Production method for glasses with secondary-injected nose support and structure of glasses

A production method and secondary injection technology, applied in the field of glasses, can solve problems such as discomfort, complicated installation, long-term wear indentation, etc., and achieve the effects of improving comfort, improving efficiency and saving labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

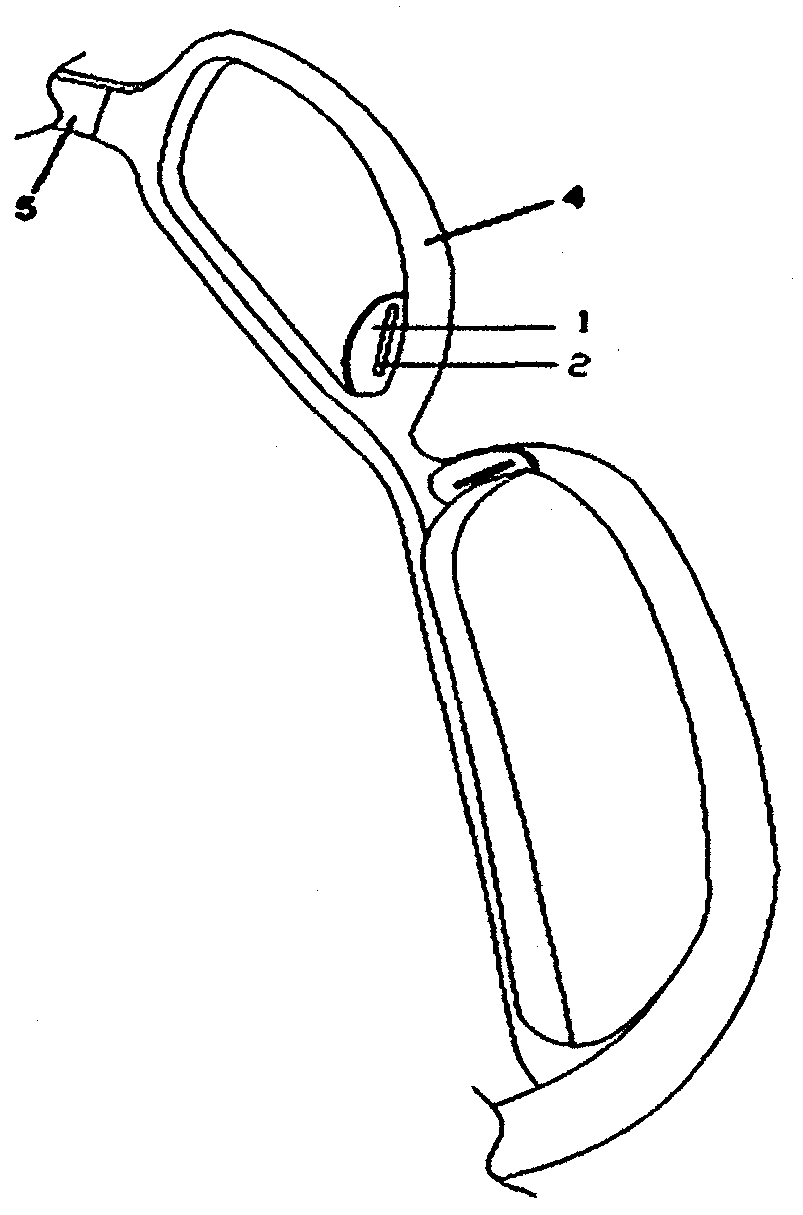

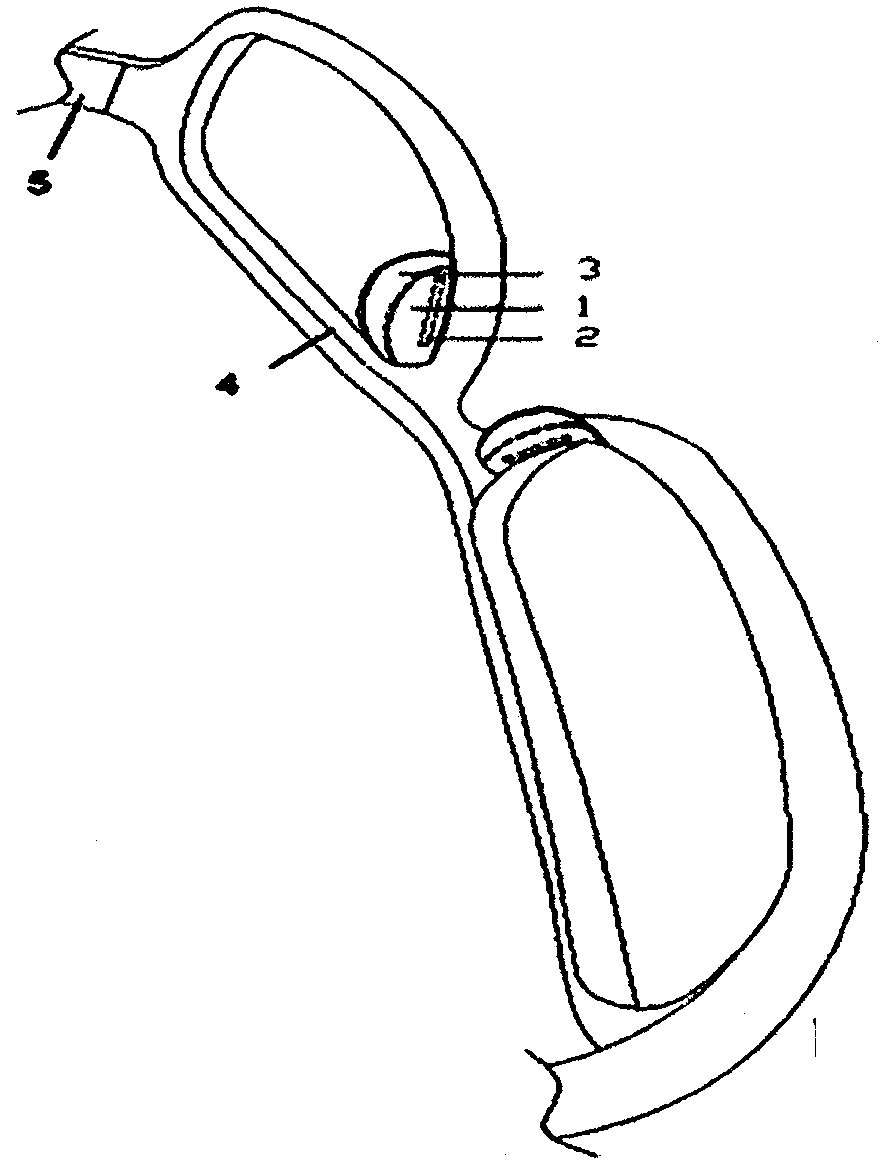

[0016] A kind of production method of secondary injection nose pad glasses of the present invention, its steps are:

[0017] 1) In the spectacle frame mould, the spectacle frame raw material polylaurolactam (referred to as PA12) is injected at a temperature of 150°C-220°C into the spectacle frame with nose pad fixing bumps, cooled and shaped and trimmed. Paint (or essential oil) after finishing;

[0018] 2) Place the nose pad fixing bump of the formed spectacle frame at the corresponding position of the nose pad mold, inject the nose pad raw material (HA60) at a temperature of 150°C-220°C for a second time, and inject the nose pad on the The nose pad of the spectacle frame is fixed on the bump, cooled and fixed for molding, and finely polished after molding;

[0019] 3) Inject the temples into the temple mold, cool the molding, demould and trim, and then paint and spray paint (or essential oil) after trimming;

[0020] 4) Assemble finished glasses frames and temples.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com