Continuous cold-rolling and steaming dyeing process and equipment of active dyestuff

A technology of reactive dyes and dyeing equipment, which is applied in the field of continuous cold rolling and steaming dyeing process of reactive dyes and dyeing equipment, can solve the problems of low production efficiency, long dyeing process, sewage, etc., and achieve the improvement of production efficiency, reduction of environmental pollution, and labor intensity. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

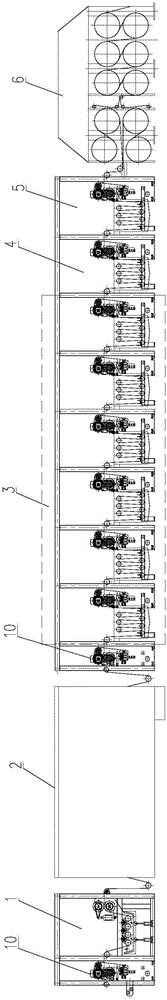

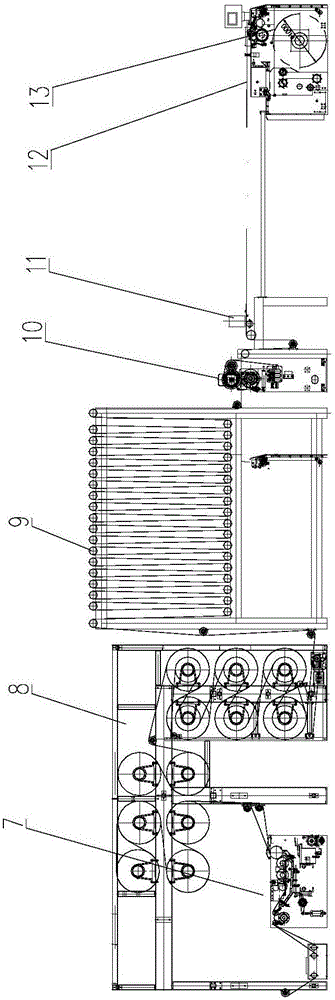

[0029] A reactive dye continuous cold pad steaming dyeing process, comprising the following process steps: 1. dye padding; 2. steaming to fix the color; 3. soaping; 4. pickling; Dry.

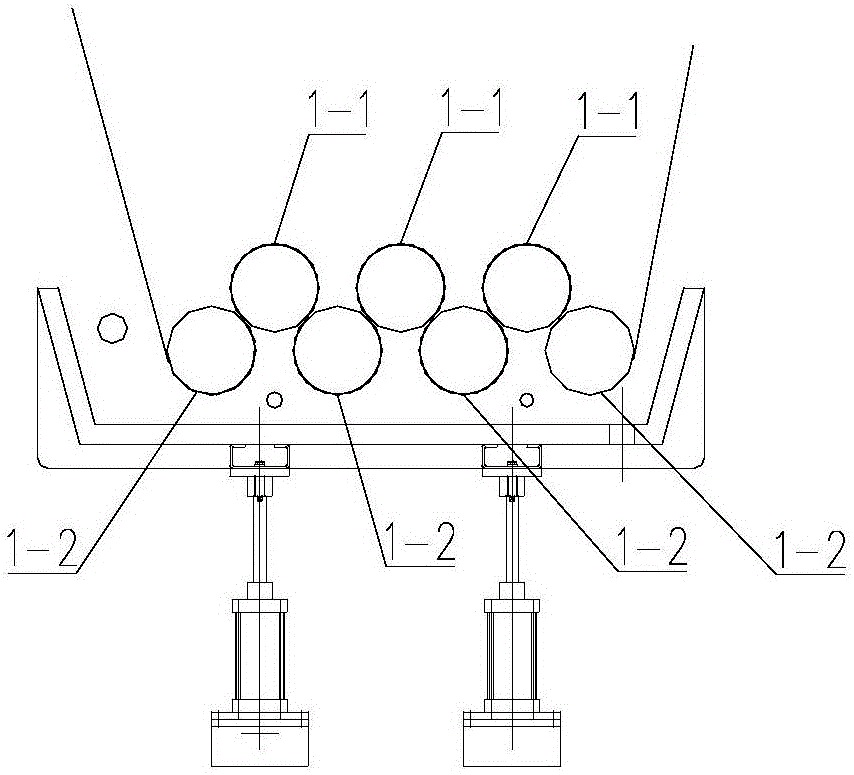

[0030] When dyeing loose fibers, the loose fibers are first arranged into a uniform flat carcass; then, the carcass is sandwiched between the upper interlayer and the lower interlayer, and the upper interlayer, the carcass and the lower interlayer are stitched together by a sewing device , become a suture body that can be continuously transported, and the upper interlayer and the lower clamping are planar through-hole flexible materials; then the suture body is sequentially subjected to padding dyeing, steam color fixing, soaping, pickling, and softness through continuous transportation. Color fixation and water drying.

[0031] When dyeing yarn or fabric, the yarn or fabric is sequentially carried out by means of continuous conveying, dye padding, steam fixation, soaping, pickling, softening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com