An Extrusion Blow Molding Process Optimization Method Combining Quality Objectives and Equipment Performance

A technology of extrusion blow molding and equipment performance, applied in the direction of instruments, adaptive control, control/regulation systems, etc., can solve the problems of poor equipment operation stability, low product quality qualification rate, lack of theoretical basis, etc., and achieve stable production process. , saving time and improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with specific embodiments and accompanying drawings.

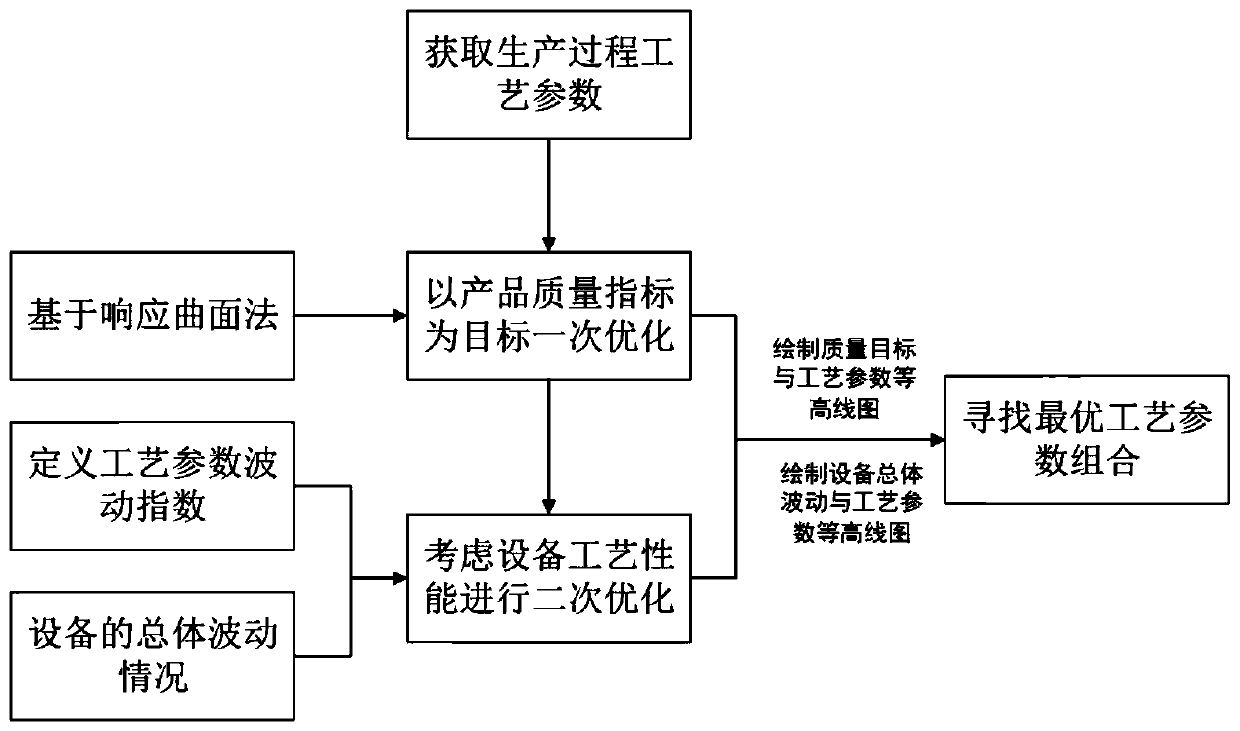

[0037] see figure 1 , the present invention comprises the following steps:

[0038] 1) Obtain real-time parameters of the production process, mainly including screw speed, mold temperature, oil temperature, inflation pressure, and establish a database for storage;

[0039] 2) Based on the response surface method, an optimization is carried out according to the quality target constraints: the first step is to determine the optimization target (quality index) and influencing factors (i.e. real-time parameters) according to the accumulated data statistics, and determine the interval range of each influencing factor, namely:

[0040] The variable y is the optimization target, and the variable x i is the impact factor, i=(1,2,...,p-1,p), the test is called p-factor test, each impact factor x 1 ,...,x p Both have a range, and the upper and lower boun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com