Process for producing a multilayer coating

A coating and coating technology, applied in the direction of coating, metal material coating process, device for coating liquid on the surface, etc., can solve the problem of not being able to provide adhesion to metal substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

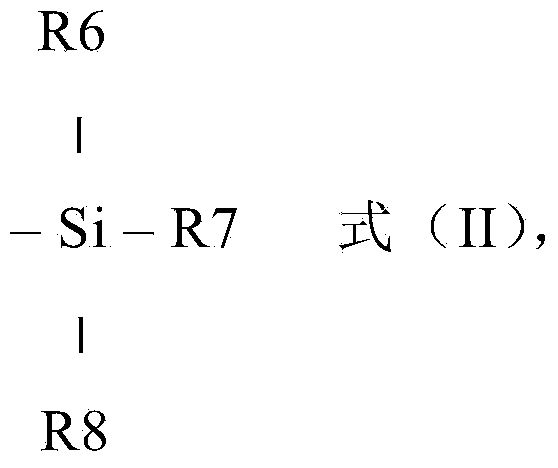

[0066] According to one embodiment, the surfacer coating composition comprises at least one compound comprising at least one alkoxysilane group and at least one epoxy group (epoxysilane compound). The epoxysilane compound can be a monomeric, oligomeric or polymeric compound. Examples of suitable monomeric, oligomeric or polymeric epoxysilane compounds are those having at least one alkoxysilane group according to formula (II).

[0067]

[0068] wherein R6, R7, R8 are the same or different organic groups having 1-30 carbon atoms per molecule, with the proviso that at least one of the residues R6, R7 and R8 is an alkoxy group having 1-4 carbon atoms base.

[0069] In addition to the alkoxysilane groups, monomeric, polymeric and oligomeric alkoxysilane compounds also contain at least one epoxy group. The epoxy silane compound is preferably a monomeric compound, more preferably a compound of general formula (III):

[0070]

[0071] where Z represents residues where m is 1-...

Embodiment 1

[0096] Example 1 - Preparation of pretreatment composition

[0097] Pretreatment compositions 1.1 and 1.2 were prepared with the ingredients shown in Table 1.

[0098] Table 1

[0099]

[0100] In addition to this, commercially available pretreatment composition 1.3 and pretreatment wipes 1.4 and 1.5 were used:

Embodiment 13

[0101] Example 1.3: 5717S - Phosphoric acid based metal conditioner from DuPont Refinish

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com