Dipping machine for producing continuous carbon fibers

A technology of dipping machine and carbon fiber, which is applied in the fields of fiber chemical characteristics, liquid/gas/steam fiber/sliver/roving treatment, textile and paper making, etc. It can solve the problems of increasing fiber surface machinery and damage, and achieve processing and manufacturing costs Low, improve treatment efficiency, improve the effect of diffusion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

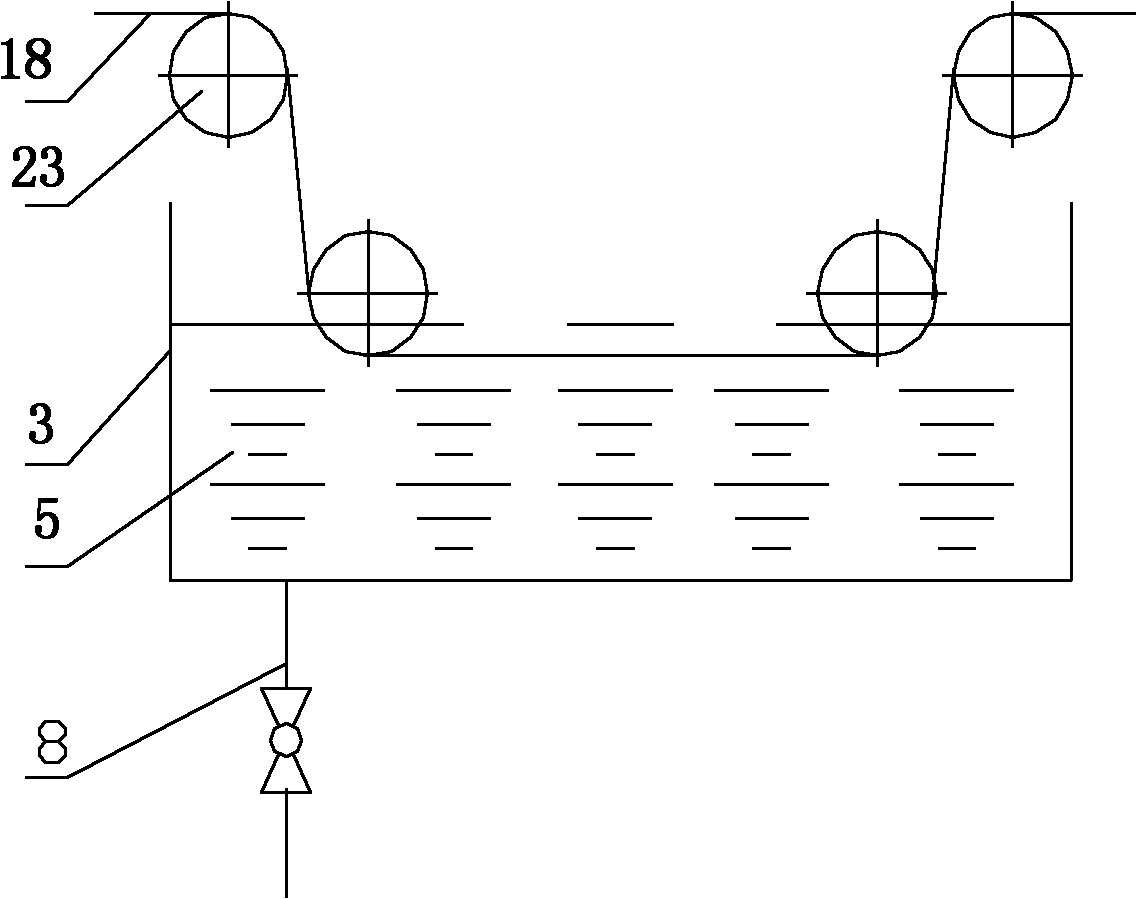

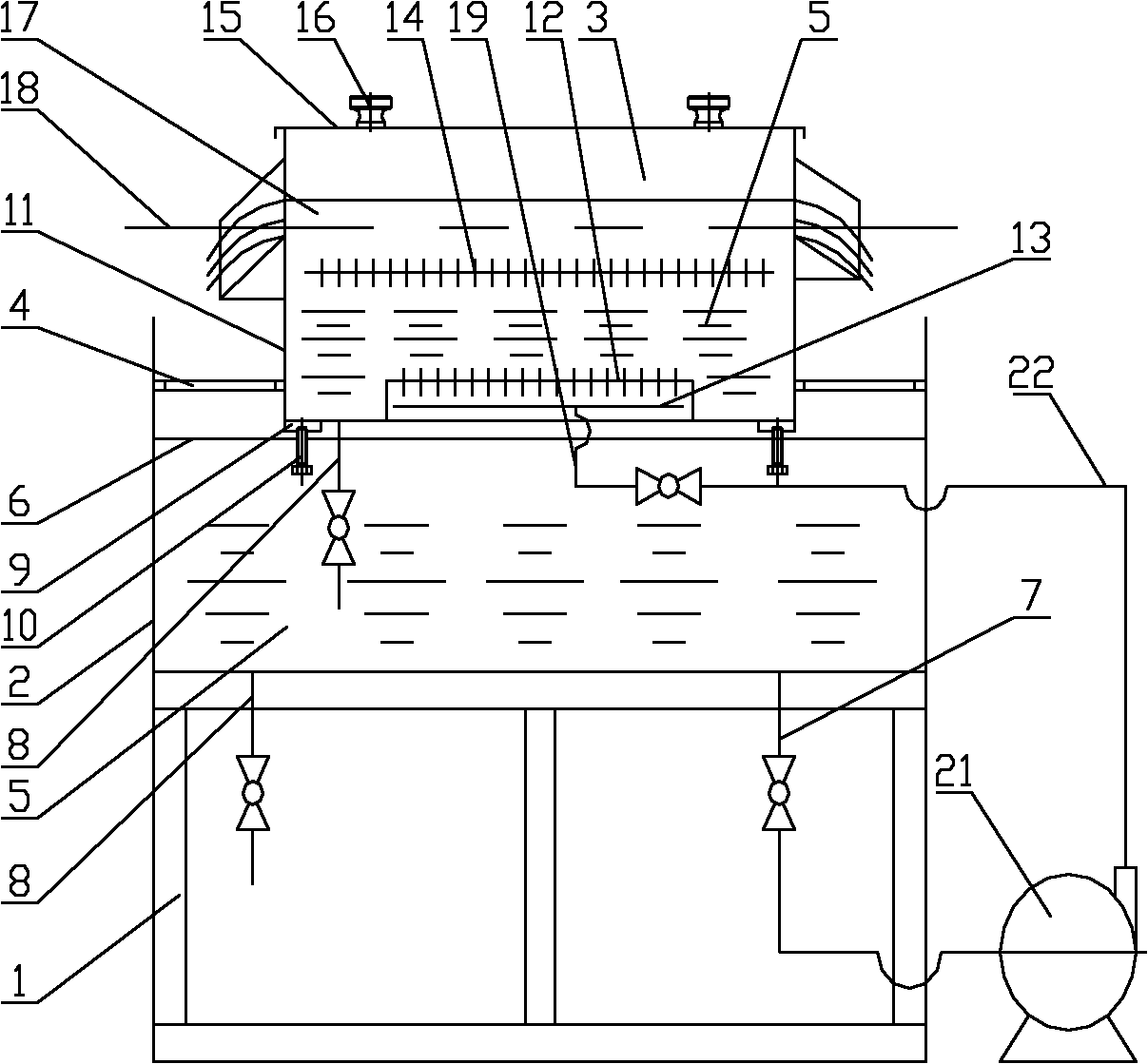

[0020] The present invention is used for the immersion machine of continuous production carbon fiber such as figure 2 , image 3 As shown, it mainly includes machine base 1, liquid storage tank 2, immersion liquid tank 3, and filter device 4; The front