Patents

Literature

65results about How to "In line with the concept of energy saving and emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

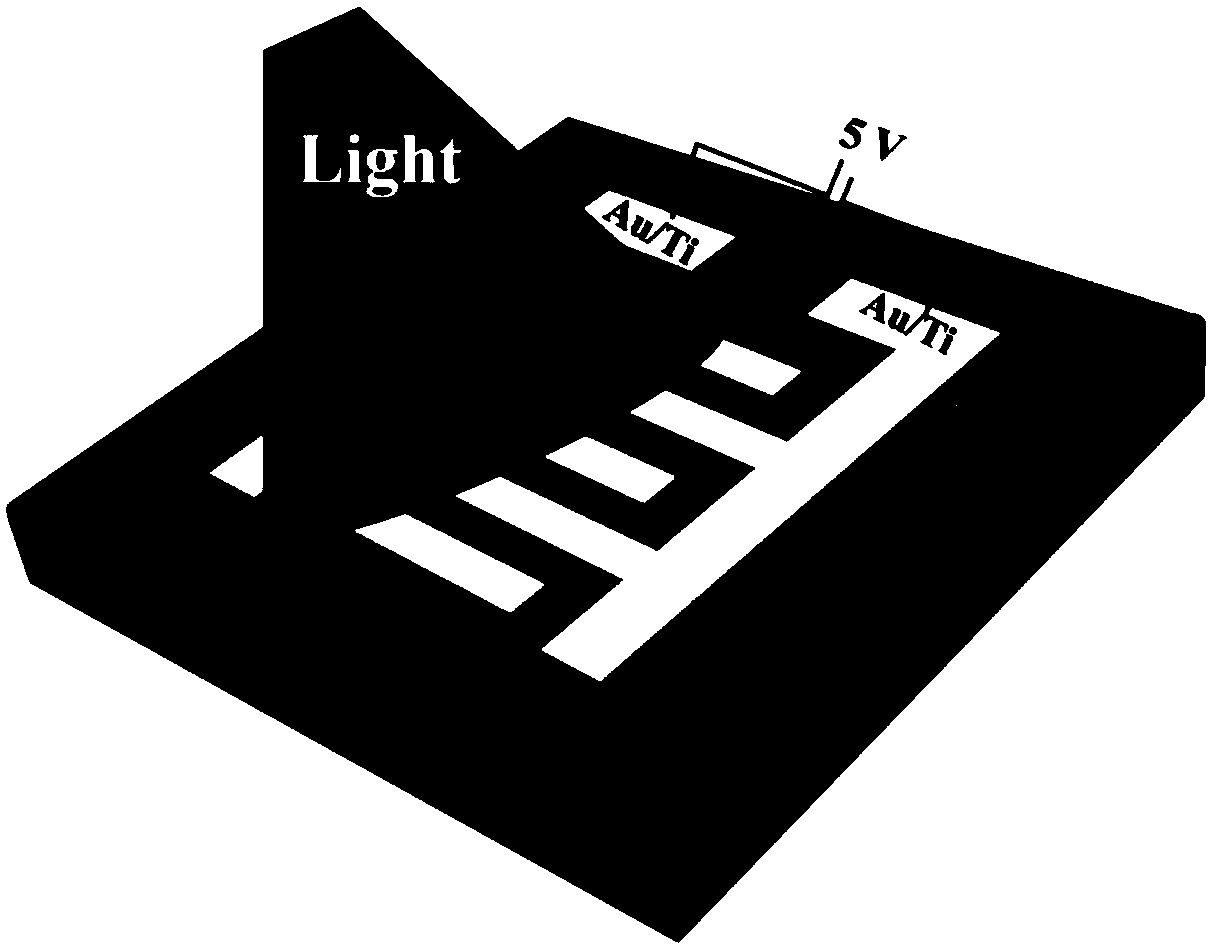

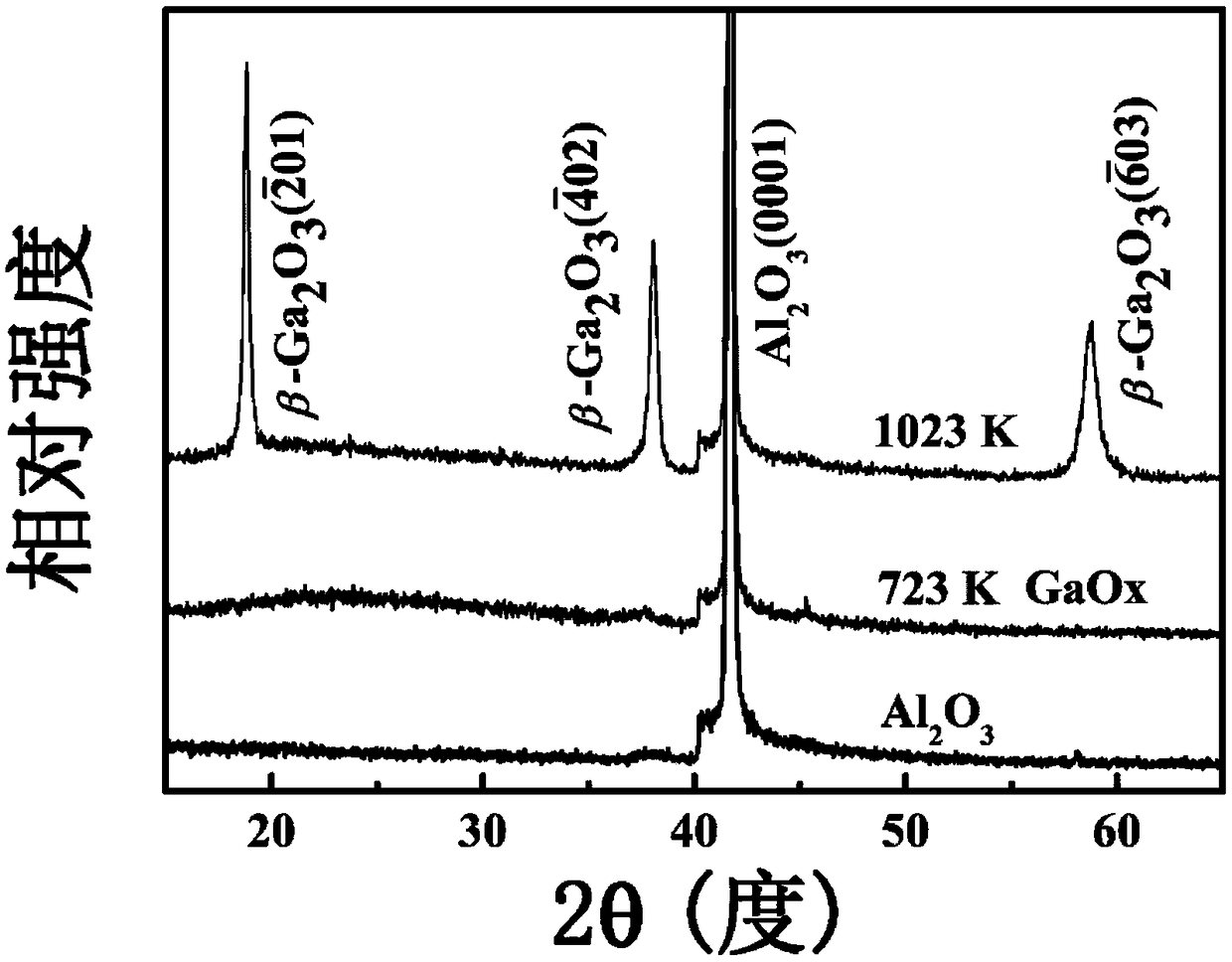

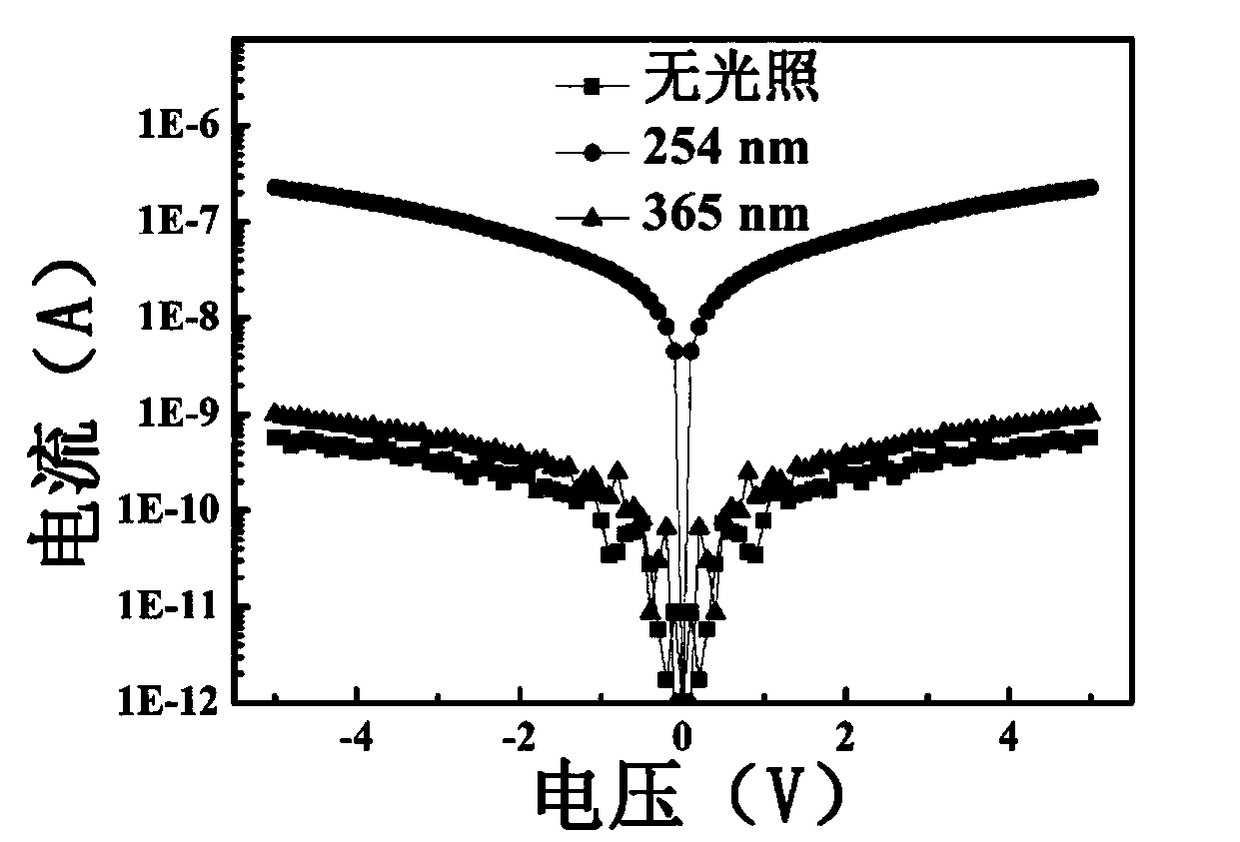

Solar blind ultraviolet photoelectric detector based on amorphous gallium oxide film and preparation method thereof

InactiveCN108666395AUniform textureLow growth temperatureFinal product manufactureVacuum evaporation coatingManufacturing technologyRadio frequency magnetron sputtering

The invention discloses a solar blind ultraviolet photoelectric detector based on an amorphous gallium oxide film and a preparation method thereof, and belongs to the technical field of photoelectricdetectors. The method comprises the steps that the crystal face (0001) Al2O3 is adopted as a substrate, and the substrate is cleaned; then, the cleaned substrate is fed into a settling chamber, a radio frequency magnetic control sputtering technology is applied to the substrate to grow a gallium oxide film; finally, a hollow interdigital mask plate is used for shielding on the amorphous gallium oxide film, a direct current magnetic control sputtering method is adopted for sputtering an interdigital metal electrode on the interdigital mask plate to obtain the solar blind ultraviolet photoelectric detector, the structure is an MSM type sandwiched structure, and the Al2O3 substrate, the amorphous gallium oxide film material and the Ti / Au interdigital metal electrode are arranged from bottom to top. The manufacturing technology is simple, the repeatability is good, dark current is small, the stability is high, the response speed is high, the ultraviolet visible restrain ratio is high, andthe detector conforms to the energy-saving and emission-reducing theory, is suitable for large-scale production, and has the wide development prospect.

Owner:BEIJING UNIV OF POSTS & TELECOMM

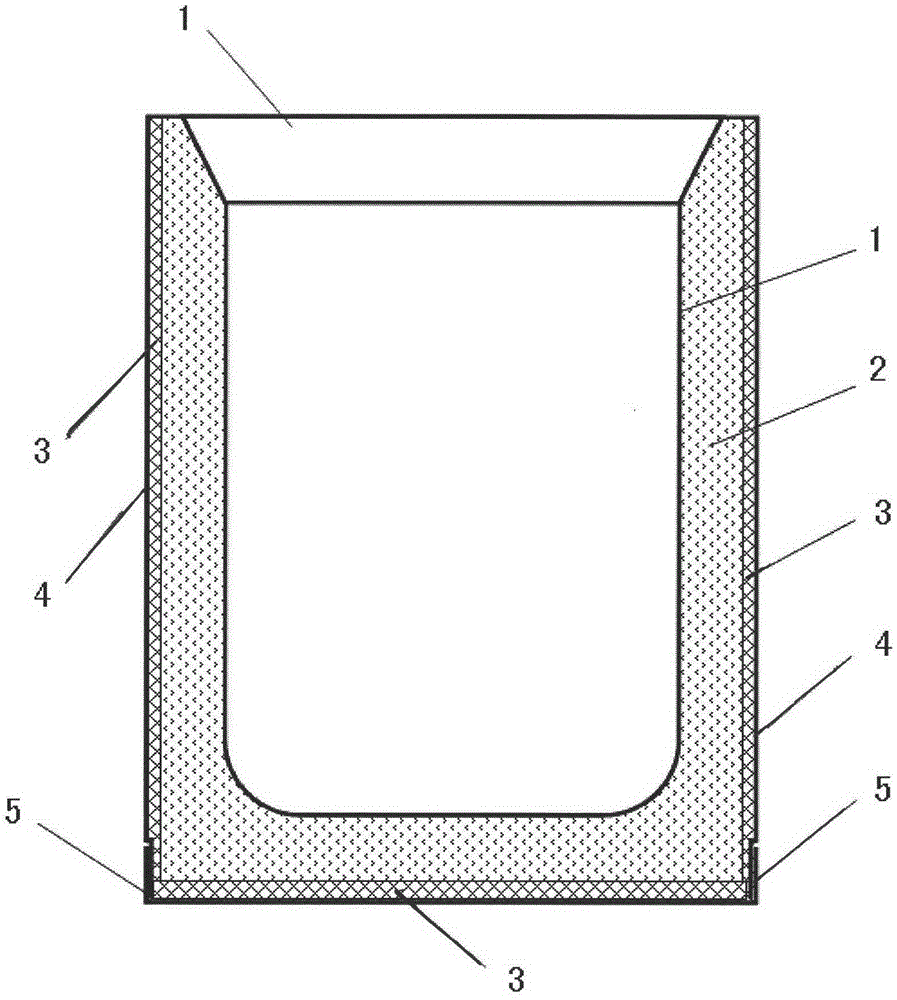

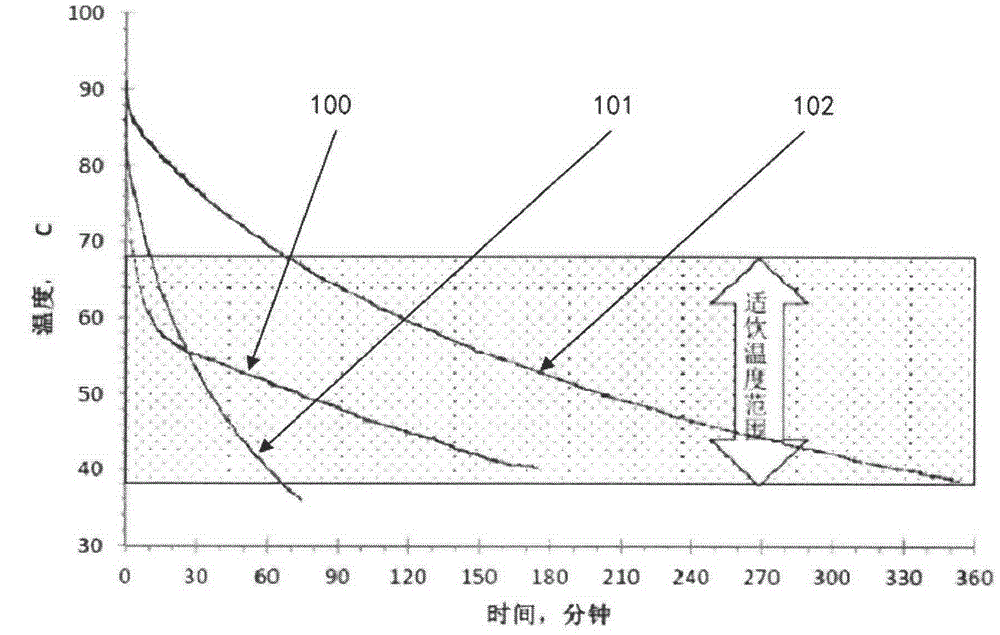

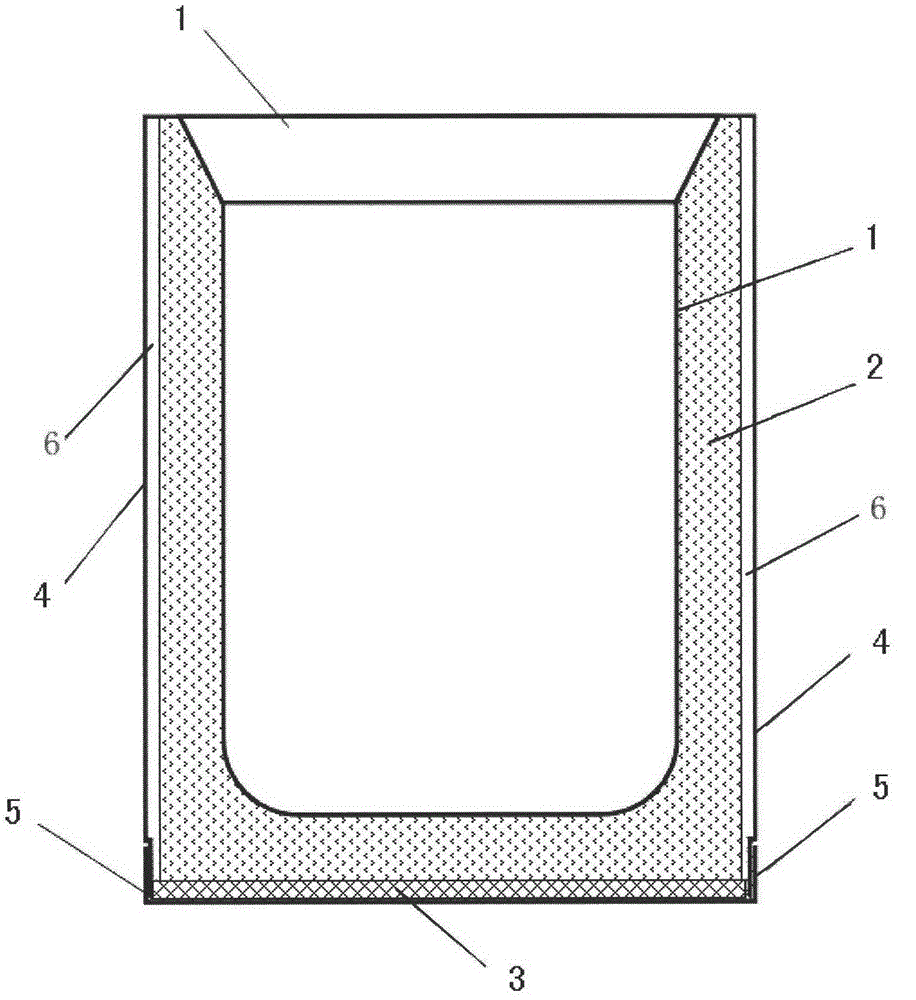

Thermostatic container utilizing phase-change material to perform automatic temperature regulation and control

InactiveCN105982481AEnable recyclingIn line with the concept of energy saving and emission reductionDrinking vesselsInsulation layerProcess engineering

The invention relates to the technical field of thermostatic containers, in particular to a thermostatic container utilizing a phase-change material to perform automatic temperature regulation and control. The thermostatic container is composed of an inner container, a heat storage layer, a heat insulation layer, a housing and a bottom cover. Under the situation that the thermostatic container is kept to be similar to a traditional container in weight and appearance, the thermostatic container utilizing the phase-change material to perform automatic temperature regulation and control can give consideration to the two functions of rapid cooling and long-time heat preservation to liquid inside the container and meanwhile has the remarkable functions of energy saving, environmental friendliness, convenient usage and the like.

