Loose fiber cold pad-batch dyeing machine

A cold pad batch and dyeing machine technology, applied in the field of dyeing machines, can solve the problems of difficult washing, low dyeing rate, color difference between inner and outer layers, etc., and achieve less labor, short dyeing process and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

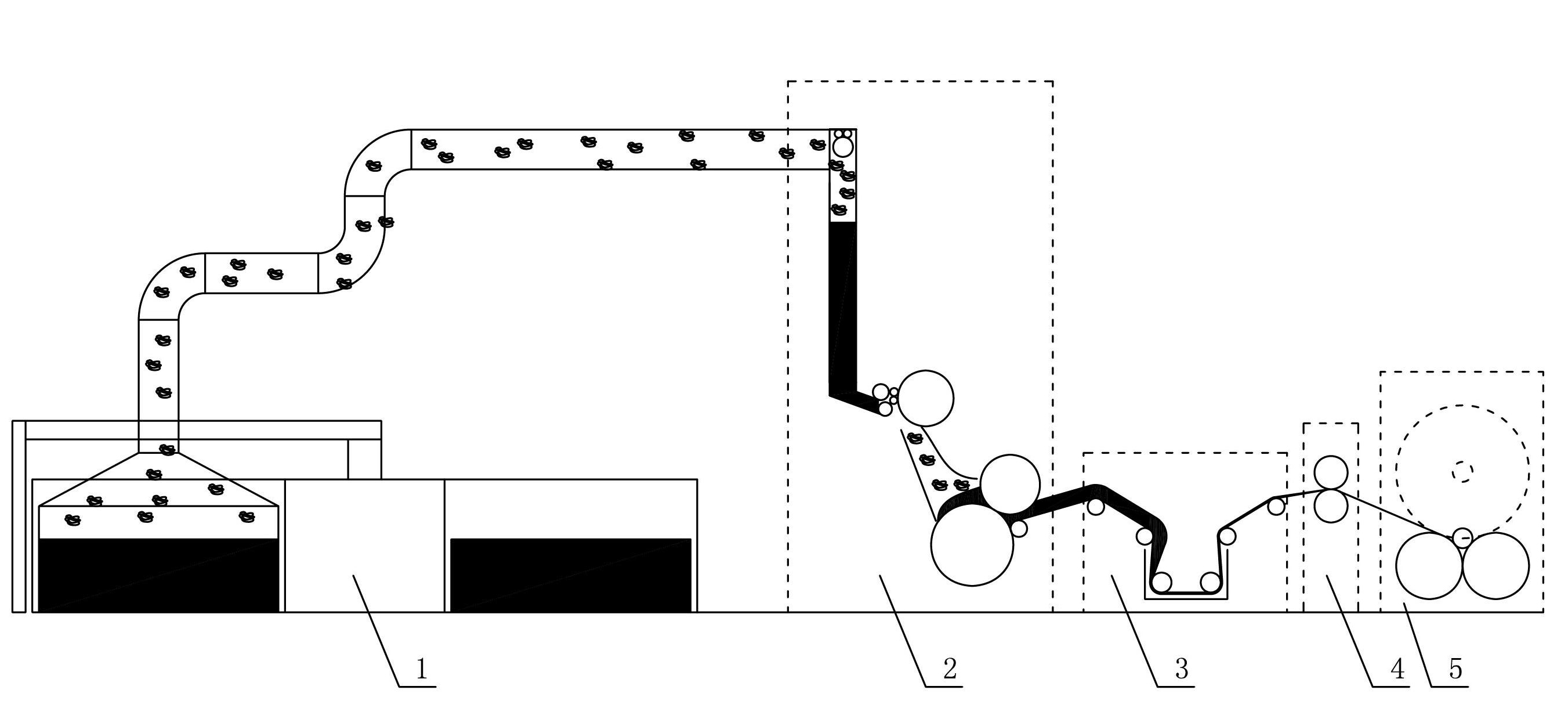

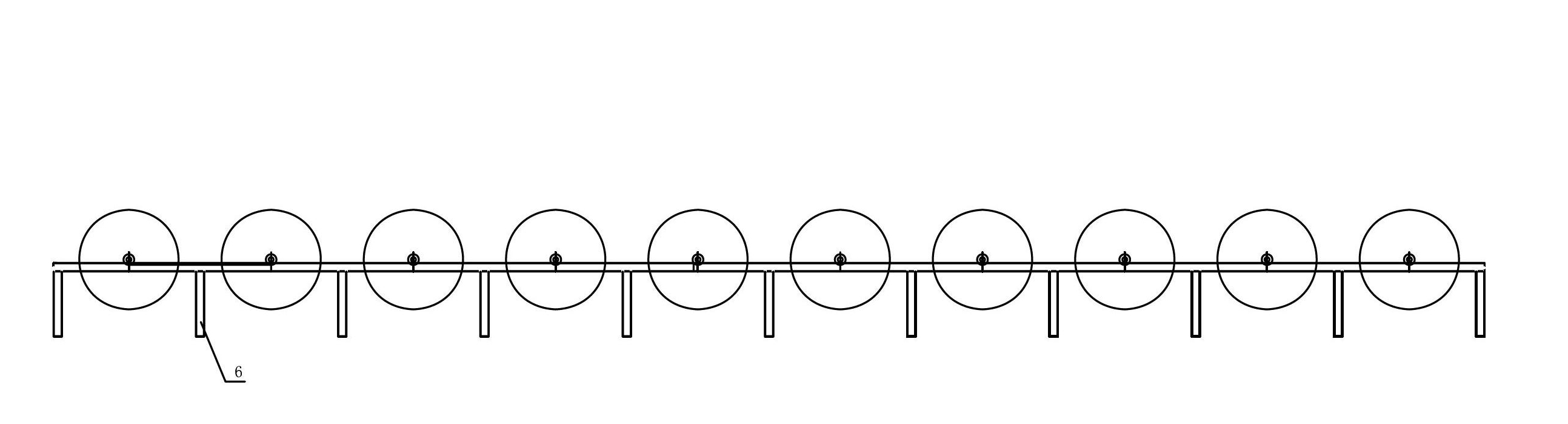

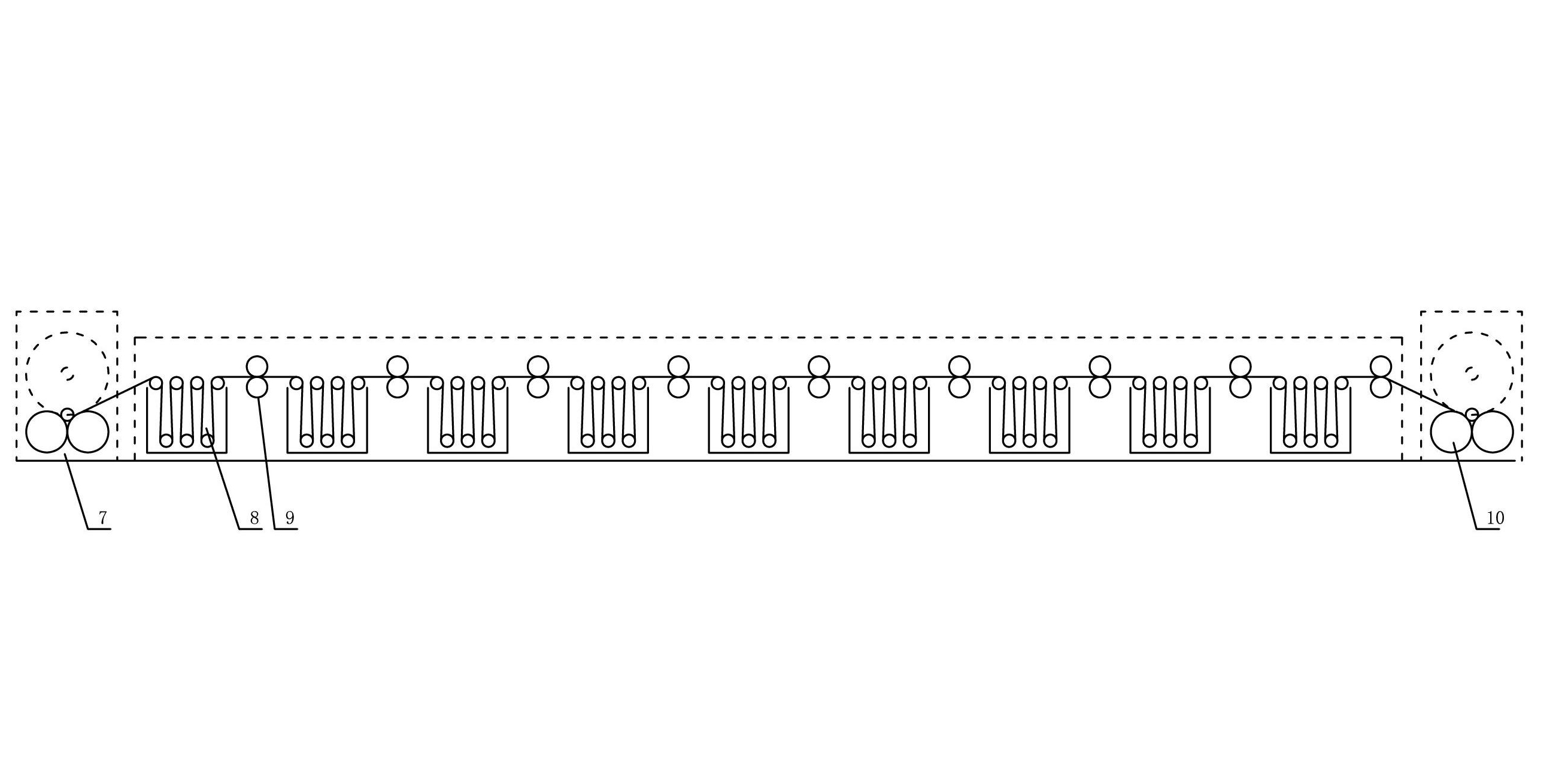

[0024] Such as Figure 1 to Figure 6 As shown, the cold pad-batch dyeing machine for loose fibers of the present invention comprises an automatic plucking machine 1, a web forming machine 2, a soaking tank 3 with an automatic batching system, an even padding car 4, a lapping machine-5, and a cooling machine arranged in sequence. Stacking unit 6, uncoiler one 7, washing machine 8, water rolling machine 9, coiler two 10, uncoiler two 11, dryer 12, baler 13. Wherein, in the cotton storage box of the web forming machine 2, a centrifugal fan 14 is arranged below the nail roller 15, and the centrifugal fan 14 communicates with the nail roller 15 through the circulating air duct 16; The shower pipe 19, the shower head 17 on the high-speed circulation shower pipe 19 is facing the fiber layer 18 above it (that is, the shower head 17).

[0025] There are three centrifugal fans 14 arranged side by side on the same plane, and the centrifugal fans 14 are high-speed centrifugal fans.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com