Method for modification, dyeing and multifunctional composite finishing of aramid fiber

A kind of aramid fiber, multi-functional technology, applied in the direction of dyeing, fiber treatment, physical treatment, etc., can solve the problems of inability to meet continuous production, poor wettability of aramid fiber, long processing time, etc., to achieve good anti-ultraviolet aging, dyeing The effect of low temperature and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

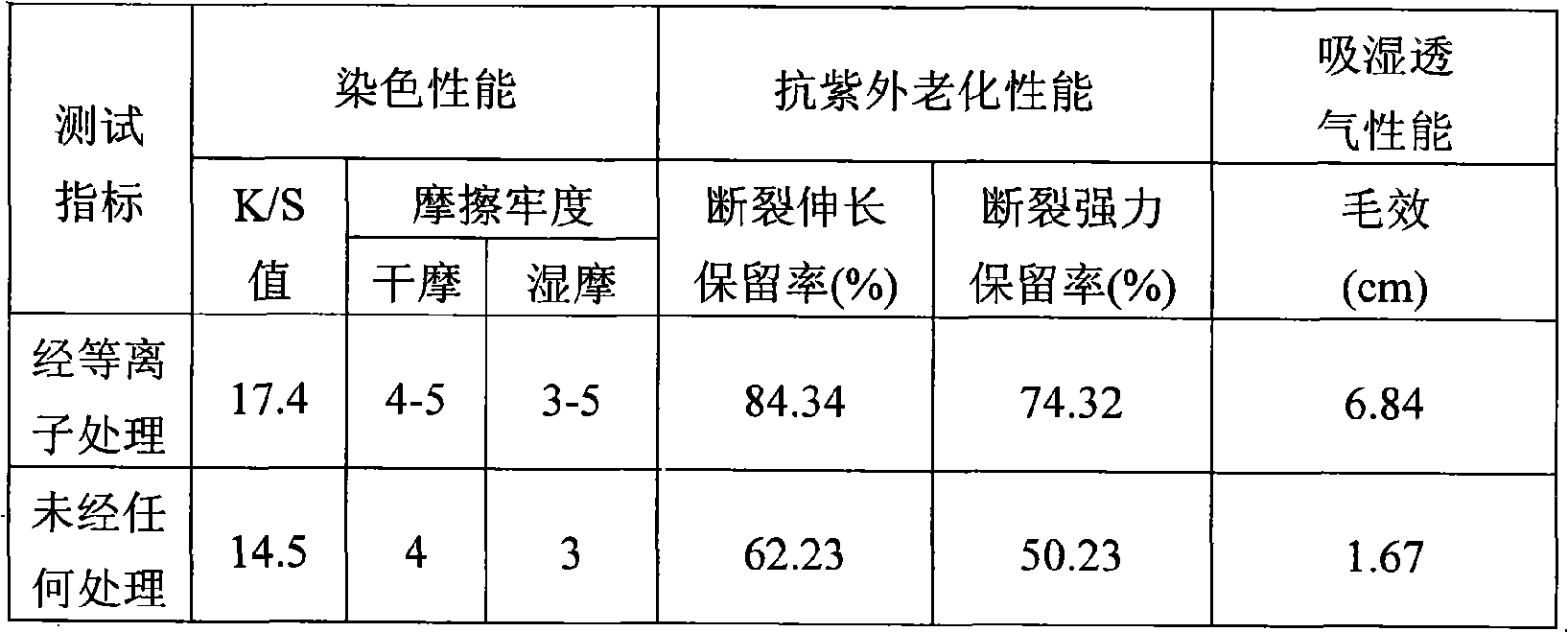

Embodiment 1

[0031] Example 1: The sample selected in this example is aramid yarn, the selected pretreatment method is low-temperature plasma pretreatment, the selected dyeing carrier is acetophenone, the selected finishing solution is titanium / zinc composite sol, and the selected The moisture-absorbing and air-permeable finishing agent is silicone.

[0032] Take 20g of aramid yarn and carry out dyeing pretreatment according to the following process: alkali washing (NaOH 6g / L, degreasing agent DO5g / L, liquor ratio 1:20, temperature 100°C, time 45min), water washing, drying, plasma Body pretreatment (2% air, temperature 25°C, power 100W, treatment time 5min, pressure 25Pa).