Owner:SUZHOU WEINA ENERGY SAVING TECH CO LTD

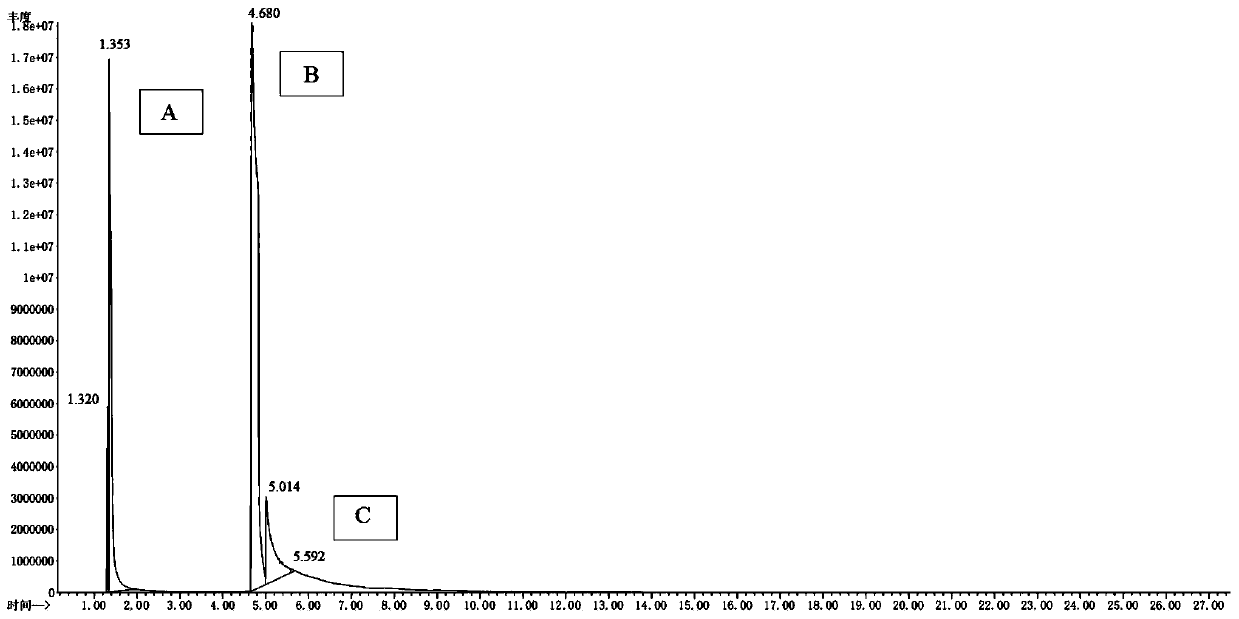

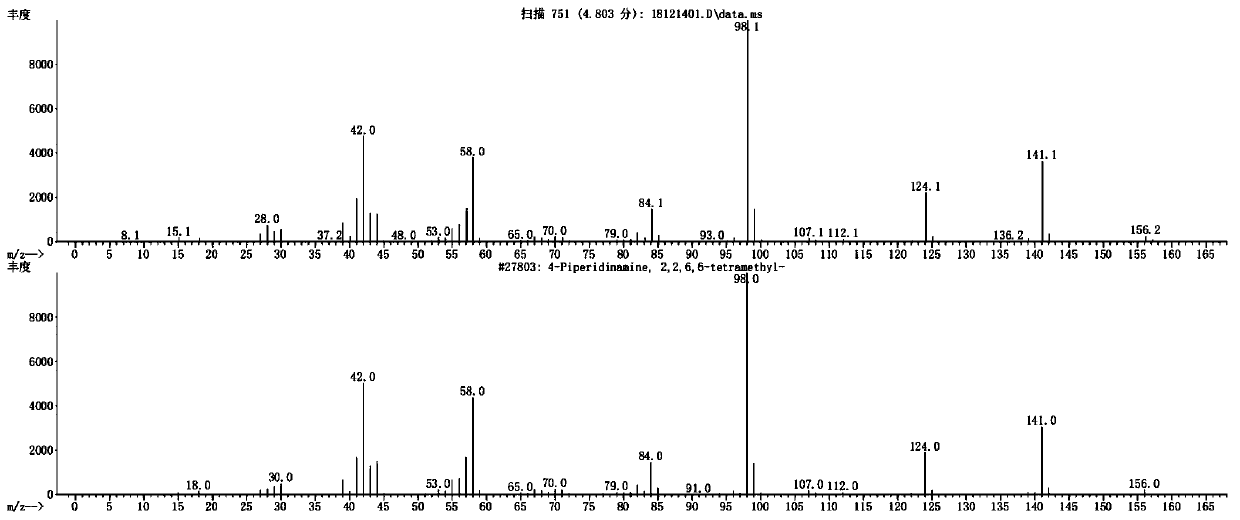

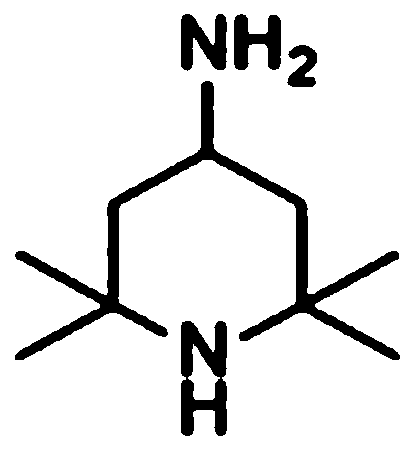

Synthetic method of amino-2,2,6,6-tetramentylniperidine with specific pH range

PendingCN109836370AReduce ring-opening productsHigh selectivityOrganic chemistryDistillation2,2,6,6-Tetramethylpiperidine

The invention discloses a synthetic method of amino-2,2,6,6-tetramentylniperidine with a specific pH range, and the method comprises the following steps: taking 2,2,6, 6-tetramethyl piperidone as a raw material, adding the raw material and ammonia water into a high-pressure kettle, first adjusting the pH value to 12.0-13.0, adding framework nickel serving as a catalyst, carrying out hydrogenationreaction at temperature of 55-65 DEG C under a set pressure value of 1.5-2.5 mpa, stopping the reaction until the pressure in the kettle is always not lower than 2% of a set pressure value in one hour; and carrying out normal pressure distillation on the reaction liquid, and then carrying out reduced pressure rectification to obtain the product amino-2,2,6,6-tetramentylniperidine. According to themethod disclosed by the invention, the conversion rate of the tetramethyl piperidone is improved, and the product yield is improved.

Owner:安徽新秀化学股份有限公司 +1

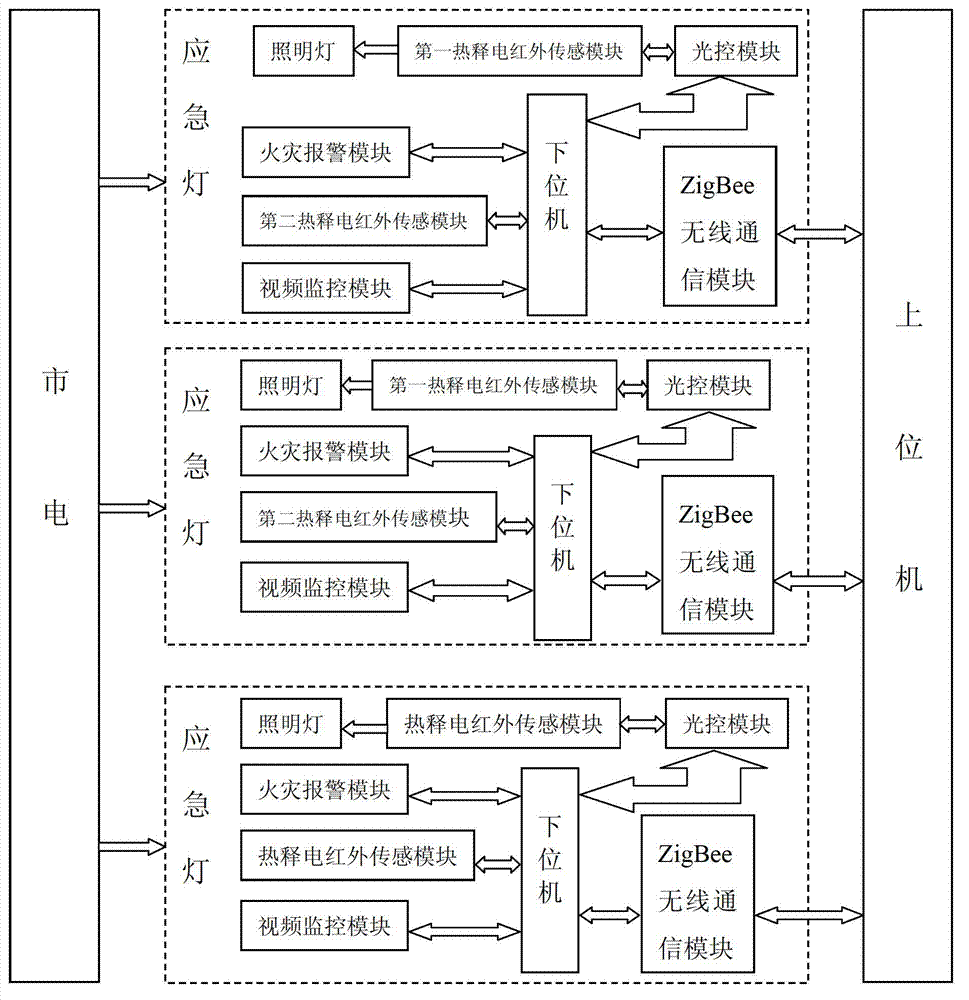

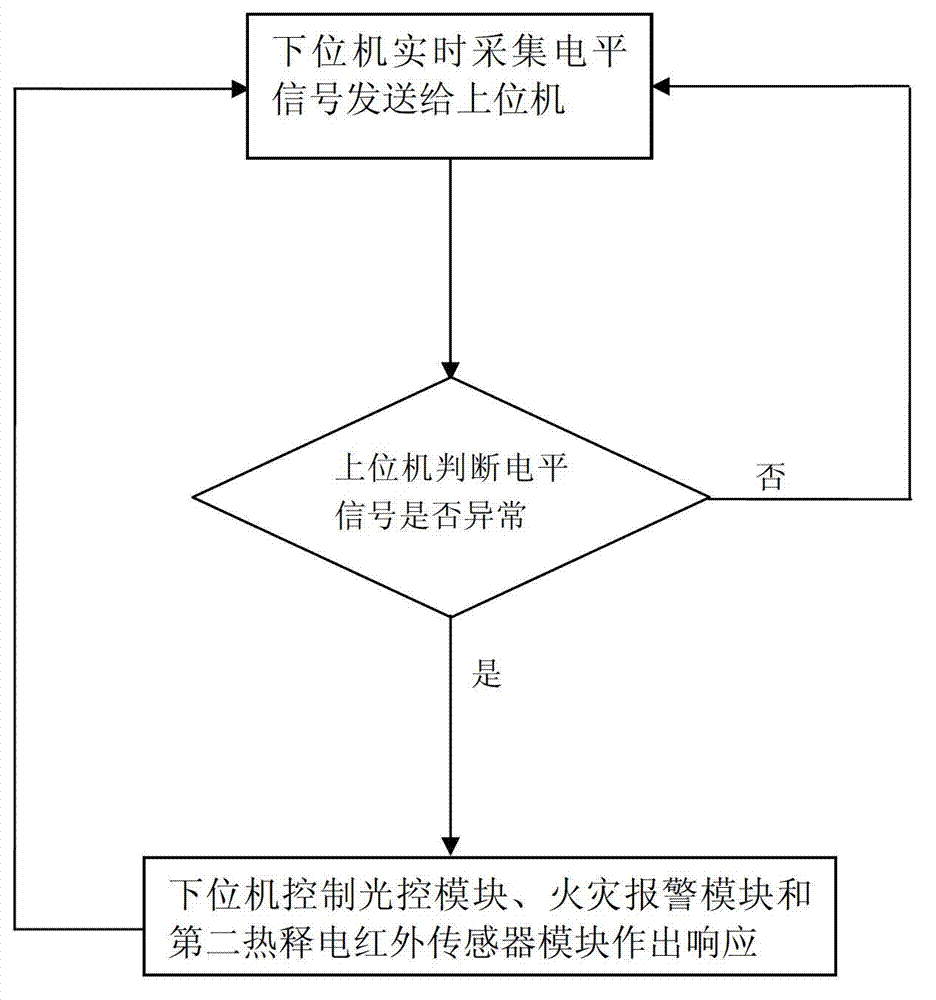

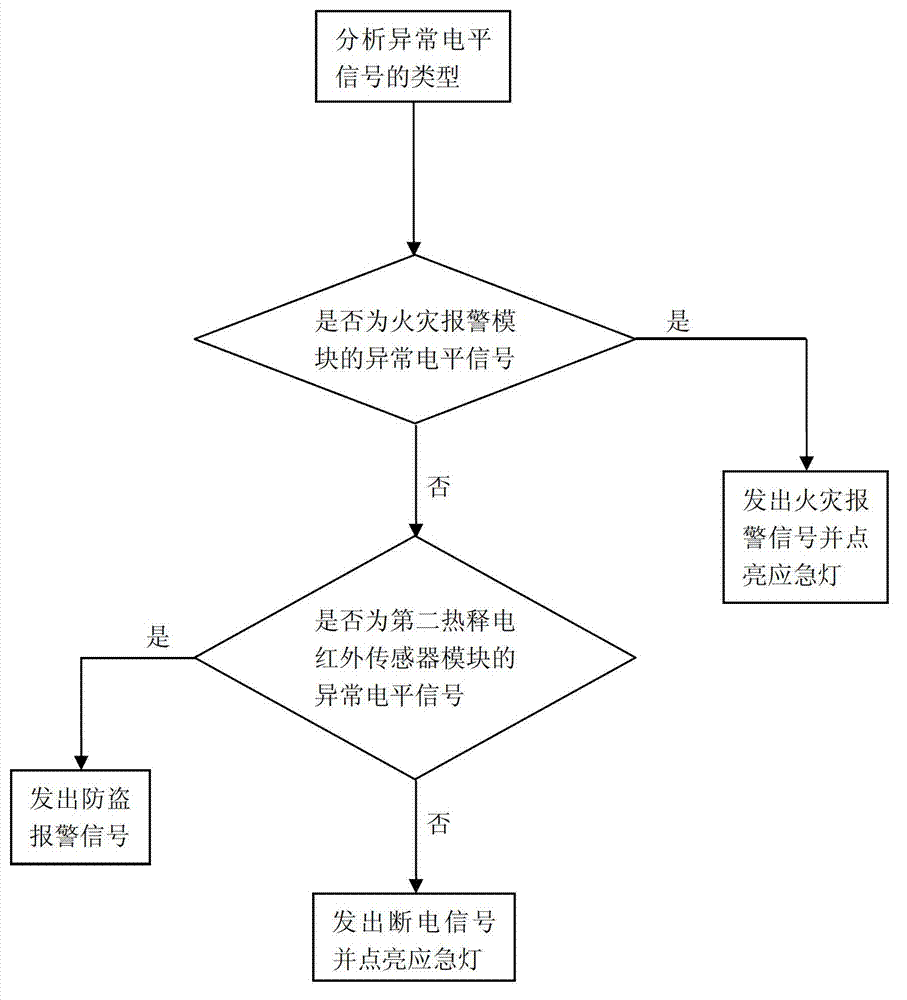

Multifunctional emergency lamp control system and control method thereof

InactiveCN102821525AEasy to controlReduce casualtiesElectric light circuit arrangementFire alarmsRelevant informationControl system

A multifunctional emergency lamp control system comprises an upper computer and a plurality of emergency lamps. Each emergency lamp comprises a wireless communication module, a light operated module, a fire alarm module, a second pyroelectric infrared sensor module and a first pyroelectric infrared sensor module. The control method of the multifunctional emergency lamp control system includes steps of firstly, acquiring level signals in real time and sending the level signals to the upper computer by a lower computer, continuously acquiring the level signals and sending the level signals to the upper computer by the lower computer if finding no abnormal level signals, and otherwise, executing the next step; secondly, sending numbers of the emergency lamps which send out the abnormal level signals and types of the abnormal level signals to the upper computer by the lower computer, and simultaneously, enabling the light operated module, the fire alarm module and the second pyroelectric infrared sensor module to make response under control of the lower computer; and thirdly, displaying relevant information through the upper computer. The emergency lamp control system has multiple functions of power-off illumination, burglary prevention and fire alarm, and has the advantages of high practicability and the like.

