Recovery technology of methylamino avermectin benzoate amination solvent

A technology of emamectin and ammonium benzoate, which is applied in the new process field of solvent recovery for emamectin benzoate amination, can solve the problem of high cost, difficult separation of azeotropes, High energy consumption and other issues, to achieve the effect of low cost, less equipment investment, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

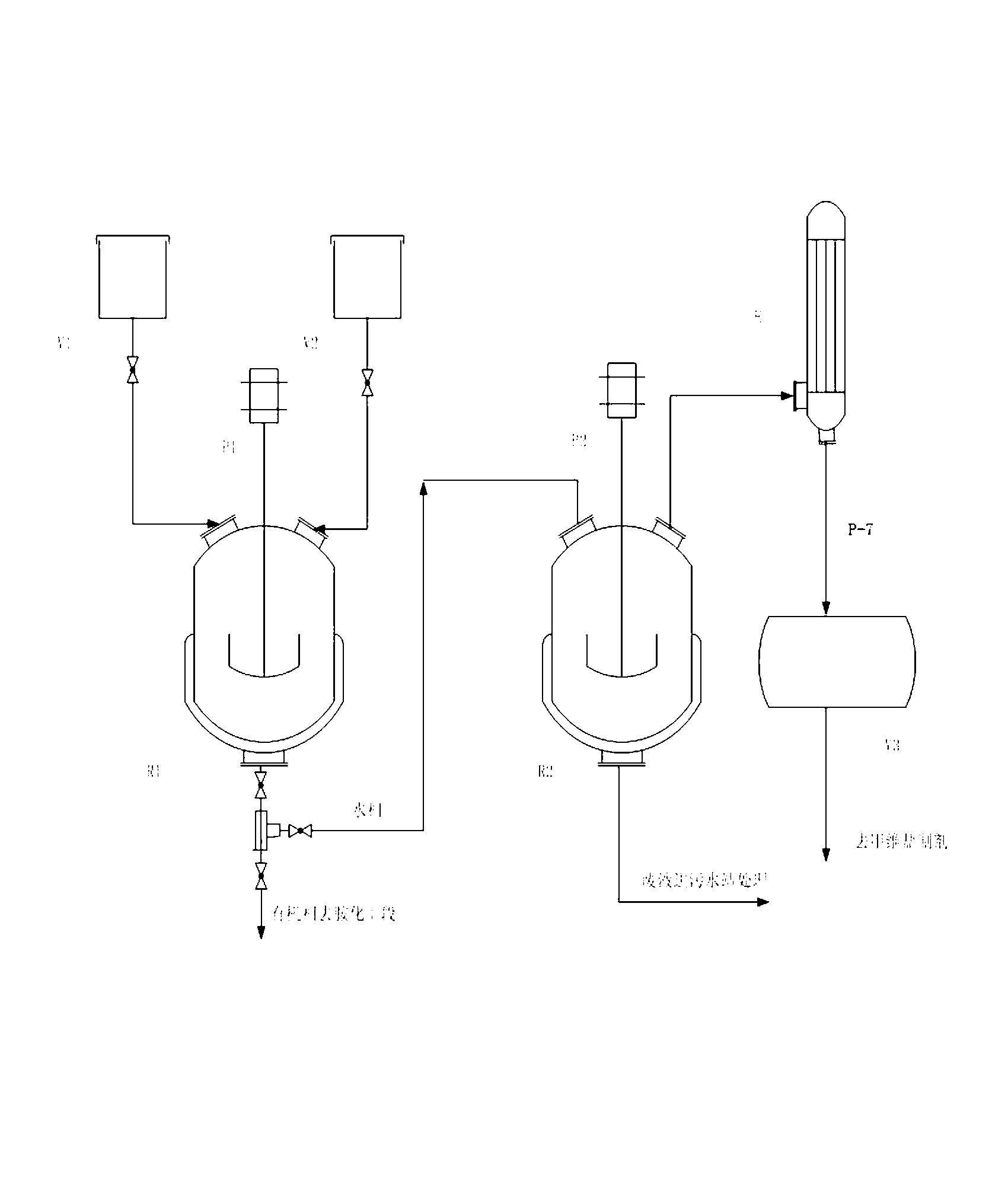

Method used

Image

Examples

Embodiment 1

[0019] Add 500mL of amination solvent into the water washing kettle (the content of methylene chloride is 89.8%, and the content of methanol is 10.2%), start stirring, and add 250mL of sodium carbonate washing solution with a mass content of 3%. After stirring for 20 minutes, the layers were separated for 2 hours. The lower organic phase was collected and weighed 449g. The content of dichloromethane in the organic phase detected by gas chromatography was 99.44%, the moisture content was 0.09%, and the methanol content was 0.04%; the upper inorganic aqueous phase was distilled at 85°C for 2 hours to obtain 52.2g condensate, the methanol content in the condensate was detected to be 88%, and the moisture content was 12%. According to the synthesis process of the amination section of emamectin benzoate, the ammonium compound synthesized by reclaiming dichloromethane and industrial grade dichloromethane as an amination solvent is compared, and the aminated compound synthesized by r...

Embodiment 2

[0021] Add 500mL of amination solvent into the water washing kettle (the content of methylene chloride is 89.1%, and the content of methanol is 10.9%), start stirring, and then add 500mL of sodium carbonate washing solution with a mass content of 3%. After stirring for 30 minutes, the layers were separated for 2 hours. The lower organic phase was collected and weighed 446g. The content of dichloromethane in the organic phase was detected by the gas phase as 99.47%, the water content was 0.1%, and the methanol content was 0.02%; the upper inorganic aqueous phase was distilled at 85°C for 3 hours to obtain 54.5 g condensate, after testing, the methanol content in the condensate is 90%, and the moisture content is 10%. According to the synthesis process of the amination section of emamectin benzoate, the ammonium compound synthesized by reclaiming dichloromethane and industrial grade dichloromethane as an amination solvent is compared, and the aminated compound synthesized by rec...

Embodiment 3

[0023] Add 500mL of amination solvent into the washing kettle (with a methylene chloride content of 89.5% and a methanol content of 10.5%), start stirring, and then add 1000mL of sodium carbonate washing solution with a mass content of 3%. After stirring for 30 minutes, the layers were statically separated for 4 hours. The lower organic phase was collected and weighed 447g. The content of dichloromethane in the organic phase was detected by gas phase as 99.44%, the moisture content was 0.07%, and the methanol content was 0.09%; the upper inorganic aqueous phase was distilled at 85°C for 5 hours to obtain 52.5 g condensate, the methanol content in the condensate was detected to be 88.3%, and the moisture content was 11.7%. According to the synthesis process of the amination section of emamectin benzoate, the ammonium compound synthesized by reclaiming dichloromethane and industrial grade dichloromethane as an amination solvent is compared, and the aminated compound synthesized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com