High-pressure flexible rubber hose and joint connecting method thereof

A rubber hose, flexible technology, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the problems of penetration, stainless steel sleeve failure, weak capacity, etc., to achieve the elimination of displacement and creep, excellent flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

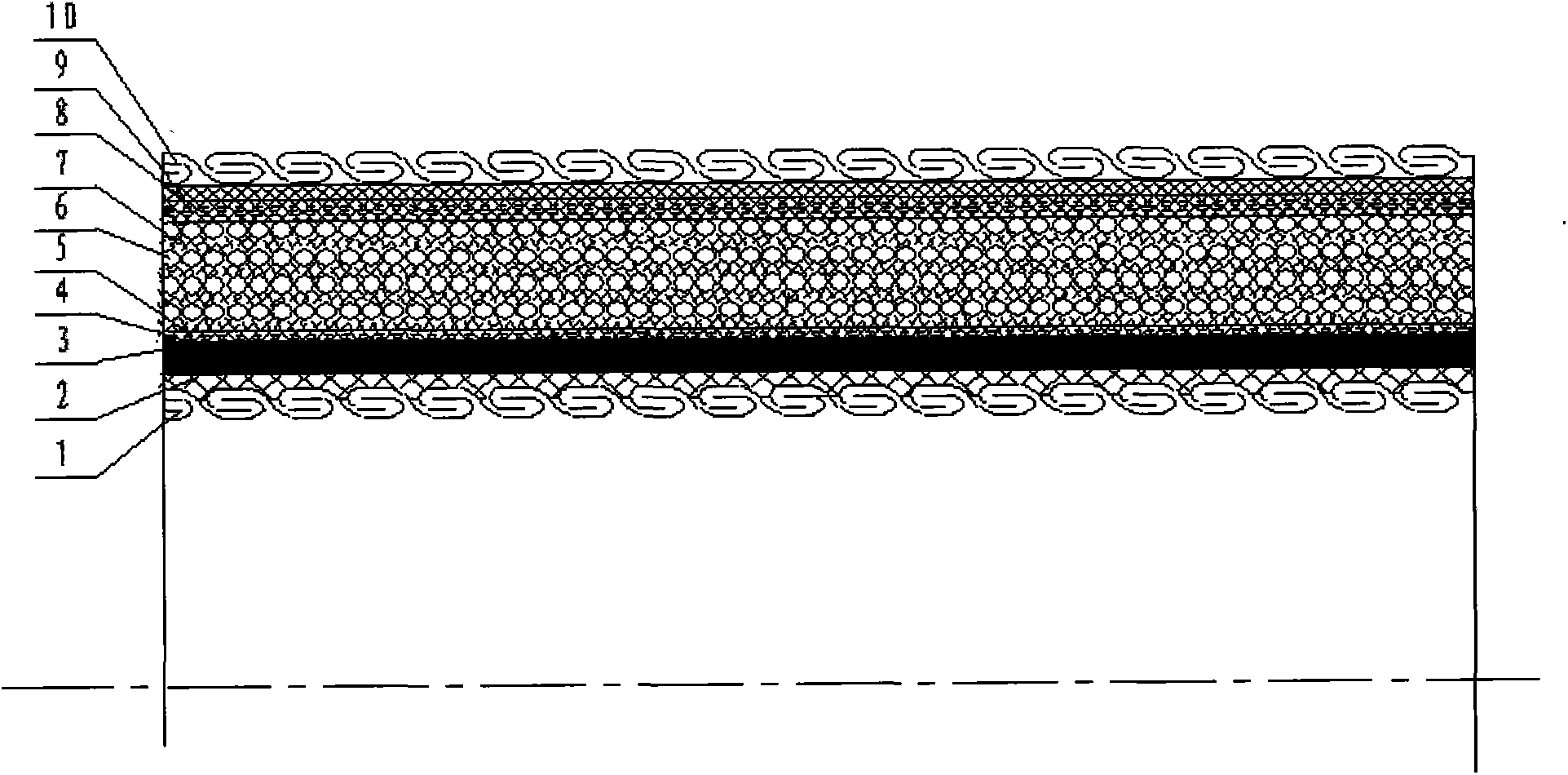

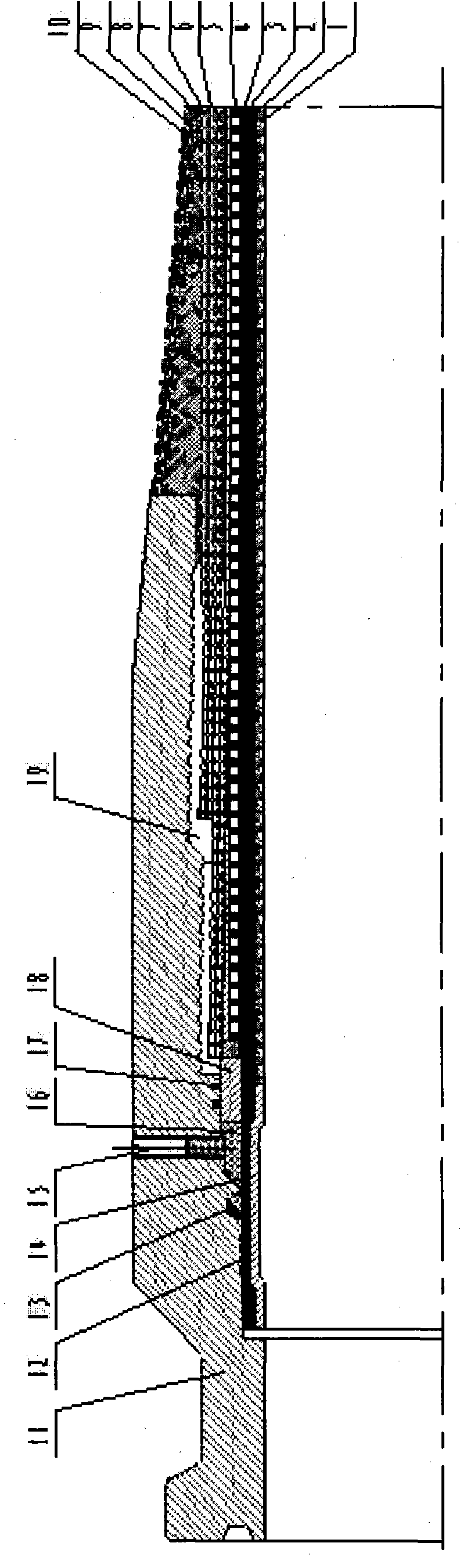

[0038] like image 3The high-pressure flexible rubber hose shown includes, from the inside to the outside, an inner stainless steel spiral bushing, an adhesive and buffer layer 1, a semi-crystalline thermoplastic bushing, an adhesive and buffer layer 2, an inner rubber cloth layer, a steel wire rope reinforcement layer, Adhesive buffer middle rubber layer, heat insulation layer, fire-resistant flame-retardant layer, stainless steel outer protective layer. image 3 Shown is a joint connection method of a typical pipe body structure with inner and outer stainless steel spiral sleeves:

[0039] After the hose is inserted into the joint 11, the semi-crystalline thermoplastic bushing 3 and the metal sleeve are respectively inserted into the corresponding seams of the joint 11, and the joint and the pipe body are fixedly connected as a whole by the resin 19. The resin is a high-strength and easy-flowing two-component, preferably epoxy resin, which connects the pipe body and the joi...

