Overflow dyeing machine

An overflow dyeing machine and main body technology, which is applied in the field of dyeing machines, can solve the problems of fabric winding shrinkage, dyed fabrics are easy to fluff, and affect the effect of cloth surface, etc., achieving short dyeing time, good dyeing effect, and fast filling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

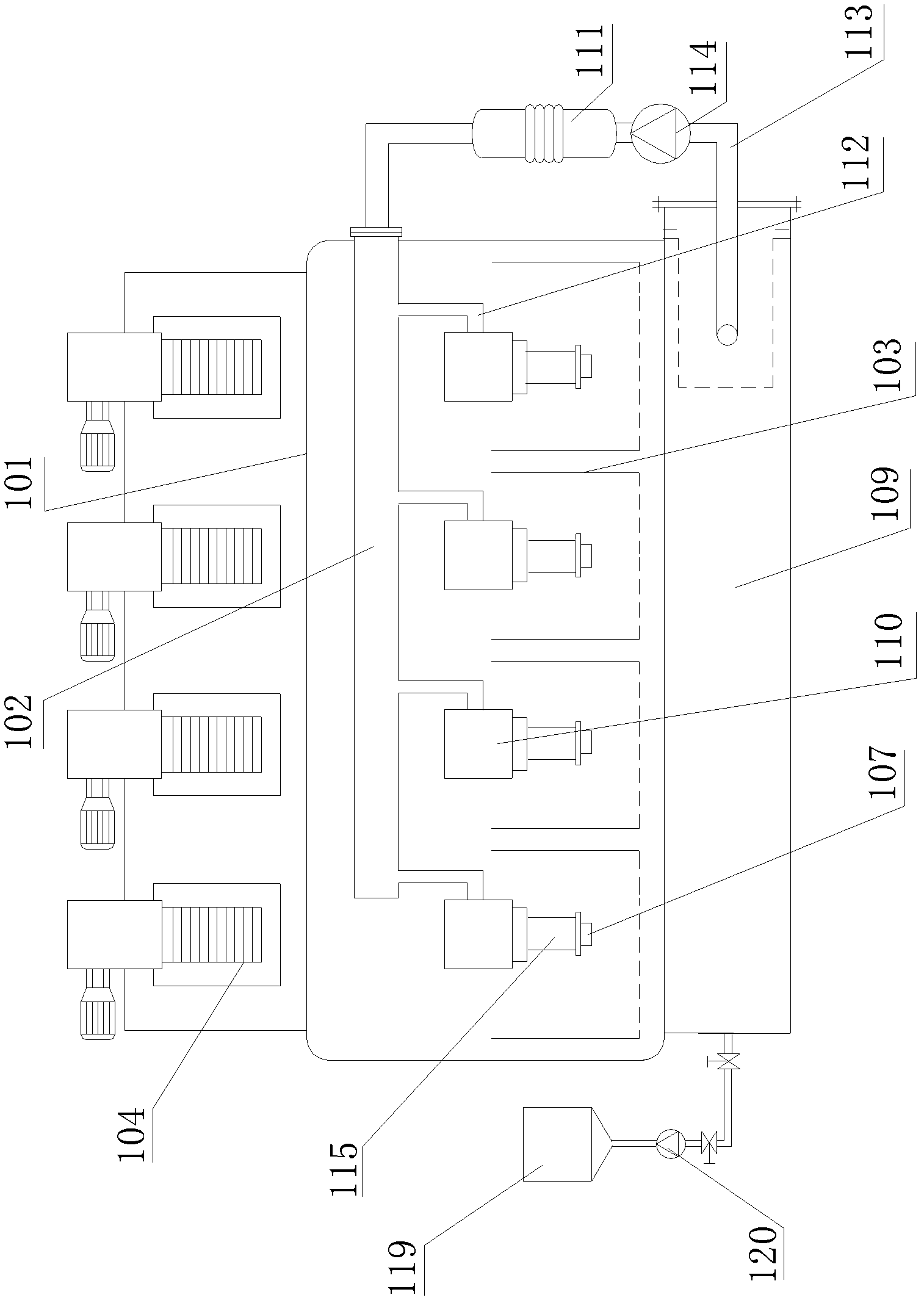

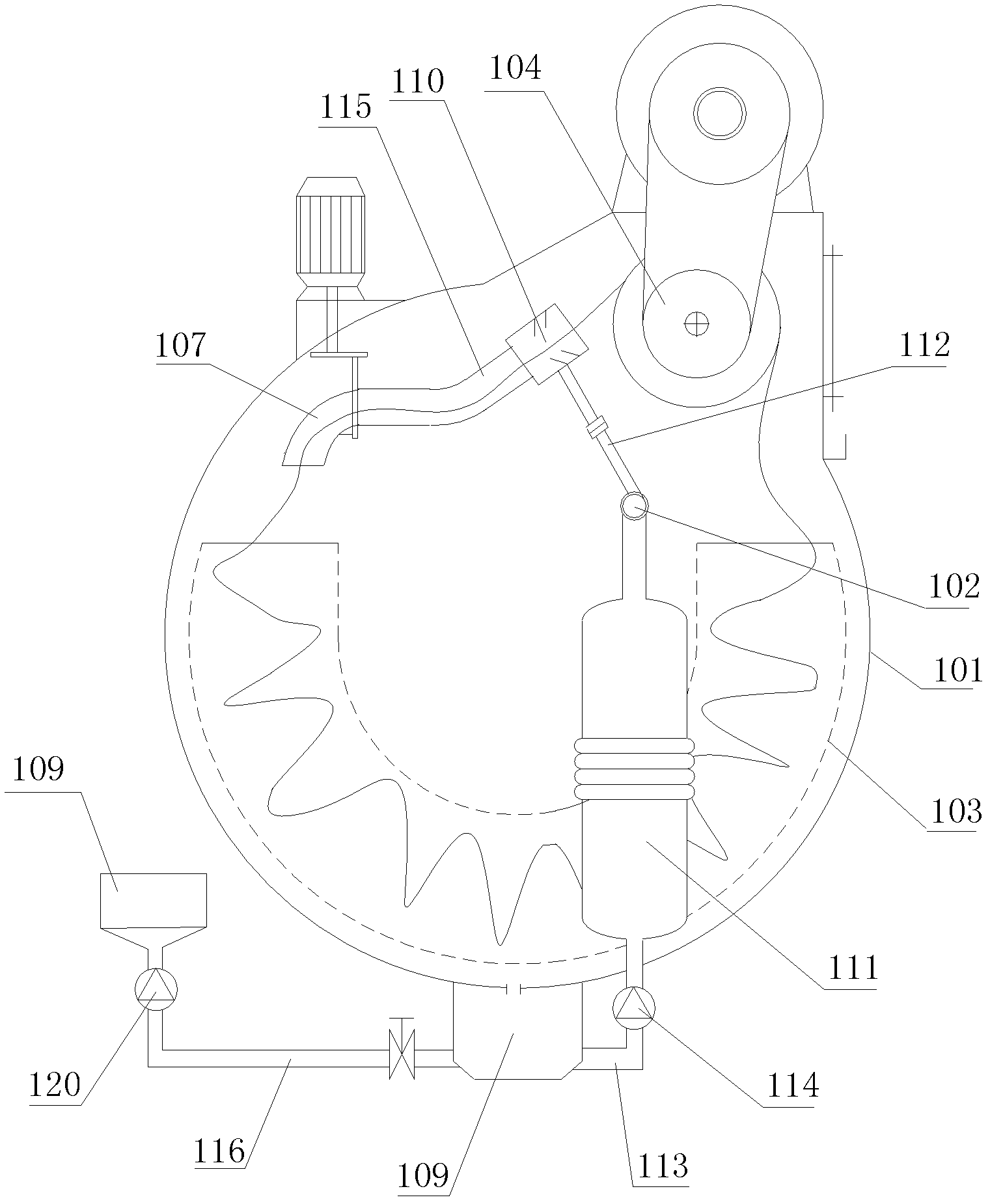

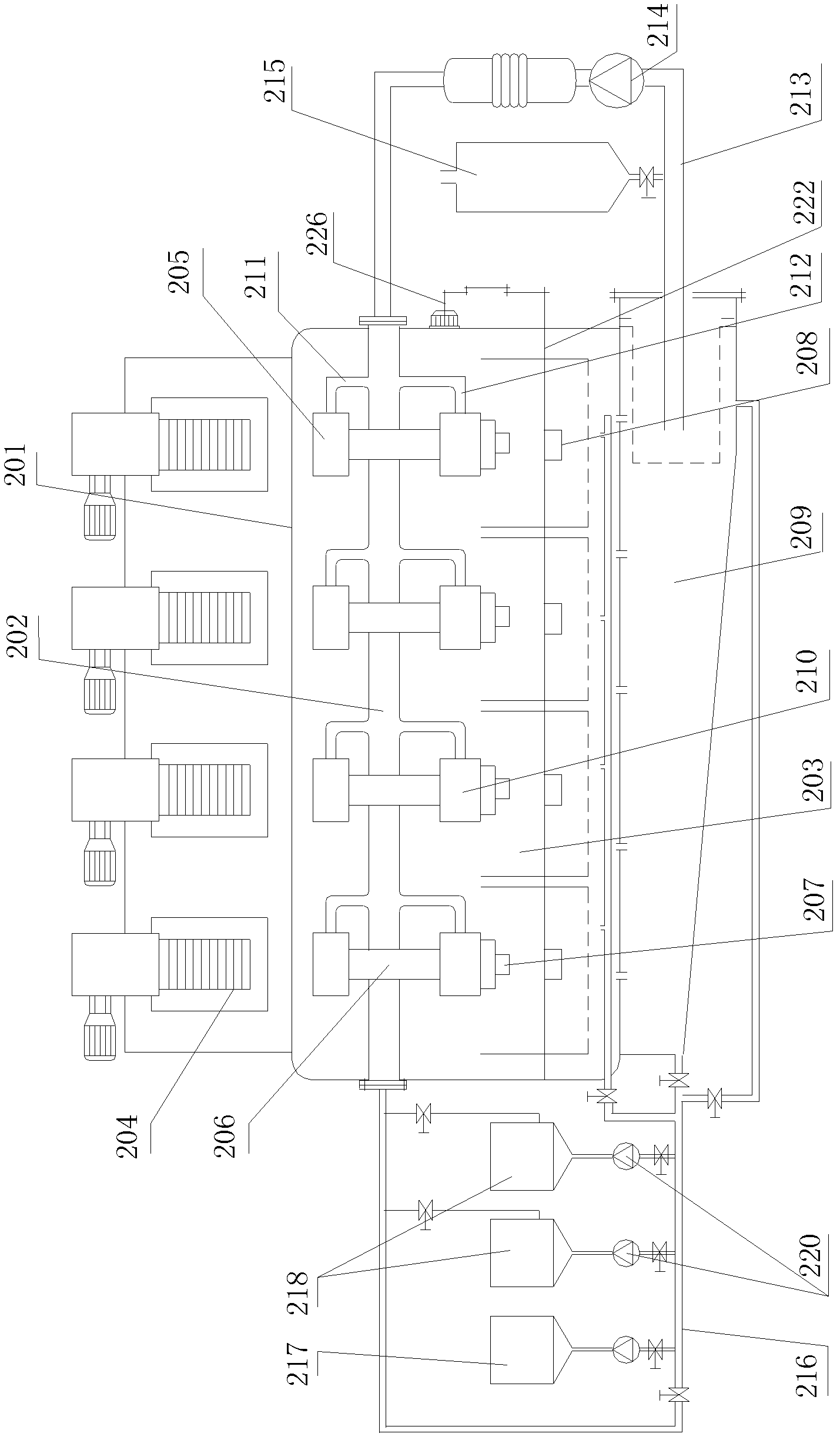

[0022] figure 2 It is a schematic front view diagram of the overall structure of the present invention, image 3 It is a schematic side view of the overall structure of the present invention. Such as figure 2 and combine image 3 As shown, an overflow dyeing machine provided by the present invention includes a main body 201, a cloth storage tank 203 is provided inside the main body 201, and a dyed fabric 232 is placed in the cloth storage tank 203, and a fabric storage tank 203 is provided above the cloth storage tank 203. There is a liquid pipe 202, one end of the liquid pipe 202 is connected to the nozzle 210, and the other end is connected to the liquid storage tank 209 through the circulation pipe 213 and the heat exchanger. The outlet of the material pipeline 216 is connected, and the chemical material cylinder 218 is communicated with the circulation pipeline 213 through the chemical material pipeline 216 . In order to make the dissolution and dilution of dyes and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com