Anti-reflection DLC film with sulfur-series infrared glass as substrate and preparation method of anti-reflection DLC film

A technology of infrared glass and DLC film, which is applied in the field of film manufacturing, can solve the problems of large thermal expansion coefficient, easy to fall off, low softening temperature, etc., and achieve the effects of easy operation, simple preparation, and excellent anti-reflection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The grade of glass used for the base layer of chalcogenide infrared glass in Example 1 is IRG202, and the grade of glass used for the base layer of chalcogenide infrared glass in Example 2 is IRG206.

[0032] Example 1

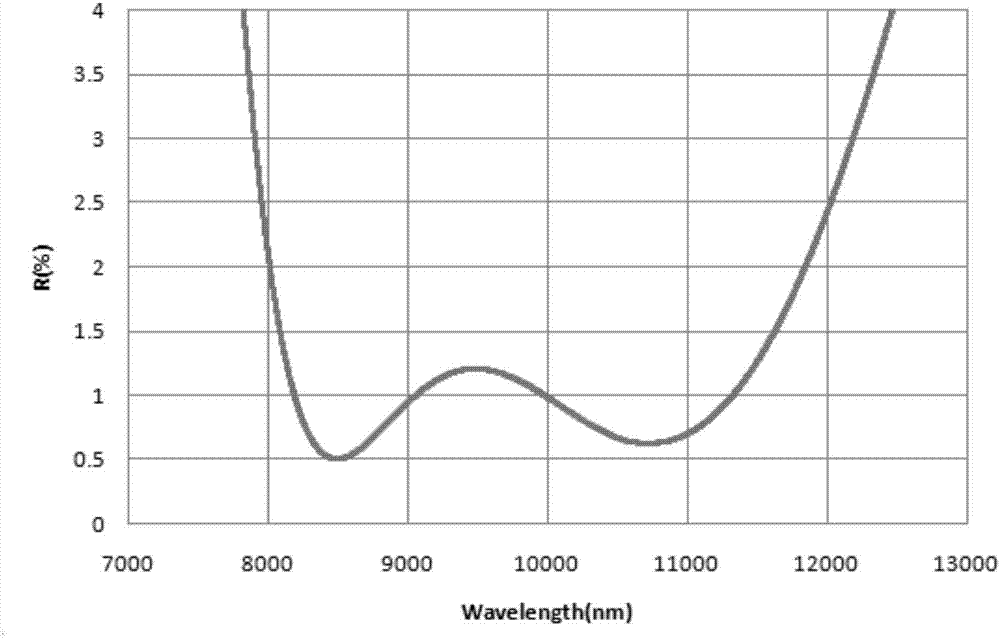

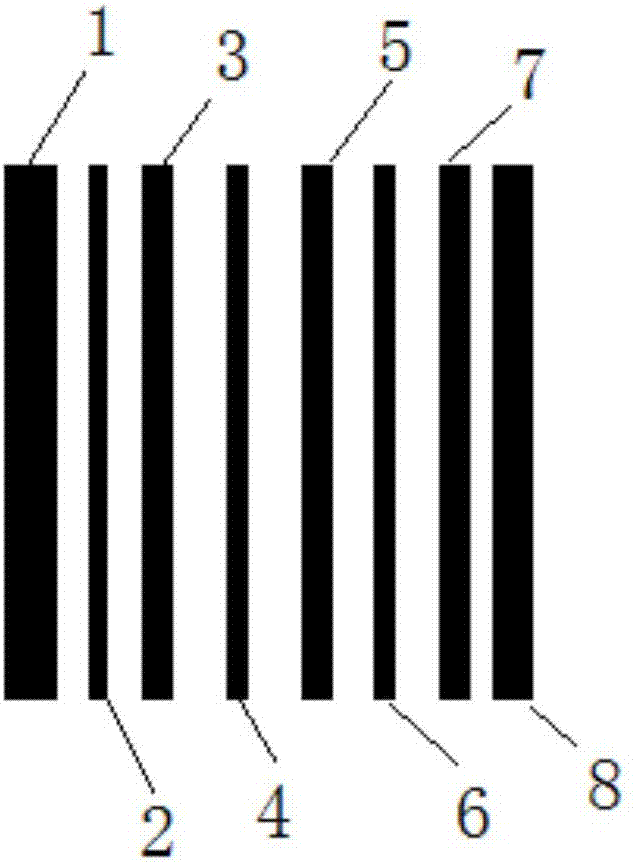

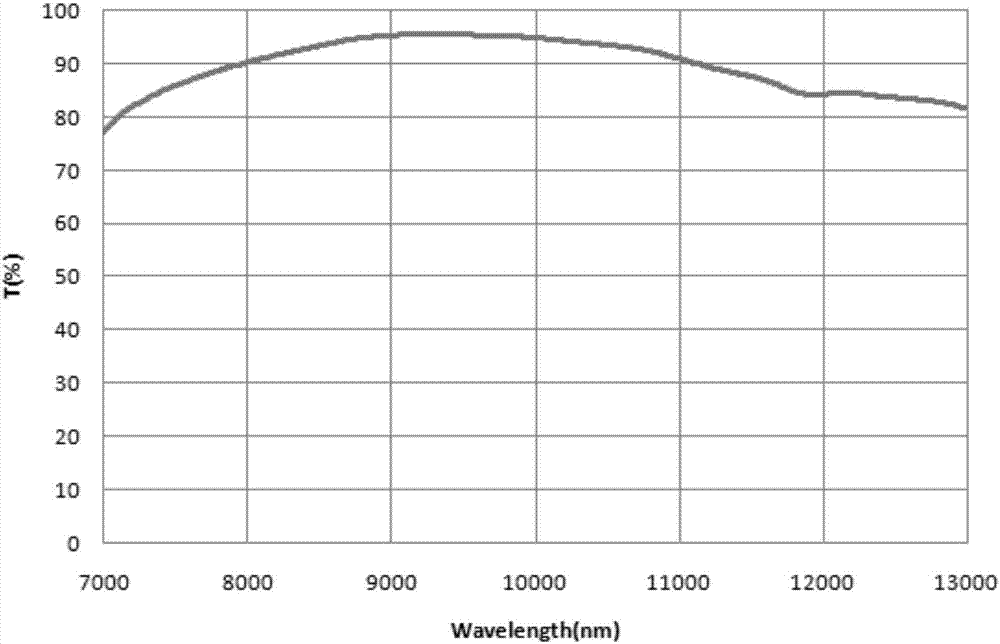

[0033]An anti-reflection DLC film based on chalcogenide infrared glass, comprising a sequentially connected chalcogenide infrared glass base layer, a first ZnSe layer, a first Ge layer, a second ZnSe layer, a second Ge layer, and a third ZnSe layer Layer, third Ge layer and DLC film layer. From the first ZnSe layer to the DLC film layer, the physical thickness of each layer is 400nm, 242nm, 246nm, 177nm, 180nm, 400nm, 1285nm, and the thickness of the chalcogenide infrared glass base layer is 8mm. The anti-reflection band of the anti-reflection DLC film is 8-12 microns.

[0034] The above-mentioned preparation method of the anti-reflection DLC film based on chalcogenide infrared glass is to make a bonding layer and a DLC film layer on the chalcogenide ...

Embodiment 2

