Patents

Literature

38results about How to "Meet quality indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Linseed kernel oil and production method thereof

InactiveCN101602978AImprove oil yieldLow residual oil rateFatty-oils/fats productionEdible oils/fatsAlpha-Linolenic acidEdible oil

The invention discloses linseed kernel oil, which is extracted by pretreating and peeling linseed and taking linseed kernel as a raw material. A production method of the linseed kernel oil comprises the following steps: cleaning and drying linseed, separating peel and kernel; crushing, cooking the linseed kernel and squeezing out oil; and filtering and precipitating to obtain a finished product. The invention provides brand new edible oil. The processing technique of the product does not add any chemical reagent and is green and pollution-free, the product has no any chemical pollution, and the processing of the product is not subjected to high temperature, keeps alpha-linolenic acid in the linseed, and enables the content of the alpha-linolenic acid of the product to reach about 60 percent. The content of crude protein in byproduct, namely linseed kernel cake is improved by 10 percent compared with that of linseed cake and reaches about 43 percent, and the anti-nutritional factors are greatly reduced, widen the application of the linseed kernel cake and improve the additional value of processing. The product is novel, and the processing technology is mature, has high oil extraction rate and is easy to popularize.

Owner:高银阁

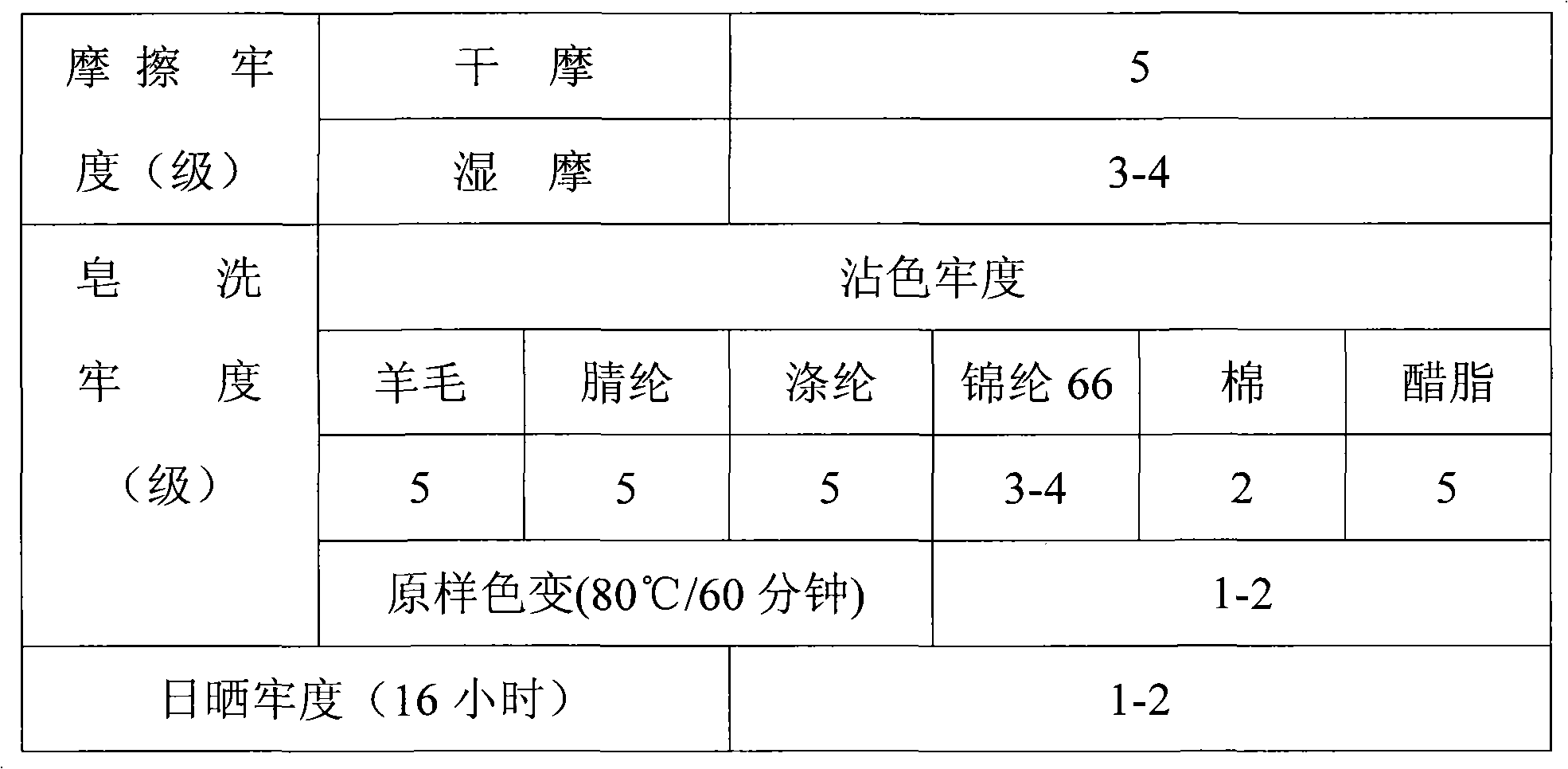

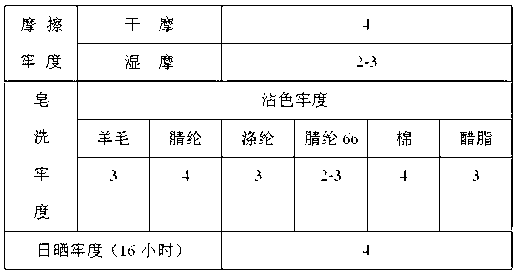

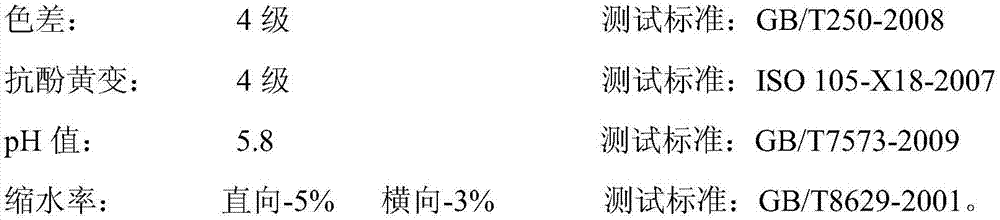

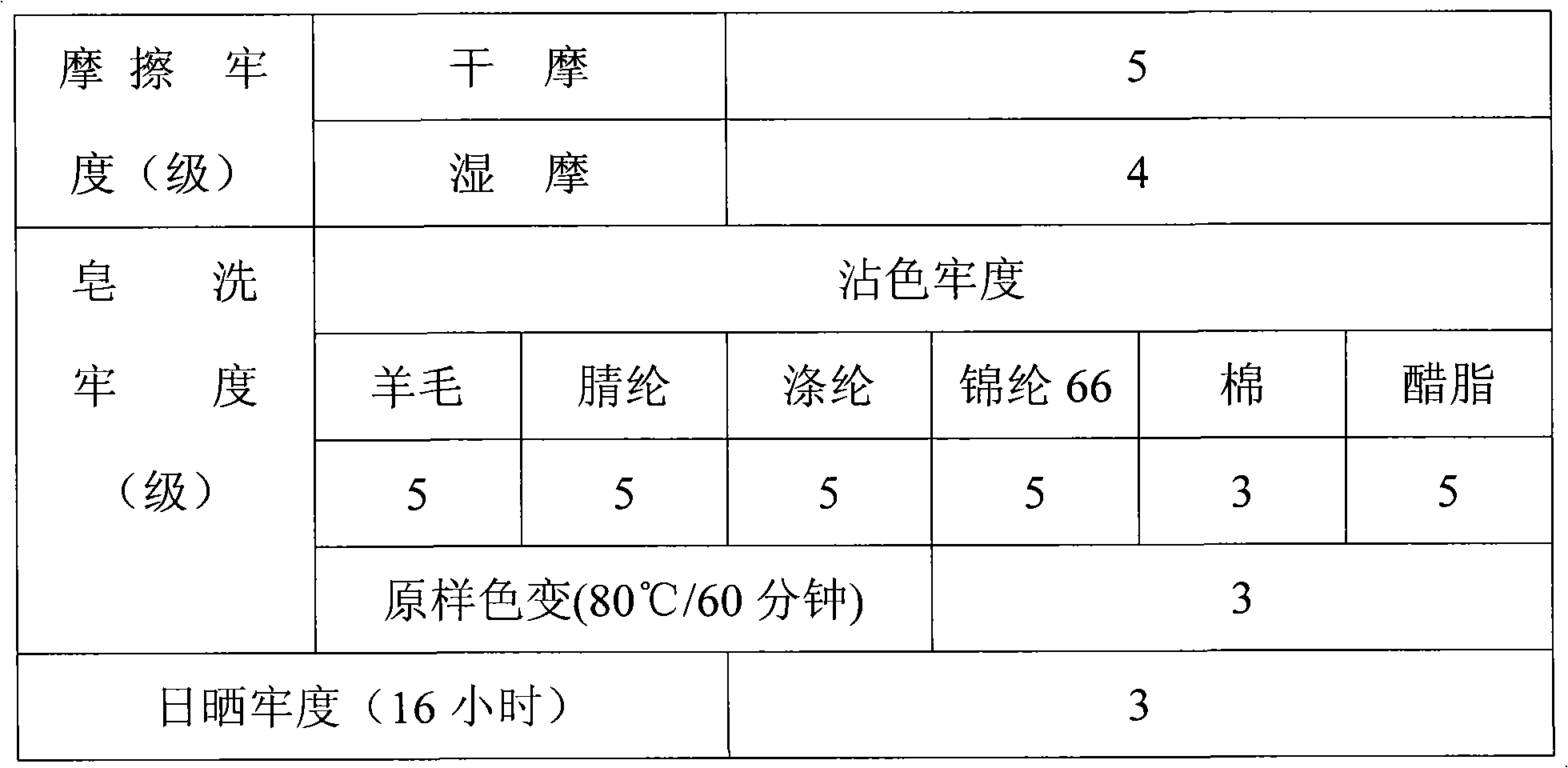

Method for dyeing vivid fluorescent green on cotton knitwear

InactiveCN101597867AMeet the requirements of bright colorMeet quality indicatorsDyeing processFluorescenceEmerald

The invention relates to a method for dyeing cotton knitwear, in particular to a method for dyeing fluorescent green on cotton knitwear. The method comprises the following steps: 1) pretreating grey cloth; 2) placing the grey cloth and eightfold weight of water into a dye vat; 3) heating the grey cloth and the water to a temperature of 60 DEG C, adding reactive emerald blue MZ-HGN, 7GFF fluorescent yellow and salt into the dye vat in sequence to reserve the temperature for 30 minutes; 4) continuously heating the mixture to a temperature of 80 DEG C, and gradually adding calcined soda for fixation, and reserving the temperature for 30minutes; 5) continuously heating the mixture to a temperature of 100 DEG C, and reserving the temperature for 15 minutes; 6) comparing the grey cloth with a sample, cooling the grey cloth to a temperature of 70 DEG C, and removing dye liquor; 7) washing the grey cloth with water twice after the steps; 8) washing the water washed grey cloth with soap once at a temperature of 90 DEG C; 9) washing the grey cloth which is washed by the soap for 2 or 3 times with water; 10) carrying out softening treatment on the water washed grey cloth at 40 DEG C, reserving the temperature for 15 minutes and taking the grey cloth out of the dye vat; 11) dehydrating the grey cloth; 12) drying the grey cloth; 13) shaping the grey cloth. The cloth dyed through the method not only can meet the requirement of clients on color brightness, but also achieves the corresponding quality index.

