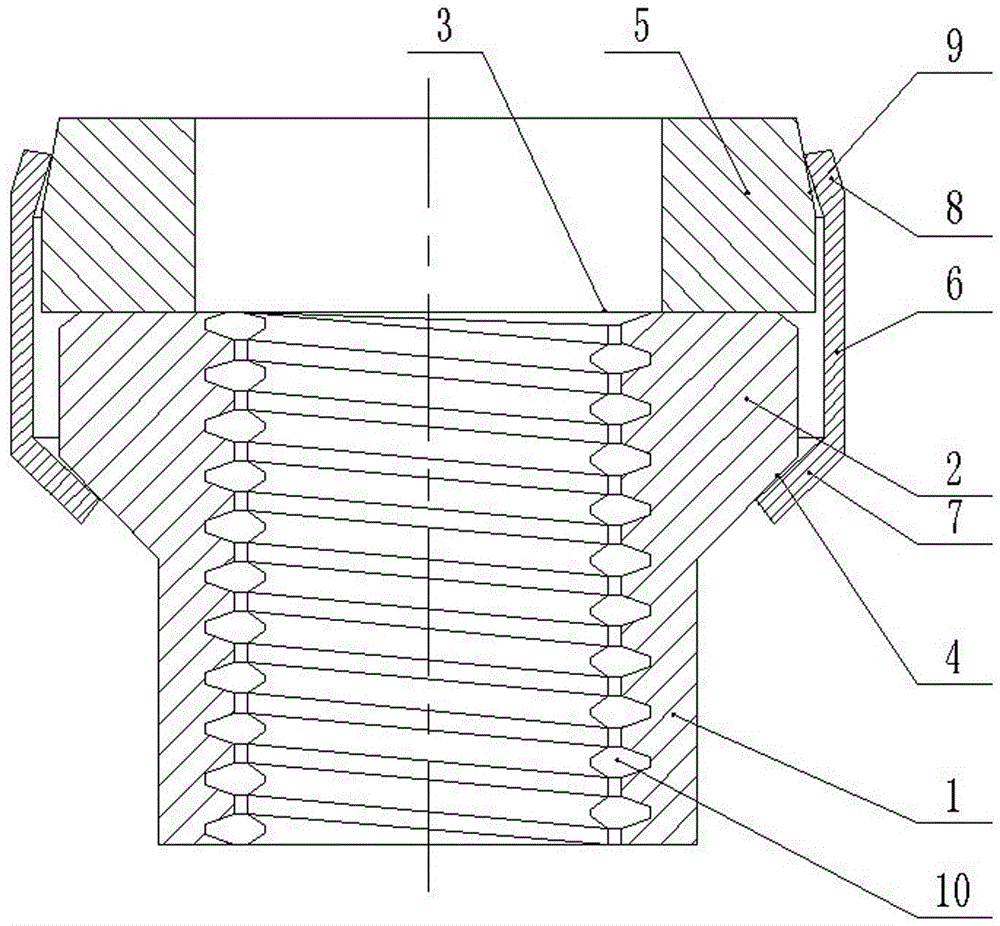

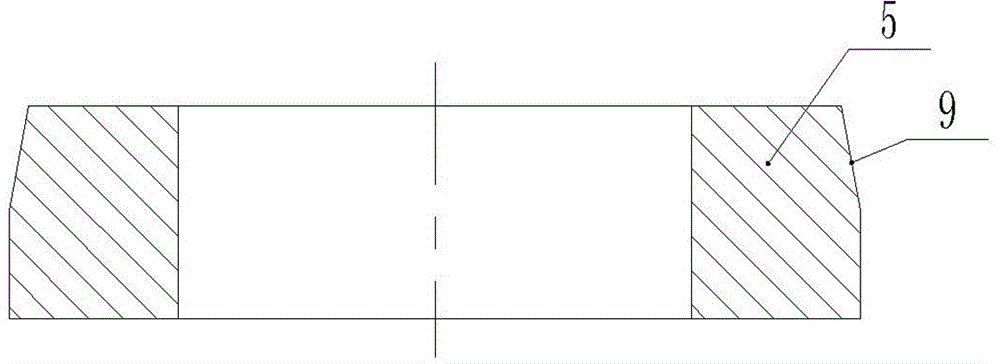

[0019] Specific embodiments of the flange nut washer assembly of the present invention, such as Figure 2 to Figure 6 As shown, among them, 1 is the hexagonal section of the hexagonal flange nut, 2 is the flange section of the hexagonal flange nut, 3 is the flange end face of the hexagonal flange nut, 4 is the ring skirt of the hexagonal flange nut, 5 is the washer, and 6 is the Bushing, 7 is the first pressing part of the bushing, 8 is the second pressing part of the bushing, 9 is the outer chamfer of the washer, and 10 is a locking type wire screw sleeve.

[0020] The washer 5 is arranged coaxially with the hexagonal flange nut, the end face of the washer 5 is attached to the flange end face 3 of the hexagonal flange nut, and the washer 5 is far away from the end of the hexagonal flange nut (ie figure 2 The upper end shown) is provided with the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com