[0033]Aramid fiber dyeing: put the above-mentioned pretreated aramid fiber into water containing 60 mL / L of acetophenone, the water temperature is 40° C., and the bath ratio is 1:20. Raise the temperature to 70°C at a rate of 1°C / min, and gradually add cationic dyes with a concentration of about 6% (owf) and Na at a c...

Embodiment 2

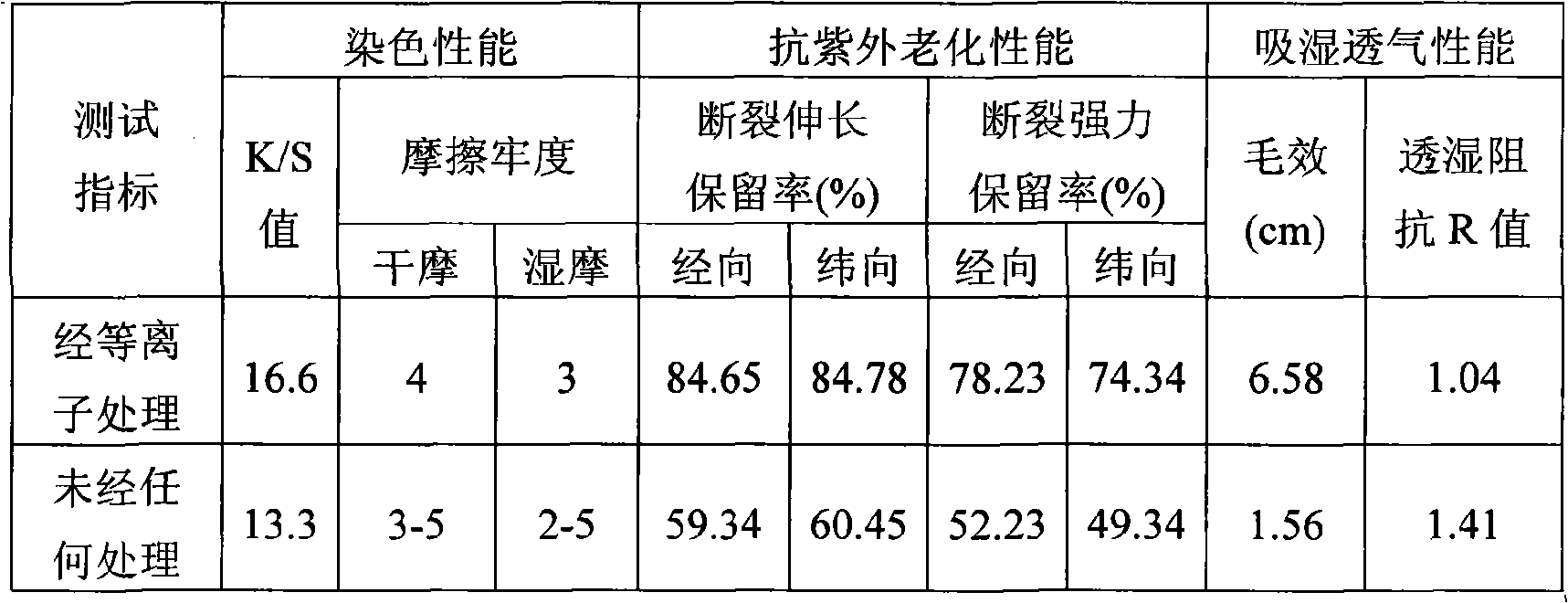

[0038] Example 2: The sample selected in this example is aramid fabric, the selected pretreatment method is plasma pretreatment, the selected dyeing carrier is benzyl alcohol, the selected finishing solution is silicon / titanium composite sol, and the selected moisture absorption and air-permeable finishing The agent is epoxy resin type hydrophilic finishing agent.

[0039] Take 20g of aramid fabric and carry out dyeing pretreatment according to the following process: alkali washing (NaOH 5g / L, degreasing agent DO4g / L, liquor ratio 1:30, temperature 100°C, time 40min), rinse with water, dry at 80°C, Plasma pretreatment (2% oxygen, temperature 25°C, power 75W, treatment time 10min, pressure 5Pa).

[0040] Aramid fabric dyeing: put the above pretreated aramid fabric into water containing 70 mL / L benzyl alcohol, the water temperature is 50° C., and the bath ratio is 1:30. Raise the temperature to 75°C at a rate of 1°C / min, gradually add cationic dyes with a concentration of about...