Owner:ZHEJIANG YINHE PRINTING & DYEING

Enamel prepared from waste ceramic and its preparation method

The invention provides a ceramic glaze and preparation method from waste ceramic. Wherein, the product comprises: 18~25% waste ceramic powder, 20~30% quartz, 10~20% feldsparú¼8~12% China clayú¼0~5% zinc oxide, 0~10% dolomiteú¼7~15% calciteú¼and 0.2~0.5% methylcellulose. The preparation method comprises: cleaning and dedusting the ceramic powder, drying, breaking, and screening; putting said materials into ball grinder with proper water; screening, adding prepared ceramic powder; grinding and screening to prepare glaze slurry; adding methylcellulose into slurry to mix and obtain the product. This invention reduces cost and pollution.

Owner:林伟河

Grinding technique for aluminum alloy drum of external-drum type plate-making machine

ActiveCN101661230AAvoid disadvantagesHigh surface hardnessAnodisationElectrography/magnetographySurface cleaningHardness

The invention relates to grinding technique for an aluminum alloy drum of an external-drum type plate-making machine. The technical problem needed to be solved is as follows: the provided technique can effectively process the drum of the plate-making machine, and have the characteristics of high processing precision, good quality, high working efficiency and convenient processing. The technical scheme is that the grinding technique for the aluminum alloy drum of the external-drum type plate-making machine is implemented in sequence according to the following steps of: 1) implementing conventional metal machinery processing to basically shape the profile of the drum; 2) implementing the cleaning processing of the surface of the drum and pre-processing of anodic oxidation; 3) implementing the processing of hard anodic oxidation on the surface of the drum to lead the thickness of a hard oxidation layer to achieve 0.03-0.05mm and lead the rigidity to achieve HV390-410; and 4) grinding until the requirements are met. Rough turning, high temperature aging, semi-fine turning, middle temperature aging, assembling and milling, low temperature aging and fine turning are implemented in the step 1) in sequence; and the surface cleaning processing in the step 2) refers to the processing of degreasing and oil removing.

Owner:HANGZHOU CRON MACHINERY & ELECTRONICS CO LTD

Porcelain glaze prepared by utilizing waste porcelain and manufacturing method thereof

The invention relates to a porcelain glaze prepared by utilizing waste porcelain. The porcelain glaze consists of the following components in percentage by weight: 8-20% of waste porcelain powder, 8-12% of kaoline, 5-7% of talc, 1-2% of barium carbonate, 6-11% of ground calcium carbonate powder, 3-8% of zinc oxide, 1-5% of dolomite, 15-25% of quartz and 10-30% of feldspar. A manufacturing method of the porcelain glaze comprises the following steps: washing old porcelain with water, after dust removal and drying, crushing, and putting the components in a ball grinding mill, adding an appropriate amount of water, ball-milling for 20 h, adding manufactured waste porcelain powder for combination and regrinding for 2 h, and standing to obtain glaze slip. The utilization ratio of the glaze slip prepared by the method for using the waste porcelain can be up to about 20%. The waste porcelain selected and used in the method takes the place of a portion of quartz, feldspar and some high-lead raw materials, and thus the production cost of porcelain raw materials is greatly reduced; meanwhile, the environmental pollution is effectively reduced, the waste porcelain is sufficiently and reasonably utilized, and the waste is turned into wealth; the glaze slip completely meets the technological requirements of the glaze for porcelain for daily use or porcelain for artistic, and accords with all quality indexes.

Owner:FUJIAN DEHUA XIEFA GUANGYANG POTTERY

Production process for refining glucosamine hydrochloride through membrane separation

InactiveCN102408458AMeet quality indicatorsNo pollution in the processSugar derivativesSugar derivatives preparationUltrafiltrationGlucosamine Hydrochloride

The invention discloses a production process for refining glucosamine hydrochloride through membrane separation. The production process comprises the following steps: based on citric acid waste residue as a raw material, hydrolyzing, performing suction filtering, and concentrating to obtain crude glucosamine hydrochloride, and refining the crude glucosamine hydrochloride through membrane separation to obtain the finished glucosamine hydrochloride, wherein a membrane is an ultrafiltration membrane, a mass transfer material is water and the driving force of mass transfer is pressure difference. The production process disclosed by the invention is simple, the product purity is high, and the glucosamine hydrochloride product produced by using the citric acid waste residue obtained through the fermentation production of citric acid as the raw material is vegetarian glucosamine hydrochloride, has no fishy smell and heavy metal pollution, is safe and environmentally friendly and meets the quality index of glucosamine hydrochloride in developed countries such as Europe and the United States.

Owner:NANTONG FOREIGN TRADE MEDICINES & HEALTH PRODUCTS CO LTD +1

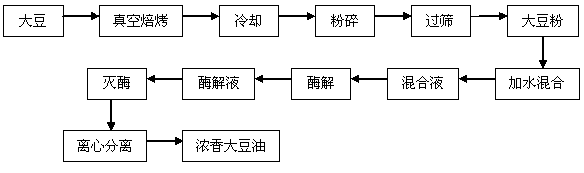

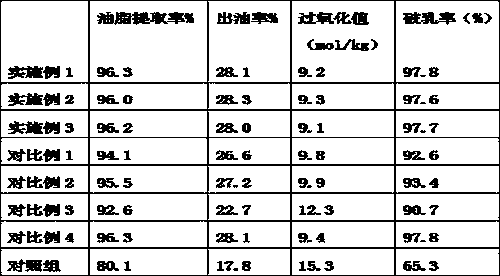

Preparation method for superfine fragrant soybean oil

ActiveCN103627511AHigh transparencyMeet quality indicatorsFatty-oils/fats productionEdible oils/fatsSOYBEAN SEED OILChemistry

The invention provides a preparation method for superfine fragrant soybean oil and belongs to a vegetable oil and fat extracting preparation technique. The method comprises the following steps: (1) spreading soybeans in a tray and putting the tray into a vacuum oven to bake the soybeans; (2) cooling the baked soybeans to the room temperature, then crushing and sieving to obtain soybean flour, and blending the soybean flour with distilled water to form a mixed solution; (3) sequentially adding cellulose, compound polysaccharide for vegetable hydrolysis, and alkaline protease into the mixed solution for enzymolysis, and obtaining an enzymatic hydrolysate after enzymolysis; (4) heating the enzymatic hydrolysate in a boiling water bath to deactivate enzyme, and then centrifugally separating to obtain the superfine fragrant soybean oil. The source of the raw material is natural; the preparation method is green and environment-friendly; since vacuum baking treatment is adopted, contact between the soybeans and the air is avoided so as to inhibit the formation of hydroperoxide; the acid value of the obtained soybean oil is less than 1 mgKOH / g, the smell is strong, the color is reddish yellow, the soybean oil is not muddy, the transparence is good, and the quality index of superfine fragrant soybean oil is met.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

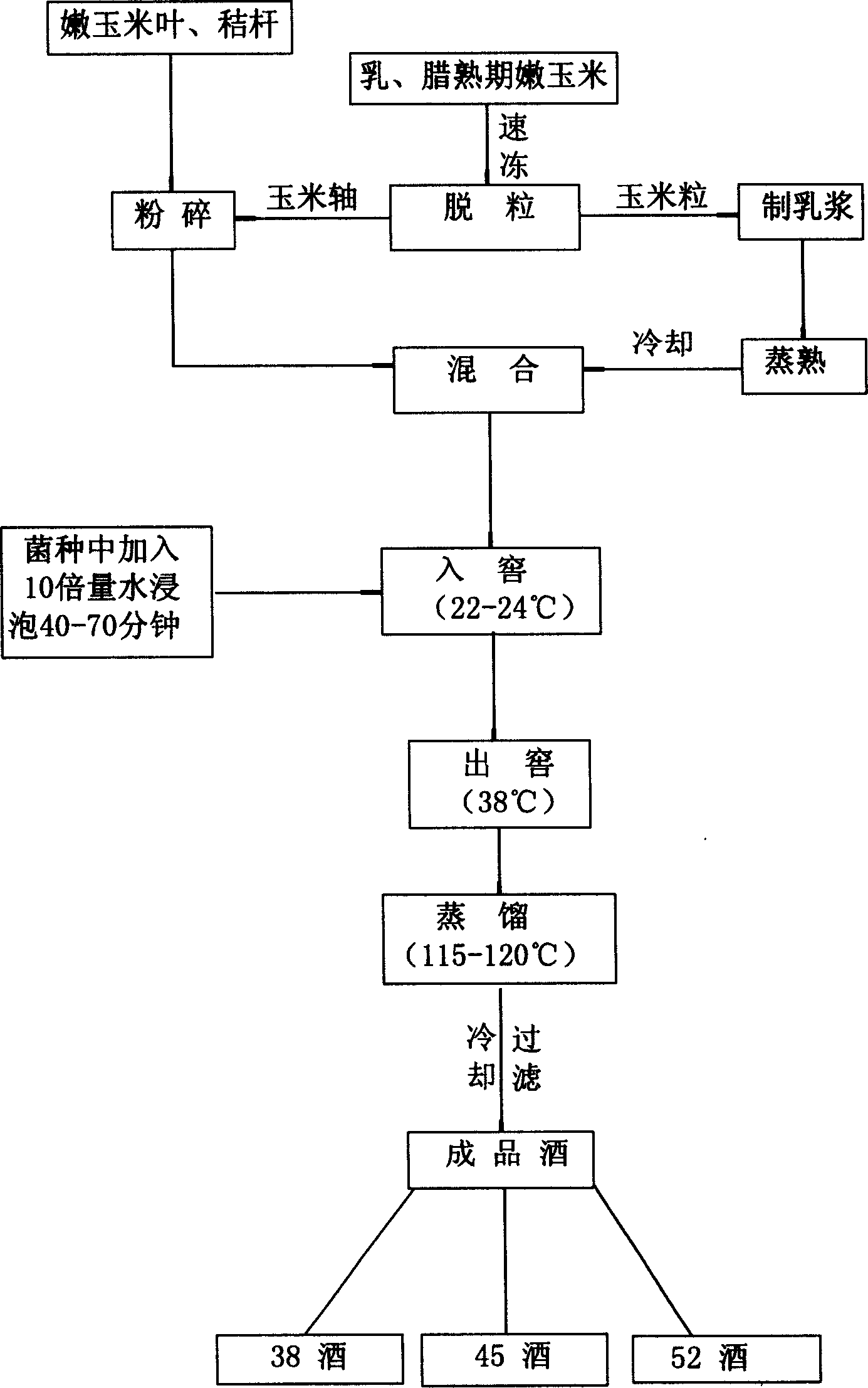

Formula for brewing white spirit by tender corn emulsion and its production

The invention publishes a kind of wine, produced by using tender corn serum, and its prescription and producing method. It is produced by main material made of tender corn serum, rice and water, assistant material made of crushed tender corn axes, leaves and original rice bacteria. The proportion of the main material and assistant material is 3:1 and the proportion of the bacteria and main material is 0.4-0.5%. The producing method is: first, mix and braize the main material and assistant material and when the temperature is down to 22-24 deg.C, insert and mix around active bacteria to ferment. And then instill it. Secondly, mix less and off-pan material by proper proportion and ferment, and then instill it. Thirdly, the cut fraction of every instillation is the production. In short, the invention has a good taste and the material is easily available. Additionally, it is economic and has high nutrition value.

