Manufacturing method of soft glue mat and glue filling device

A manufacturing method and technology of soft rubber pads, which are applied in lamination devices, chemical instruments and methods, adhesives, etc., can solve the problems of unretrieved reports on soft rubber pad production methods and rubber filling devices, etc., and achieve good resilience, Good touch, good texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

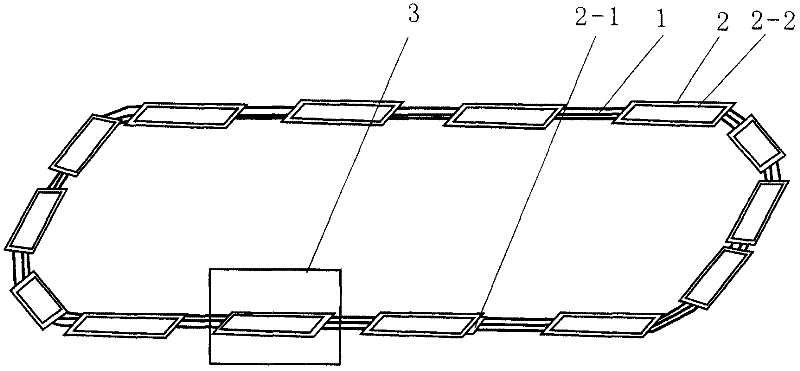

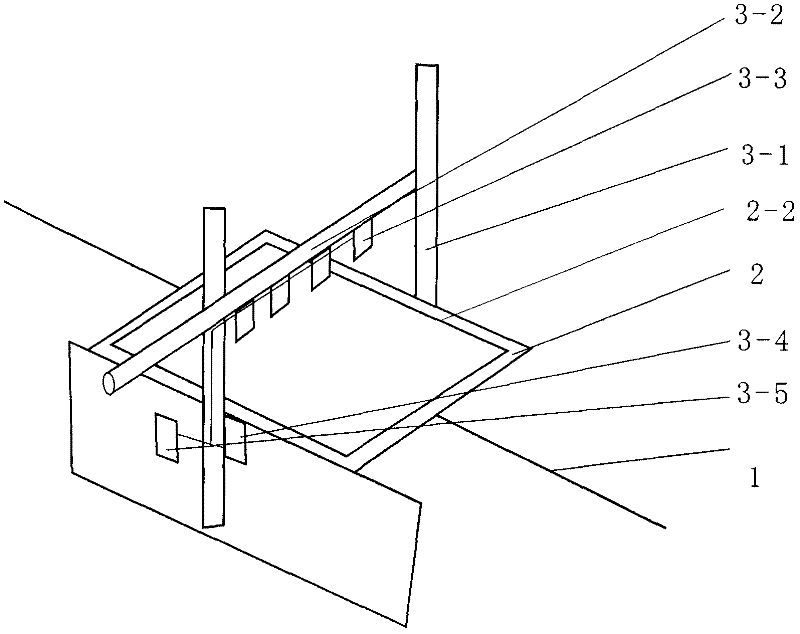

Image

Examples

Embodiment Construction

[0028] The manufacture method of soft rubber pad of the present invention may further comprise the steps:

[0029] 1. Preparation:

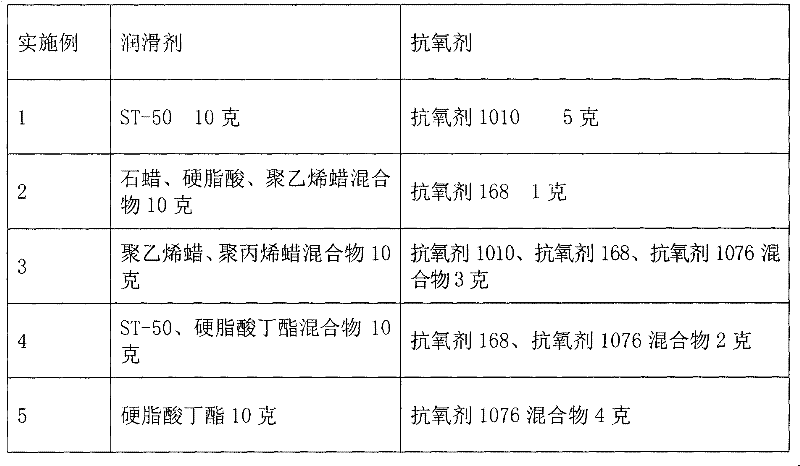

[0030] 1. Preparation of thermoplastic elastomer

[0031] The thermoplastic rubber SEBS, white oil and processing aid are mixed to prepare thermoplastic elastomer ingredients, and the mass ratio of the thermoplastic rubber SEBS, white oil and processing aid is 100:400-500:1-10. The processing aid is a lubricant and an antioxidant, and in the processing aid, the mass ratio of the lubricant and the antioxidant is 1:0.1-0.5. The lubricant is one or more mixtures of ST-50, butyl stearate, polyethylene wax, polypropylene wax, and butyl stearate. The antioxidant is one or a mixture of antioxidant 1010, antioxidant 168, and antioxidant 1076.

[0032] The selection and ratio of processing aids are shown in Table 1

[0033] Table 1

[0034]

[0035] The components of thermoplastic elastomers are detailed in Table 2

[0036] Table 2

[0037] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com