Drying method for carbon fiber having been subjected to sizing

A drying method, carbon fiber technology, applied in the direction of drying solid materials, method combination to dry solid materials, drying, etc., can solve the problems of high repair and maintenance costs, affecting temperature stability, fire, etc., to achieve easy construction and maintenance, The effect of high heat utilization efficiency and strong material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

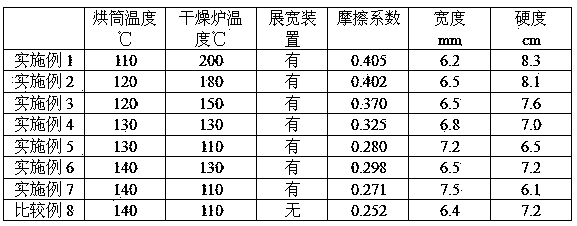

Examples

Embodiment 1

[0021] Embodiment 1, a kind of drying method after carbon fiber sizing, its steps are as follows:

[0022] After the surface treatment, the carbon fiber tow is impregnated with sizing agent, and after the excess water is removed by the squeeze roller, it is firstly pre-dried by the steam-heated drying drum. The wrap angle of the carbon fiber tow on the drying drum is greater than 180°, and the contact time 50S, the surface temperature of the drying drum is 120°C, after pre-drying, the carbon fiber tow with a water content of ≤1% is obtained, and the sizing agent is formed into a film on the surface of the carbon fiber tow. A carbon fiber tow widening device is arranged between the steam-heated drying drum and the horizontal hot-air drying furnace. The pre-dried carbon fiber tow is stretched by a stretching device, and then passed through a horizontal hot air drying furnace for non-contact drying. The temperature in the horizontal hot air drying furnace is 200 ° C, and the dryi...

Embodiment 2

[0023] Embodiment 2, a drying method after carbon fiber sizing, the steps are as follows:

[0024] After the surface treatment, the carbon fiber tow is impregnated with sizing agent, and after the excess water is removed by the squeeze roller, it is firstly pre-dried by the steam-heated drying drum. The wrap angle of the carbon fiber tow on the drying drum is greater than 180°, and the contact time It is 55S, and the surface temperature of the drying drum is 120°C. After pre-drying, carbon fiber tows with a water content of ≤1% are obtained, and the sizing agent is formed into a film on the surface of the carbon fiber tows. A carbon fiber tow widening device is arranged between the steam-heated drying drum and the horizontal hot-air drying furnace. The pre-dried carbon fiber tow is stretched by a stretching device, and then passed through a horizontal hot air drying furnace for non-contact drying. The temperature in the horizontal hot air drying furnace is 180°C, and the dryin...

Embodiment 3

[0025] Embodiment 3, a drying method after carbon fiber sizing, the steps are as follows:

[0026] After the surface treatment, the carbon fiber tow is impregnated with sizing agent, and after the excess water is removed by the squeeze roller, it is firstly pre-dried by the steam-heated drying drum. The wrap angle of the carbon fiber tow on the drying drum is greater than 180°, and the contact time 50S, the surface temperature of the drying drum is 120°C, after pre-drying, the carbon fiber tow with a water content of ≤1% is obtained, and the sizing agent is formed into a film on the surface of the carbon fiber tow. A carbon fiber tow widening device is arranged between the steam-heated drying drum and the horizontal hot-air drying furnace. The pre-dried carbon fiber tow is stretched by a stretching device, and then passed through a horizontal hot air drying furnace for non-contact drying. The temperature in the horizontal hot air drying furnace is 150 ° C, and the drying time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com