Owner:徐海林

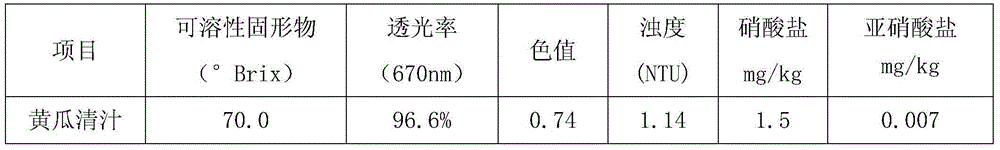

Method for removing nitrate and nitrite during cucumber clear juice processing

InactiveCN104397508AHigh elution rateMeet quality indicatorsFood adsorptionFood preparationActivated carbonNitrite

The invention relates to a method for removing nitrate and nitrite during cucumber clear juice processing. The method comprises the following steps: crushing to prepare cucumber pulp, squeezing to prepare cucumber normal juice, carrying out enzymolysis and centrifugal treatment on the cucumber normal juice to obtain cucumber clear juice, adding active carbon in the cucumber clear juice to carry out stirring adsorption, carrying out ultrafiltration, heating to 45-50 DEG C, obtaining clarified cucumber clear juice through a resin adsorption column, and carrying out vacuum concentration, sterilization and filling on the cucumber clear juice to obtain the nitrate and nitrite removed cucumber clear juice. According to the method, macroporous resin is used for adsorbing the nitrate and nitrite in the cucumber juice during cucumber clear juice processing, so that the removal cost is low, the efficiency is high and the quality index of the domestic and export fruit and vegetable juice can be fully satisfied; meanwhile, the macroporous resin can be repeatedly used through elution, and the elution rate is up to above 90%.

Owner:JINAN INST OF FRUIT PRODS CHINA GENERAL SUPPLY & MARKETING COOP

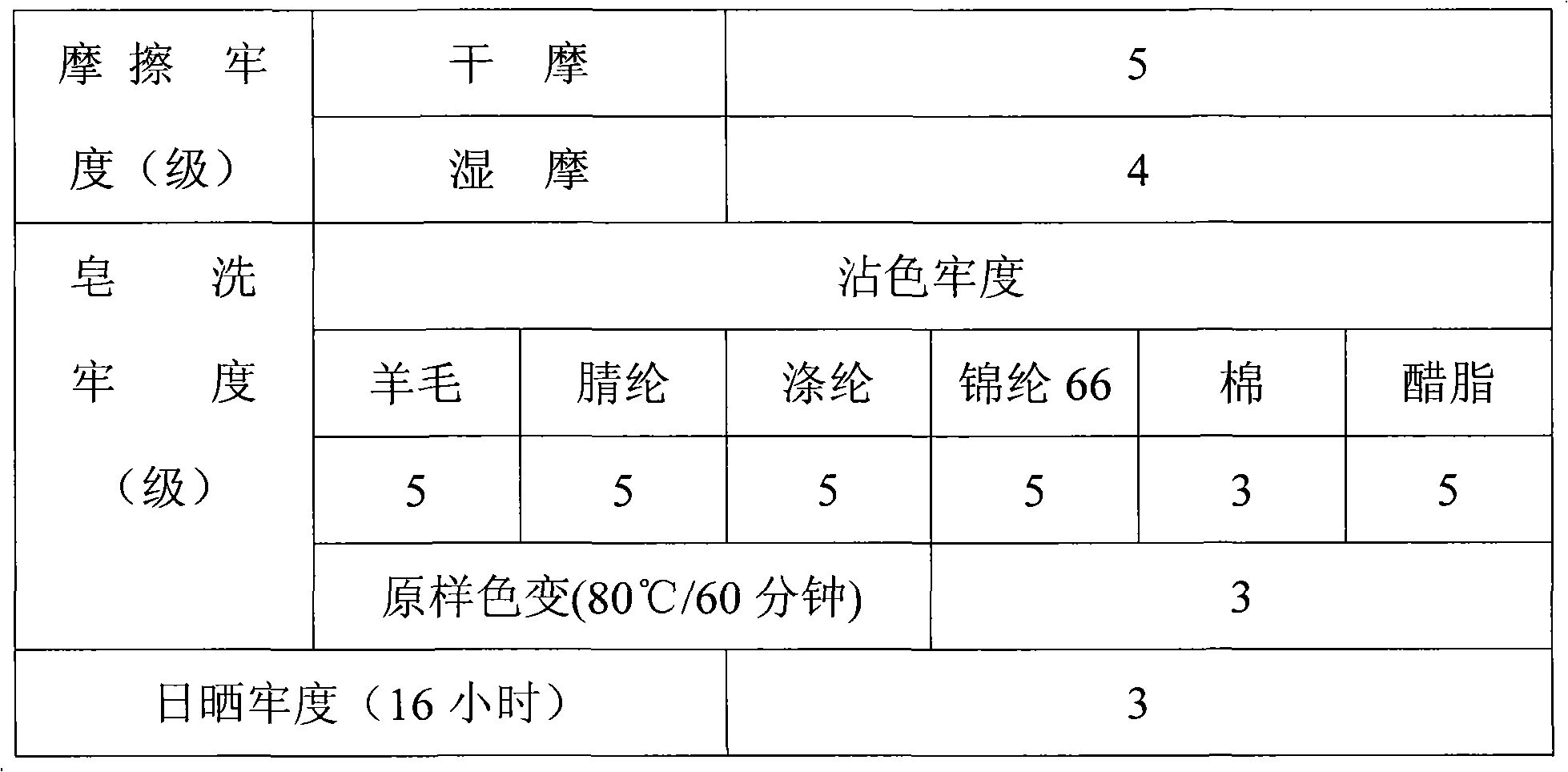

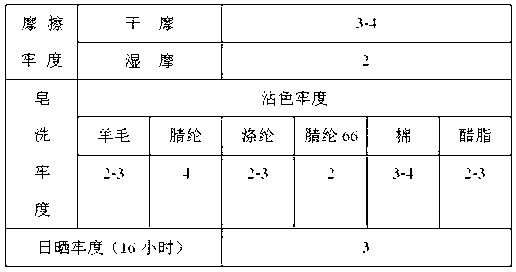

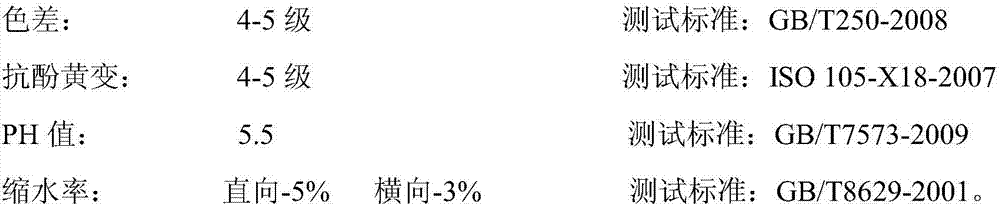

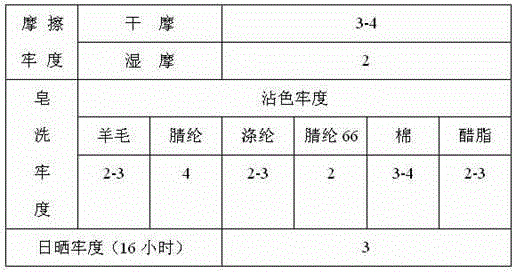

Method for dyeing cotton knitwear in bright fluorescent pink

ActiveCN102912653AMeet the requirements of bright colorMeet the requirements of fastnessBleaching apparatusDyeing processAdenylate kinaseFluorescence

The invention relates to a method for dyeing cotton knitwear, in particular to a method for dyeing cotton knitwear in bright fluorescent pink. The method includes firstly, removing hair in an air cylinder before high-temperature pretreatment; secondly, dyeing an overflowing cylinder, and adding HAC (ethanoic acid) to regulate PH to 5-6; thirdly, measuring and adding ADK (adenylate kinase)-260 cation modifier; fourthly, discharging water once; fifthly, allowing for water inflowing, and adding fluorescent pigment vermilion S-004; sixthly, performing sample comparison; seventhly, washing twice after sample comparison, and taking out of the cylinder; eighthly, soaking in a scoop outside the cylinder, and adding ADK-101 adhesive; ninthly, dewatering and drying; and tenthly, shaping. The condition that reactive dye cannot be used to dye bright fluorescent pink conventionally is broken through, the fluorescent pigment is selected for dyeing, and accordingly gorgeous and bright fluorescent dyeing effect is achieved. By the steps of the method, the requirement of customers for color brightness is met, and corresponding quality index is met.

Owner:ZHEJIANG YINHE PRINTING & DYEING

Preparation method of titanium dioxide for chemical fiber

The invention discloses a preparation method of titanium dioxide for chemical fiber, which comprises the following steps of dispersion, ball milling, sand grinding, ion grading, post treatment, press filtering, spray drying, air flow crushing, magnetic suction and package. The preparation method is characterized in that in the dispersing step, titanium white kiln falling products are dispersed by deionized water with the pH value being 10 through being stirred for 0.5 to 1 hour at the rotating speed being 800 to 1200 r / min. The indexes of the prepared titanium dioxide such as the whiteness, the purity, the fineness, the iron trioxide content and the like completely reach the quality index of titanium white for the chemical fiber.

Owner:SHANGHAI PENGBO TITANIUM DIOXIDE

Method for recovering aminothiazoly loximate

The invention belongs to the technical field of medicines, and particularly relates to a method for recovering aminothiazoly loximate. Hydrolysate generated in the aminothiazoly loximate production process is subjected to electrodialysis concentration to obtain a concentrated solution, the concentrated solution is pre-decolorized to obtain an aminothiazoly loximate one-step crude product, the aminothiazoly loximate one-step crude product is subjected to reverse adjustment decolorization to obtain an aminothiazoly loximate two-step crude product, and the aminothiazoly loximate two-step crude product is refined to obtain an aminothiazoly loximate finished product. The reverse-regulation decolorization comprises the following steps: dissolving the aminothiazoly loximate one-step crude product in water, dropwise adding liquid caustic soda to perform reverse-regulation, dissolved clarification, and decolorizing to obtain an aminothiazoly loximate two-step crude product. According to the method, qualified aminothiazoly loximate product can be recycled, the wastewater treatment amount is reduced, the process is efficient, simple, environmentally friendly and high in profit, and the method is suitable for large-scale industrial production.

