Thermostatic container utilizing phase-change material to perform automatic temperature regulation and control

A technology of phase change materials and composite phase change materials, which is applied in the field of constant temperature containers that use phase change materials to automatically control the temperature, and can solve problems such as poor heat preservation effect, inability to be effectively recycled, and inability to store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

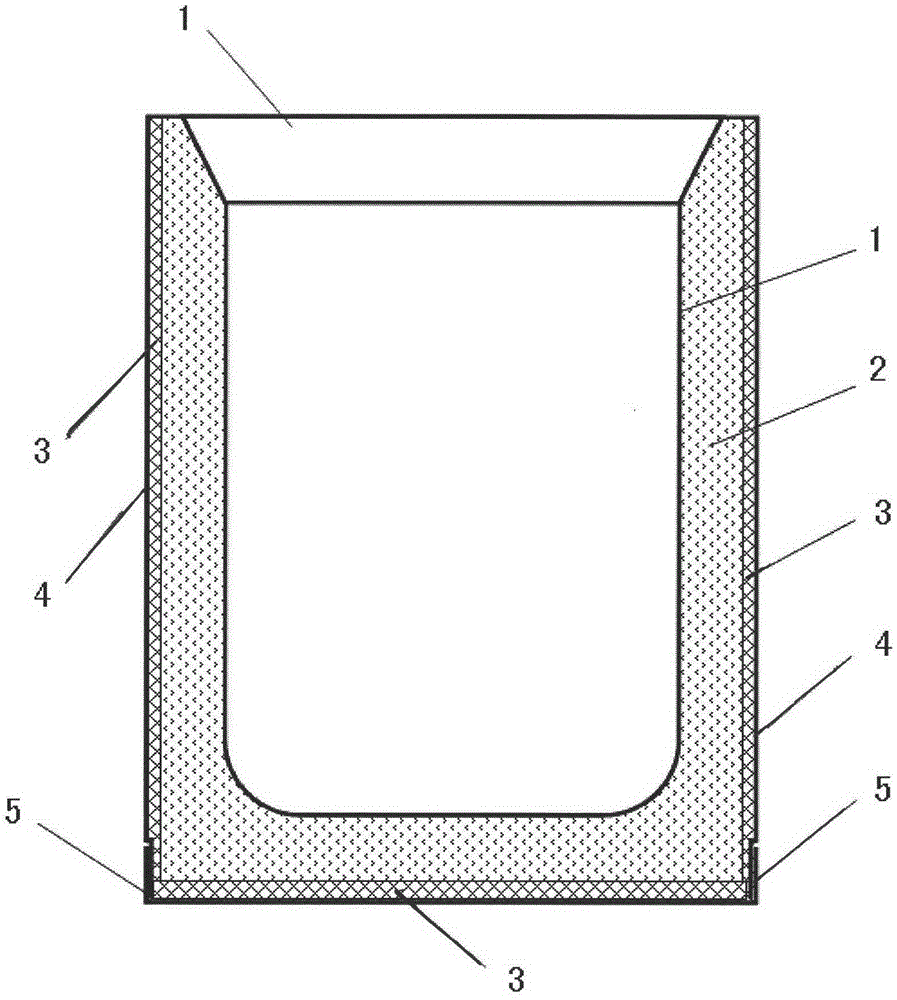

[0021] Specific embodiment one: please refer to figure 1 , a constant temperature container that uses phase change materials to automatically regulate the temperature, characterized in that: the constant temperature container is composed of an inner tank 1, a heat storage layer 2, a heat insulation layer 3, an outer shell 4 and a bottom cover 5, and the storage The heat layer 2 is close to the outer wall of the inner tank 1, and the inner tank 1 and the outer shell 4 are fixedly connected together at the mouth of the container. The inner tank 1 and the outer shell 4 are made of stainless steel, and the outer shell 4 and the bottom cover 5 A heat insulating layer 3 is provided between the heat storage layer 2, and the inner wall surface of the inner tank 1 is coated with a food-grade protective coating, and the inner wall of the inner tank 1 can be processed into a wave shape, and the heat storage layer 2. Composed of a composite phase change material with high phase change ent...