and rear walls inside the body are provided with support plates 6, and the support plates 6 are used to install and fix the immersion tank 3, and the bottom of the tank body of the liquid storage tank 2 is provided with a circulating liquid outlet 7 and a cleaning port 8. The liquid immersion tank 3 is installed directly above the liquid storage tank 2, and the outer bottom surface of the tank body of the liquid immersion tank 2 is provided with a positioning block 9, which is fixed with the support plate 6 provided in the liquid storage tank 2 by the height adjuster 10, and adjusted. corresponding height position.

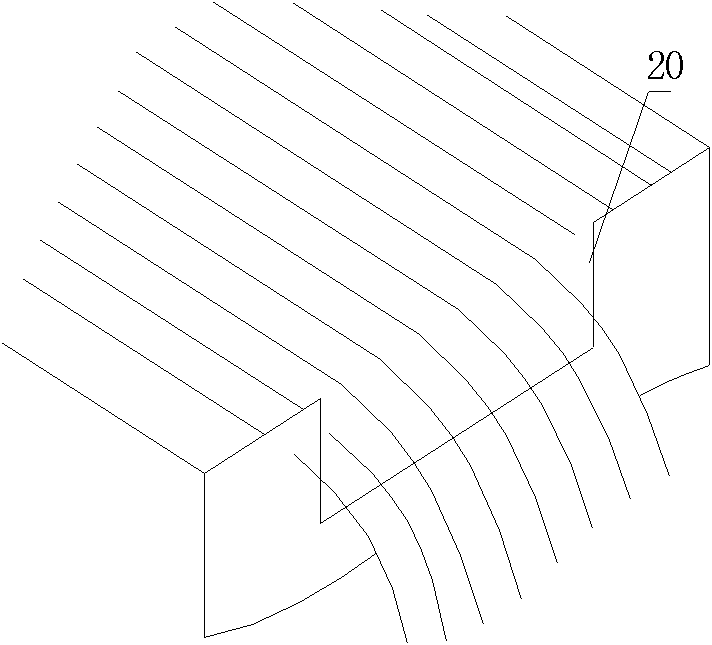

[0021] The immersion tank 3 is mainly composed of a tank body 11, a liquid distribution plate 12, a liquid dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com