Owner:SHANDONG JINCHENG PHARMACCUTICAL CHEM CO LTD

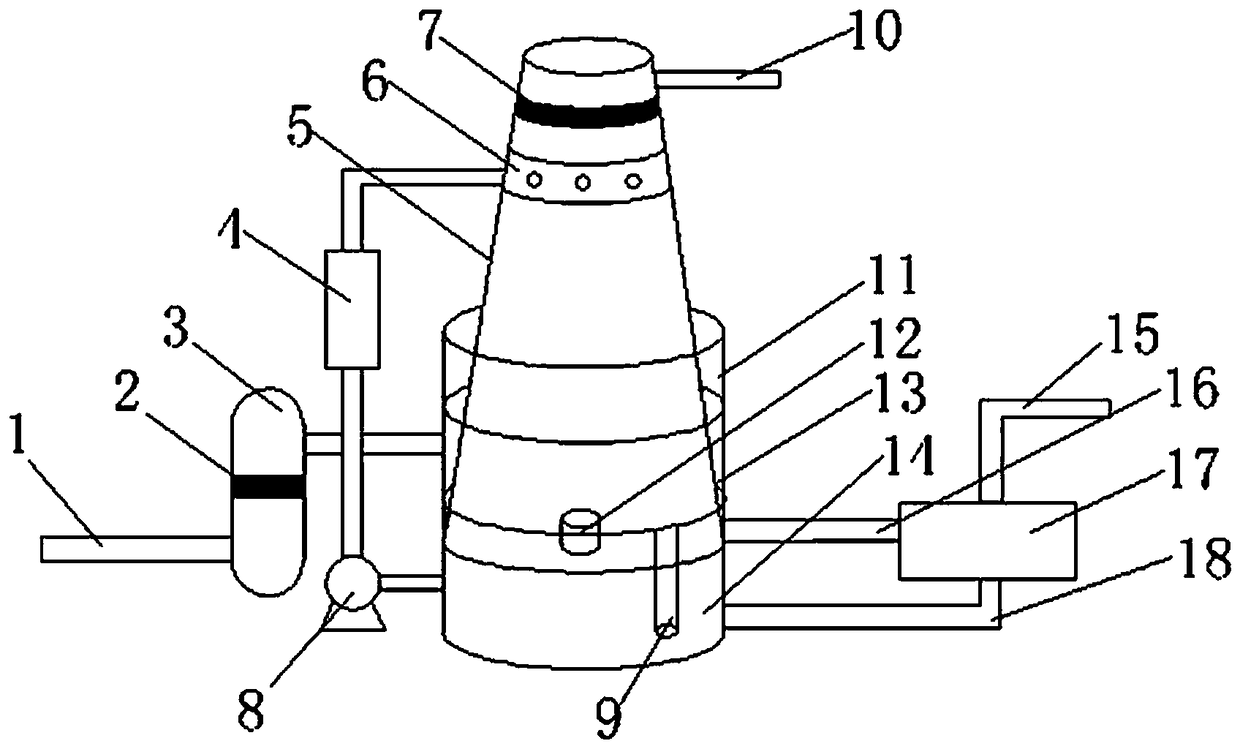

Small natural gas desulphurization device and application method thereof

The invention relates to a small natural gas desulphurization device and an application method thereof and belongs to the technical field of natural gas purification equipment. Natural gas enters a raw material separation device through a natural gas inlet pipeline, enters a natural gas storage box after being separated and purified by the raw material separation device, enters a reaction solutionstorage tank through a natural gas pipeline and reacts with a reaction solution in the reaction solution storage tank, so that a part of sulfides in the natural gas is removed; then, the natural gasenters a reaction tower through a gas pipeline, the reaction solution in the reaction solution storage tank enters an atomization device through a high-pressure pump, is sprayed into the reaction tower by a spraying device after being atomized and is subjected to a secondary reaction with the natural gas, so that sulfur is removed; the reacted natural gas is discharged through a natural gas discharging pipeline after being demisted by a wire mesh demister; the reacted reaction solution falls into the bottom of the reaction tower and enters a regeneration device through a lean amine solution pipeline; the regenerated reaction solution enters the reaction solution storage tank through a rich amine solution pipeline; and the sulfides generated in the regeneration device are collected througha waste gas outlet.

Owner:常州聚盛节能工程有限公司

Method used for preparing soybean oil through enzymatic hydrolysis

InactiveCN108277080AStrong smellColor red and yellowFatty-oils/fats refiningFatty-oils/fats productionEnzymatic hydrolysisHazardous substance

The invention discloses a method used for preparing soybean oil through enzymatic hydrolysis, and belongs to the technical field of grain and oil. The method comprises following steps: 1, soybean powder is prepared; 2, soybean slurry is prepared; 3, enzyme treatment is carried out; 4, low pressure plasma treatment is carried out; and 5, cold pressing is carried out. The method is capable of avoiding generation of harmful substances such as trans-fatty acids and grease polymers in grease; denaturation of soybean meal obtained via oil extraction is avoided, and high added value utilization can be realized; the prepared soybean oil is thick in fragrance, is red and yellow in color, and is high in transparency.

Owner:凤阳县金祥粮油食品有限公司

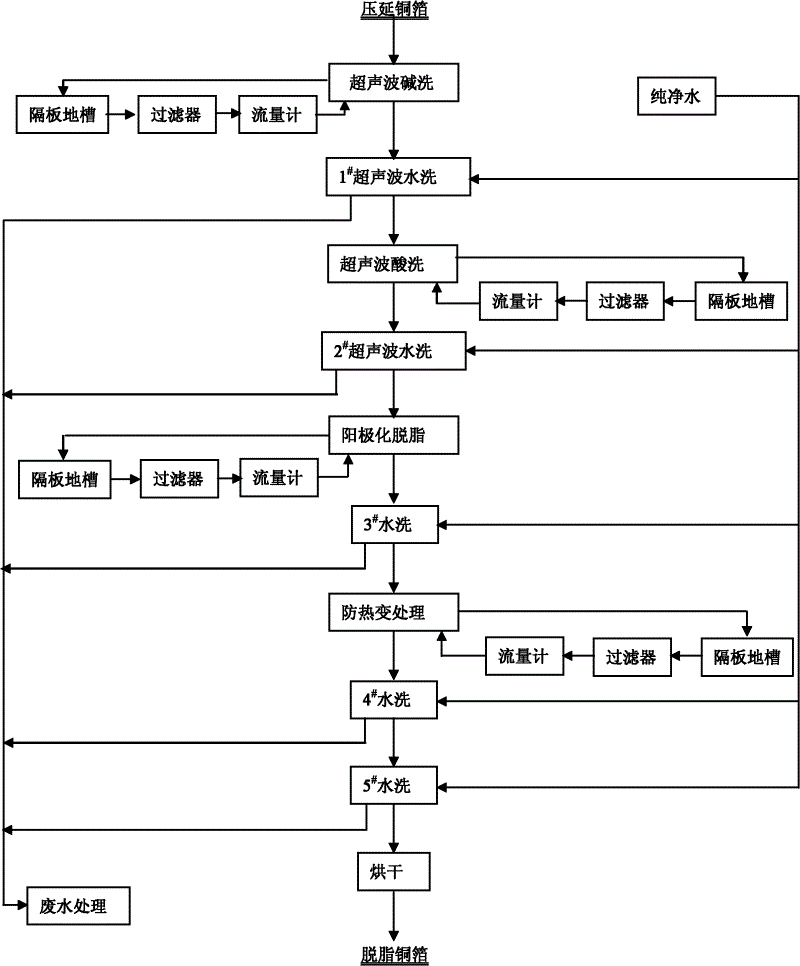

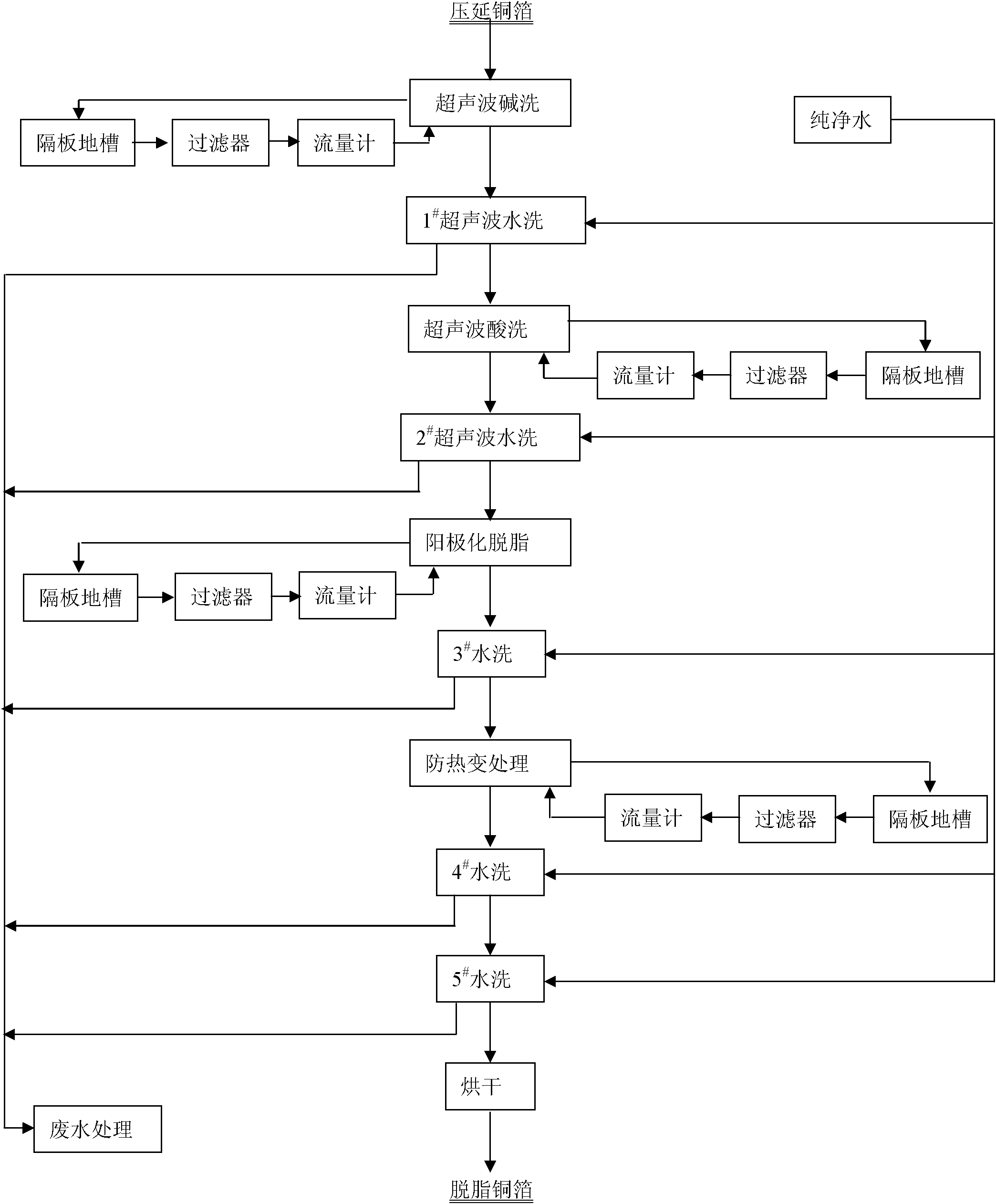

Method for removing rolling oil from double surfaces of rolled copper foil

ActiveCN102618876ABreak efficiencyBreak cleaningWork treatment devicesMetal rolling arrangementsSupersonic wavesCopper foil

The invention relates to a method for removing rolling oil from double surfaces of a rolled copper foil. The method for removing rolling oil from double surfaces of a rolled copper foil comprises the following steps: 1, degreasing with an alkaline aqueous solution under supersonic wave, and then washing with purified water under the supersonic wave; 2, degreasing with an acidic aqueous solution under the supersonic wave, and then washing with the purified water under the supersonic wave; 3, anodizing to degrease, and then washing with the purified water; and 4, carrying out autotherimic processing, and washing with the purified water. The method of the invention, which subverts traditional degreasing methods with low efficiencies, avoids defects of complex process, low cost, low safety factor and the like of degreasing and washing methods using current advanced organic degreasing agents, and reaches purposes of degreasing effect enhancement, labor productivity improvement, and production cost reduction.

Owner:中铜华中铜业有限公司

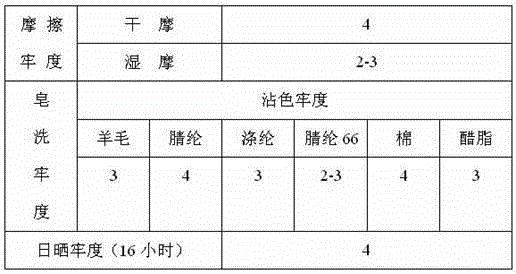

Cotton knitwear activated dye imitation old dyeing method

ActiveCN107034705AMeet the requirements of color and luster imitating the color and luster of old clothesMeet quality indicatorsHeating/cooling textile fabricsLiquid/gas/vapor removalAcetic acidSodium bicarbonate

The invention relates to a cotton knitwear activated dye imitation old dyeing method which is characterized by including steps: 1) pretreatment of a gray fabric; 2) removal of wool; 3) dyeing of activated dyes; 4) treatment by the aid of sodium bicarbonate; 5) water washing after comparison between a sample and a dyed fabric; 6) treatment by the aid of glacial acetic acid; 7) taking out of the dyed fabric from a cylinder and dewatering of the dyed fabric; 8) dying; 9) product sizing at the temperature of 130 DEG C. The method changes a present situation that a conventional activated dye cannot make imitation old color, wool on the fabric surfaces is removed after the gray fabric is pretreated, the activated dyes are treated by the aid of the sodium bicarbonate after dyeing and washing with a soap, so that activated colors are in weakly-alkaline solution, the colors change dark under influential effects of temperature and time, the dyed fabric is circularly dried in a loop drying machine, so that the dyed fabric can mutually rub, fabric surfaces have whiting fuzzy effects, and finished products are sized by adding steam in a dry manner, and cotton knitted gray fabrics have imitated old feel.

