Method used for preparing soybean oil through enzymatic hydrolysis

A technology of soybean oil and enzymatic hydrolysis, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc., can solve the problems that cannot be used with high added value, can only be used as feed or fertilizer, and soybean meal has a high degree of denaturation. Achieving favorable effects of hydrolysis, good transparency and strong smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

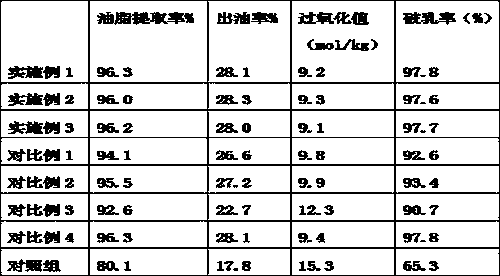

Examples

Embodiment 1

[0019] A method for preparing soybean oil by enzymatic hydrolysis, comprising the following steps:

[0020] (1) Preparation of soybean powder: Soak soybeans in an amino acid solution with a mass fraction of 3.5-5.5 for 15-20 minutes, then take them out, drain them, and fumigate the drained soybeans with steam for 10-12 minutes, and then fumigate them The finished soybeans are put into an oven for drying treatment, dried until the water content reaches 10%, and then crushed to obtain soybean powder;

[0021] (2) Preparation of soybean slurry: Add 40-50% of the mass of distilled water to the soybean powder prepared in step (1), stir at 1500r / min for 10 minutes, and then add 500W microwave with 2.1-2.3% of the mass of soybean powder Process the chestnut starch for 15s, and continue to stir for 15min to obtain soybean slurry;

[0022] (3) Enzyme treatment: Weigh the compound enzyme according to 1.2-1.5% of the mass of the soybean slurry, add distilled water 5-7 times its mass to ...

Embodiment 2

[0032] A method for preparing soybean oil by enzymatic hydrolysis, comprising the following steps:

[0033] (1) Preparation of soybean powder: Soak soybeans in an amino acid solution with a mass fraction of 3.5-5.5 for 15-20 minutes, then take them out, drain them, and fumigate the drained soybeans with steam for 10-12 minutes, and then fumigate them The finished soybeans are put into an oven for drying treatment, dried until the water content reaches 10%, and then crushed to obtain soybean powder;

[0034] (2) Preparation of soybean slurry: Add 40-50% of the mass of distilled water to the soybean powder prepared in step (1), stir at 1500r / min for 10 minutes, and then add 500W microwave with 2.1-2.3% of the mass of soybean powder Process the chestnut starch for 15s, and continue to stir for 15min to obtain soybean slurry;

[0035] (3) Enzyme treatment: Weigh the compound enzyme according to 1.2-1.5% of the mass of the soybean slurry, add distilled water 5-7 times its mass to ...

Embodiment 3

[0045] A method for preparing soybean oil by enzymatic hydrolysis, comprising the following steps:

[0046] (1) Preparation of soybean powder: Soak soybeans in an amino acid solution with a mass fraction of 3.5-5.5 for 15-20 minutes, then take them out, drain them, and fumigate the drained soybeans with steam for 10-12 minutes, and then fumigate them The finished soybeans are put into an oven for drying treatment, dried until the water content reaches 10%, and then crushed to obtain soybean powder;

[0047] (2) Preparation of soybean slurry: Add 40-50% of the mass of distilled water to the soybean powder prepared in step (1), stir at 1500r / min for 10 minutes, and then add 500W microwave with 2.1-2.3% of the mass of soybean powder Process the chestnut starch for 15s, and continue to stir for 15min to obtain soybean slurry;

[0048] (3) Enzyme treatment: Weigh the compound enzyme according to 1.2-1.5% of the mass of the soybean slurry, add distilled water 5-7 times its mass to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com