Preparation method of core glue for high-temperature resistant steel mesh conveyor belt

A conveyor belt and high-temperature-resistant technology, which is applied in the field of core rubber of high-temperature-resistant steel mesh conveyor belts, can solve the problems of decreased adhesion of steel wires, sudden reduction of glue attached to steel wires, and low strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

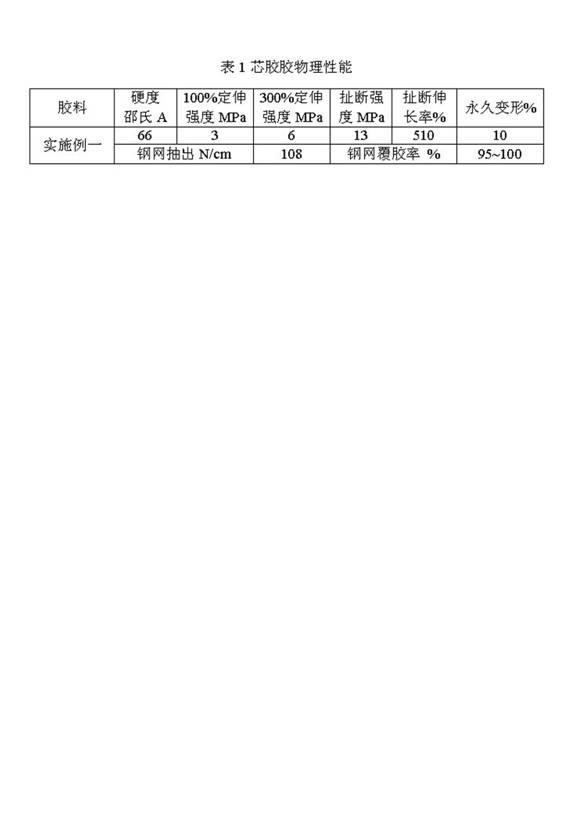

Embodiment 1

[0019] Embodiment 1: A kind of preparation method that is used for the core glue of high temperature resistant steel mesh conveyor belt, its component ratio is counted by weight, comprises the following process steps:

[0020] (1) Mixing: Add 50 parts of ethylene-propylene rubber, 50 parts of neoprene rubber and 20 parts of carbon black into the internal mixer for mixing, the mixing time is 60 seconds, and the refining temperature is 120°C;

[0021] (2) Two-stage internal mixing: Add 5 parts of zinc oxide, 1 part of stearic acid, and 1 part of antioxidant RD: 1,2-dihydro-2,2,4-trimethyl to the rubber obtained after mixing Quinoline, 1 part of accelerator CZ: N-cyclohexyl-2-benzothiazole sulfenamide, 1 part of binder RS, 5 parts of white carbon black, 5 parts of calcium carbonate, 2 parts of cobalt boroacylate and 5 parts 1 part of rubber oil (2280) was banburyed on a banbury mixer for a period of 110 seconds, and the banbury temperature was 160°C; after the end of a period of ...

Embodiment 2

[0024] Embodiment 2: A kind of preparation method that is used for the core glue of high temperature resistant steel mesh conveyor belt, its component ratio is counted by weight parts, comprises the following process steps:

[0025] (1) Mixing: add 100 parts of ethylene propylene rubber and 50 parts of carbon black to the internal mixer for mixing, the mixing time is 100 seconds, and the refining temperature is 120°C;

[0026] (2) Two-stage internal mixing: Add 15 parts of zinc oxide, 3 parts of stearic acid, and 4 parts of antioxidant RD: 1,2-dihydro-2,2,4-trimethyl to the rubber obtained after mixing Quinoline, 3 parts of accelerator CZ: N-cyclohexyl-2-benzothiazole sulfenamide, 5 parts of binder RS, 20 parts of white carbon black, 25 parts of calcium carbonate, 6 parts of cobalt boroacylate and 20 parts 1 part of rubber oil (2280) was banburyed on a banbury mixer for a period of 130 seconds, and the banbury temperature was 130°C; after the end of a period of banbury mixing,...

Embodiment 3

[0029] Embodiment 3: A kind of preparation method that is used for the core rubber of high temperature resistant steel mesh conveyor belt, its component ratio is counted by weight parts, comprises the following process steps:

[0030] (1) Mixing: Add 75 parts of ethylene-propylene rubber, 25 parts of neoprene rubber and 30 parts of carbon black into the internal mixer for mixing, the mixing time is 80 seconds, and the refining temperature is 130°C;

[0031] (2) Two-stage internal mixing: add 10 parts of zinc oxide, 2 parts of stearic acid, and 3 parts of antioxidant RD: 1,2-dihydro-2,2,4-trimethyl to the rubber obtained after mixing Quinoline, 2 parts of accelerator CZ: N-cyclohexyl-2-benzothiazole sulfenamide, 3 parts of binder RS, 10 parts of white carbon black, 10 parts of calcium carbonate, 3 parts of cobalt boroacylate and 15 parts 1 part of rubber oil (2280) was banburyed on the internal mixer for a period of 120 seconds, and the banburying temperature was 150°C; after t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com