Owner:ZHEJIANG YINHE PRINTING & DYEING

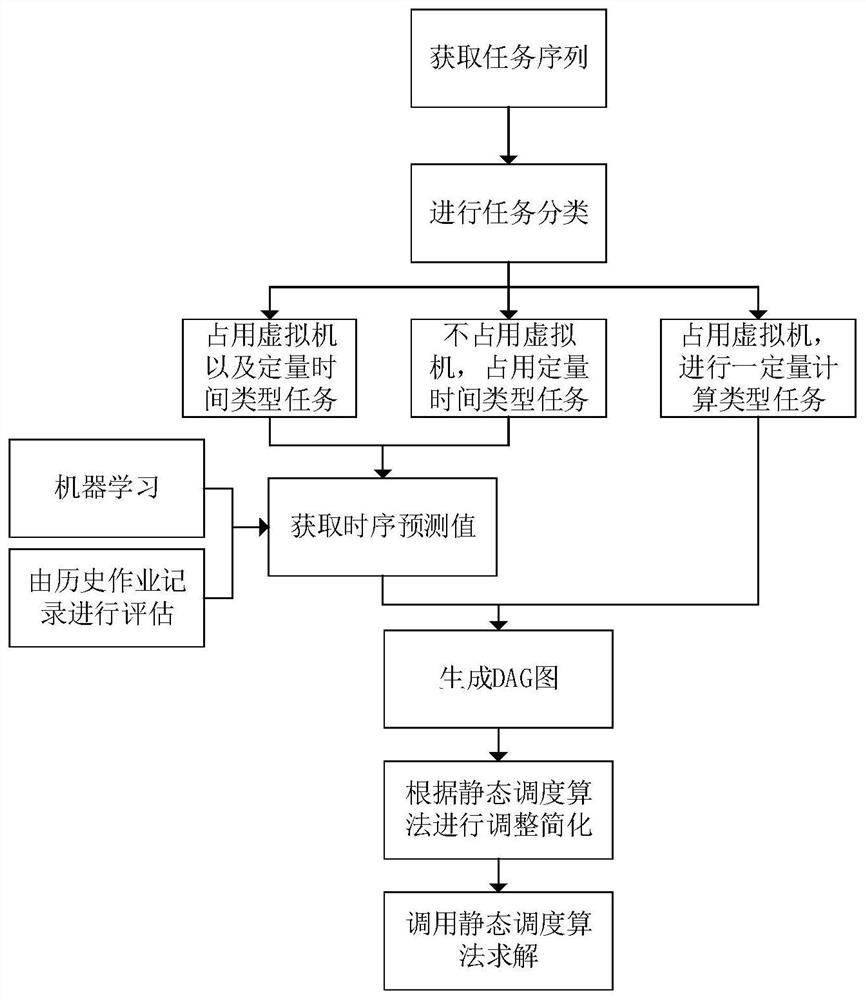

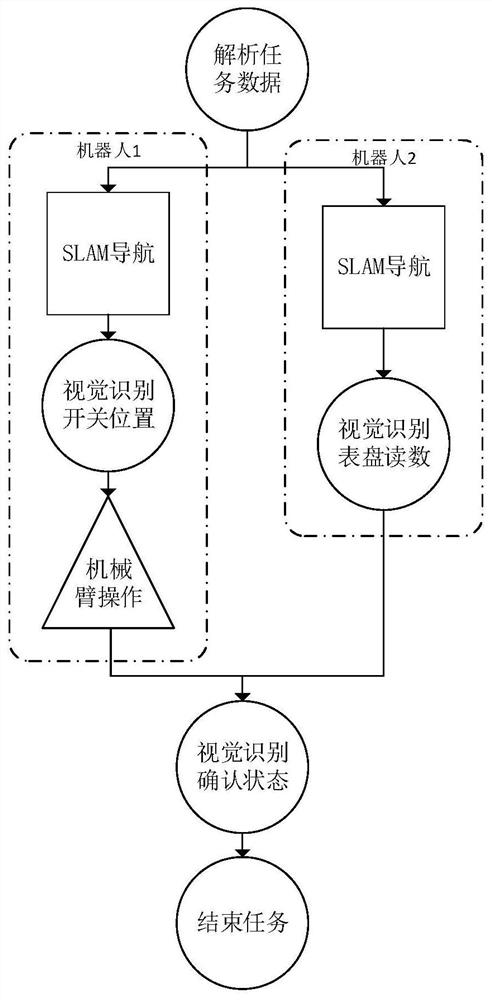

Cloud robot resource scheduling method and system based on task classification and time sequence prediction

PendingCN113568747AOptimizing Static Task Scheduling MethodMeet quality indicatorsResource allocationCharacter and pattern recognitionWorkflow schedulingDistributed computing

The invention provides a cloud robot resource scheduling method and system based on task classification and time sequence prediction, and relates to the technical field of cloud computing resource scheduling, and the method comprises the steps: S1, obtaining a job task sequence of a cloud robot; S2, classifying the tasks according to the dependency relationship between the cloud robot operation tasks and the cloud virtual machine; S3, obtaining an estimated value of the job duration of each job task; S4, converting cloud robot operation task scheduling into a workflow scheduling problem expressed by a directed acyclic graph (DAG); S5, simplifying the DAG generated in the step S4 according to the characteristics of the job task; and S6, solving the final DAG by using various static scheduling methods. According to the method, static analysis can be finally carried out on the operation task of the cloud robot through some preprocessing means, and a better solution for the scheduling problem can be found from the global perspective.

Owner:SHANGHAI JIAO TONG UNIV +2

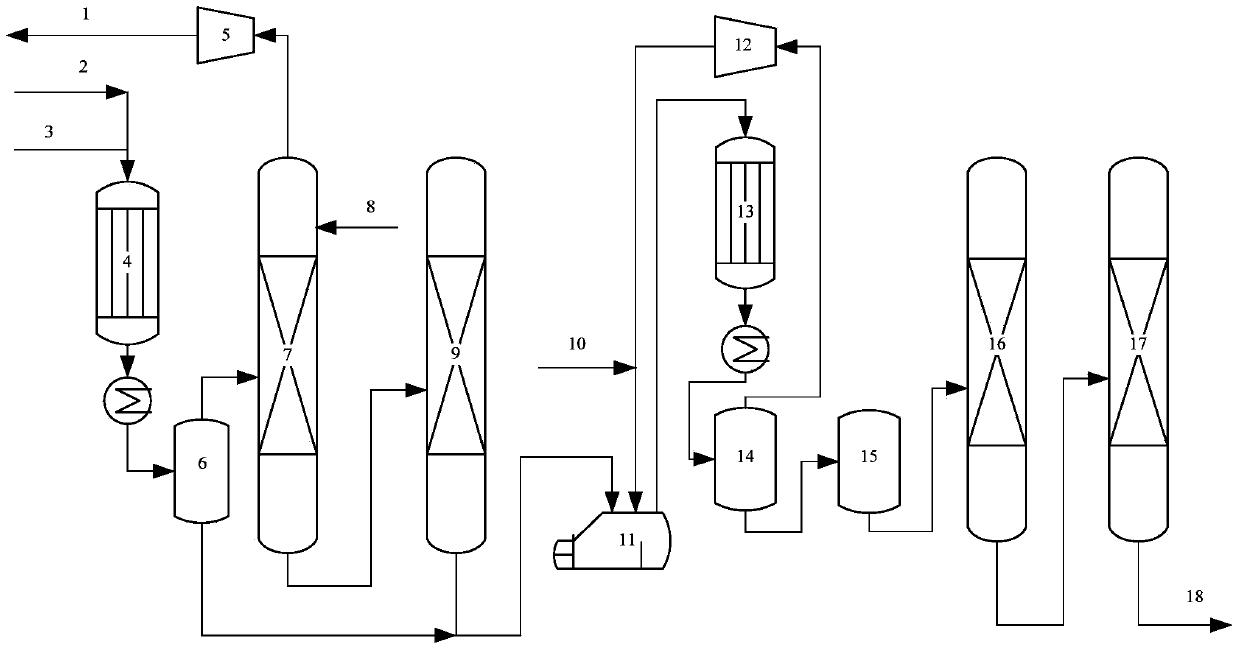

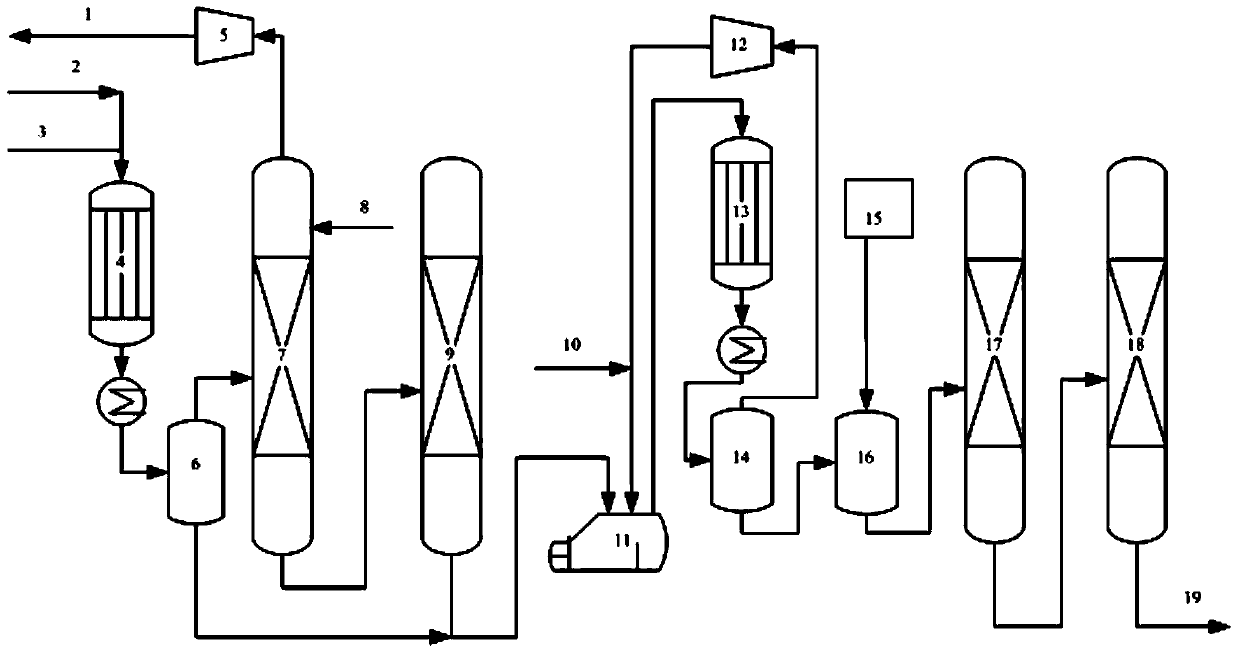

Method and device for increasing chroma of finished ethylene glycol product

InactiveCN103435446AGuaranteed chromaticityMeet quality indicatorsOrganic compound preparationHydroxy compound preparationMethanolFlange

The invention relates to a method for increasing the chroma of a finished ethylene glycol product, which is implemented through adding prepared alkaline liquor from a spare flange port at the top of a crude ethylene glycol tank in an industrial device for producing ethylene glycol by using synthesis gas, wherein the alkaline liquor is prepared from 90% of methanol and 10% of alkali; and after the alkaline liquor is added into the crude ethylene glycol tank, stirring the obtained product. After the method and device disclosed by the invention are applied to a process of producing ethylene glycol by using synthesis gas, a situation that the chroma of an ethylene glycol product reaches a required quality index can be ensured.

