Method for dyeing cotton knitwear in bright fluorescent pink

A knitwear and bright technology, applied in the field of dyeing bright fluorescent pink for cotton knitwear, can solve the problems of complex process, high cost, failure to meet customer requirements, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

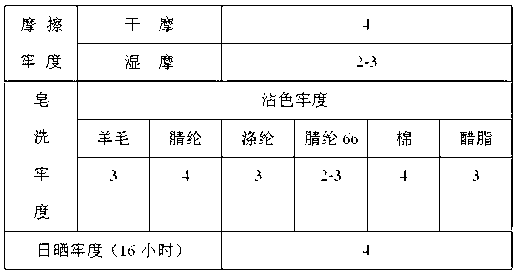

Embodiment 1

[0027] The method for dyeing bright fluorescent pink on cotton knitwear comprises the following process steps:

[0028] 1) The gray cloth is firstly depilated in the air cylinder, and then pre-treated at a high temperature of 110°C;

[0029] 2) Dyeing in the overflow tank, the bath ratio is 1:25, first add glacial acetic acid HAC 0.5% to adjust the pH value to 5-6;

[0030] 3) Raise the temperature to 40°C for 15 minutes and add 6-8% of ADK-260 cationic modifier. After running for 5 minutes, raise the temperature to 70°C at 1°C / min and keep it for 40 minutes;

[0031] 4) Drain once;

[0032] 5) Inlet water, bath ratio 1:25, run for 5 minutes, heat up to 40°C, measure for 20 minutes, add fluorescent paint orange red S-004 7-9%, run for 5 minutes, then raise to 70°C at 1°C / min Cut the sample after 40 minutes of heat preservation;

[0033] 6) Proof;

[0034] 7) After checking the sample, wash it twice with water and take it out of the tank;

[0035] 8) Soak in the bucket out...

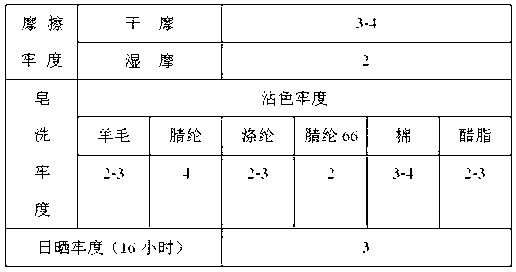

Embodiment 2

[0041] The method for dyeing bright fluorescent pink on cotton knitwear comprises the following process steps:

[0042] 1) The gray cloth is firstly depilated in the air cylinder, and then pre-treated at a high temperature of 110°C;

[0043] 2) Dyeing in the overflow tank, the bath ratio is 1:25, first add glacial acetic acid HAC 0.5% to adjust the pH value to 5-6;

[0044] 3) Raise the temperature to 40°C for 15 minutes and add 7% of ADK-260 cationic modifier. After running for 5 minutes, raise the temperature to 70°C at 1°C / min and keep it for 40 minutes;

[0045] 4) Drain once;

[0046] 5) Inlet water, bath ratio 1:25, after running for 5 minutes, raise the temperature to 40°C and measure for 20 minutes, add fluorescent paint orange red S-004 8%, after running for 5 minutes, then raise the temperature to 70°C at 1°C / min and keep warm for 40 cut in minutes;

[0047] 6) Proof;

[0048] 7) After checking the sample, wash it twice with water and take it out of the tank;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com