Split type vortex street effusion meter

A vortex flowmeter, a split-type technology, applied in the direction of volume/mass flow generated by mechanical effects, dynamic effects by detecting fluid flow, etc. Effects of Interference Ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

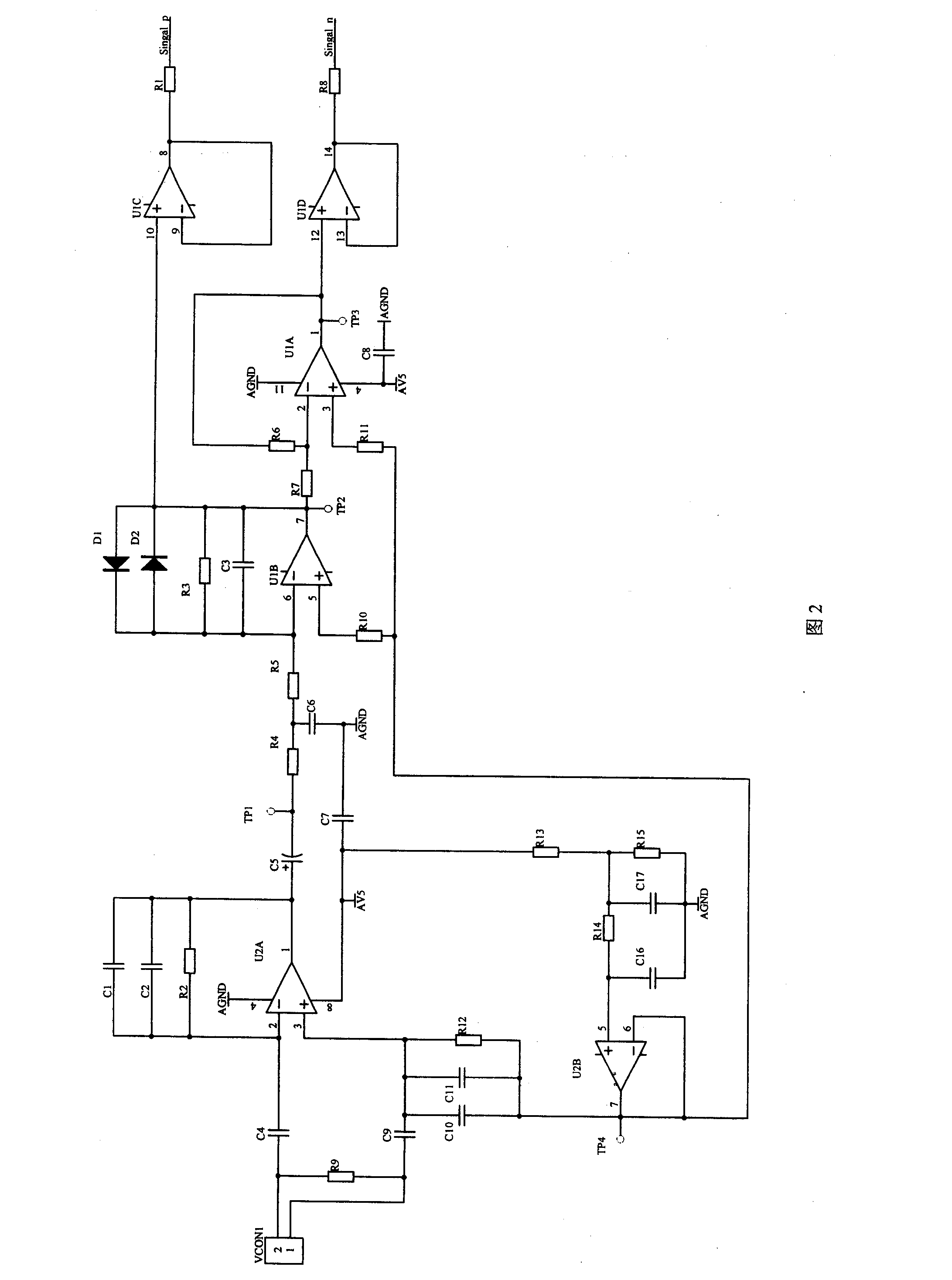

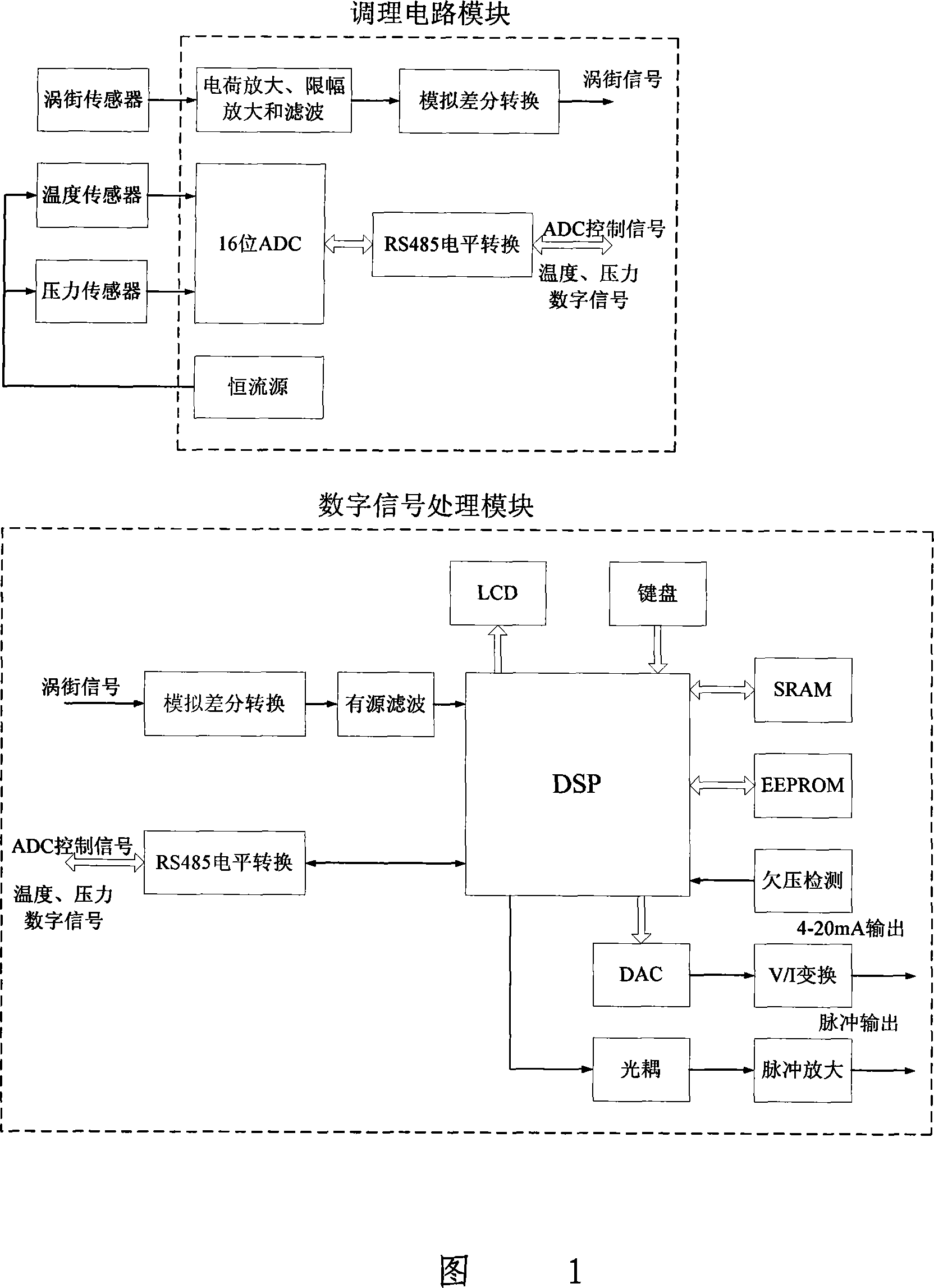

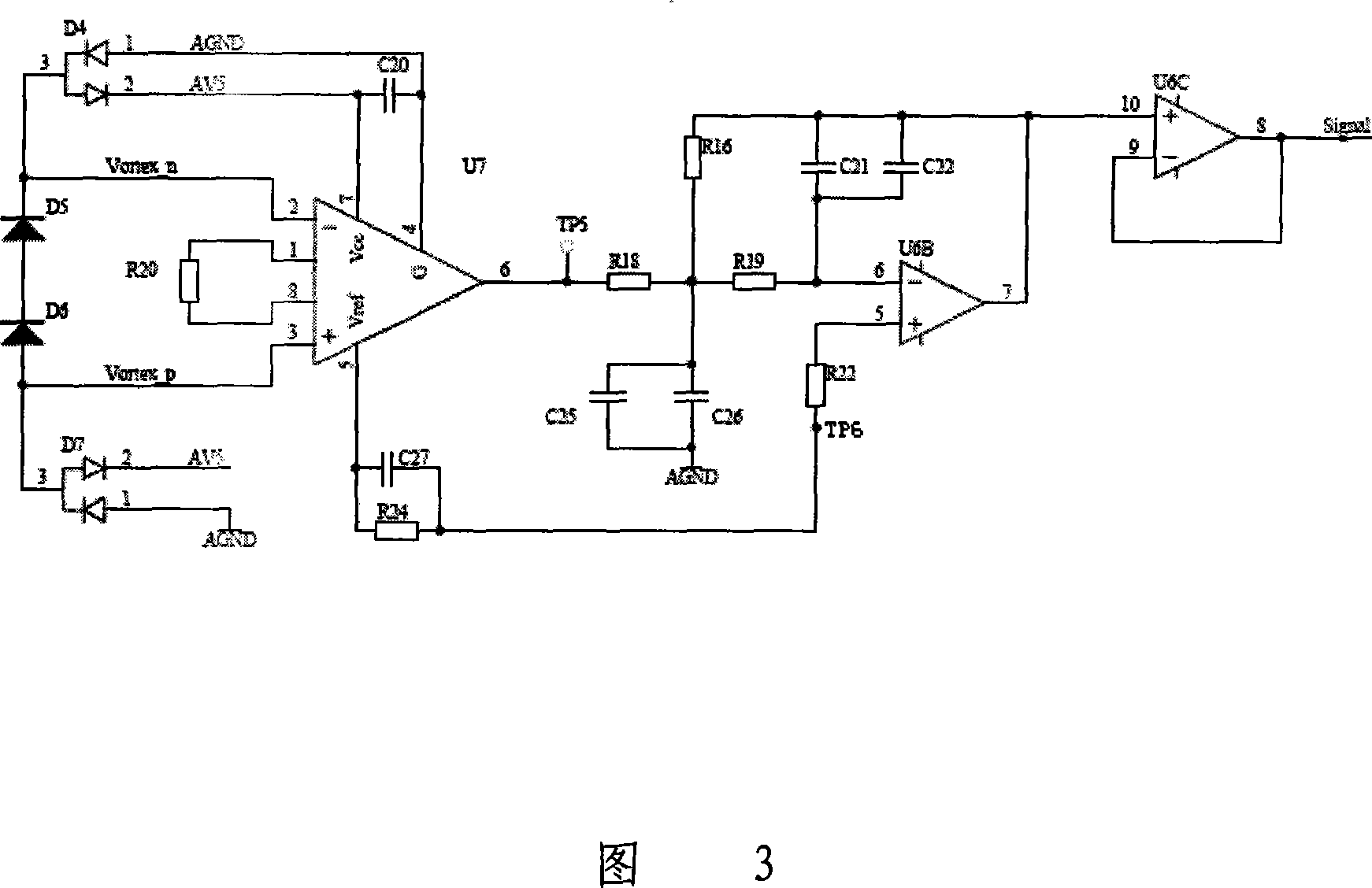

[0034] The invention will be further described below in conjunction with the accompanying drawings.

[0035] The design concept of the present invention is to separate the vortex flow sensor, temperature and pressure sensor and conditioning circuit module from the digital signal processing module, and connect them with a shielded cable. Place the sensor and conditioning circuit on the site to be tested, while the digital signal processing module is placed at a normal temperature away from high temperature. This is because the output signal of some sensors is very weak and the output impedance is high, and direct long-distance transmission will be disturbed by noise. Therefore, the sensor and the conditioning circuit module are made in a meter and placed on the site under test. However, even if devices such as DSP work at normal temperature, their own temperature will be tens of degrees higher than the ambient temperature. If they work in an environment of 100°C, their core wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com