Production method of secondary ejection nose pad spectacles and structure thereof

A production method, secondary injection technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

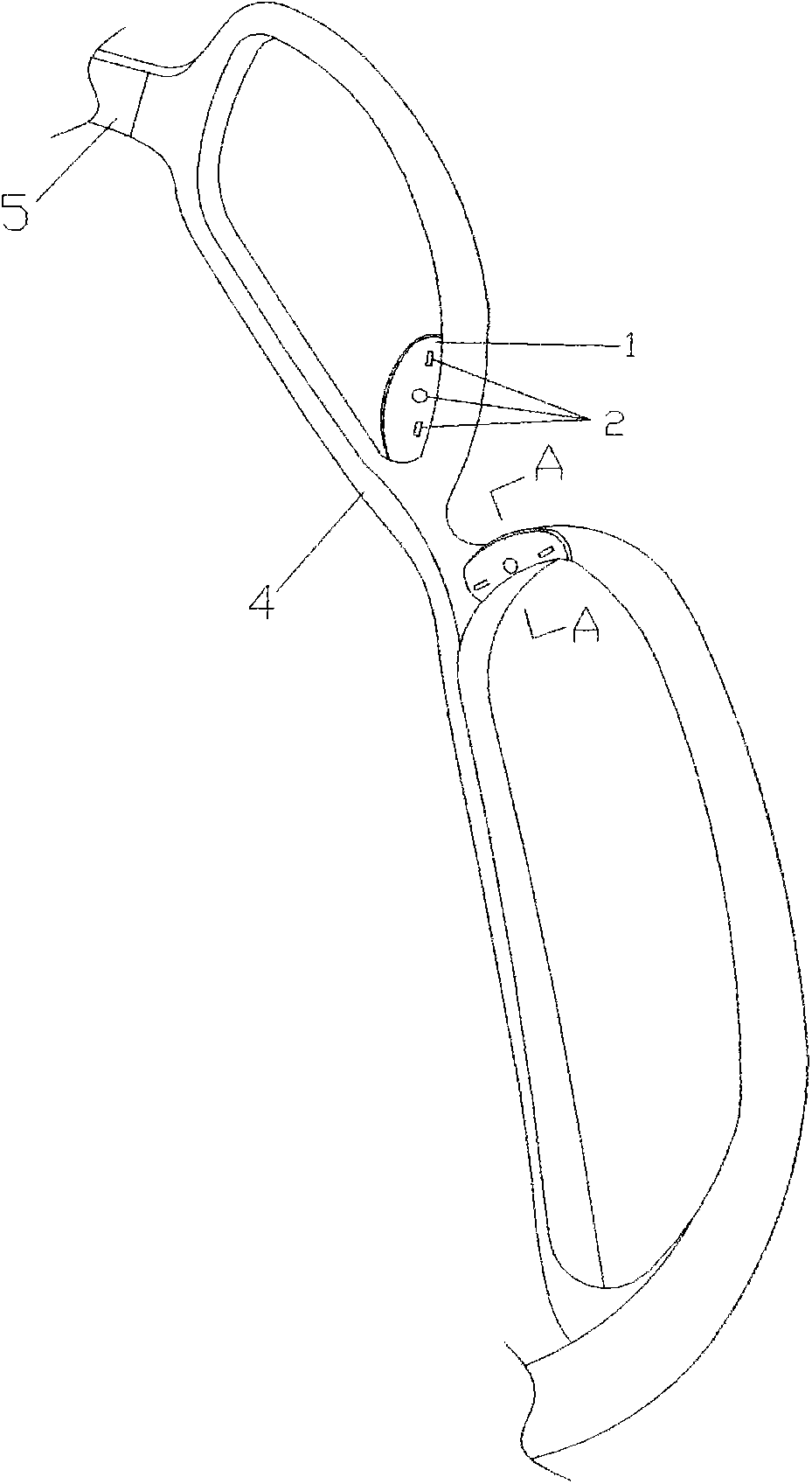

[0030] A kind of production method of secondary injection nose pad glasses of the present invention, its steps are:

[0031] 1) In the spectacle frame mold, the spectacle frame raw material is injected into the spectacle frame with the nose pad fixing bump at one time in a high-temperature liquid state, cooled and shaped and trimmed;

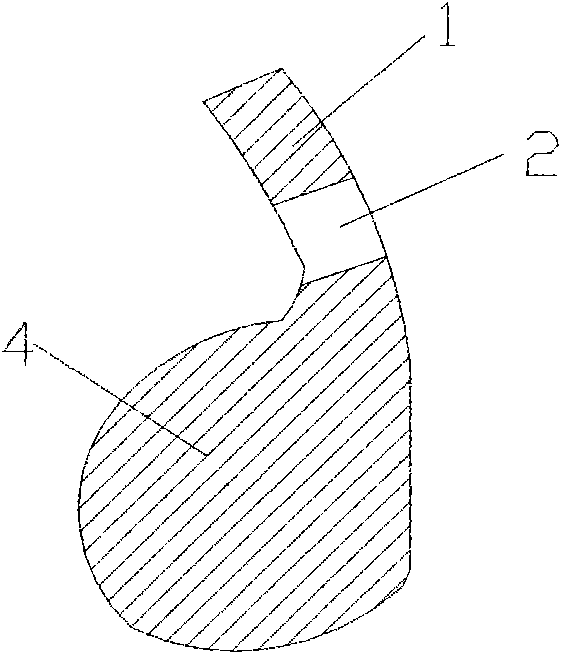

[0032] 2) Place the nose pad fixing bump of the molded spectacle frame at the corresponding position of the nose pad mold, perform a second injection, inject high-temperature liquid nose pad material into the nose pad mold, and inject the nose pad material into the spectacle frame On the bump, cooling and fixing molding, forming a nose pad fixed on the bump, shaping and trimming;

[0033] 3) Inject the temples into the temple mold, cool the molding, release the mold and trim, and then paint and spray paint (or essential oil) after trimming:

[0034] 4) Assemble finished glasses frames and temples.