Owner:ANHUI HUAIHUA

Method for preventing color difference during short-liquor cotton knitwear-whitening heather grey immersion

ActiveCN107268303AAvoid chromatic aberrationPrevention of jumping light chromatic aberrationDyeing processAcetic acidColor changes

The invention relates to a cotton knitwear immersion method, and in particular to an operating method for preventing color difference during short-liquor cotton knitwear-whitening heather grey immersion. The method includes the following technical steps: (1) pre-inspection of greige cloth; (2) immersion; (3) glacial acetic acid treatment; (4) addition of softener; (5) slitting and drying; (6) final product shaping; (7) packaging. The invention changes the conventional operating technique of heather grey immersion, the pre-inspection of greige cloth is chosen to judge whether thee heather grey immersed greige cloth is whitened or not, moreover, the technical temperature of the whole production process is controlled, the step of neutralizing color difference by glacial acetic acid is added, the packaging method is then improved for substitution, and thereby the technical problem in the prior art that color difference and color change are often caused during heather grey immersion for whitening can be solved.

Owner:ZHEJIANG YINHE PRINTING & DYEING

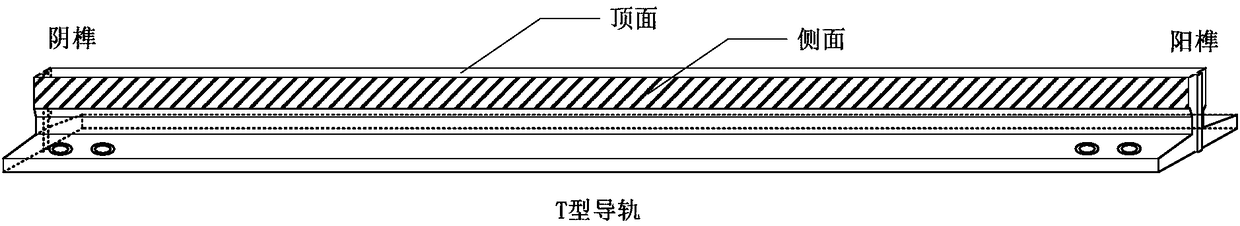

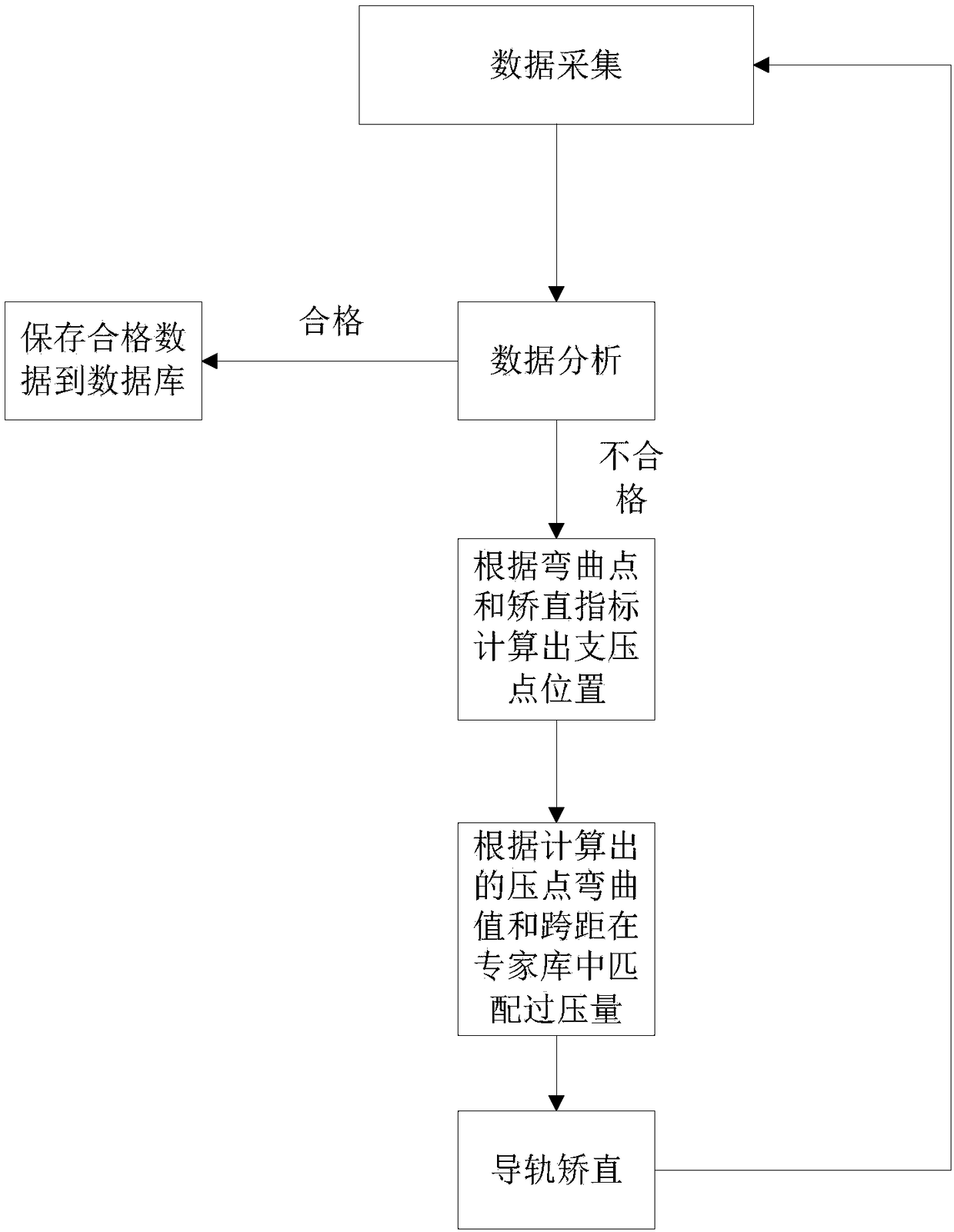

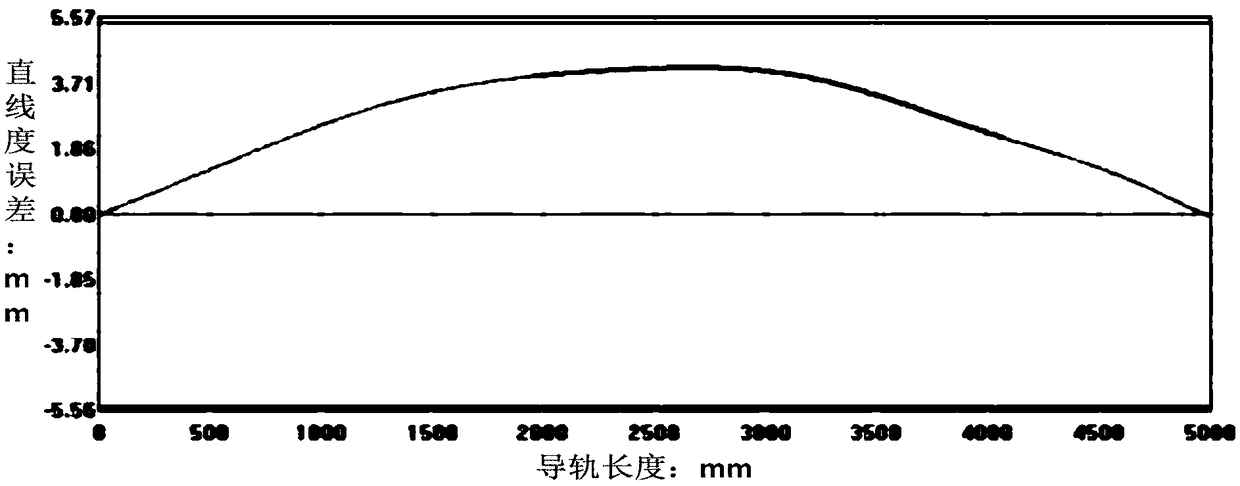

An automatic straightening method for elevator guide rails based on expert database technology

ActiveCN107127225BReduce labor costsImprove yield rateMetal working apparatusProduction lineEngineering

The invention discloses an automatic lift guide rail straightening method based on the expert database technology. The automatic lift guide rail straightening method based on the expert database technology comprises the steps that firstly, manual straightening success experience in the early stage is utilized to constitute an expert database; secondly, straightness information of a guide rail is collected, fitting of a straightness curve is conducted according to the collected data, data analysis is conducted on the fitted curve in a extreme value point traversal method so as to select press points as reference points; thirdly, unqualified points are found according to the guide rail straightness qualification index, and the final press point is determined from the press point reference points; fourthly, after the press point is readjusted and determined, according to the principle of span maximization, the positions of the supporting points are symmetrically determined on the two sides of the press point; and finally, the bending values and the spans of the press point are normalized, according to the normalized bending value and span of the pressing point, the corresponding press amount is found from the expert database through matching and used for straightening of the guide rail, if various indexes of the straightened guide rail meet requirements, all the index data are stored in the database, and otherwise next straightening is conducted. By the adoption of the automatic lift guide rail straightening method based on the expert database technology, the labor cost of production is reduced, and the yield of a production line is improved.

Owner:NANJING UNIV OF SCI & TECH

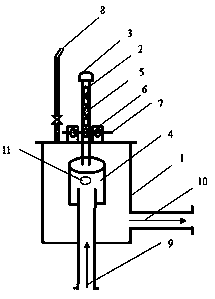

Device and method for regulating tar and ammonia water separation effect

InactiveCN111035965AMeet quality indicatorsAdjust interface heightLiquid separation auxillary apparatusThermodynamicsProcess engineering

The invention relates to a device and a method for regulating tar and ammonia water separation effect, and belongs to the technical field of tar and ammonia water separation equipment for coking production. The technical scheme is that a movable bush (4) is positioned in a tank body (1), a positioning seat (6) is fixed at the top of the tank body (1), an adjusting rod (2) is vertically fixed on the positioning seat (6) through a positioning pin (7), the lower end of the adjusting rod (2) is fixedly connected with the movable bush (4), the bottom of the tank body (1) is connected with a tar inlet pipe (9), the tar inlet pipe (9) extends into the movable bush (4), the side surface of the tank body (1) is connected with a tar outlet pipe (10), and the top of the tank body (1) is connected with a diffusing cylinder (8). With the device and the method, the interface height of tar and ammonia water in the separation tank is adjusted by adjusting the movable bush up and down, so that the separated tar does not contain ammonia water, the separated ammonia water does not contain tar, and the safe and stable production of coke ovens and coal gas purification is guaranteed.