Embodiment 2

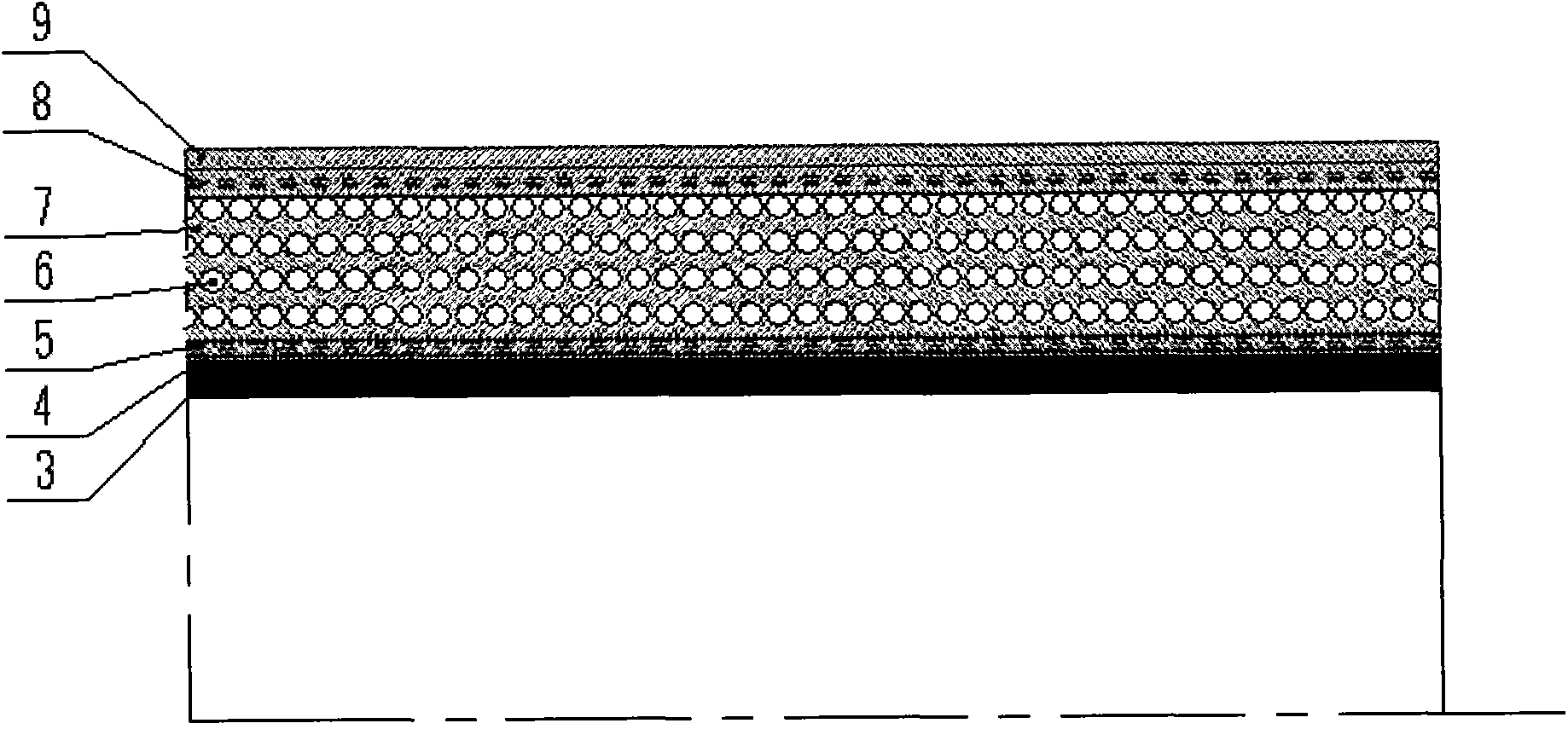

[0049] As shown in Figure 4, the high-pressure flexible rubber hose includes, from the inside to the outside, an inner stainless steel spiral bushing, an adhesive and buffer layer 1, a semi-crystalline thermoplastic bushing, an adhesive and buffer layer 2, an inner rubber cloth layer, Steel wire rope reinforcement layer, bonded buffer intermediate rubber layer, heat insulation layer, fire-resistant and flame-retardant layer. like Figure 4 As shown, it is a joint connection method with an inner stainless steel helical sleeve and no outer protective layer of stainless steel helical sleeve. The structure lacks the sealing area 12, and the sealing ring 13 acts on the semi-crystalline thermoplastic bushing 3 Changed to act on the tapered sleeve.

[0050] After the hose is inserted into the joint 11, the semi-crystalline thermoplastic bushing 3 and the metal sleeve 18 are respectively inserted into the corresponding seams of the joint 11, and the joint and the pipe body are fixedl...

Embodiment 3

[0058] According to the above-mentioned hose structure design, an air hose with an inner diameter of 76mm was produced, and the working pressure of the hose was 52Mpa. After coating adhesive on the surface of the inner stainless steel spiral sleeve 1, lay a buffer rubber layer, place a semi-crystalline thermoplastic bushing, the bushing wall thickness is 4mm, made of PVDF, coat the inside and outside with adhesive, lay buffer glue, Build the inner tape layer, wrap 4 layers of polyester canvas, and wind 4 layers of 4.5mm steel wire rope to make the hose skeleton layer to bear the blasting strength. Adhesive buffer middle rubber layer is laid between the layers and inside and outside of each layer of steel wire rope, laid in it during the winding of the steel wire rope, filled in the gap of the steel wire rope after vulcanization, and bonded to the surface of the steel wire rope to play the role of cushioning pad and bonding effect. The cord or canvas woven with glass fiber is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com