Method for dyeing vivid fluorescent green on cotton knitwear

A technology for fluorescent green and knitwear, applied in the field of bright fluorescent green dyeing of cotton knitwear, can solve the problems of not reaching the degree of green brightness, quality not meeting basic requirements, loss of light fastness of 7GFF fluorescent yellow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

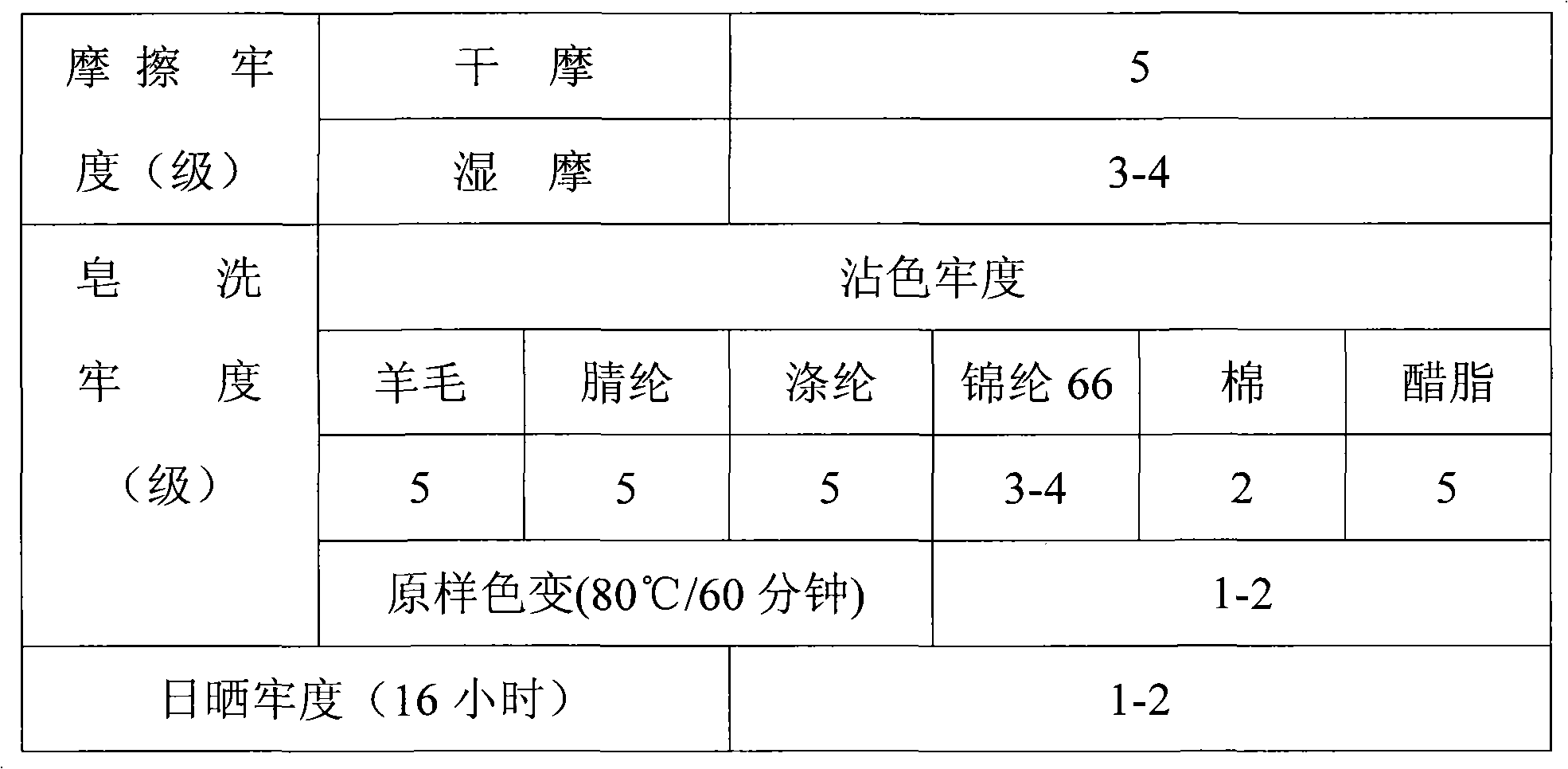

Embodiment 1

[0032] The method for dyeing bright fluorescent green of cotton knitwear comprises the following process steps:

[0033] 1) Pre-treatment of gray cloth;

[0034] 2) Put the gray cloth in the dyeing vat, add water with 8 times the weight of the gray cloth;

[0035] 3) Heat the gray cloth and water described in step 2) to 50-70°C, add active Cuilan MZ-HGN with 0.7-0.9% gray cloth weight, 7GFF fluorescent yellow with 0.05-0.15% gray cloth weight and 10% gray cloth weight -20% table salt, keep warm for 30 minutes;

[0036] 4) Continue heating to 70-90°C, then slowly add soda ash with a weight of 5-15% of the gray cloth to fix the color, and keep it warm for 30 minutes;

[0037] 5) Continue heating to 100°C and keep warm for 15 minutes;

[0038] 6) After the gray cloth is compared to the sample, the temperature is lowered to 60-80°C, and the dyeing solution is removed;

[0039] 7) washing the gray cloth after the above steps for 2 times;

[0040] 8) Soaping the washed gray clo...