Owner:JINAN UNIVERSITY

Shaddock ped noodle

InactiveCN103404793ARefreshing tasteFull of nutritionFood preparationEconomic IncomeNutrient content

The invention relates to shaddock ped noodle. Debitterized shaddock ped powder is added in the noodle preparing process so as to increase the nutrient content and change the single taste of noodle. The shaddock ped noodle is fresh in mouth feeling, rich in nutrition and has the food-therapy health-care functions of regulating qi-flowing for eliminating phlegm, moistening lung, gutting purge, enriching blood and tonifying spleen. Besides, waste shaddock can be changed into wealth, so that the economic income of fruit growers is increased. The shaddock ped noodle is a health green food which conforms to the advocated concepts of energy conservation and emission reduction.

Owner:戴友曾

Recycling process of methyl sulcotrione solvent

ActiveCN104086438ASolve the problem of high cost and high energy consumptionReduce energy consumptionAmino compound purification/separationHalogenated hydrocarbon separation/purificationTriethylamine sulfateDistillation

The invention discloses a recycling process of a methyl sulcotrione solvent. The recycling process comprises the following steps: transferring a methyl sulcotrione dichloroethane solution which is subjected to condensation and rearrangement and contains triethylamine into a triethylamine salifying kettle and adding water under the condition that the volume ratio of dichloroethane to the water is 1 to (1-5) (v / v) (Volume Per Volume), starting stirring, slowly dripping a 80% to 91% dilute sulphuric acid solution according to the condition that the molar ratio of the triethylamine to the dilute sulphuric acid is 1 to (0.5-0.8) (mol / mol), regulating pH within 1 to 1.5, stirring for 15 minutes, separating out a methyl sulcotrione dichloroethane solution at a lower layer, and carrying out reduced pressure distillation for recycling the dichloroethane containing the water; putting a triethylamine sulfate aqueous solution at an upper layer into a storage tank; and simultaneously treating the obtained dichloroethane containing the water and the triethylamine sulfate aqueous solution. According to the recycling process, an acid-base neutralization salifying theory is adopted; the performances of dehydration and water absorption of materials are utilized, so that the whole recycling process is low in energy consumption, low in cost, mutually complementary, less in equipment investment and simple to operate, and is used for completely solving the problems of high cost and high energy consumption of the solvent separated in a distillation recycling manner. Thus, the recycling process disclosed by the invention conforms to the ideals of energy conservation and emission reduction in China.

Owner:ZHEJIANG ZHONGSHAN CHEM IND GRP

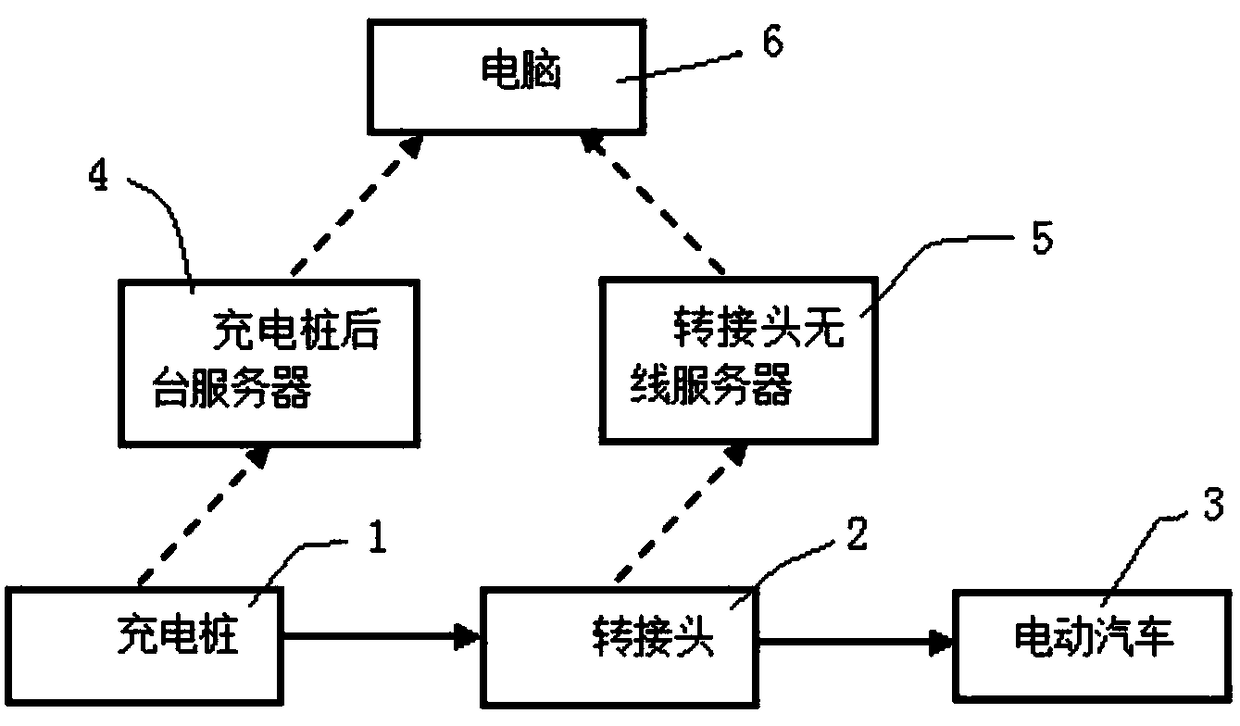

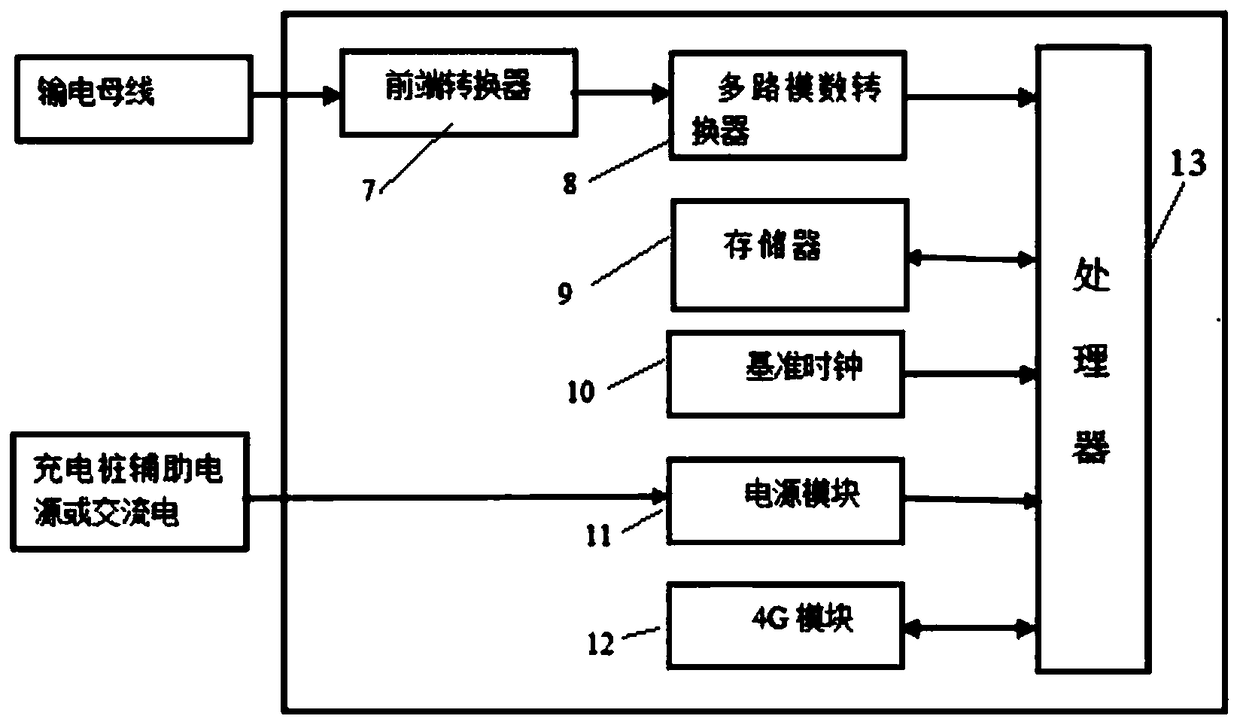

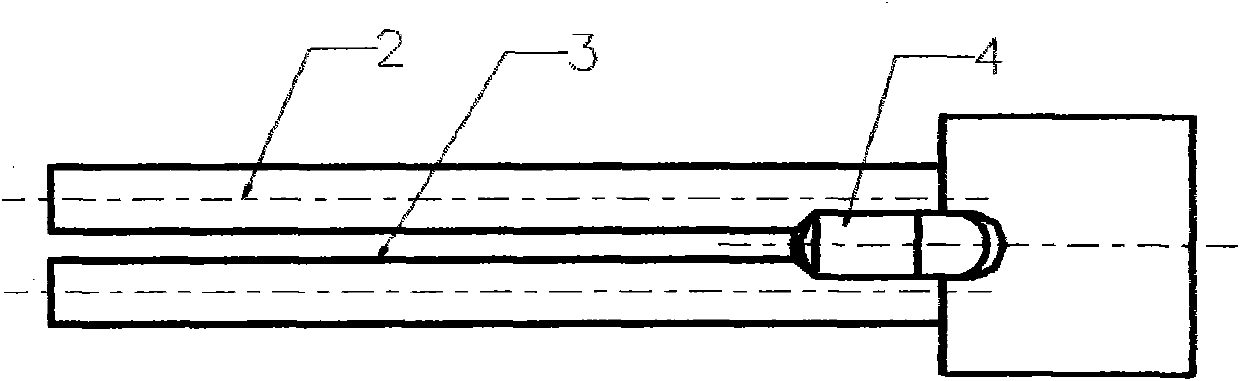

Verification method for embedded online real-time measurement of electric energy error of charging pile

InactiveCN109061291AReduce volumeSimple wiringElectrical measurementsElectric energyMarket development

The present invention aims to provide a verification method for embedded online real-time measurement of an electric energy error of a charging pile, for solving the technical problem of measuring theelectric energy error of the charging pile on line and in real time. One end of an adapter is provided with a charging gun plug, the other end thereof is provided with a charging gun socket, and theadapter is embedded with a calibrator; the charging gun is connected with the charging pile and an electric load through the adapter; the calibrator is wirelessly connected with an adapter wireless server, and the charging pile is connected with a background server thereof; a verification computer performs data interaction with the adapter wireless server and the background server of the chargingpile in a wireless manner; and the verification computer realizes verification of the electric quantity error by comparing the data acquired by the adapter wireless server and the data acquired by thecharging pile background server. The verification method for embedded online real-time measurement of an electric energy error of a charging pile in the invention has the advantages of small volume and light weight and can adapt to the needs of market development.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

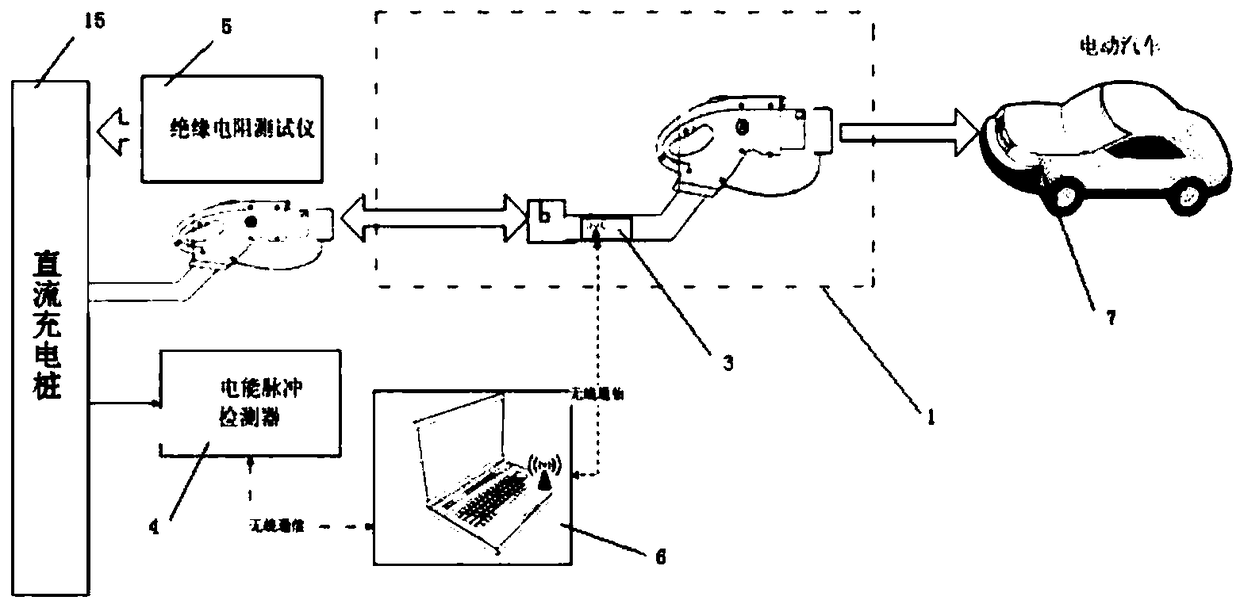

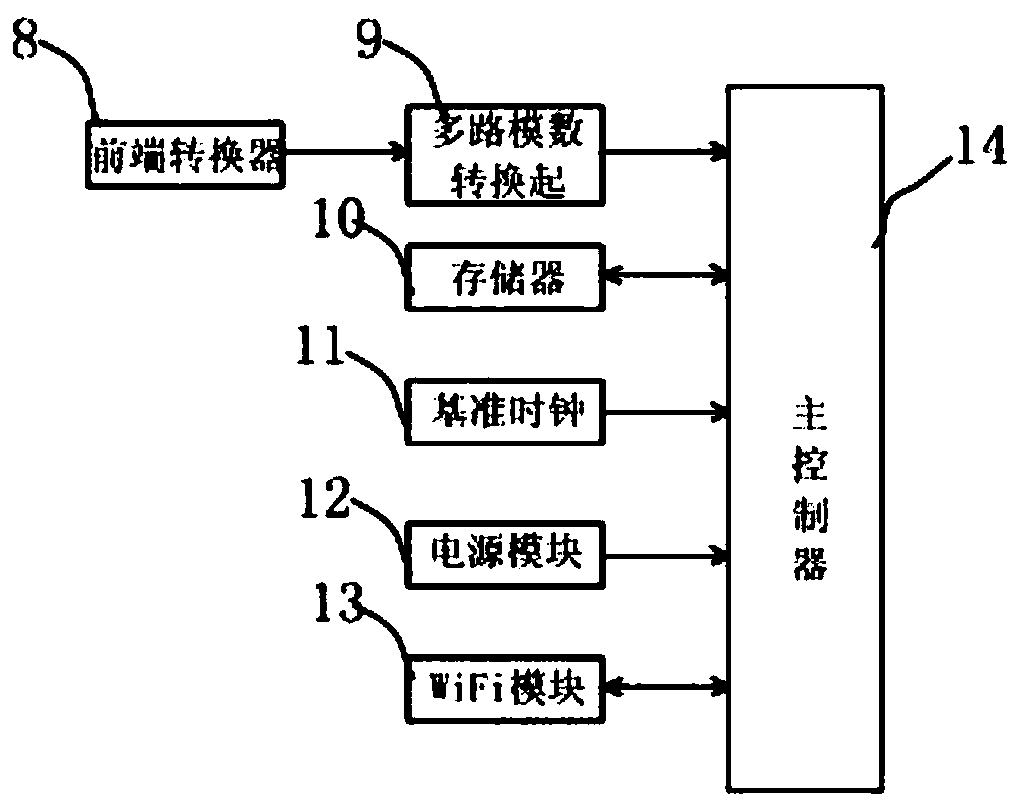

Examination method that realizes DC charging pile electrical energy error verification function

InactiveCN108828359AReduce volumeReduce weightVery high resistance measurementsElectrical testingElectricityExamination method

The invention aims to provide an examination method that realizes a DC charging pile electrical energy error verification function, and aims to solve the DC charging pile detection technical field; anintelligent charging gun with a built-in check meter is connected with the DC charging pile and a power load, and the check meter can obtain an electric energy signal of the power load; an electric energy pulse detector obtains an electric energy pulse signal of the DC charging pile; a computer can exchange data with the check meter and the electric energy pulse detector via a wireless mode, compares the data collected by the check meter with the data obtained by the electric energy pulse detector, thus verifying the electric energy quantity error. The advantages are that the method can solvethe problems that a conventional DC charging pipe examination device is large in size and heavy in weight, and solves the problems that conventional detection equipment cannot measure in a long timeand hard to remotely monitor.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Multifunctional chemical system used for scouring and bleaching cotton-polyester blended fabrics and dyeing polyester components in one bath

ActiveCN103174019ASimplify the dyeing and finishing processIncrease productivityFibre treatmentBleaching apparatusPolyesterTriphenylethylene

The invention provides a multifunctional chemical system used for scouring and bleaching cotton-polyester blended fabrics and dyeing polyester components in one bath. The multifunctional chemical system comprises one or more of the following components: fatty alcohol-polyoxyethylene ethers, hydroxyethyl butyl ethers, glycerin polyoxyethylene ether oleate, fatty alcohol sulfate, triphenylethylene phenol polyoxyethylene ethers, polyoxyethylene ether oleate, solubilizers and water. The chemical system can be absolutely used for scouring and bleaching cotton-polyester blended fabrics and dyeing polyester components in one bath and ensures that the obtained fabric products have excellent quality and styles; the polyester dyeing effect of the chemical system can reach the traditional process level; and meanwhile, the chemical system is simple and convenient, effective and environment-friendly, simplifies the dyeing and finishing processes, improves the production efficiency and conforms to the concept of energy conservation and emission reduction.

