Waste flue gas waste heat cascade recovery hydropower generation system and working method

A technology for cascade recovery and waste flue gas, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of thermal economy being limited by scale, consuming high-grade electric energy, and increasing production costs and other problems, to achieve the effect of compact structure, simple structure and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

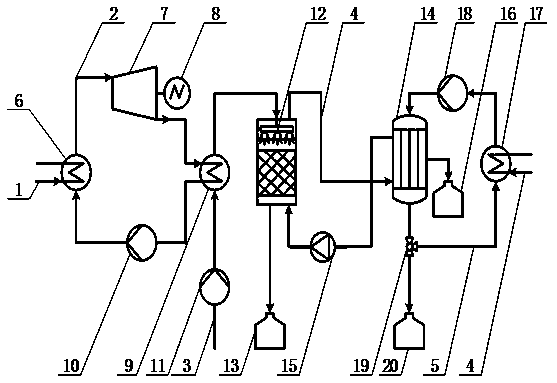

[0030] Refer to the attached figure 1 Describe the working process of the cascade recovery waste flue gas cogeneration system.

[0031] First, start the turbine 7, the working fluid pump 10, the brine pump 11, the fresh water pump 18, and the fan 15 in sequence;

[0032] The high-temperature exhaust gas 1 enters the inlet of the hot side of the evaporator 6, heats the refrigerant 2 that enters the cold side of the evaporator 6 through the working medium pump 10, and is vaporized into superheated steam;

[0033] The superheated steam of the refrigerant 2 enters the turbine 7 and expands to do work, and outputs high-grade electric energy through the motor 8. The exhausted steam of the refrigerant 2 after the expansion works enters the hot side of the condenser 9, is condensed by the low-temperature dilute brine 3 on the cold side, and passes through The working medium pump 10 enters the cold side of the evaporator 6 to start the next cycle.

[0034] The low-temperature dilute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com