Technology for producing high water absorption silky non-woven fabric

A technology of silk non-woven fabric and production process, which is applied in non-woven fabrics, textiles, papermaking, and textile materials processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

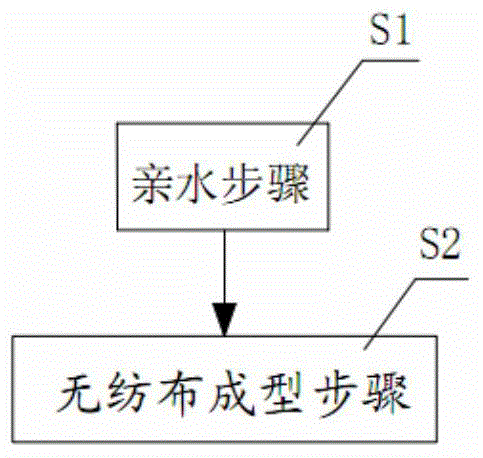

[0039] Such as figure 1 with figure 2 As shown, the present embodiment provides silk non-woven fabric production process, and this production process comprises successively:

[0040] S1, the hydrophilic step, the hydrophilic step processes the silk fiber by soaking, and then obtains the silk fiber after drying;

[0041] S2. The non-woven fabric forming step, however, in the non-woven fabric forming step, water-absorbent silk fibers are produced through a spunlace process to obtain a highly water-absorbent silk non-woven fabric. In addition, the silk fiber is mixed with viscose, polyester or polypropylene fiber at a weight ratio of 1:0.01 before entering the spunlace process.

