Manufacturing method of high-elasticity cotton/polyurethane knitted fabric

A knitted fabric and elastic technology, which is applied in the field of textile preparation, can solve problems such as fabrics that cannot meet high elastic functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

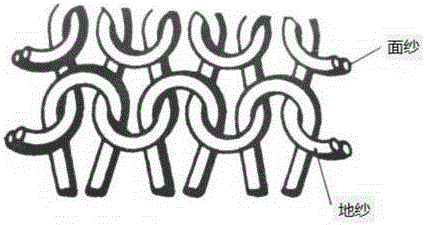

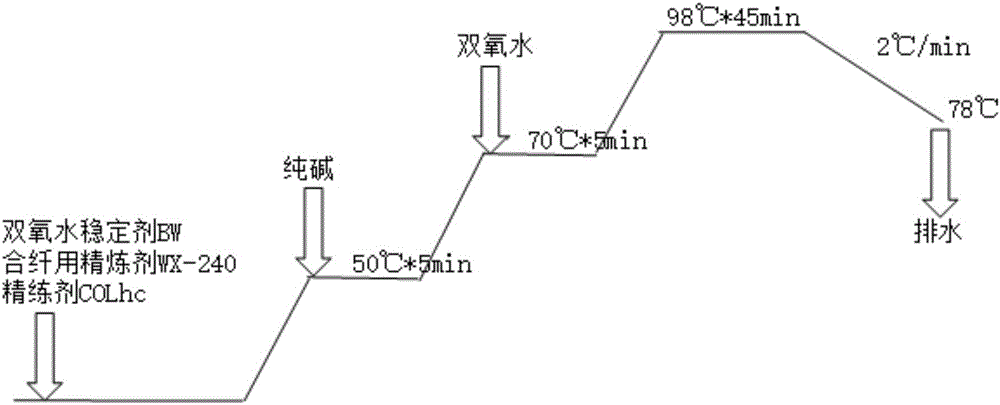

[0041] combine figure 1 with figure 2 Shown, a kind of preparation method of cotton spandex high elastic knitted fabric comprises the following steps:

[0042] 1) Prepare raw materials: 60S / 1 Pima cotton, the spinning method is compact spinning, and the spandex yarn is 40D Lycra;

[0043] 2) Weaving process: use a 34-inch 24G single-sided open-width machine to weave into a flat-knit all-plated structure, Pima cotton as the veil, 40D Lycra as the ground yarn, and the veil is always on the front of the fabric; the length of the Pima cotton thread is 14.0cm / 50 needles, 40D Lycra cable length is 5.2cm / 50 needles,

[0044] 3), pre-setting process: pre-setting the fabric prepared in the step 2), setting the temperature of the setting machine to 195°C, and the speed of the vehicle to 22m / min;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com