Owner:DYMATIC CHEM +1

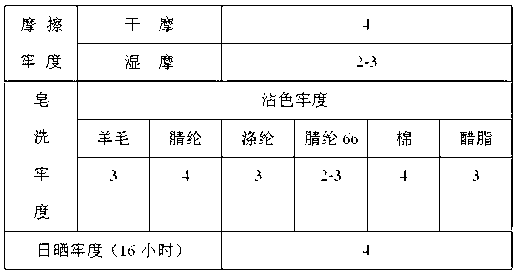

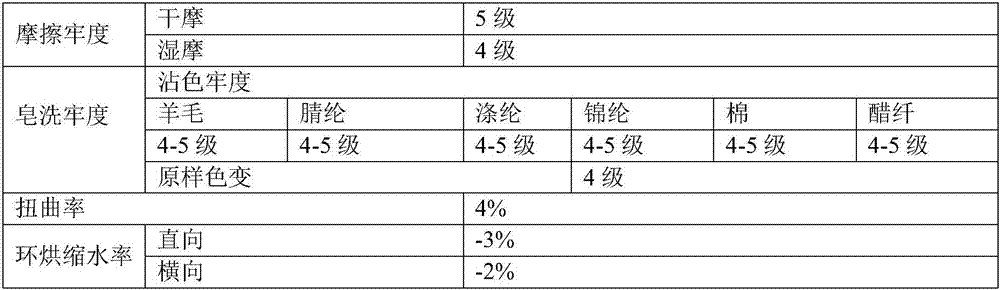

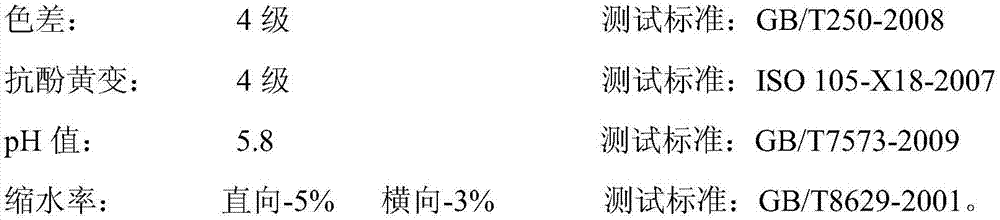

Method for dyeing cotton knitwear in bright fluorescent pink

ActiveCN102912653AMeet the requirements of bright colorMeet the requirements of fastnessBleaching apparatusDyeing processAdenylate kinaseFluorescence

The invention relates to a method for dyeing cotton knitwear, in particular to a method for dyeing cotton knitwear in bright fluorescent pink. The method includes firstly, removing hair in an air cylinder before high-temperature pretreatment; secondly, dyeing an overflowing cylinder, and adding HAC (ethanoic acid) to regulate PH to 5-6; thirdly, measuring and adding ADK (adenylate kinase)-260 cation modifier; fourthly, discharging water once; fifthly, allowing for water inflowing, and adding fluorescent pigment vermilion S-004; sixthly, performing sample comparison; seventhly, washing twice after sample comparison, and taking out of the cylinder; eighthly, soaking in a scoop outside the cylinder, and adding ADK-101 adhesive; ninthly, dewatering and drying; and tenthly, shaping. The condition that reactive dye cannot be used to dye bright fluorescent pink conventionally is broken through, the fluorescent pigment is selected for dyeing, and accordingly gorgeous and bright fluorescent dyeing effect is achieved. By the steps of the method, the requirement of customers for color brightness is met, and corresponding quality index is met.

Owner:ZHEJIANG YINHE PRINTING & DYEING

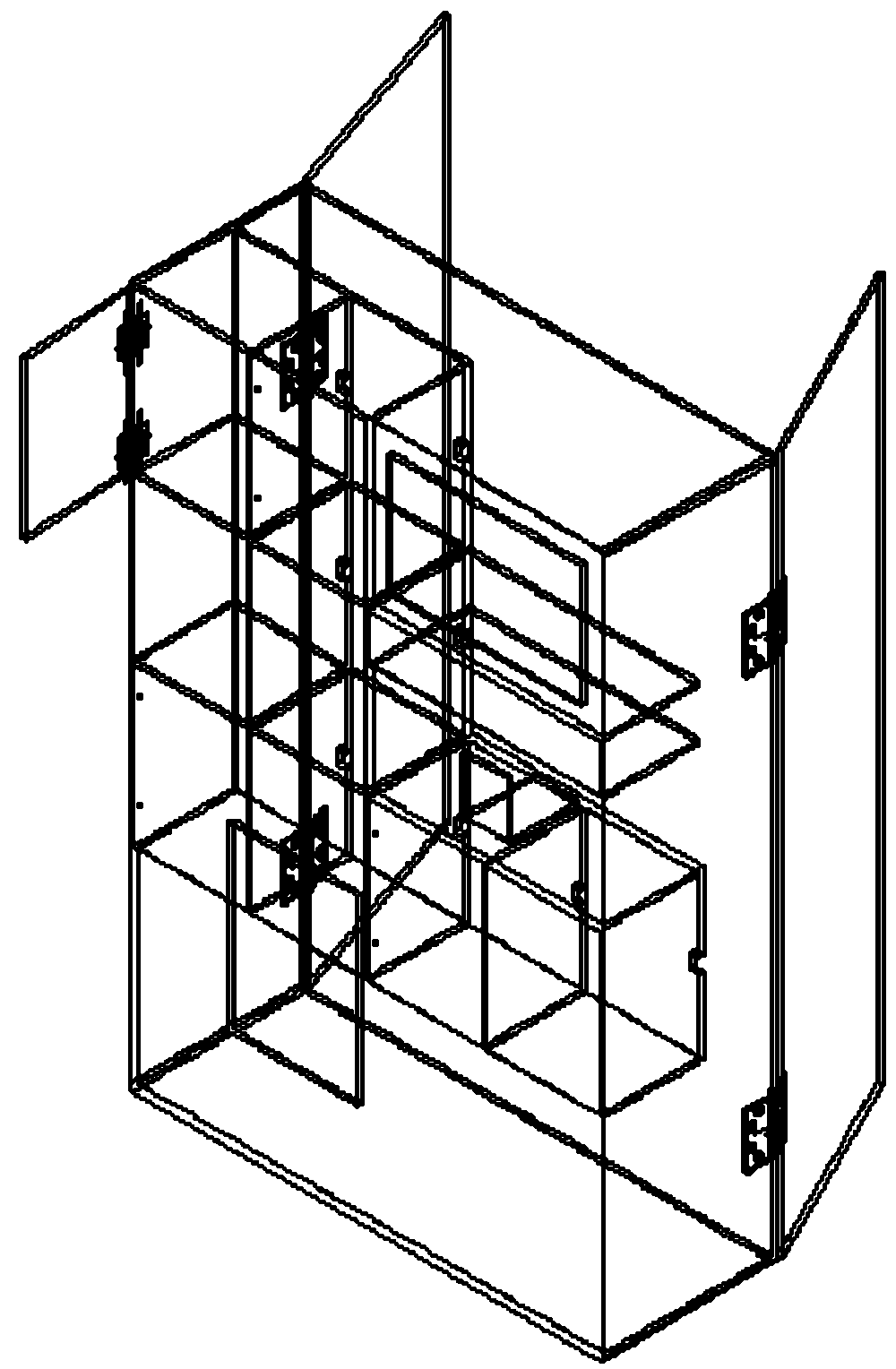

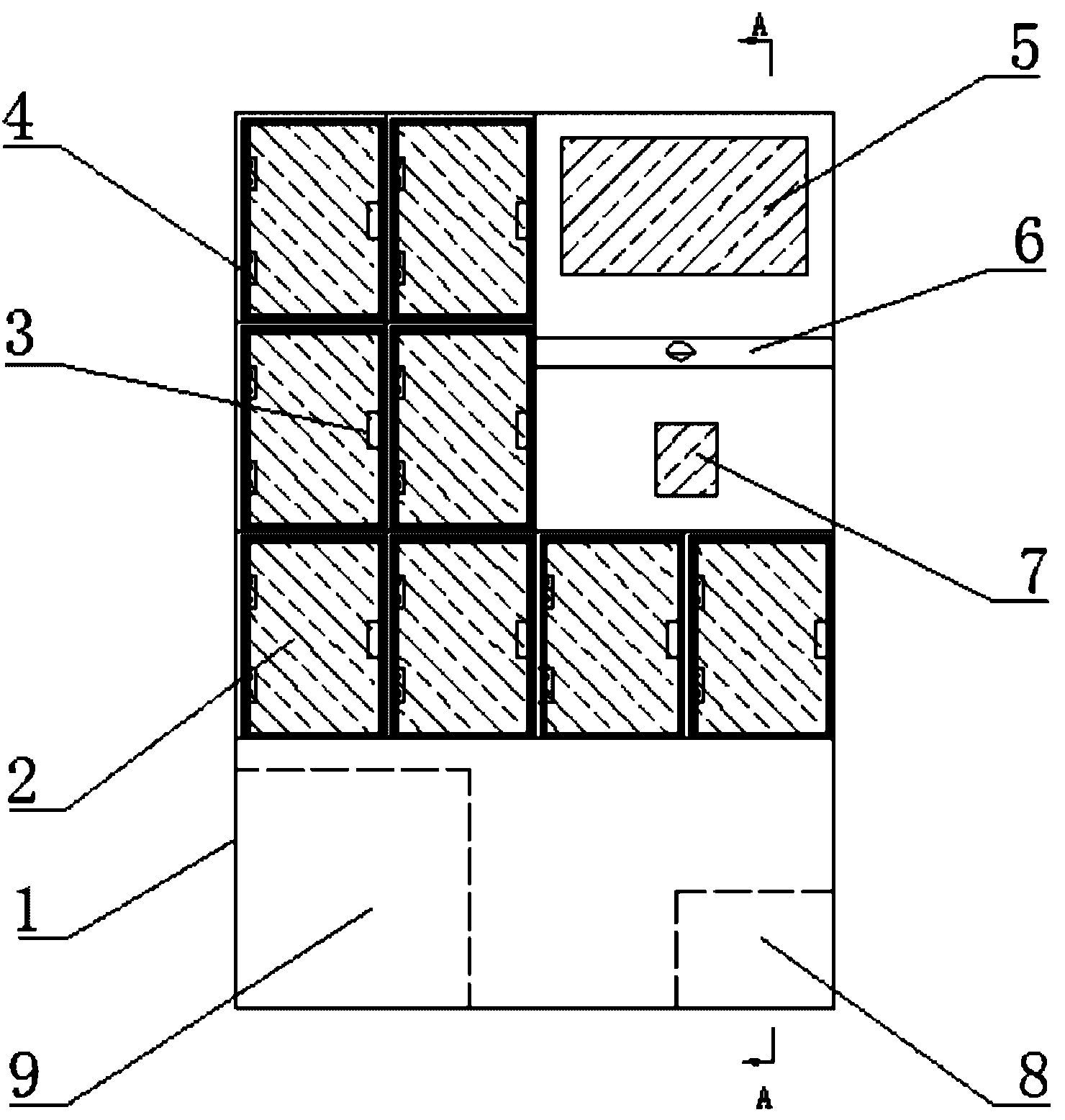

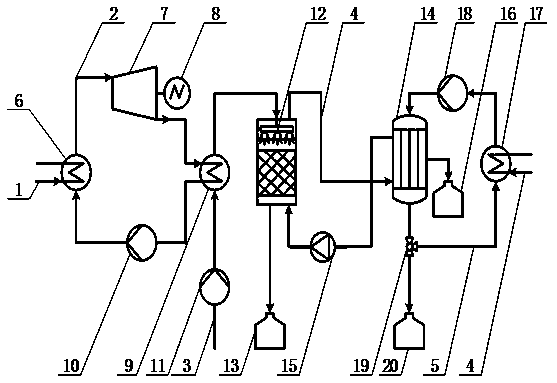

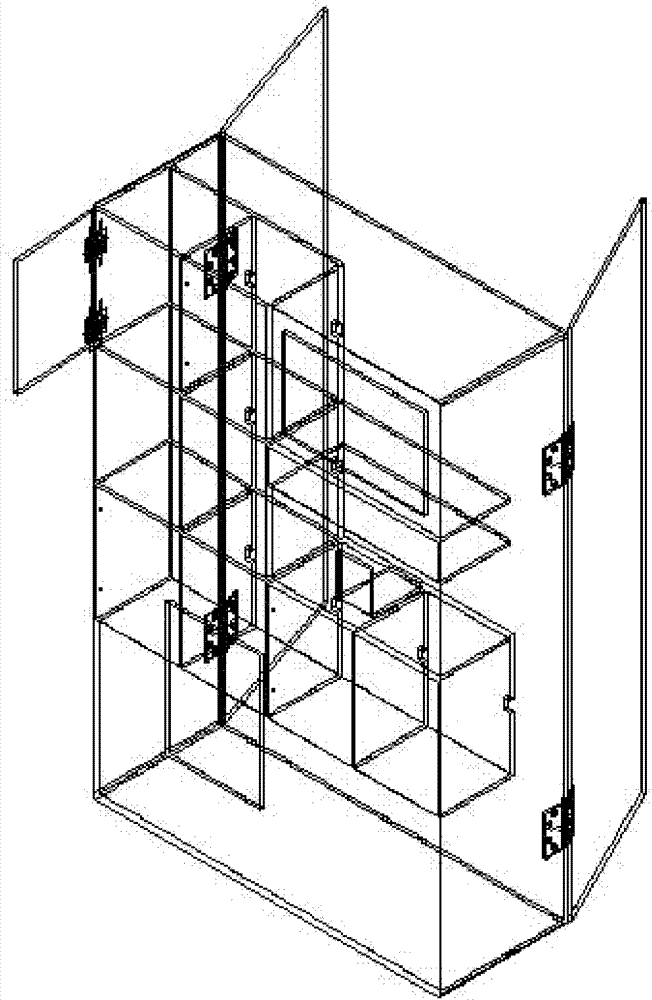

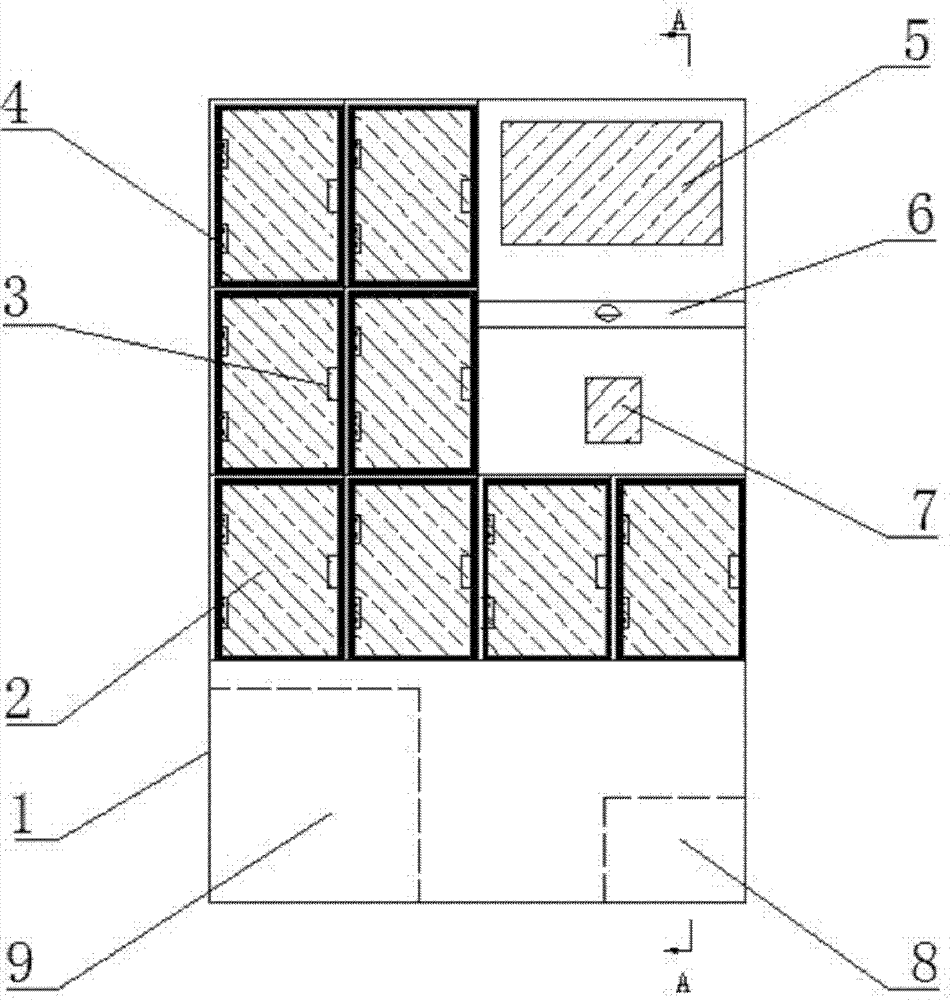

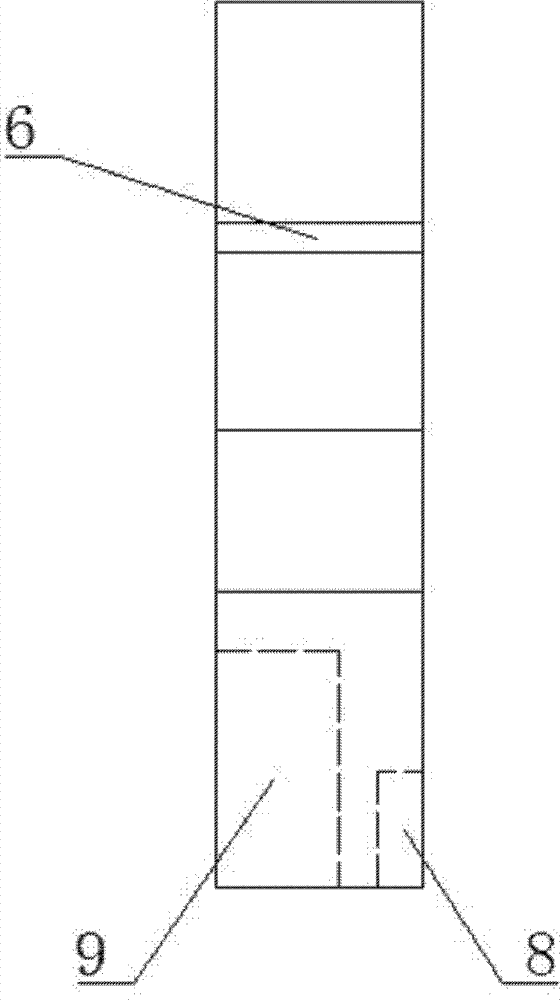

Multi-functional secondhand book self-service transaction machine employing transfer-type IC (Integrated Circuit) card

InactiveCN102881077ARealize the buying and selling linkUnique functionCoded identity card or credit card actuationDisplay deviceCard reader

The invention relates to a multi-functional secondhand book self-service transaction machine employing a transfer-type IC (Integrated Circuit) card. The multi-functional secondhand book self-service transaction machine comprises a cabinet body, a display, a keyboard, a card reader, a switch power supply and a host computer, wherein the display, the keyboard, the card reader, the switch power supply and the host computer are arranged inside the cabinet body; the display, the keyboard and the card reader are respectively connected with the host computer; the host computer is connected with the switch power supply; the cabinet body comprises a frame; two split doors are arranged at the back side of the frame; a plurality of spacers with electronic lock doors are arranged inside the frame; and each electronic lock door comprises a door body and an electronic lock, and the electronic lock is connected with the host computer. Compared with the prior art, the multi-functional secondhand book self-service transaction machine has the advantages of unique function, good environment benefit and wide application range.