specific Embodiment 2

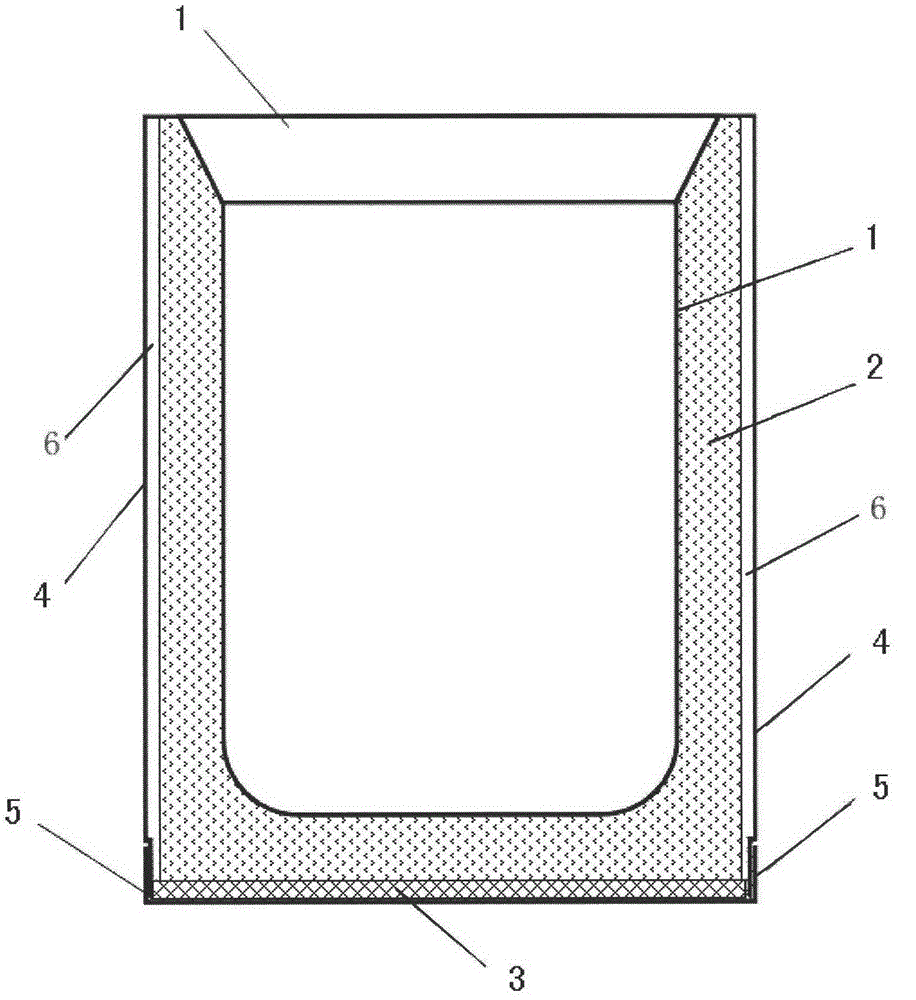

[0024] Specific embodiment two: please refer to image 3 , a constant temperature container that uses a phase change material to automatically regulate the temperature, the constant temperature container is composed of an inner tank 1, a heat storage layer 2, a heat insulation layer 3, an outer shell 4 and a bottom cover 5, and the heat storage layer 2 is tight Paste the outer wall of the liner 1, the liner 1 and the shell 4 are fixedly connected at the mouth of the container, the liner 1 and the shell 4 are made of stainless steel, the shell is a double-layer structure, and the inside of the shell forms a vacuum Insulation cavity 6, the outer shell 4 is close to the heat storage layer 2, a heat insulation layer 3 is provided between the bottom cover 5 and the heat storage layer 2, and the inner wall surface of the inner tank 1 is not coated with food-grade protective coating Layer, the inner tank 1 wall can be processed to be connected with heat exchange fins, the heat storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com