Owner:宣化钢铁集团有限责任公司

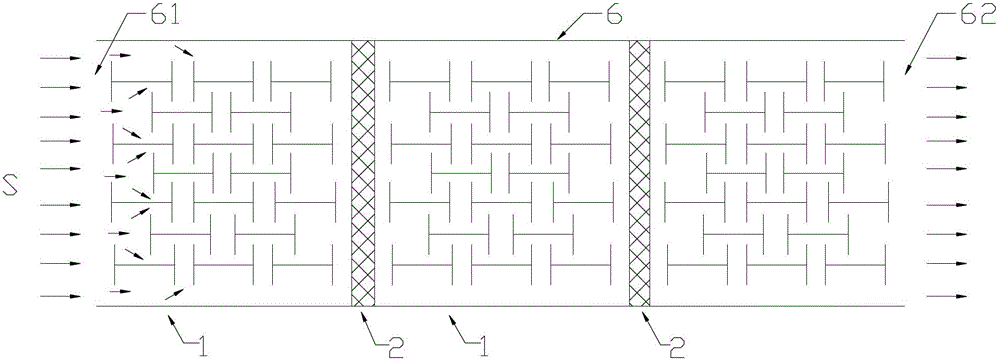

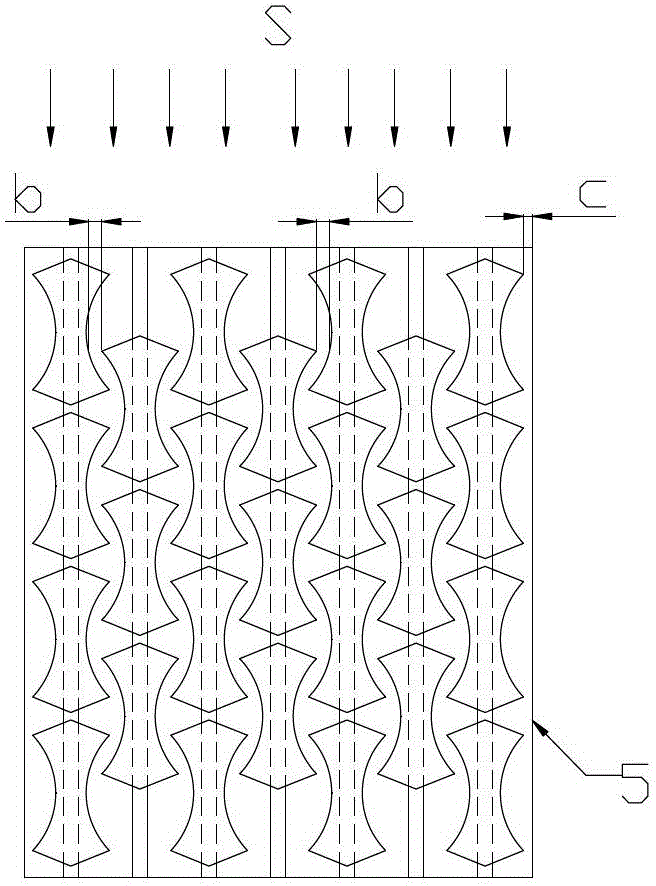

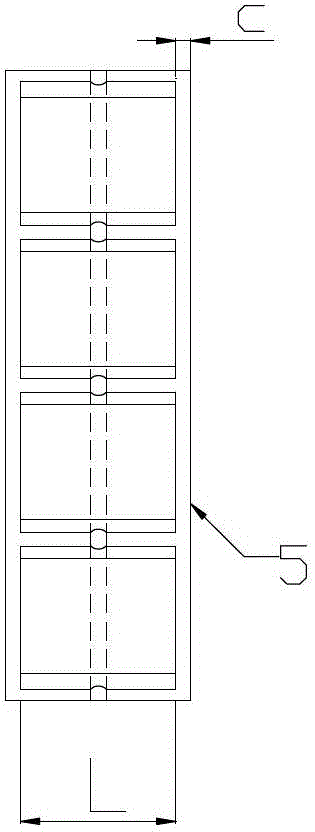

Static sensitization device and its cutting body

ActiveCN102731224BWell mixedMeet quality indicatorsExplosive working-up apparatusFoaming agentEmulsion explosive

The invention discloses a static sensitizing device which can be produced continuously, and a cutting blade body of the static sensitizing device. The static sensitizing device comprises an inlet, an outlet, and a channel between the inlet and the outlet, wherein the channel from the inlet to the outlet comprises at least two first units; cutting blades are distributed at intervals in the first units, and the distribution density of the cutting blades is determined according to technical requirements; a second unit is arranged between every two adjacent first units and comprises at least one layer of grids; and the quantity of meshes of the grids, the number of the layers of the grids, and the spacing of the grids are determined according to the technical requirements. The cutting blade body is I-shaped, and provided with four edges of which a plane is different from a plane of the centre line of an axle hole; and each edge is cut to form each cutting blade. With adoption of the static sensitizing device, an emulsifying base and foaming agent can be uniformly mixed, the sensitizing process can be continuously carried out, the technical quality index of emulsion explosives can be completely met, and explosion accidents caused by agitating at a high speed of equipment can be avoided; and the static sensitizing device is particularly suitable for the field of emulsion explosive production.

Owner:PANZHIHUA HENGWEI CHEM +1

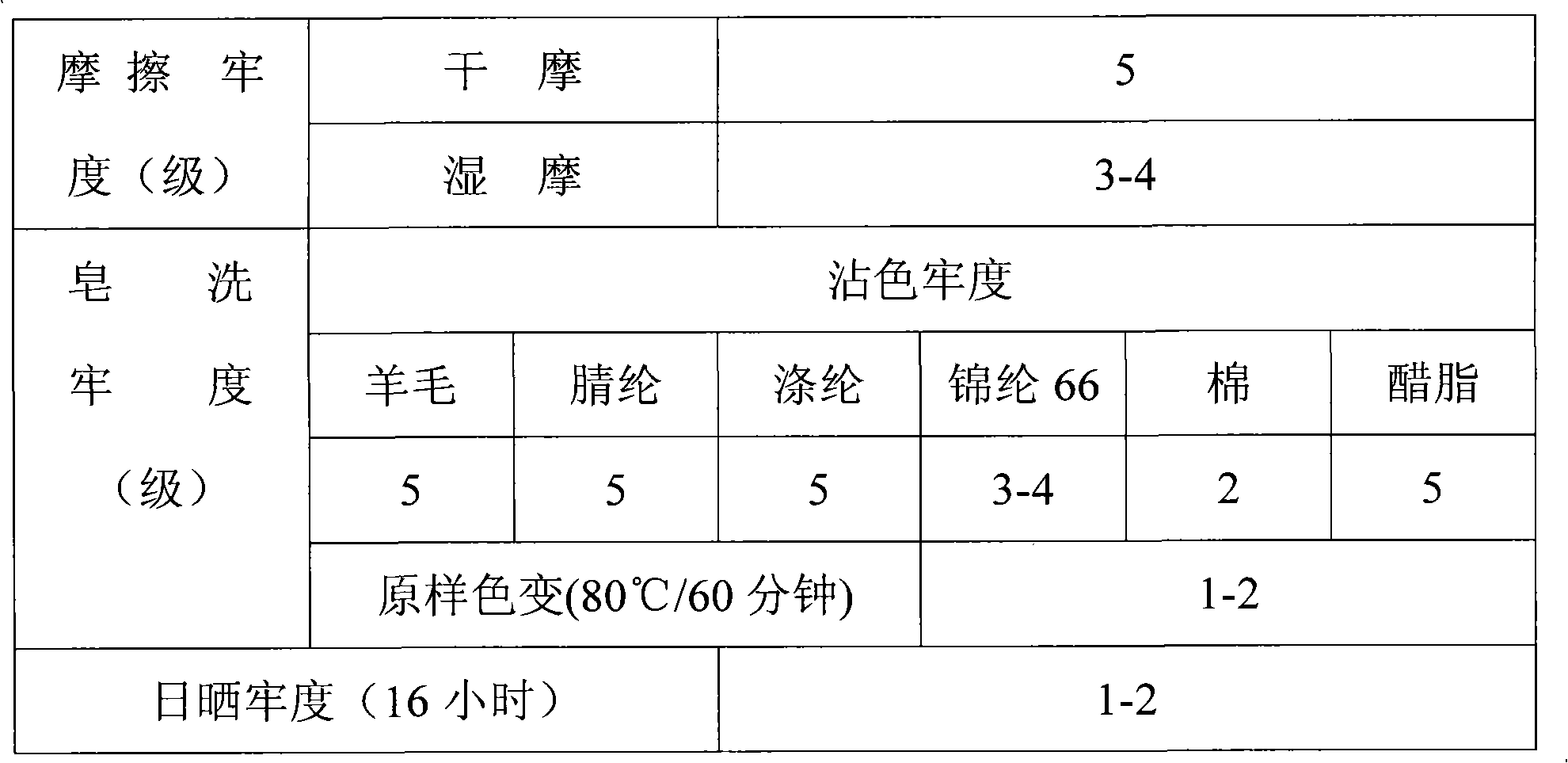

Method for dyeing vivid fluorescent green on cotton knitwear

InactiveCN101597867BMeet the requirements of bright colorMeet quality indicatorsDyeing processFluorescenceEmerald

The invention relates to a method for dyeing cotton knitwear, in particular to a method for dyeing fluorescent green on cotton knitwear. The method comprises the following steps: 1) pretreating grey cloth; 2) placing the grey cloth and eightfold weight of water into a dye vat; 3) heating the grey cloth and the water to a temperature of 60 DEG C, adding reactive emerald blue MZ-HGN, 7GFF fluorescent yellow and salt into the dye vat in sequence to reserve the temperature for 30 minutes; 4) continuously heating the mixture to a temperature of 80 DEG C, and gradually adding calcined soda for fixation, and reserving the temperature for 30minutes; 5) continuously heating the mixture to a temperature of 100 DEG C, and reserving the temperature for 15 minutes; 6) comparing the grey cloth with a sample, cooling the grey cloth to a temperature of 70 DEG C, and removing dye liquor; 7) washing the grey cloth with water twice after the steps; 8) washing the water washed grey cloth with soap once at a temperature of 90 DEG C; 9) washing the grey cloth which is washed by the soap for 2 or 3 times with water; 10) carrying out softening treatment on the water washed grey cloth at 40 DEG C, reserving the temperature for 15 minutes and taking the grey cloth out of the dye vat; 11) dehydrating the grey cloth; 12) drying the grey cloth; 13) shaping the grey cloth. The cloth dyed through the methodnot only can meet the requirement of clients on color brightness, but also achieves the corresponding quality index.

Owner:ZHEJIANG YINHE PRINTING & DYEING

Method for removing rolling oil from double surfaces of rolled copper foil

ActiveCN102618876BEfficient removalMeet factory requirementsWork treatment devicesMetal rolling arrangementsSupersonic wavesCopper foil

The invention relates to a method for removing rolling oil from double surfaces of a rolled copper foil. The method for removing rolling oil from double surfaces of a rolled copper foil comprises the following steps: 1, degreasing with an alkaline aqueous solution under supersonic wave, and then washing with purified water under the supersonic wave; 2, degreasing with an acidic aqueous solution under the supersonic wave, and then washing with the purified water under the supersonic wave; 3, anodizing to degrease, and then washing with the purified water; and 4, carrying out autotherimic processing, and washing with the purified water. The method of the invention, which subverts traditional degreasing methods with low efficiencies, avoids defects of complex process, low cost, low safety factor and the like of degreasing and washing methods using current advanced organic degreasing agents, and reaches purposes of degreasing effect enhancement, labor productivity improvement, and production cost reduction.

Owner:中铜华中铜业有限公司

Method for dyeing cotton knitwear in bright fluorescent pink

ActiveCN102912653BMeet the requirements of bright colorMeet the requirements of fastnessBleaching apparatusDyeing processAdenylate kinaseFluorescence

The invention relates to a method for dyeing cotton knitwear, in particular to a method for dyeing cotton knitwear in bright fluorescent pink. The method includes firstly, removing hair in an air cylinder before high-temperature pretreatment; secondly, dyeing an overflowing cylinder, and adding HAC (ethanoic acid) to regulate PH to 5-6; thirdly, measuring and adding ADK (adenylate kinase)-260 cation modifier; fourthly, discharging water once; fifthly, allowing for water inflowing, and adding fluorescent pigment vermilion S-004; sixthly, performing sample comparison; seventhly, washing twice after sample comparison, and taking out of the cylinder; eighthly, soaking in a scoop outside the cylinder, and adding ADK-101 adhesive; ninthly, dewatering and drying; and tenthly, shaping. The condition that reactive dye cannot be used to dye bright fluorescent pink conventionally is broken through, the fluorescent pigment is selected for dyeing, and accordingly gorgeous and bright fluorescent dyeing effect is achieved. By the steps of the method, the requirement of customers for color brightness is met, and corresponding quality index is met.