Owner:TONGJI UNIV

Amino acid fermentation method using corn steep liquor hydrolysate instead of industrial phosphate

The invention relates to an amino acid fermentation method using corn steep liquor hydrolysate instead of industrial phosphate, using phytase to hydrolyze corn steep liquor to produce the corn steep liquor hydrolysate with free phosphorus content meeting production needs instead of direct use of phosphorus sources such as the corn steep liquor and phosphoric acid to an amino acid fermentation process. The invention provides a method using the corn steep liquor as a raw material and using the corn steep liquor hydrolysate hydrolyzed by the phytase instead of directly using corn steep liquor and adding phosphoric acid as the phosphorus sources in a normal amino acid fermentation production process, a production indicator is basically consistent with the normal fermentation, the cost of all phytase is far lower than the cost of the phosphoric acid capable of achieving the same effect. Therefore, the method has low cost, can effectively reduce the comprehensive production cost of the amino acid while ensuring normal production, directly provides the enterprise economic benefits, and is suitable for comprehensive promotion in production.

Owner:LINGHUA GROUP INCORPORATED COMPANY

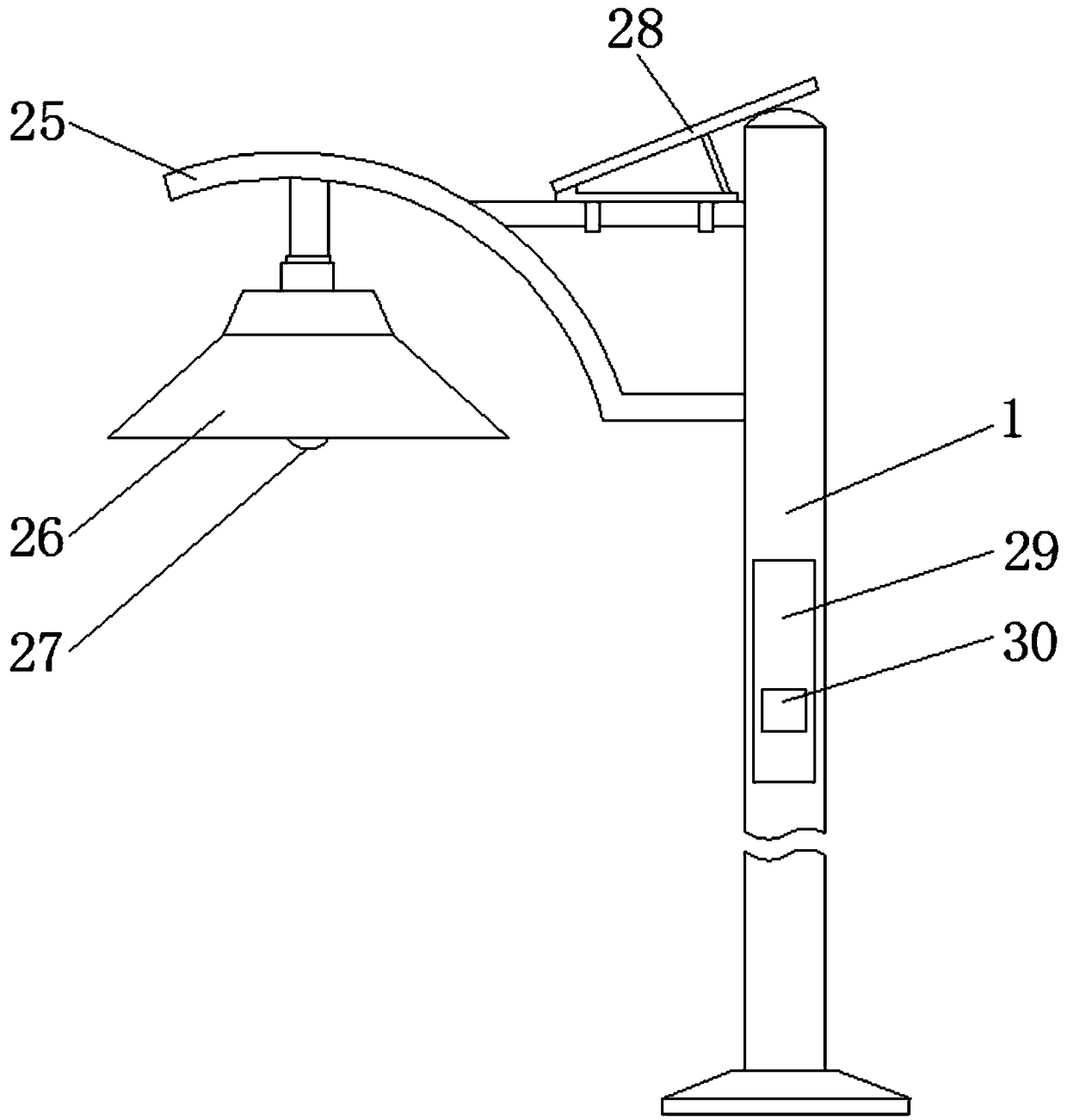

Intelligent street lamp with camera shooting function

InactiveCN108799998AThe camera effect is clearDoes not consume electricityMechanical apparatusElectric circuit arrangementsCamera lensElectric energy

The invention discloses an intelligent street lamp with a camera shooting function, relating to the technical field of street lamps. The intelligent street lamp with the camera shooting function comprises a lamp post, wherein the interior of the lamp post is fixedly connected to a supporting strip; the top of the supporting strip is fixedly connected to a wind box; the interior of the wind box isrotatably connected to a rotating shaft; and the right end of the rotating shaft penetrates the wind box and extends to the right side of the wind box. According to the intelligent street lamp with the camera shooting function, an electromagnetic block is not electrified at ordinary times; a prism can be adsorbed by using the magnetic force of a small magnetic block; natural wind is used for blowing fan blades, so that a rotating shaft can rotate, and then a small-sized power generation box can be used for generating electric power which enables an electronic component to work normally; afterbeing electrified, the magnetic block adsorbs the prism, so that a rotating disc is connected to the rotating shaft and can be driven to rotate; a push rod is used for enabling a hairbrush plate to lift and drop, and the hairbrush plate can automatically clear dust on the surface of a camera lens in combination with bristles so as to enable a camera to have a camera shooting effect; and natural wind is used for clearing dust, so that no electricity is consumed, electricity can be generated, and therefore, the intelligent street lamp with the camera shooting function conforms to the idea of energy saving and emission reduction.

Owner:安徽艾塔智能科技有限公司

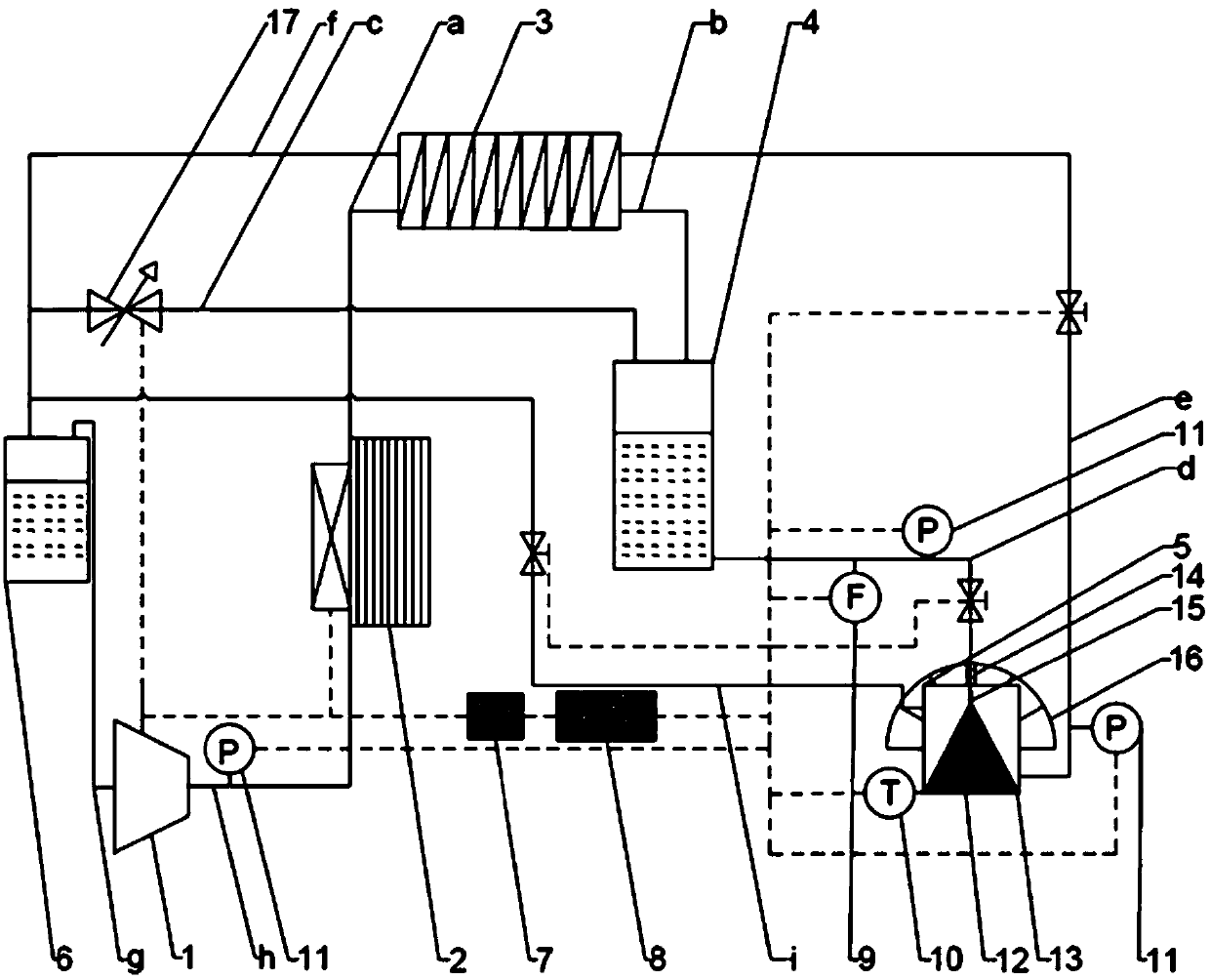

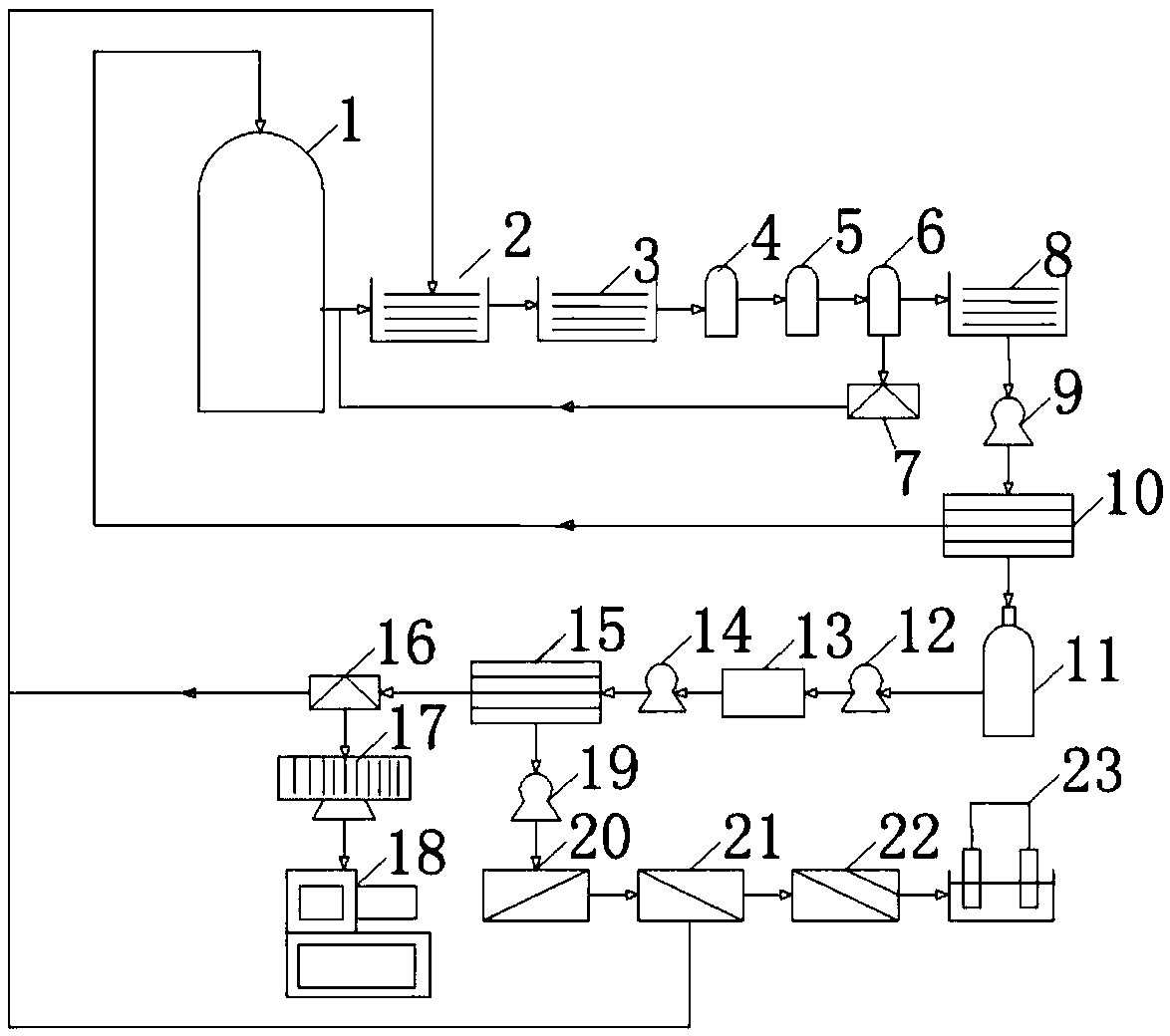

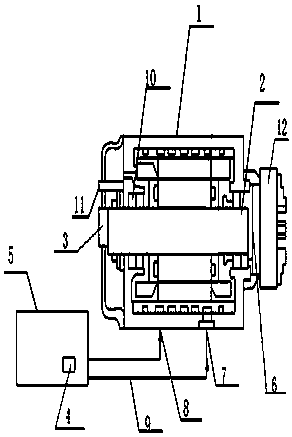

Electron device flash spray circulation cooling system with self-optimizing characteristic

ActiveCN107894114AMeet thermal requirementsImprove heat transfer efficiencyMechanical apparatusFluid circulation arrangementVapor–liquid separatorOptimal control

The invention discloses an electron device flash spray circulation cooling system with a self-optimizing characteristic. The electron device flash spray circulation cooling system with the self-optimizing characteristic comprises a compressor, a condenser, a heat regenerator, a liquid storage tank, a mist spraying cavity and an air-liquid separator, wherein an outlet of the compressor is connectedwith an inlet of the condenser through a pipeline; the condenser is connected with an inlet of a first passage of the heat regenerator through a pipeline; an outlet of the first passage of the heat regenerator is connected with an inlet of the liquid storage tank through a pipeline; a lower outlet of the liquid storage tank is connected with an inlet of the mist spraying cavity through a pipeline; a lower liquid outlet of the mist spraying cavity is connected with an inlet of a second passage of the heat regenerator through a pipeline; an upper air outlet of the mist spraying cavity is connected with an inlet of the air-liquid separator through a pipeline; an outlet of the second passage of the heat regenerator is connected with the inlet of the air-liquid separator through a pipeline; and the air-liquid separator is connected with an inlet of the compressor through a pipeline. The system realizes optimal control over heat exchange intensity by regulating the parameters such as the opening degree of a bypass valve, the frequency of the compressor and the height and dip angle of mist spraying, and rapidness and stability of the system are guaranteed.

