Ultrahigh molecular weight polyethylene fiber/rubber composite material and preparation method thereof

A polyethylene fiber and ultra-high molecular weight technology, applied in the field of polymer material processing, can solve the problems of high energy consumption of electron beam irradiation technology, high test environment requirements, and unfavorable industrial production, so as to avoid fiber surface defects and reduce raw materials. and process energy consumption, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

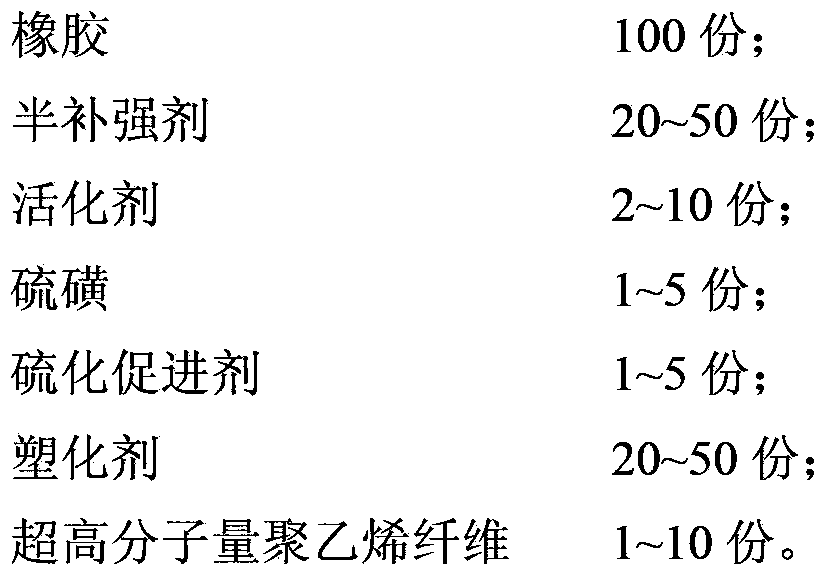

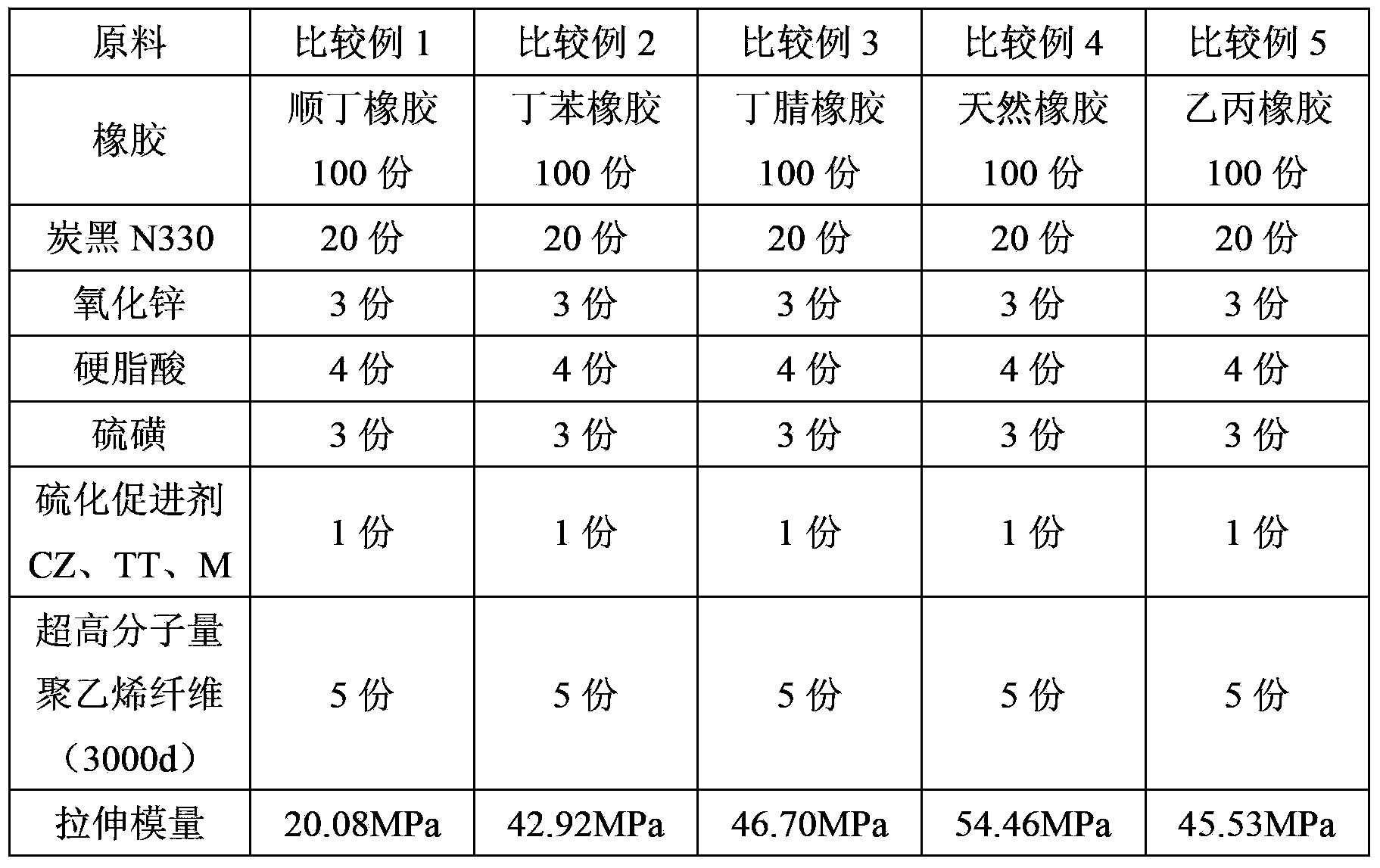

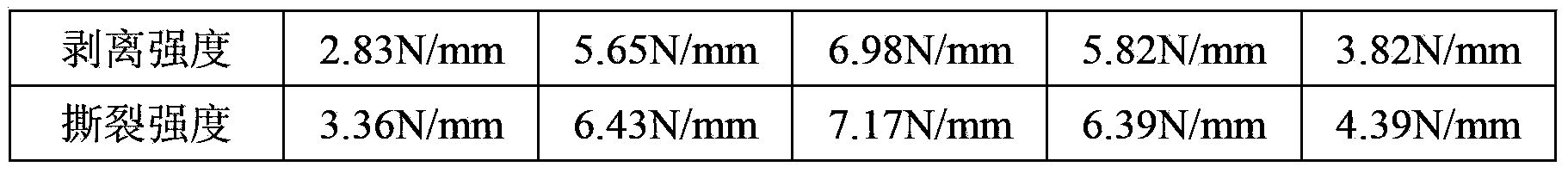

[0026] Formula design according to the following components and contents:

[0027] rubber

[0028] Weigh according to the above-mentioned proportion, carry out kneading on the open rubber mixer for 15 minutes, and then carry out composite vulcanization with fibers. The vulcanization temperature is 150°C, the vulcanization pressure is 20MPa, and the vulcanization time is 20min. After the vulcanization is completed, the product is taken out from the mold, placed in a temperature control system, and the temperature is lowered at a constant rate. After the product has cooled to room temperature, the test is carried out. The obtained composite material had a peel strength of 4.45 N / mm and a tear strength of 4.81 N / mm.

Embodiment 2

[0030] Formula design according to the following components and contents:

[0031] rubber