Owner:ZHEJIANG YINHE PRINTING & DYEING

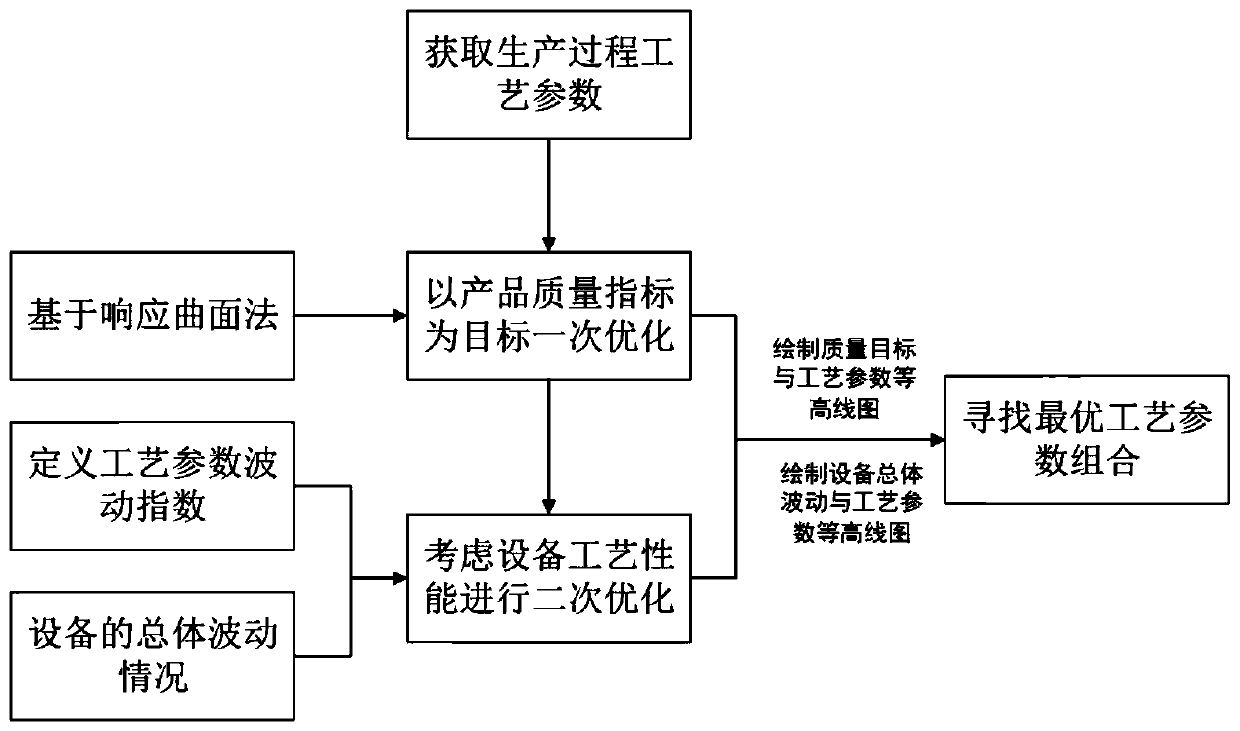

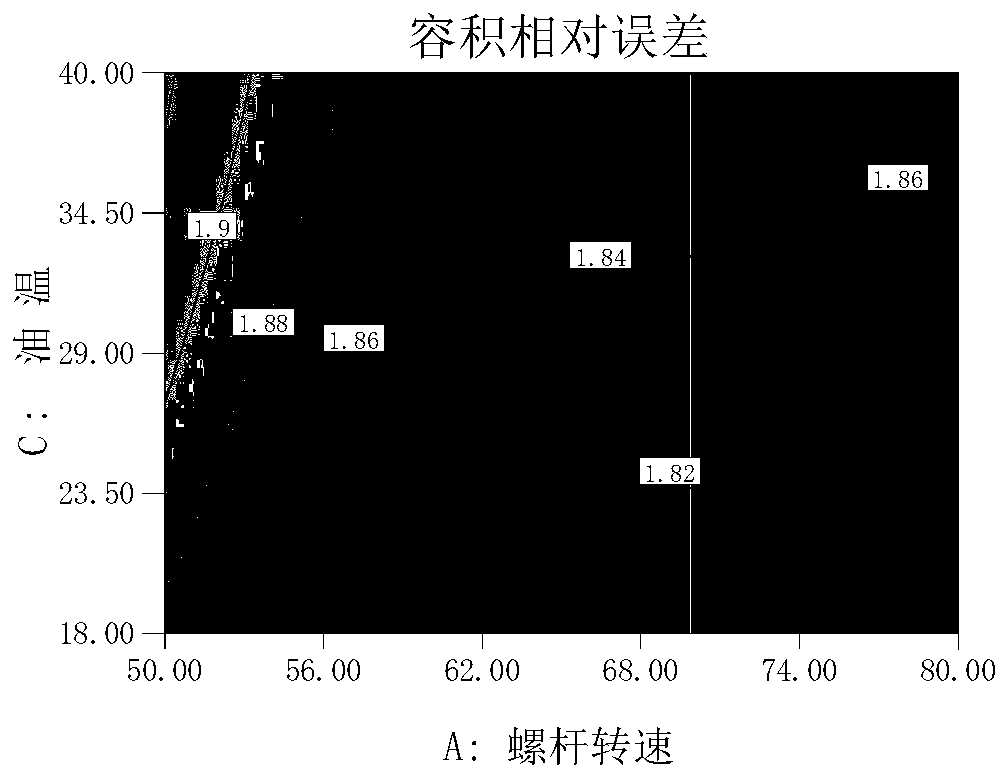

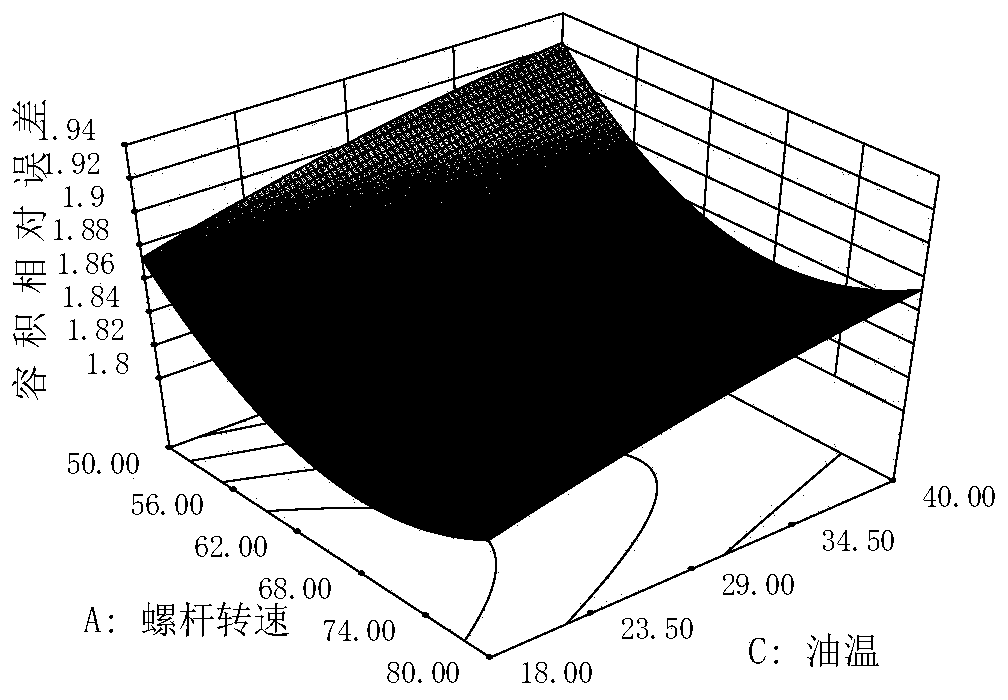

An Extrusion Blow Molding Process Optimization Method Combining Quality Objectives and Equipment Performance

The invention discloses a method for optimizing an extrusion blow molding process through integrated quality target and device performance. The method comprises the steps that first optimizing is carried out through a quality target, and the regression equation of process parameters and quality indexes is established; the fluctuation situation of the process parameters is statistically analyzed when set parameters are different, and at the same time equation fitting is carried out; and finally, on the basis of the first optimizing, second optimizing is carried out by considering the work performance of a device. According to the invention, the stability of the device throughout the operation is ensured; the overall product quality is improved; and the production efficiency of an enterprise is improved.

Owner:XI AN JIAOTONG UNIV

Method for preparing starch powdered oil and fat by ultrahigh pressure micro-jet method

The invention provides a method for preparing starch powdered oil and fat by an ultrahigh pressure micro-jet method to solve the problems that the conventional process for producing microencapsulated powdered oil and fat is complex, production cost is high, and a large amount of food additives are needed to be added during production. The method comprises the following specific steps of: preparing emulsified liquid by using oil and deionized water, adding starch into the emulsified liquid, stirring and mixing to prepare suspension, performing pregelatinization on starch, cooling, performing ultrahigh pressure micro-jet homogenizing, and spray-drying. The content of the prepared powdered oil and fat and product granularity can be adjusted, the production process is simple and production cost is low, food additives are not used during preparation, and the product has high safety.

Owner:HARBIN INST OF TECH

Enamel prepared from waste ceramic and its preparation method

The invention provides a ceramic glaze and preparation method from waste ceramic. Wherein, the product comprises: 18-25% waste ceramic powder, 20-30% quartz, 10-20% feldspar, 8-12% China clay, 0-5% zinc oxide, 0-10% dolomite, 7-15% calcite, and 0.2-0.5% methylcellulose. The preparation method comprises: cleaning and dedusting the ceramic powder, drying, breaking, and screening; putting said materials into ball grinder with proper water; screening, adding prepared ceramic powder; grinding and screening to prepare glaze slurry; adding methylcellulose into slurry to mix and obtain the product. This invention reduces cost and pollution.

Owner:林伟河

Grinding technique for aluminum alloy drum of external-drum type plate-making machine

ActiveCN101661230BAvoid disadvantagesHigh surface hardnessAnodisationElectrography/magnetographySurface cleaningHardness

Owner:HANGZHOU CRON MACHINERY & ELECTRONICS CO LTD

The recovery method of aminothixamic acid

ActiveCN111548323BProfitableEasy to operateOrganic chemistryPulp and paper industryOrganic chemistry

The invention belongs to the technical field of medicine, and in particular relates to a method for recovering aminothiaxamic acid. The hydrolyzate produced in the production process of aminothiaxamic acid is concentrated by electrodialysis to obtain a concentrated solution, which is pre-decolorized to obtain a first-step crude product of aminothiaxamic acid, which is reversed and decolorized to obtain a second-step crude product of aminothiaxamic acid, which is refined in two steps to obtain a finished product of aminothiaxamic acid; reversed decolorization The first-step crude product of aminothiaxamic acid is dissolved in water, liquid caustic soda is added dropwise to carry out reverse adjustment for dissolving, and then the color is decolorized to obtain the second-step crude product of aminothiaxamic acid. The invention can recycle qualified aminothioxamic acid products, reduces the amount of waste water treatment, has high efficiency, simplicity, environmental protection and high profit, and is suitable for large-scale industrial production.

Owner:SHANDONG JINCHENG PHARMACCUTICAL CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com