Owner:XI AN JIAOTONG UNIV

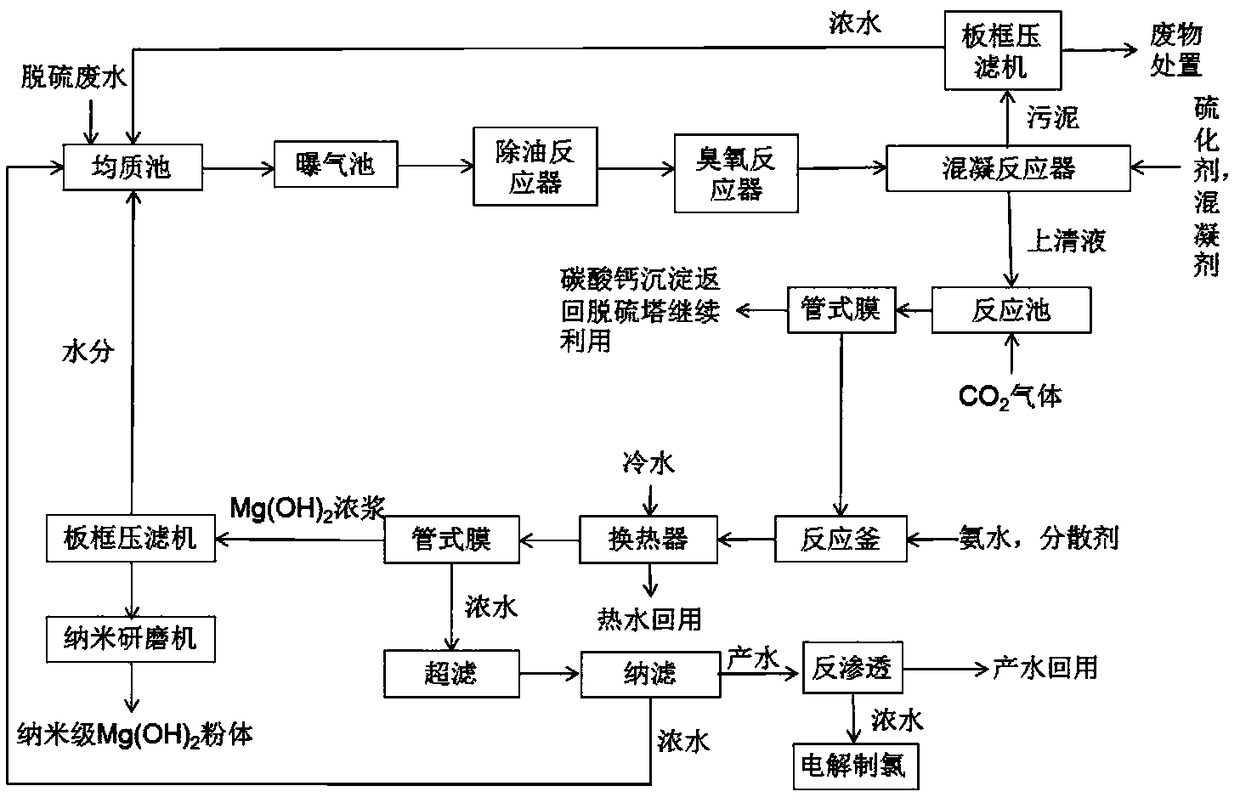

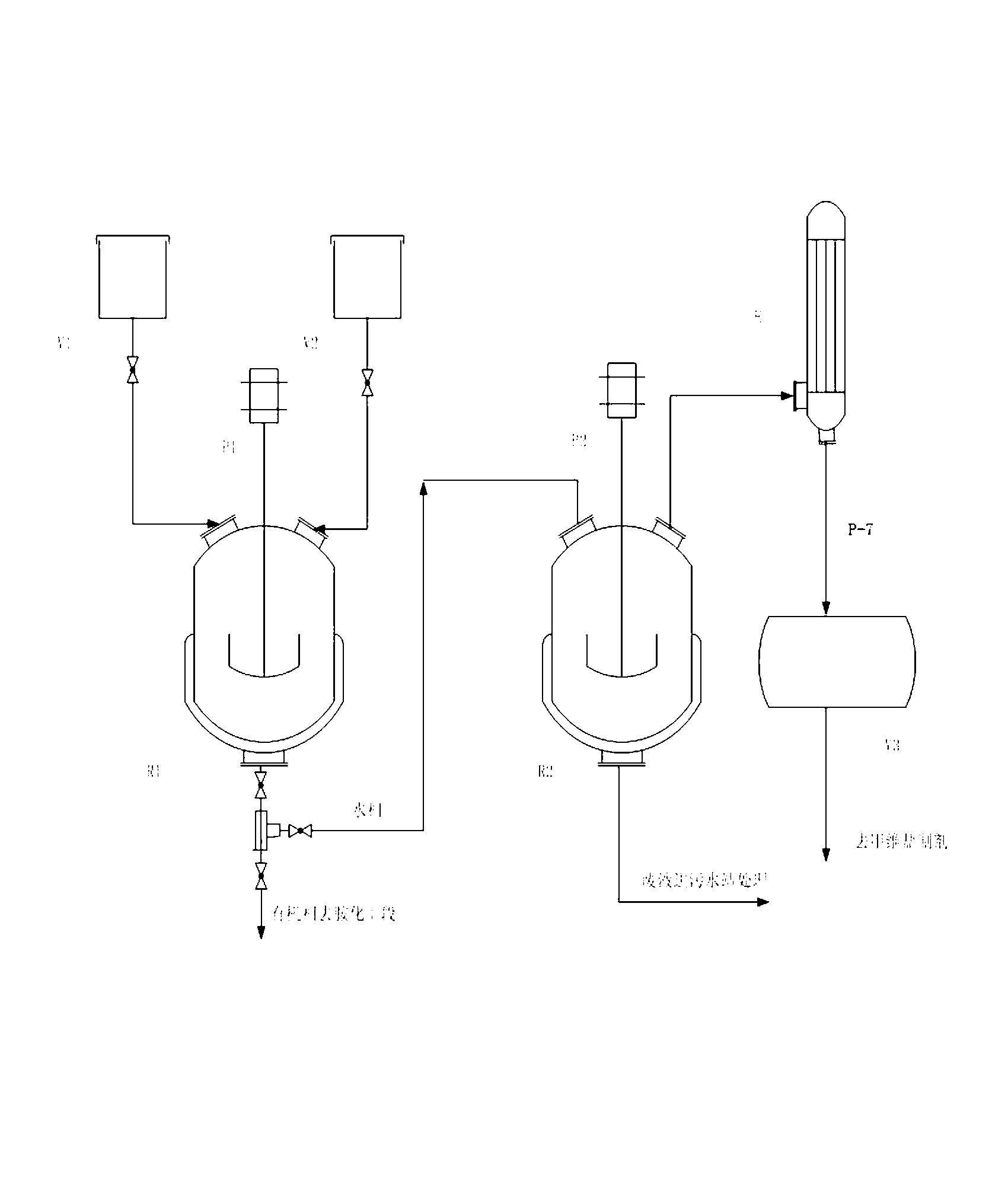

Desulfurization wastewater resourceful treatment system and application method

PendingCN109368850AEmission reductionTurn waste into treasureCalcium/strontium/barium carbonatesFatty/oily/floating substances removal devicesElectrolysisProduced water

The invention relates to a desulfurization wastewater resourceful treatment method. The desulfurization wastewater resourceful treatment method comprises the following steps: homogenizing, pretreating, separating calcium carbonate from carbon dioxide in flue gas, preparing magnesium hydroxide by adding ammonia water, and preparing sodium hypochlorite by electrolyzing, thereby realizing the comprehensive utilization of resources in the desulfurization wastewater softening process. In the treatment process, all produced water can reversely flow to the front end for continuous treatment; the zerodischarge of desulfurization wastewater is realized; meanwhile water resources are saved; and the treatment cost of desulfurization wastewater is reduced. The desulfurization wastewater resourceful treatment method recycles the desulfurization wastewater of power plants and the flue gas of desulfurizing towers to the maximum extent and has great guiding significance for control on the environmental pollution caused by the power plants.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

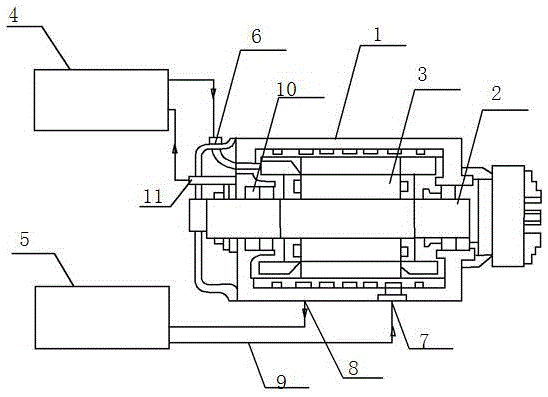

System and method for removing smoke dust by cyclically heating steam through combination of cooking range waste heat and solar energy

The invention relates to a system and a method for removing smoke dust by cyclically heating steam through combination of cooking range waste heat and solar energy, and belongs to the technical field of energy environmental protection. The system comprises a rainwater recovery system, a vegetable washing water recovery system and a heating system, wherein the heating system comprises a communicating water pipe, a water steam delivery pipe, a water steam pipe, a chimney spiral heating pipe and a chimney; the rainwater recovery system and the vegetable washing water recovery system are connected with the communicating water pipe in the heating system; the communicating water pipe is connected with the water steam pipe through the water steam delivery pipe; the communicating water pipe, the water steam delivery pipe, the water steam pipe and the chimney spiral heating pipe are arranged in the chimney; the communicating water pipe is concretely distributed on an inner wall of the chimney. According to the system and the method provided by the invention, the resident cooking range waste heat and solar energy are utilized for heating an air medium in the chimney to be energy, and outdoor rainwater and daily vegetable washing waste water are recovered to be as a water source, so that energy conservation and emission reduction are realized, and high-efficient cyclic utilization of the energy is the aim and the idea of new rural construction.

Owner:KUNMING UNIV OF SCI & TECH

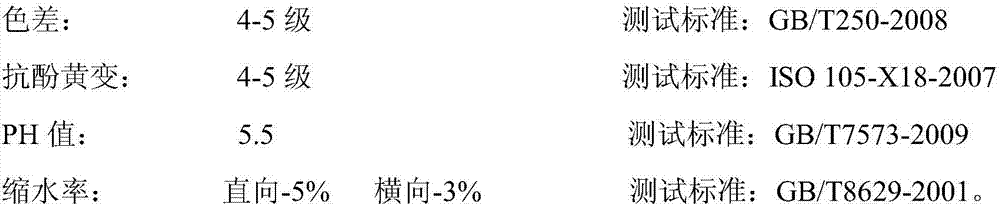

Finishing method for improving shrinkage rate of napped lints of cotton knitted goods and quality of plush

ActiveCN107287803AIncrease contact surfaceImprove uniformityLiquid/gas/vapor removalHeating/cooling textile fabricsShrinkage rateEngineering

The invention relates to the field of a finishing method of cotton knitted goods and discloses a finishing method for improving the shrinkage rate of napped lints of the cotton knitted goods and the quality of plush. The finishing method comprises the following steps: (1) dyeing grey cloth, dewatering and arranging the cloth; (2) sizing and drying a pulling needle; (3) napping and raising; (4) tentering and sizing; (5) fully overfeeding and tentering for sizing; (6) carrying out flat-screen loose type drying; and (7) adding steam to pre-shrink a felt for sizing. The finishing method disclosed by the invention has the advantages that the prior art is improved, the traditional steps of washing and drying are omitted, the steps of fully overfeeding and tentering for sizing and carrying out flat-screen loose type drying are added for alternation, and the technical problems of high shrinkage rate of finished products and low quality of the plush in the prior art can be solved.