Embodiment 2

[0047] The method for dyeing bright fluorescent green of cotton knitwear comprises the following process steps:

[0048] 1) Pre-treatment of gray cloth;

[0049] 2) Put the gray cloth in the dyeing vat, add water with 8 times the weight of the gray cloth;

[0050] 3) Heat the gray cloth and water described in step 2) to 55-65°C, add active Cuilan MZ-HGN of 0.75-0.85% of gray cloth weight, 7GFF fluorescent yellow of 0.08-0.12% of gray cloth weight and 12% of gray cloth weight -18% table salt, keep warm for 30 minutes;

[0051] 4) Continue heating to 75-85°C, then slowly add soda ash with a weight of 8-12% of the gray cloth to fix the color, and keep it warm for 30 minutes;

[0052] 5) Continue heating to 100°C and keep warm for 15 minutes;

[0053] 6) After the gray cloth is compared to the sample, the temperature is lowered to 65-75°C, and the dyeing solution is removed;

[0054] 7) washing the gray cloth after the above steps for 2 times;

[0055] 8) Soaping the washed g...

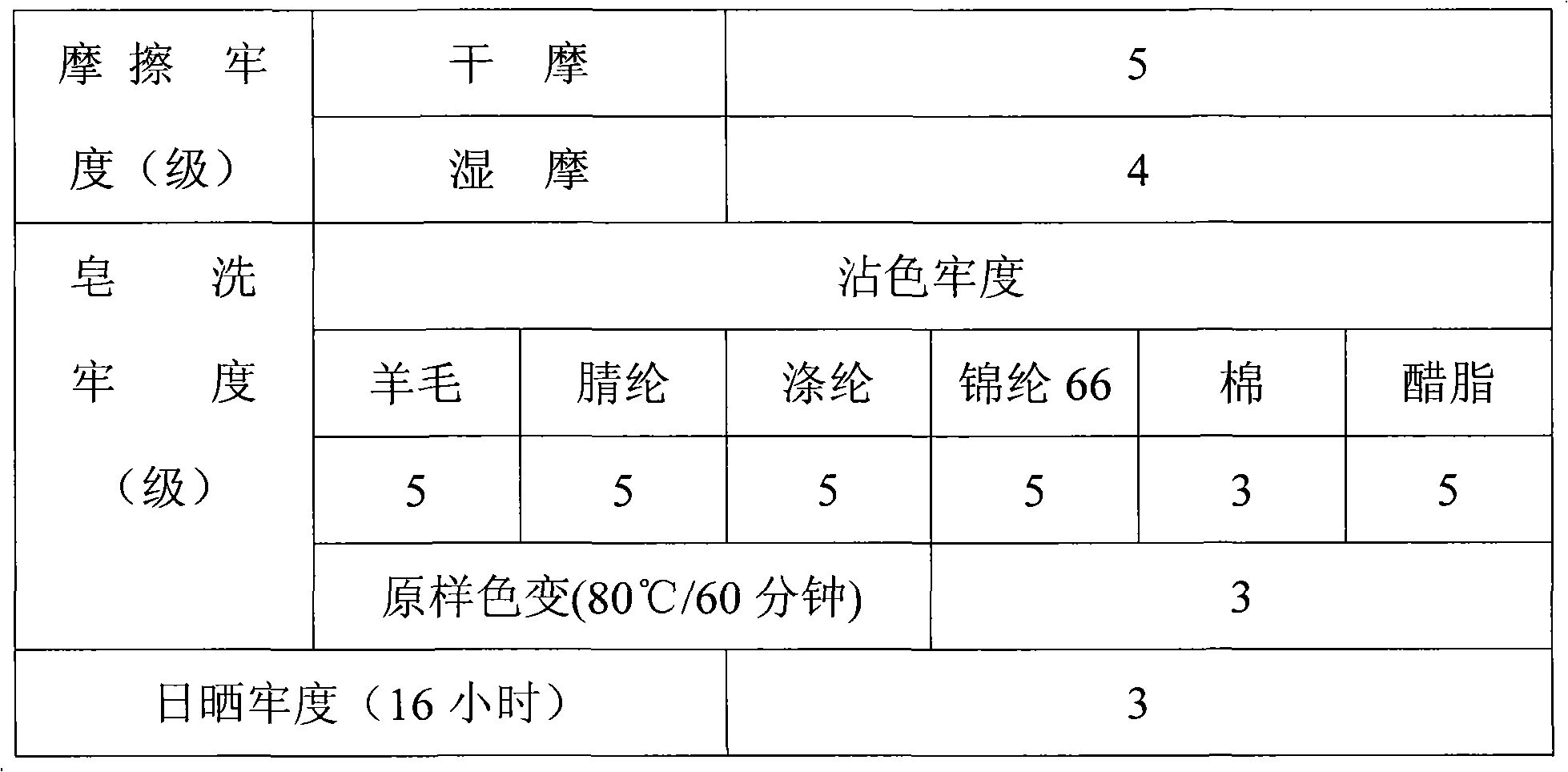

Embodiment 3

[0062] The method for dyeing bright fluorescent green of cotton knitwear comprises the following process steps:

[0063] 1) Pre-treatment of gray cloth;

[0064] 2) Put the gray cloth in the dyeing vat, add water with 8 times the weight of the gray cloth;

[0065] 3) Heat the gray cloth and water described in step 2) to 60°C, add 0.8% of the gray cloth weight active Cuilan MZ-HGN, 0.1% gray cloth weight of 7GFF fluorescent yellow and 15% gray cloth weight of salt, and keep warm for 30 minute;

[0066]4) Continue heating to 80°C, then slowly add soda ash with 10% gray cloth weight to fix the color, and keep it warm for 30 minutes;

[0067] 5) Continue heating to 100°C and keep warm for 15 minutes;

[0068] 6) After the gray cloth is compared to the sample, the temperature is lowered to 70°C, and the dyeing solution is removed;

[0069] 7) washing the gray cloth after the above steps for 2 times;

[0070] 8) Soaping the washed gray cloth once at a temperature of 90°C;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com