Embodiment 3

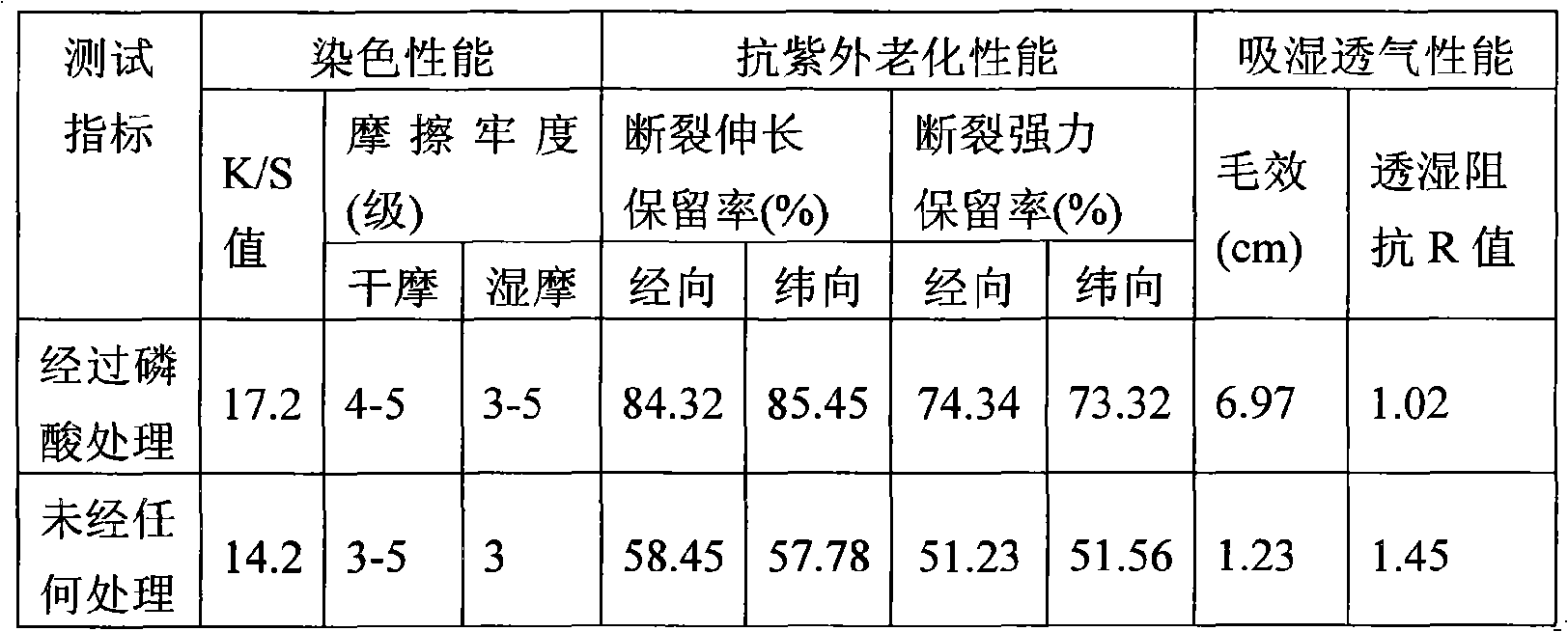

[0045] Example 3: The sample selected in this example is aramid fabric, the selected pretreatment method is phosphoric acid pretreatment, the selected dyeing carrier is acetophenone, the selected finishing solution is silicon / titanium / zinc composite sol, and the selected moisture absorption The air-permeable finishing agent is a block copolymer of polyester and polyether.

[0046] Take 20g of aramid fabric and carry out dyeing pretreatment according to the following process: alkali washing (NaOH 5g / L, degreasing agent DO5g / L, liquor ratio 1:40, temperature 90°C, time 50min), rinse with water, dry at 70°C, Phosphoric acid pretreatment (phosphoric acid 20%, temperature 100°C, treatment time 50min), rinse with water, and dry.

[0047] Aramid fabric dyeing: put the above pretreated aramid fabric into water containing 70mL / L of acetophenone, the water temperature is 55°C, and the bath ratio is 1:25. Raise the temperature to 70°C at a rate of 1°C / min, and gradually add cationic dye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com