Natural antibacterial bamboo fiber sock

A natural antibacterial and antibacterial bamboo technology, applied in fiber treatment, plant fiber, biochemical fiber treatment and other directions, can solve the problems of not meeting the needs of daily life, reducing friction and sweating between toes and socks, and the socks are not resistant to washing. Ultraviolet blood circulation, increase antibacterial effect, good effect of antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

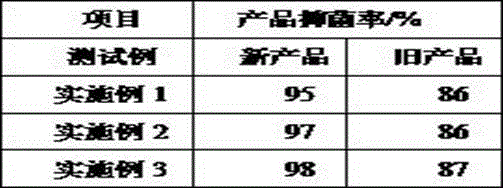

Embodiment 1

[0026] A kind of natural antibacterial bamboo fiber socks is obtained by blending raw materials in the following weight ratios:

[0027] Bamboo fiber 90%

[0028] Lilai fiber 3%

[0030] Milk Fiber 2%

[0031] Seaweed Fiber 1%.

[0032] A preparation method of natural antibacterial bamboo fiber socks, comprising the steps of:

[0033] (1) Blend bamboo fiber, Lilai fiber, aloe fiber, milk fiber and seaweed fiber according to the ratio in the formula to obtain natural antibacterial fiber;

[0034] (2) Soak the natural antibacterial fiber in the chitosan solution for 30 minutes, take it out and dry it;

[0035] (3) Immerse the natural antibacterial fiber in the compound enzyme preparation, the dosage is 0.8% owf, pH 5.2, the temperature is 45°C, keep warm for 45 minutes, raise the temperature to 90°C, keep warm for 10 minutes to inactivate the enzyme, rinse and cool;

[0036] (4) Smash natto, orange peel, Phellodendron cork, capillary, Eucalyptus...

Embodiment 2

[0042] A kind of natural antibacterial bamboo fiber socks is obtained by blending raw materials in the following weight ratios:

[0043] Bamboo fiber 90%

[0044] Lilai fiber 3%

[0045] Aloe Vera Fiber 4%

[0046] Milk Fiber 2%

[0047] Seaweed Fiber 1%.

[0048] A preparation method of natural antibacterial bamboo fiber socks, comprising the steps of:

[0049] (1) Blend bamboo fiber, Lilai fiber, aloe fiber, milk fiber and seaweed fiber according to the ratio in the formula to obtain natural antibacterial fiber;

[0050] (2) Soak the natural antibacterial fiber in the chitosan solution for 32 minutes, take it out and dry it;

[0051] (3) Soak the natural antibacterial fiber in the compound enzyme preparation, the dosage is 1% owf, pH 5.2, the temperature is 45°C, keep warm for 45 minutes, raise the temperature to 90°C, keep warm for 10 minutes, inactivate the enzyme, rinse and cool;

[0052] (4) Smash natto, orange peel, Phellodendron cork, capillary, Eucalyptus eucaly...

Embodiment 3

[0058] A kind of natural antibacterial bamboo fiber socks is obtained by blending raw materials in the following weight ratios:

[0059] Bamboo fiber 90%

[0060] Lilai fiber 3%

[0061] Aloe Vera Fiber 4%

[0062] Milk Fiber 2%

[0063] Seaweed Fiber 1%.

[0064] A preparation method of natural antibacterial bamboo fiber socks, comprising the steps of:

[0065] (1) Blend bamboo fiber, Lilai fiber, aloe fiber, milk fiber and seaweed fiber according to the ratio in the formula to obtain natural antibacterial fiber;

[0066](2) Soak the natural antibacterial fiber in the chitosan solution for 35 minutes, take it out and dry it;

[0067] (3) Soak the natural antibacterial fiber in the compound enzyme preparation, the dosage is 1.2%owf, pH 5.2, the temperature is 45°C, keep warm for 45 minutes, raise the temperature to 90°C, keep warm for 10 minutes to inactivate the enzyme, rinse and cool;

[0068] (4) Smash natto, orange peel, Phellodendron cork, capillary, Eucalyptus euca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com