[0038] An anti-reflection DLC film based on chalcogenide infrared glass, comprising a sequentially connected chalcogenide infrared glass base layer, a first ZnSe layer, a first Ge layer, a second ZnSe layer, a second Ge layer, and a third ZnSe layer layer, the third Ge layer, the fourth ZnSe layer, the fourth Ge layer and the DLC film layer. From the first ZnSe layer to the DLC film layer, the physical thickness of each layer is 400nm, 242nm, 246nm, 177nm, 180nm, 400nm, 150nm, 365nm, 1285nm, and the thickness of the chalcogenide infrared glass base layer is 5mm. The anti-reflection band of the anti-reflection DLC film is 8-12 microns.

[0039] The preparation method is the same as in Example 1.

Embodiment 3

[0041] The above anti-reflection and DLC film layer is coated on the convex surface of the chalcogenide glass lens, which mainly plays the role of anti-scratch and anti-sand dust, and the other side of the chalcogenide glass lens is also coated with an anti-reflection film to improve the performance of the lens. overall transmittance. On the one hand, the anti-reflection coating on the chalcogenide glass will play the role of anti-reflection, and also need to solve the problem of the firmness of the film layer. The other side of the anti-reflection DLC film obtained in Example 1 is according to G / H / L / H In the order of / L / M / A, increase the anti-reflection layer, wherein, G represents glass, H represents ZnSe, L represents YF3, M represents ZnS, A represents air, each film layer H / L / H / L / M (from The physical thicknesses from the chalcogenide infrared glass layer to the air layer) are: 865nm, 105nm, 296nm, 1046nm, 200nm, where the evaporation rate of ZnSe is 0.4nm / s, YF 3 The eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com