Owner:ZHEJIANG YINHE PRINTING & DYEING

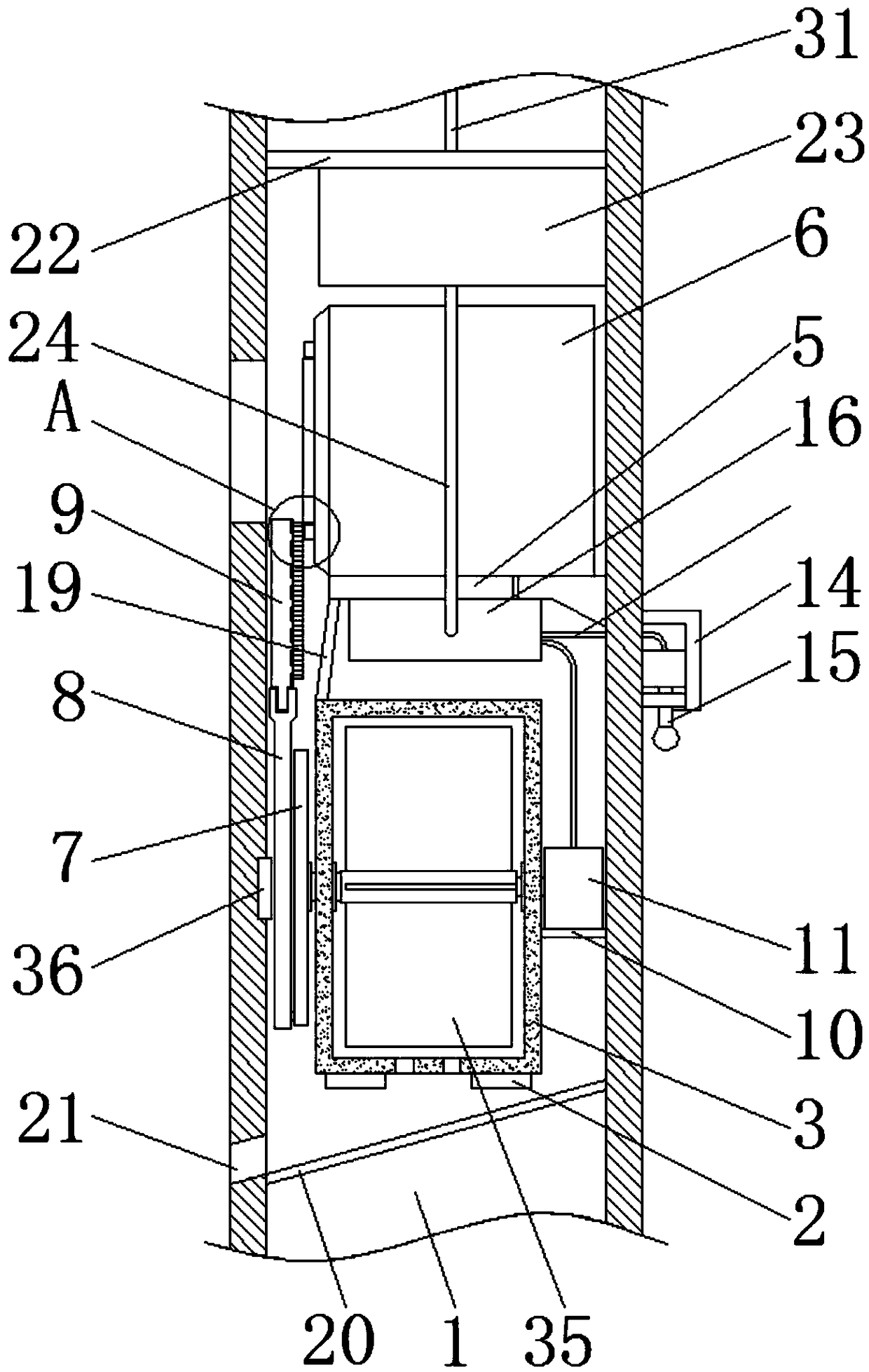

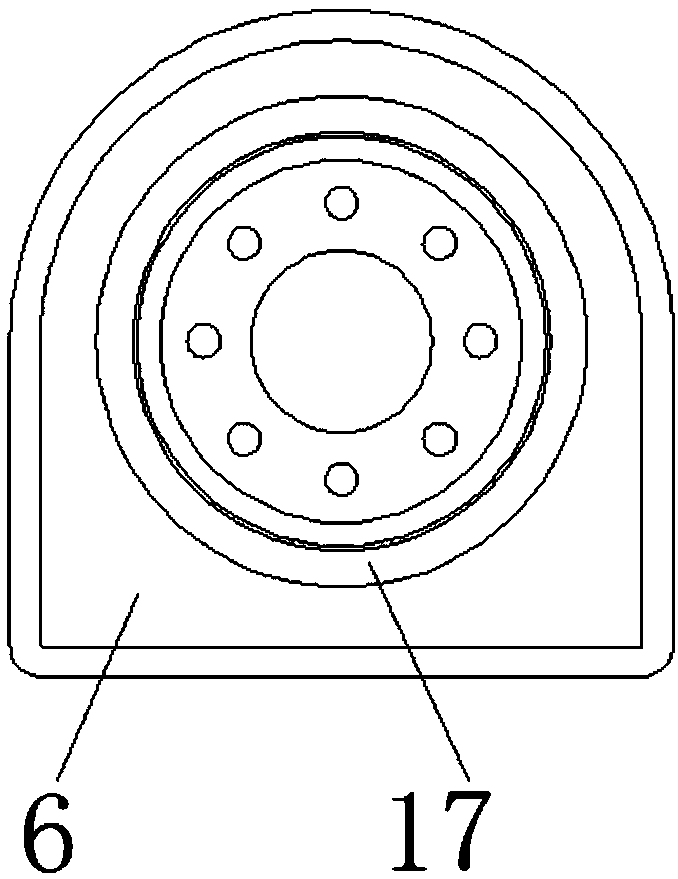

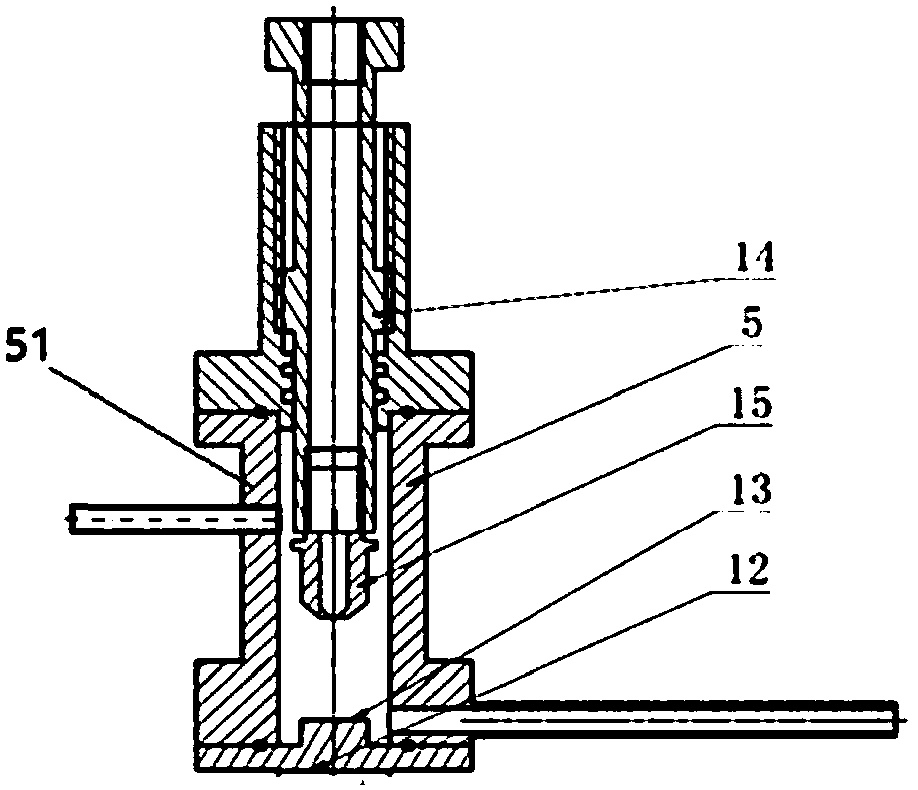

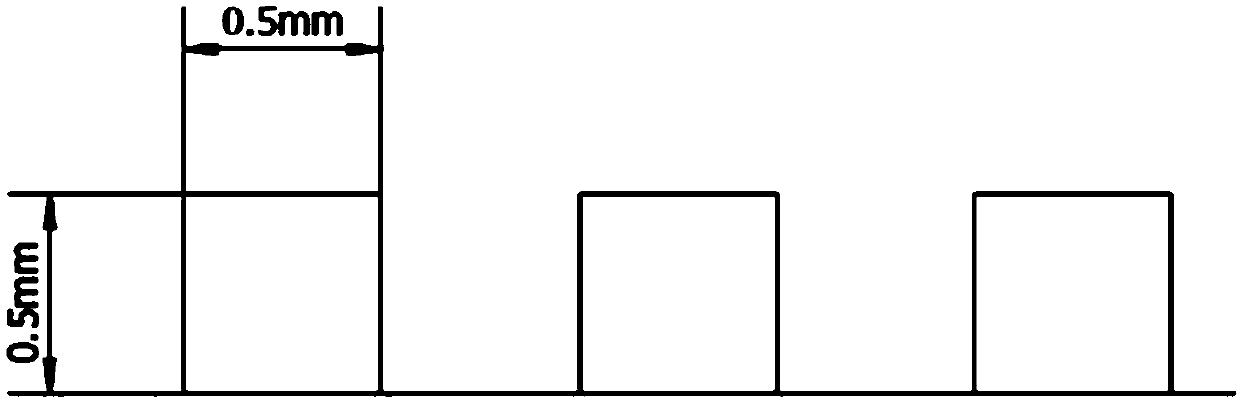

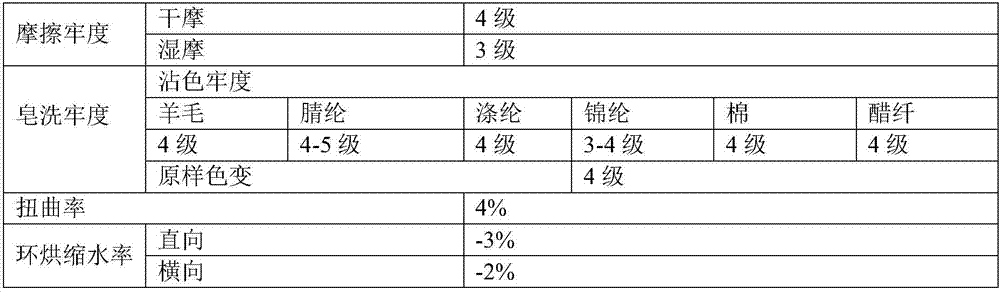

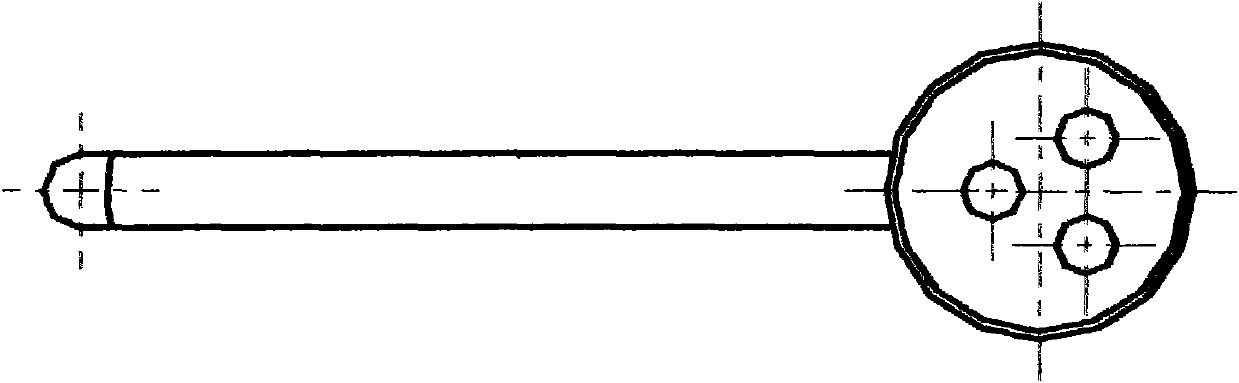

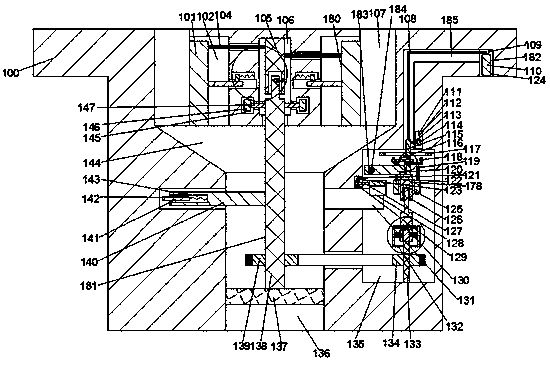

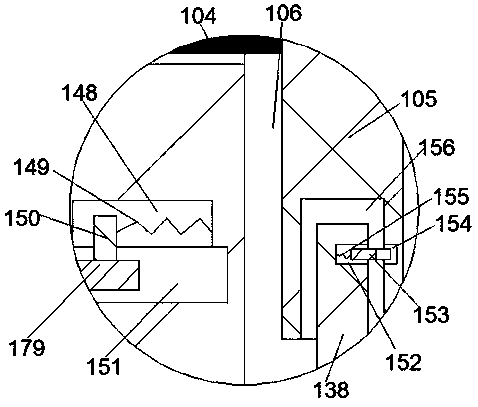

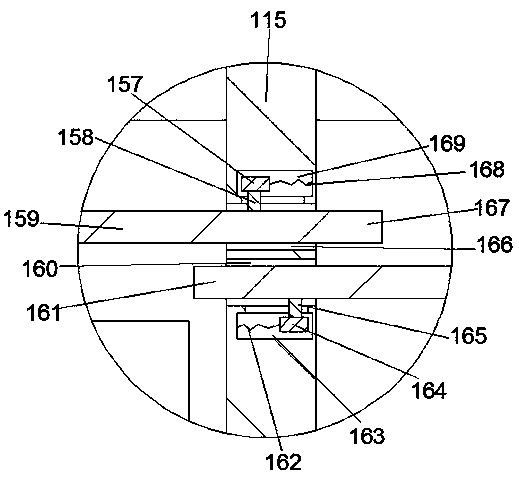

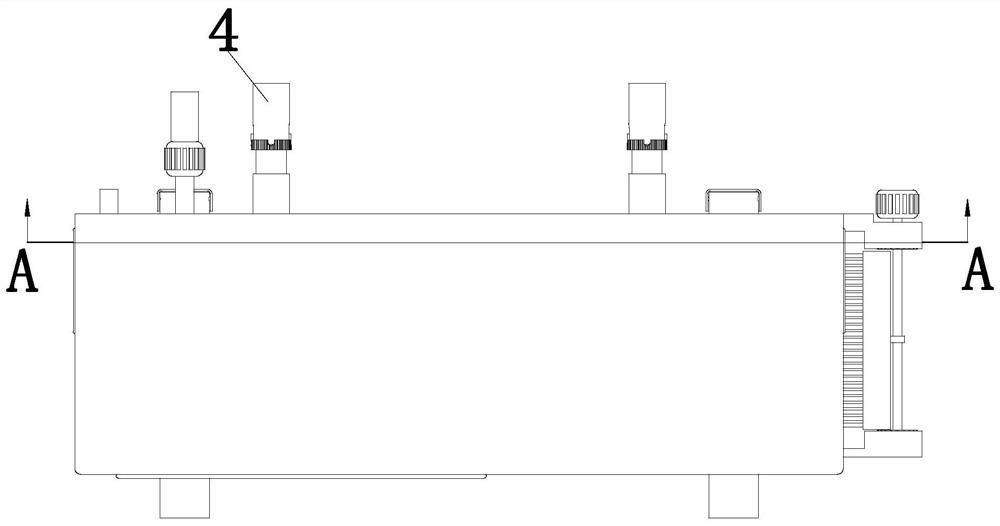

Electric spindle of numerical control machine tool

InactiveCN106513717AReduce mechanical temperatureReasonable structural designLarge fixed membersMaintainance and safety accessoriesNumerical controlMotor drive

The invention discloses an electric spindle of a numerical control machine tool. The electric spindle comprises a spindle shell (1), a spindle body (2), a spindle motor (3), a motor drive module (4) and a cooling device (5); the spindle body (2) is sleeved with the spindle shell (1), the spindle motor (3) is arranged in the spindle shell (1) and is matched with the spindle body (2), a power adapter (6) is arranged on the spindle shell (1) and is matched with the motor drive module (4), the power adapter (6) is electrically connected with the spindle motor (3), a cooling inlet (7) and a cooling outlet (8) are formed in the spindle shell (1), and the cooling device (5) is connected with the cooling inlet (7) and the cooling outlet (8) through a pipeline (9). The electric spindle has the beneficial effects of being reasonable in structural design and capable of saving energy consumption.

Owner:JIANGSU CHUANGWEI CNC CO LTD

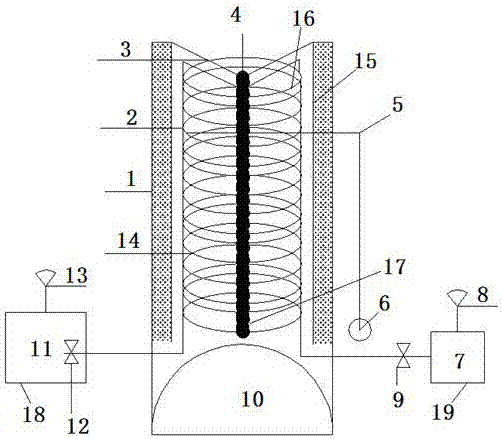

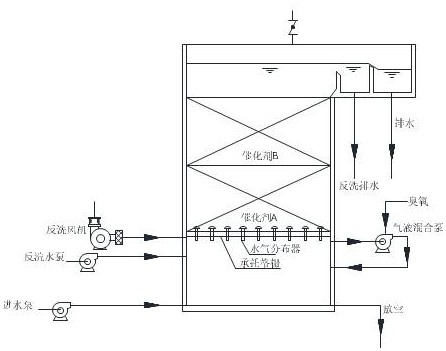

Catalytic ozonation reactor for sewage treatment

PendingCN113526649AThoroughly oxidizedReduce churnWater treatment compoundsSpecific water treatment objectivesPtru catalystCatalytic oxidation

The invention relates to a catalytic ozonation reactor for sewage treatment, and aims to solve the technical problem that an existing catalytic ozonation reactor is unreasonable in structural design, large in catalyst filling amount, complex in aeration and backwashing system, low in reaction depth, high in concentration of gas-phase residual ozone after reaction and the like. A catalyst supporting grid is designed to divide a reactor into a lower ozone direct oxidation zone and an upper ozone catalytic oxidation zone, and the catalytic oxidation zone is filled with a catalyst A and a catalyst B in sequence. The reactor not only utilizes ozone direct oxidation and free radical indirect oxidation processes, but also utilizes the characteristics of different catalysts to carry out ordered matching, so that the ozone utilization efficiency is improved, the heavy metal content in effluent is reduced, and meanwhile, ozone and sewage are fully mixed by using a gas-liquid mixing pump. According to the scheme, the efficiency problem of an existing ozone reactor is well solved, and the reactor is particularly suitable for advanced treatment of sewage.

Owner:大连一名环保科技有限公司

Metal plastic coated mixing valve body and manufacturing method thereof

InactiveCN102563164AGood anti-leakage performanceLow costMultiple way valvesValve housingsWork in processCompressive strength

The invention discloses a metal plastic coated mixing valve body and a manufacturing method thereof. An internal cavity made of stainless steel or copper is arranged inside the valve body and the surface of the valve body is coated with plastic so that the valve body looks the same in appearance with an ideal valve. The manufacturing method includes the steps of: (1) blanking and punching a stainless steel plate or a copper plate and molding a cavity of the mixing valve body through drawing process for standby use; (2) blanking a stainless steel pipe or a copper pipe and bending the pipe to form a water inlet and outlet pipeline for standby use; (3) taking the semi-finished products from step (2) and step (2), welding the two semi-finished products to form the internal cavity of the mixing valve body for standby use; (4) finally, putting the welded internal cavity obtained from step (3) in an injection mold for coating plastic. The mixing valve body can meet the desired requirements without polishing or electrofacing the surface. The mixing valve body and the manufacturing method have the beneficial effects that: the disadvantages of the prior art are solved; under the precondition that the mixing valve body has the same compression strength and service life with the prior art, the manufacturing method can greatly reduce the production cost, improves the production efficiency and is more environment-friendly.

Owner:叶建科

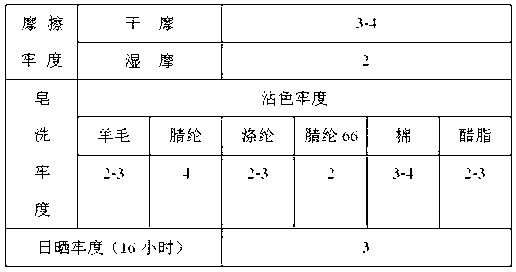

Cotton knitwear activated dye imitation old dyeing method

ActiveCN107034705AMeet the requirements of color and luster imitating the color and luster of old clothesMeet quality indicatorsHeating/cooling textile fabricsLiquid/gas/vapor removalAcetic acidSodium bicarbonate

The invention relates to a cotton knitwear activated dye imitation old dyeing method which is characterized by including steps: 1) pretreatment of a gray fabric; 2) removal of wool; 3) dyeing of activated dyes; 4) treatment by the aid of sodium bicarbonate; 5) water washing after comparison between a sample and a dyed fabric; 6) treatment by the aid of glacial acetic acid; 7) taking out of the dyed fabric from a cylinder and dewatering of the dyed fabric; 8) dying; 9) product sizing at the temperature of 130 DEG C. The method changes a present situation that a conventional activated dye cannot make imitation old color, wool on the fabric surfaces is removed after the gray fabric is pretreated, the activated dyes are treated by the aid of the sodium bicarbonate after dyeing and washing with a soap, so that activated colors are in weakly-alkaline solution, the colors change dark under influential effects of temperature and time, the dyed fabric is circularly dried in a loop drying machine, so that the dyed fabric can mutually rub, fabric surfaces have whiting fuzzy effects, and finished products are sized by adding steam in a dry manner, and cotton knitted gray fabrics have imitated old feel.

Owner:ZHEJIANG YINHE PRINTING & DYEING

Outdoor network security base station

InactiveCN109972664ASimple structureSimple and efficient operationArtificial islandsUnderwater structuresSeweragePotential energy

Owner:杭州谷典服饰有限公司

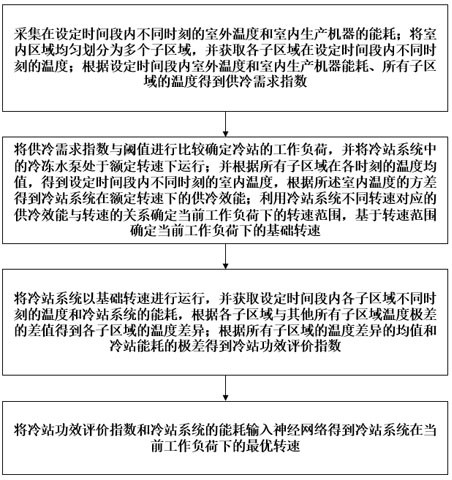

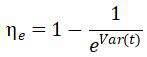

Method for optimizing operation of cold station system

ActiveCN114811857AIn line with the concept of energy saving and emission reductionMechanical apparatusThermodynamicsNerve network

The invention relates to the technical field of data processing, in particular to a cold station system operation optimization method, which comprises the following steps of: acquiring outdoor temperature and energy consumption of an indoor production machine; the indoor area is evenly divided into a plurality of sub-areas, and the temperature of each sub-area is obtained; obtaining a cold supply demand index according to the outdoor temperature, the indoor production machine energy consumption and the temperatures of all the sub-regions; calculating the cold supply efficiency of the cold station system; determining a rotating speed range under the current working load by utilizing the relationship between the cooling efficiency and the rotating speed, and determining a basic rotating speed based on the rotating speed range; the cold station system is operated at the basic rotating speed, and the temperature difference of all the sub-areas is calculated; obtaining a cold station efficacy evaluation index according to the mean value of the temperature differences of all the sub-regions; and inputting the cold station efficacy evaluation index into a neural network to obtain the optimal rotating speed of the cold station system. The cold station system can be prevented from working under high load all the time, and the concept of energy conservation and emission reduction is met under the condition that it is guaranteed that the indoor temperature is appropriate.

Owner:深圳市森辉智能自控技术有限公司

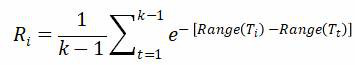

Waste flue gas waste heat cascade recovery hydropower generation system and working method

PendingCN109469521AImprove utilization efficiencyReduce pollutionWater/sewage treatmentSteam engine plantsCooling capacityTubing types

The invention discloses a waste flue gas waste heat cascade recovery hydropower generation system and a working method, and belongs to the field of energy and power. The waste flue gas waste heat cascade recovery hydropower generation system comprises an evaporator (6), a turbine (7), a motor (8), a condenser (9), a working medium pump (10), a brine pump (11), a humidification packed tower (12), astrong brine storage tank (13), a tube type heat exchanger (14), a draught fan (15), a fresh water storage tank (16), a cooler (17), a water pump (18), a three-way valve (19) and a fresh water storage tank (20). Through the waste flue gas waste heat cascade recovery hydropower generation system, cascade recovery of the waste heat of waste flue gas (1) is realized, refrigerants (2) circularly provide the heat for heating weak brine (3), and low-temperature air (4) provides the cooling capacity for cooling fresh water (5). The waste flue gas waste heat cascade recovery hydropower generation system is simple in structure, easy to operate and low in energy dissipation, achieves cascade recovery of the waste heat of the waste flue gas, improves energy utilization efficiency and realizes energyconservation and emission reduction.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

