Method for optimizing operation of cold station system

A technology for operation optimization and cooling stations, applied in the field of data processing, can solve the problems of energy waste and the lack of energy-saving optimization methods for the energy efficiency model of cold stations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] The specific scene targeted by the present invention is: taking a large comprehensive workshop as an example, the cooling energy efficiency of the cooling station system is analyzed, and the reference and guidance for the energy saving optimization of the cooling station system of other workshops are provided.

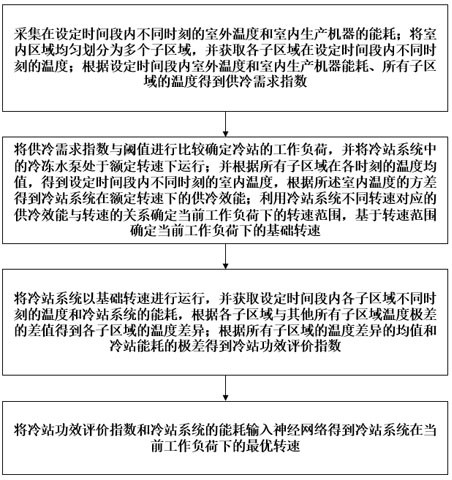

[0027] see figure 1 , which shows a flow chart of the steps of a method for optimizing the operation of a cooling station system provided by an embodiment of the present invention, and the method includes the following steps:

[0028] Step 1: Collect the outdoor temperature and the energy consumption of indoor production machines at different times within the set time period; divide the indoor area evenly into multiple sub-areas, and obtain the temperature of each sub-area at different times within the set time period; The cooling demand index is obtained by calculating the average outdoor temperature and the average energy consumption of indoor production machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com