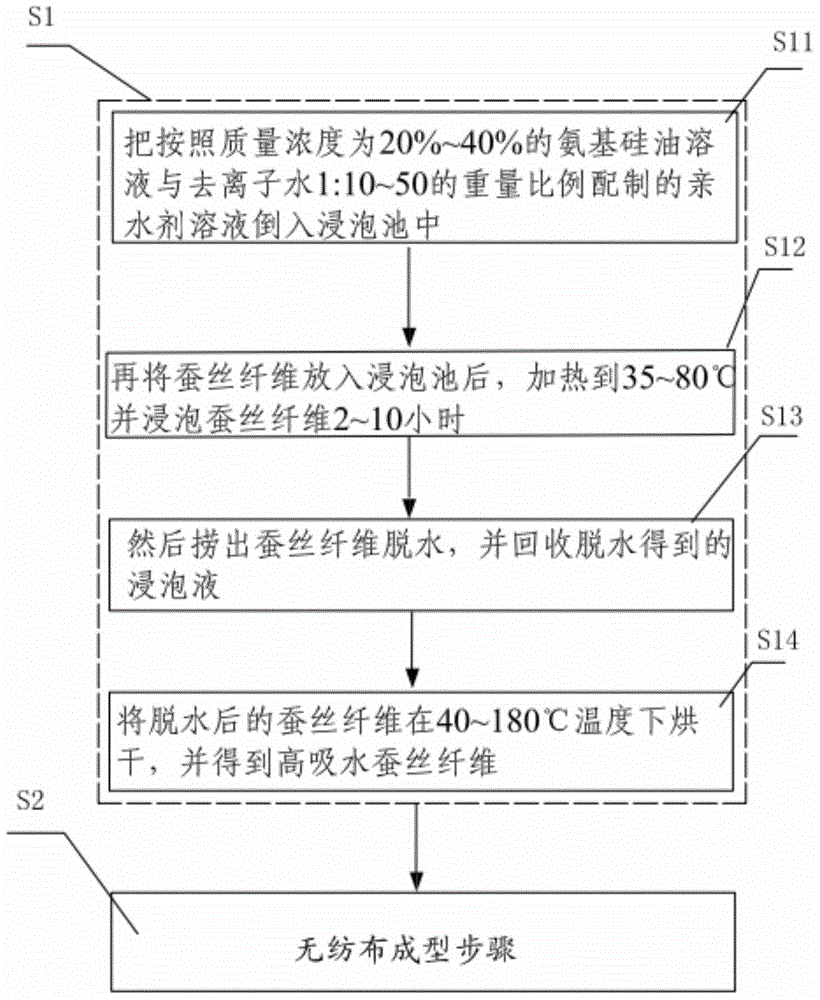

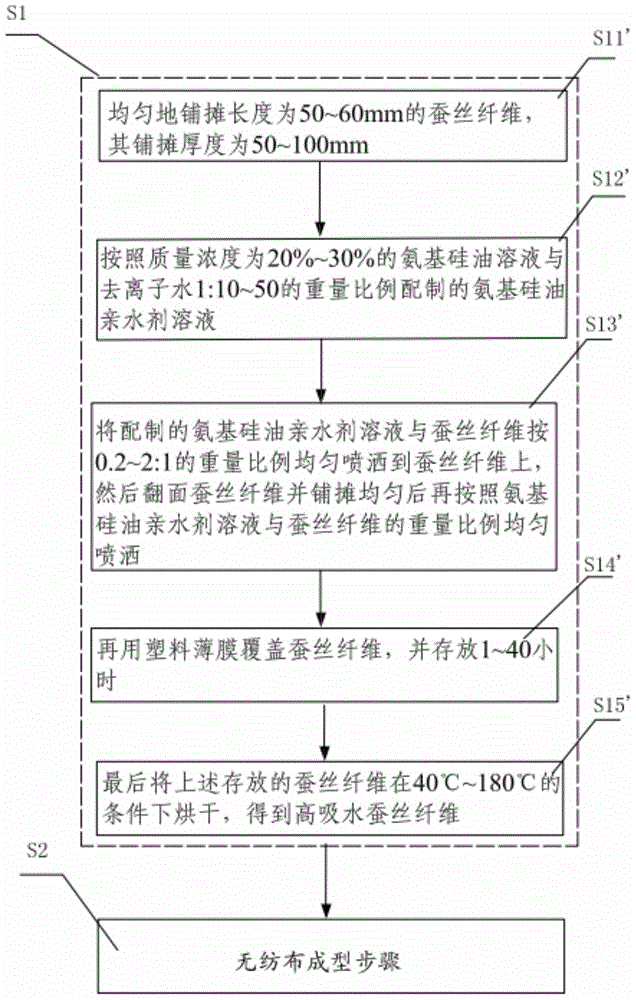

[0042] The concrete steps of described soaking method comprise:

[0043] S11. Pour the hydrophilic agent solution prepared according to the weight ratio of 20% amino silicone oil solution and deionized water into the immersion tank. In this example, a hydrophilizing agent solution prepared by adding...

Embodiment 2

[0049] Such as figure 1 with figure 2 As shown, the present embodiment provides silk non-woven fabric production process, and this production process comprises successively:

[0050] S1, the hydrophilic step, the hydrophilic step processes the silk fiber by soaking, and then obtains the silk fiber after drying;

[0051] S2. The non-woven fabric forming step, however, in the non-woven fabric forming step, water-absorbent silk fibers are produced through a spunlace process to obtain a highly water-absorbent silk non-woven fabric. In addition, the silk fiber is mixed with viscose, polyester or polypropylene fiber at a weight ratio of 1:0.32 before entering the spunlace process.

[0052] The concrete steps of described soaking method comprise:

[0053] S11. Pour the hydrophilic agent solution prepared according to the weight ratio of amino silicone oil solution with a mass concentration of 26% to deionized water of 1:26 into the soaking tank. In this embodiment, use 3000 kg of...

Embodiment 3

[0059] Such as figure 1 with figure 2 As shown, the present embodiment provides silk non-woven fabric production process, and this production process comprises successively:

[0060] S1, the hydrophilic step, the hydrophilic step processes the silk fiber by soaking, and then obtains the silk fiber after drying;

[0061] S2. The non-woven fabric forming step, however, in the non-woven fabric forming step, water-absorbent silk fibers are produced through a spunlace process to obtain a highly water-absorbent silk non-woven fabric. In addition, the silk fiber is mixed with viscose, polyester or polypropylene fiber at a weight ratio of 1:0.60 before entering the spunlace process.

[0062] The concrete steps of described soaking method comprise:

[0063] S11. Pour the hydrophilic agent solution prepared according to the weight ratio of amino silicone oil solution with a mass concentration of 35% to deionized water of 1:30 into the soaking tank. In this embodiment, use 3000 kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com