[0035] In the embodiment, the raw material o...

Embodiment 2

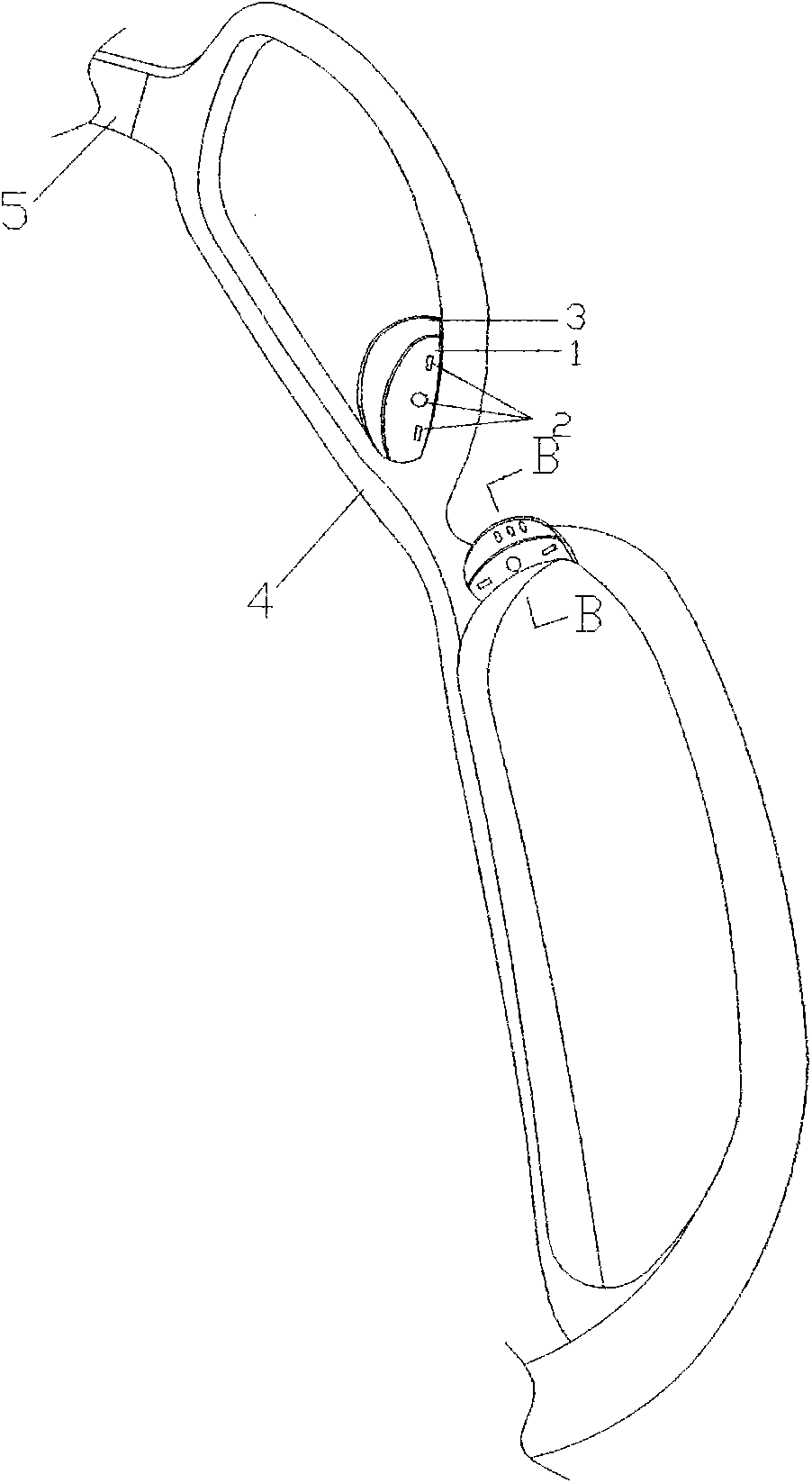

[0039] refer to Figure 5 and Figure 7 The structure of the glasses shown in this embodiment is characterized in that: the fixed bump 1 is provided with a fixing hole 2, and the fixing hole 2 is a slot hole arranged on the bump 1 of the spectacle frame. One or more ventilation holes 7 are provided. All the other are the same as the above embodiment.

[0040] The invention discloses a pair of glasses with nose pads injected twice. First, the glasses frame is injected, and the inner core of the nose pad 3 (the inner core is a bump 1) and the slot 2 of the inner core are reserved during injection, and then the second The nose pad 3 is injected for the first time, and the material of the nose pad 3 will pass through the fixing hole 2 during injection, so as not to fall off. At the same time, the viscosity of the material of the nose pad 3 will wrap around the bump 1 of the nose pad, making the bump 1 has good adhesion to the surface of the spectacle frame 4 to achieve an aesth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com