Cationic branched-chain starch wood adhesive and its preparing method

A technology of wood adhesives and pullulan, applied in the direction of amylose/pullulan derivative adhesives, adhesive types, etc., to achieve the effects of improved stability, good cohesiveness, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] formula:

[0038] 100g tapioca starch 520g water

[0039] 30% NaoH 8 g Diethyldichlorosilane 1 g

[0040] Sodium hypochlorite 0.1 g Na 2 SO 4 10 grams

[0041] Pyridine 2 g

[0042]3-Chloro-2-hydroxypropyltrimethylammonium chloride 0.1mol

[0043] Preparation:

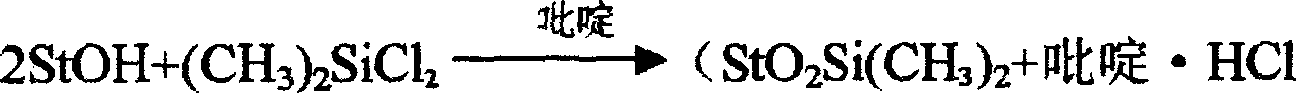

[0044] A. Take tapioca starch and 100 grams of water, add pyridine and Na 2 SO 4 or NaOH and Na 2 SO 4 Mix well, add dialkyldichlorosilane for cross-linking reaction for 1-10 hours, adjust the pH value to neutral, wash with water three times, and dry to obtain cross-linked starch for later use;

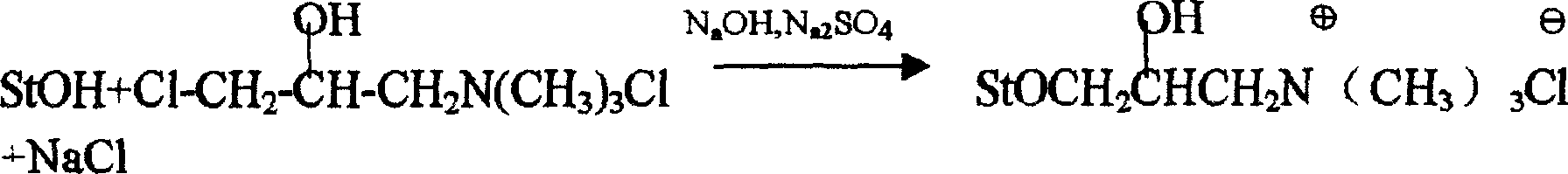

[0045] B. Add 120 grams of water, NaOH and Na to the cross-linked starch 2 SO 4 Mix evenly, then add 3-chloro-2-hydroxypropyltrimethylammonium chloride for etherification reaction for 10 hours, adjust the pH value to neutral, wash with water three times, and dry to obtain cross-linked cationic starch for later use;

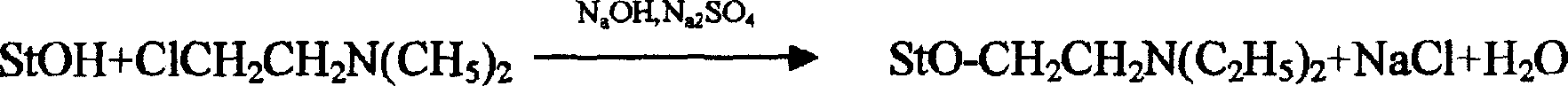

[0046] C. Add 100 grams of water, NaOH, Na to the cross-linked cationic starch 2 SO ...

Embodiment 2

[0049] formula

[0050] Waxy sorghum starch 100g water 600g

[0051] 30% NaoH 12g Diphenyldichlorosilane 5g

[0052] Sodium hypochlorite 1 g Na 2 SO 4 20 grams

[0053] 3-Chloro-2-hydroxypropyltrimethylammonium chloride 0.3mol pyridine 4 grams

[0054] The preparation method is the same as in Example 1, and the adhesive is obtained after preparation.

Embodiment 3

[0056] formula:

[0057] 100g glutinous rice starch 800g water

[0058] 30% NaoH 10g Epichlorohydrin 3g

[0059] Quaternary ammonium salt 0.3mol Hydrogen peroxide 0.5g

[0060] Na 2 SO 4 15 grams

[0061] The preparation method is the same as in Example 1, and the adhesive is obtained after preparation;

[0062] Another recipe:

[0063] Vinyl ethyl acetate 4 g Citric acid 1 g

[0064] Urea 0.5g Water 120g

[0065] Benzoic acid 0.1g Polyvinyl formal 10g

[0066] PVA 10g ammonium persulfate 0.5g

[0067] Preparation method: Take the above-mentioned raw materials and mix them uniformly with water to obtain the auxiliary agent. Get 40 grams of adhesive and mix evenly with 15 grams of stabilizer to get stable adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com