Finishing method for improving shrinkage rate of napped lints of cotton knitted goods and quality of plush

A knitwear and shrinkage technology, which is applied in the processing of textile materials, elongation of fabrics, textiles and papermaking, etc., can solve the problems of high shrinkage of finished products and low quality of plush, and achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A finishing method for improving the shrinkage rate and plush quality of cotton knitwear brushed fleece, comprising the following steps:

[0034] (1) gray cloth dyeing, dehydration, and cloth arrangement; the gray cloth is 340 grams of 80 / 20 cotton-polyester brushed flannelette.

[0035] (2) Stylized drying by needle drawing: the temperature is 135°C, the overfeed is 35%, the air volume is 1500r / min, the speed is 21m / min, the expanded width is the same as that of the finished product, and the moisture content of the gray cloth after drying is 5-6%.

[0036] (3) Napping and napping: Enter according to the cloth head of the napping loop, the cloth speed is 10 m / min, the gear for adjusting the speed of the napping roller is 63 teeth, the angle of the elastic frame for controlling the tension is 90 degrees, and pull three times continuously.

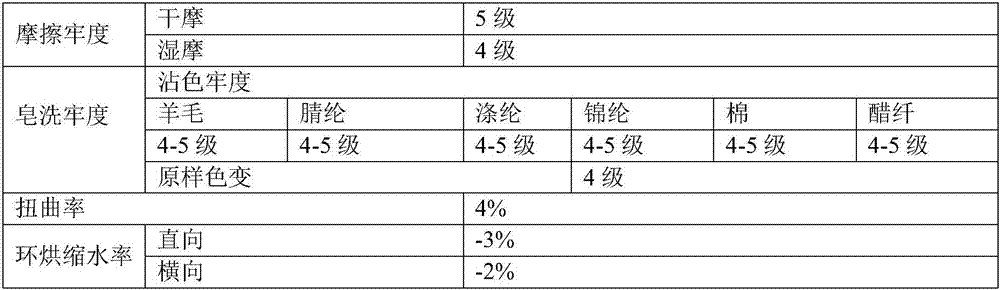

[0037] (4) Stenter setting: the temperature is 160°C, the speed is 19 m / min, the overfeed is 50%, the air volume is 1500r / min, and t...

Embodiment 2

[0045] A finishing method for improving the shrinkage rate and plush quality of cotton knitwear brushed fleece, comprising the following steps:

[0046] (1) gray cloth dyeing, dehydration, and cloth arrangement; the gray cloth is 340 grams of 80 / 20 cotton-polyester brushed flannelette.

[0047] (2) Stylized drying by needle drawing: the temperature is 130°C, the overfeed is 35%, the air volume is 1500r / min, the speed is 19m / min, the expanded width is the same as that of the finished product, and the moisture content of the gray cloth after drying is 5-6%.

[0048] (3) Napping and napping: Enter according to the cloth head of the napping loop first, the cloth speed is 10 m / min, the gear for adjusting the speed of the napping roller is 67 teeth, the angle of the elastic frame for controlling the tension is 90 degrees, and pull three times continuously.

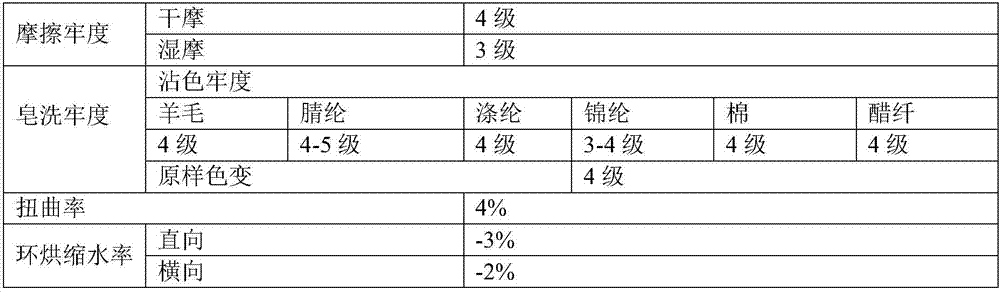

[0049] (4) Stenter setting: the temperature is 150°C, the speed is 17 m / min, the overfeed is 50%, the air volume is 1500r / min,...

Embodiment 3

[0057] A finishing method for improving the shrinkage rate and plush quality of cotton knitwear brushed fleece, comprising the following steps:

[0058] (1) gray cloth dyeing, dehydration, and cloth arrangement; the gray cloth is 340 grams of 80 / 20 cotton-polyester brushed flannelette.

[0059] (2) Styling and drying by needle drawing: the temperature is 132°C, the overfeed is 35%, the air volume is 1500r / min, the speed is 20m / min, the expanded width is the same as that of the finished product, and the moisture content of the gray fabric after drying is 5-6%.

[0060] (3) Napping and napping: Enter according to the cloth head of the napping loop first, the cloth speed is 10 m / min, the gear for adjusting the speed of the napping roller is 65 teeth, the angle of the elastic frame for controlling the tension is 90 degrees, and pull three times continuously.

[0061] (4) Stenter setting: the temperature is 155°C, the speed is 18 m / min, the overfeed is 50%, the air volume is 1500r / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com