Cotton fiber continuous dyeing and bleaching method and equipment

A dyeing equipment, cotton fiber technology, applied in liquid/gas/vapor fiber/sliver/roving processing, textile and papermaking, liquid/gas/vapor textile processing, etc., can solve the problem of low production efficiency, long dyeing process, Sewage and other problems, to achieve the effect of cost saving and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

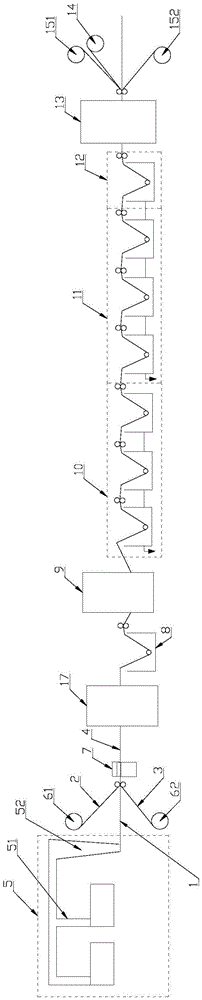

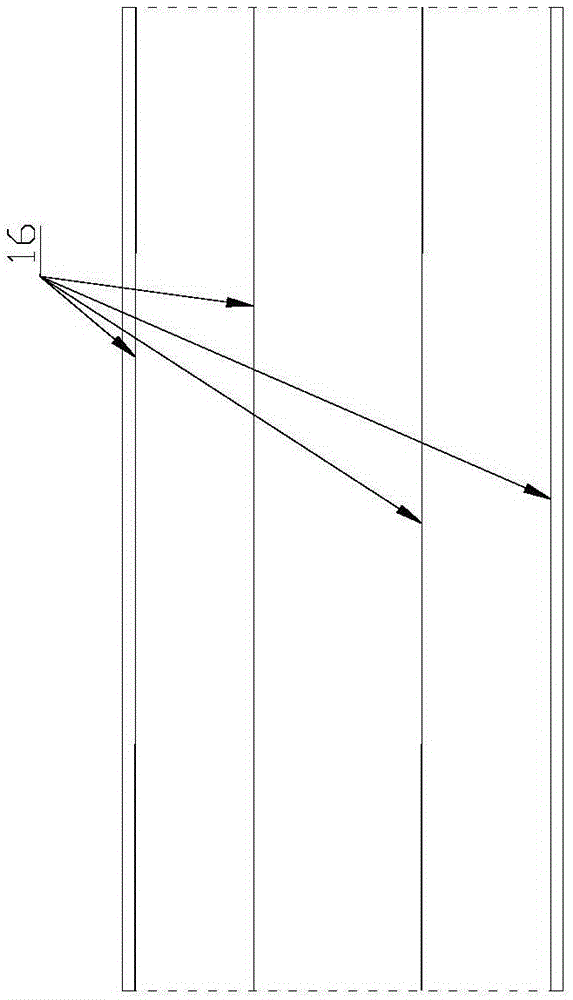

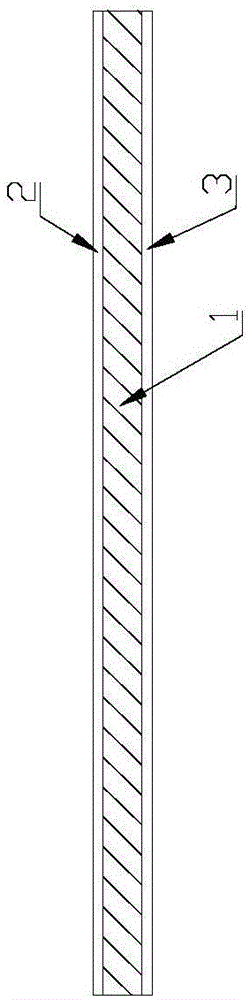

[0022] Such as figure 1 , 2 As shown in and 3, a method for continuous dyeing and bleaching of cotton fibers, the cotton fibers to be dyed or bleached are arranged, spread into a uniform flat cotton sliver 1 and sandwiched between the upper interlayer 2 and the lower interlayer 3, and The upper interlayer 2, the sliver 1 and the lower interlayer 3 are sewed together by a sewing device to form a suture body 4 that can be continuously transported. . The upper interlayer and the lower clamping are made of plane through-hole flexible materials, and the plane through-hole flexible materials are textile fabrics, fishing nets, and through-hole plastic films. The stitching of the quilting is combined into a stitched structure that can be pulled apart. This kind of suture structure that can be pulled apart is usually used for the sealing of fertilizer bags and feed bags, and the suture structure can be easily disassembled by pulling the exposed thread ends.

[0023] The stitched bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com