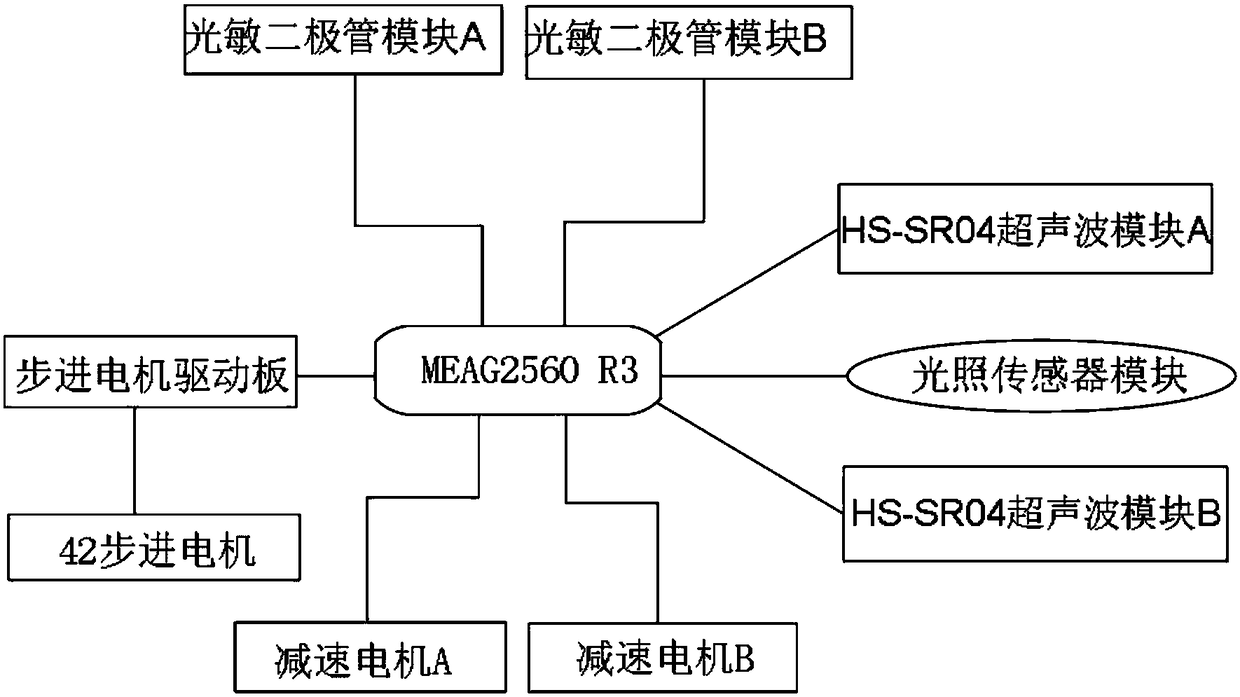

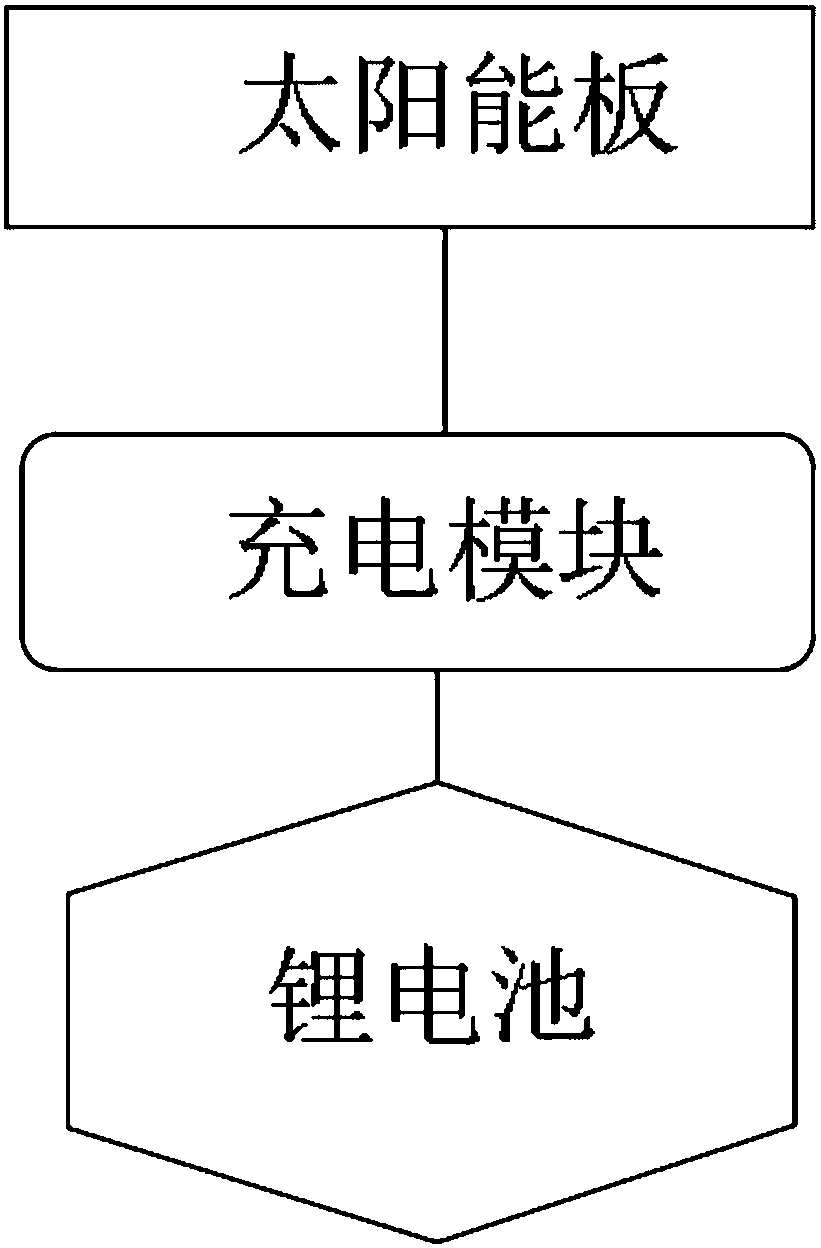

Sun-facing light-following solar energy shoe rack with drier

InactiveCN108078330ASimple structureEasy to operateWardrobesApparel holdersEngineeringEnergy conservation

The invention discloses a sun-facing light-following solar energy shoe rack with a drier. The shoe rack includes a solar panel and a second baffle; the outer surface of the bottom end of the solar panel is fixedly provided with a support frame, the outer surface of the bottom end of the support frame is fixedly provided with a stepping motor clamping groove, the outer surface of the bottom end ofthe stepping motor clamping groove is fixedly provided with a first baffle, the outer surface of the front end of the first baffle is fixedly provided with an ultrasonic module clamping groove, the portion, close to one side, of the upper surface of the first baffle is fixedly provided with a light following module clamping groove, and one side of the light following module clamping groove is provided with a shoe pad tray. The sun-facing light-following solar energy shoe rack with the drier is provided with a drier wind outlet, the light following module clamping groove, the solar panel and alight seeking module clamping groove, the shoe rack can conduct drying in a run of wet weather and the like, and solve the problem that shoes make feet feel ice-cold in winter, in addition, energy conservation and emission reduction can be conducted, and a better use prospect is brought.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

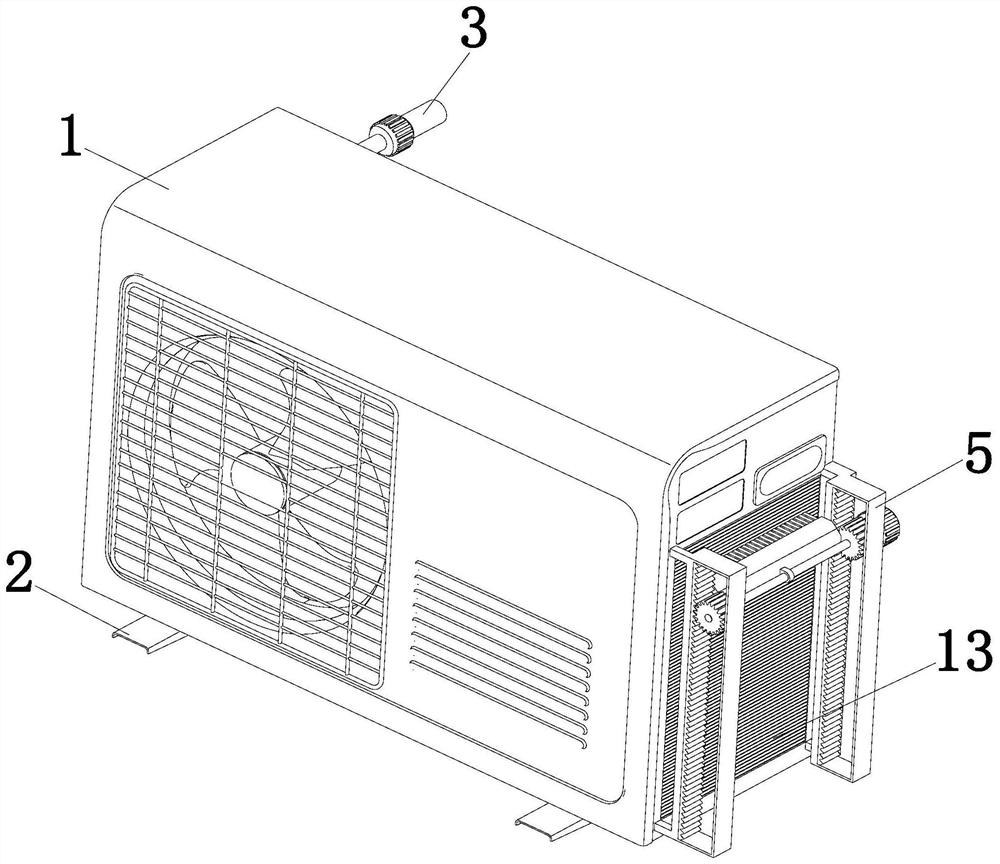

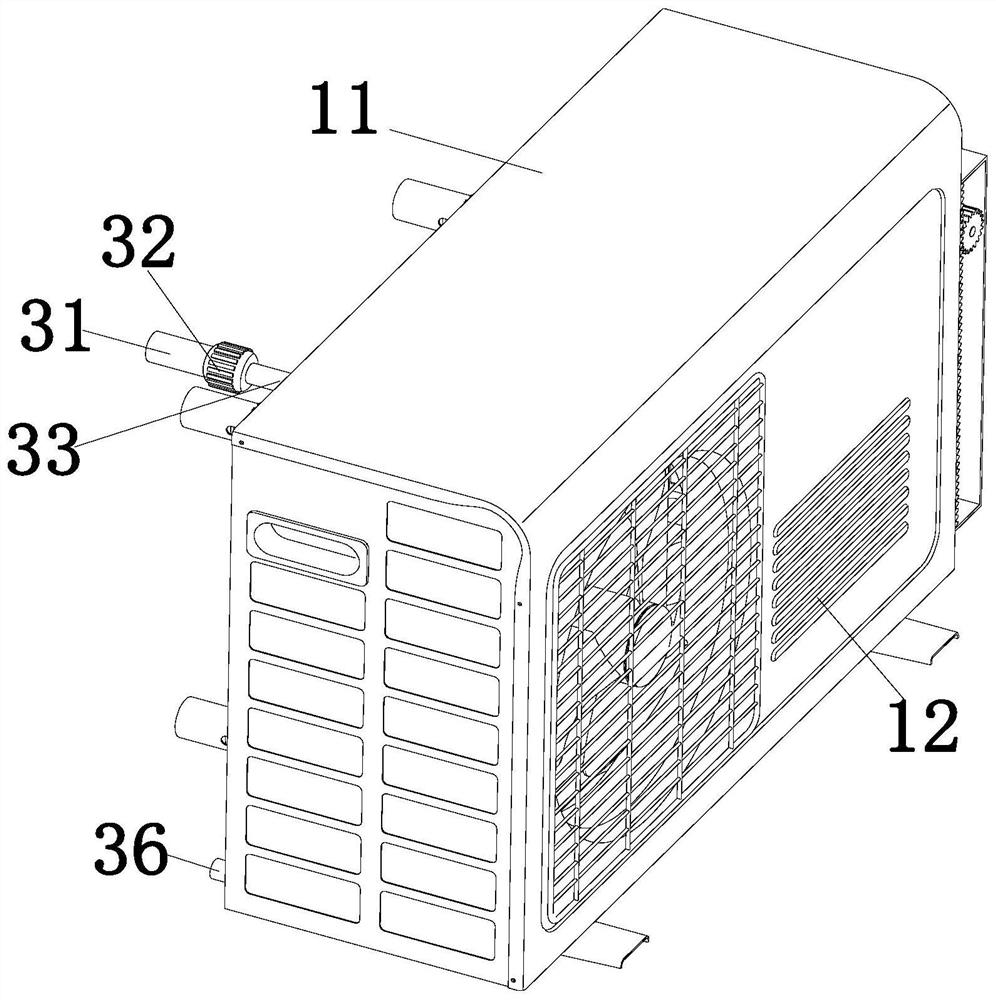

Air conditioner capable of facilitating water discharge and heat dissipation

InactiveCN112833477AEasy to disassembleEasy to installCondensate preventionLighting and heating apparatusThermodynamicsEngineering

The invention discloses an air conditioner capable of facilitating water discharge and heat dissipation, and relates to the technical field of heat dissipation of air conditioners. The air conditioner capable of facilitating water discharge and heat dissipation comprises an air conditioner external unit, supports, a water discharge mechanism, installation mechanisms and a sweeping mechanism, wherein the number of the supports is two, the two sets of supports are installed at the bottom end of the air conditioner external unit, the water discharge mechanism is fixedly arranged at the inner side of the air conditioner external unit, a plurality of the installation mechanisms are all fixedly arranged at one side of the air conditioner external unit, and the sweeping mechanism is fixedly arranged at one side of the air conditioner external unit. According to the air conditioner capable of facilitating water discharge and heat dissipation, by arranging the water discharge mechanism, through the water discharge mechanism, residual water in a condenser pipe is moved, thus water-cooling heat dissipation is conducted, by arranging the installation mechanisms, the air conditioner external unit can be conveniently detached and installed, thus water discharge operation can be conveniently conducted, by arranging the sweeping mechanism, exhaust meshes of a box are swept, and thus difficult heat dissipation is prevented, so that the purposes of heat dissipation and water discharge are achieved.

Owner:温州朗玛气动有限公司

Method for preventing color difference during short-liquor cotton knitwear-whitening heather grey immersion

ActiveCN107268303AAvoid chromatic aberrationPrevention of jumping light chromatic aberrationDyeing processAcetic acidColor changes

The invention relates to a cotton knitwear immersion method, and in particular to an operating method for preventing color difference during short-liquor cotton knitwear-whitening heather grey immersion. The method includes the following technical steps: (1) pre-inspection of greige cloth; (2) immersion; (3) glacial acetic acid treatment; (4) addition of softener; (5) slitting and drying; (6) final product shaping; (7) packaging. The invention changes the conventional operating technique of heather grey immersion, the pre-inspection of greige cloth is chosen to judge whether thee heather grey immersed greige cloth is whitened or not, moreover, the technical temperature of the whole production process is controlled, the step of neutralizing color difference by glacial acetic acid is added, the packaging method is then improved for substitution, and thereby the technical problem in the prior art that color difference and color change are often caused during heather grey immersion for whitening can be solved.

Owner:ZHEJIANG YINHE PRINTING & DYEING

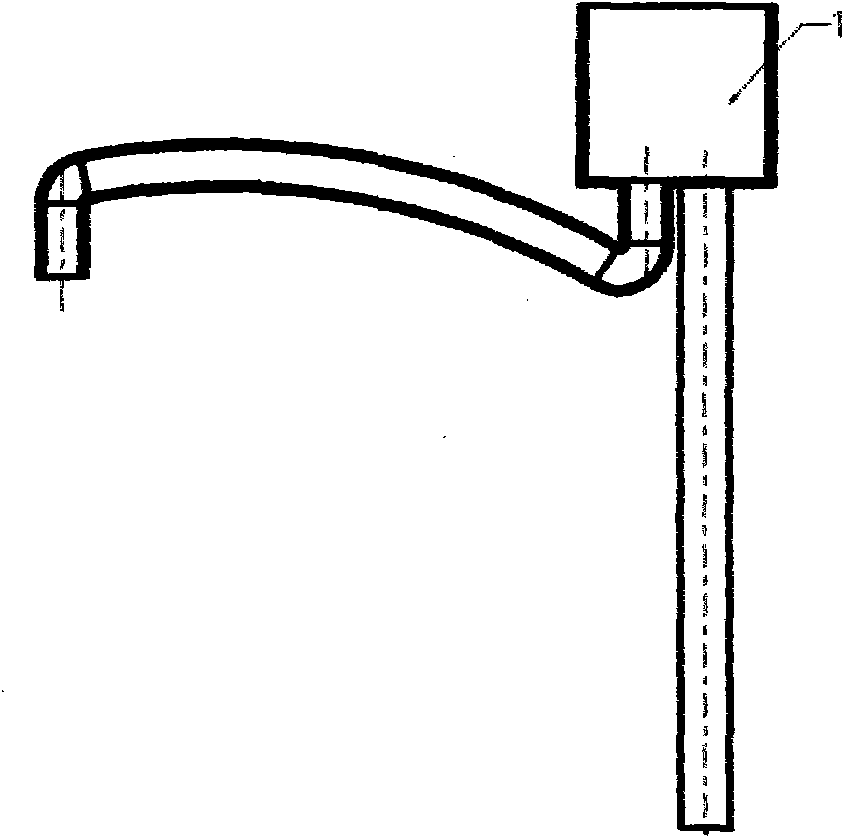

Transmission shaft body structure

InactiveCN107795672AReasonable structural designEasy to implementShaftsGear lubrication/coolingEnergy consumptionWater tanks

The invention discloses a transmission shaft body structure comprising a transmission housing (1) and a transmission shaft body (2) disposed in the transmission housing (1). A transmission shaft bodymotor (3) is arranged on one side of the transmission housing (1) and electrically connected with the transmission shaft body (2); one end of the transmission shaft body (2) is in a sleeved connectionwith a propelling shaft (6); a three-paw chuck (12) is movably arranged on the propelling shaft (6); a water inlet (7) and a water outlet (8) are arranged on the transmission housing (1); the water inlet (7) and the water outlet (8) are connected with a circulating condensate water tank (5) via pipeline bodies (9); and a circulating water pump (4) is disposed in the circulating condensate water tank (5). The transmission shaft body structure is advantaged by rational structure and energy consumption reduction.

Owner:高荣江

Multi-functional secondhand book self-service transaction machine employing transfer-type IC (Integrated Circuit) card

InactiveCN102881077BRealize the buying and selling linkUnique functionCoded identity card or credit card actuationDisplay deviceCard reader

The invention relates to a multi-functional secondhand book self-service transaction machine employing a transfer-type IC (Integrated Circuit) card. The multi-functional secondhand book self-service transaction machine comprises a cabinet body, a display, a keyboard, a card reader, a switch power supply and a host computer, wherein the display, the keyboard, the card reader, the switch power supply and the host computer are arranged inside the cabinet body; the display, the keyboard and the card reader are respectively connected with the host computer; the host computer is connected with the switch power supply; the cabinet body comprises a frame; two split doors are arranged at the back side of the frame; a plurality of spacers with electronic lock doors are arranged inside the frame; and each electronic lock door comprises a door body and an electronic lock, and the electronic lock is connected with the host computer. Compared with the prior art, the multi-functional secondhand book self-service transaction machine has the advantages of unique function, good environment benefit and wide application range.

Owner:TONGJI UNIV

Recovery technology of methylamino avermectin benzoate amination solvent

The invention relates to a recovery technology of methylamino avermectin benzoate amination solvent. Sodium carbonate aqueous solution is utilized to separate dichloromethane and methanol in the amination solvent, and contents of water and methanol in separated and purified dichloromethane solvent accord with requirements of methylamino avermectin benzoate amination workshop section on amination solvent quality; and separated dichloromethane solvent can be used indiscriminately in the methylamino avermectin benzoate amination workshop section, and the methanol solution can be used indiscriminately in methylamino avermectin benzoate amination workshop section. The invention not only solves a treatment problem of the amination solvent but also reuses resource, so as to satisfy national energy saving, emission reduction and environmental protection idea.

Owner:HUNAN GOFAR FINE CHEM IND TECH CO LDT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com