[0032] Weigh according to the above-mentioned proportion, carry out kneading on the open rubber mixer for 15 minutes, and then carry out composite vulcanization with fibers. The vulcanization temperature is 150°C, the vulcanization pressure is 20MPa, and the vulcanization time is 20min. Shearing is applied during the vulcanization compounding process, the shearing frequency is 50rad / s, and the shearing amplitude is 50%. After the vulcanization is completed, the product is taken out from the mold, placed in a temperature control system, and the temperature is lowered at a constant rate. After the product has cooled to room temperature, the test is carried out. The obtained composite material had a peel strength of 7.01 N / mm and a tear strength of 7.94 N / mm.

Embodiment 3

[0034] Formulate according to the following components and contents:

[0035] rubber

[0036] Weigh according to the above-mentioned proportion, carry out kneading on the open rubber mixer for 15 minutes, and then carry out composite vulcanization with fibers. The vulcanization temperature is 150°C, the vulcanization pressure is 20MPa, and the vulcanization time is 20min. Shearing is applied during the vulcanization compounding process, the shearing frequency is 100rad / s, and the shearing amplitude is 50%. After the vulcanization is completed, the product is taken out from the mold, placed in a temperature control system, and the temperature is lowered at a constant rate. After the product has cooled to room temperature, the test is carried out. The obtained composite material had a peel strength of 5.88 N / mm and a tear strength of 6.03 N / mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com