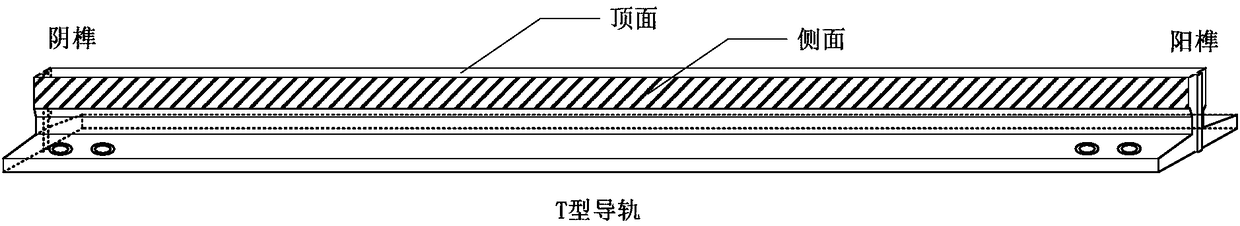

An automatic straightening method for elevator guide rails based on expert database technology

A technology of elevator guide rails and expert databases, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of no standard for manual straightening, impossibility of more accurate straightening, and no standardization of manual straightening. Achieve the effects of improving safety and comfort, meeting quality indicators, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

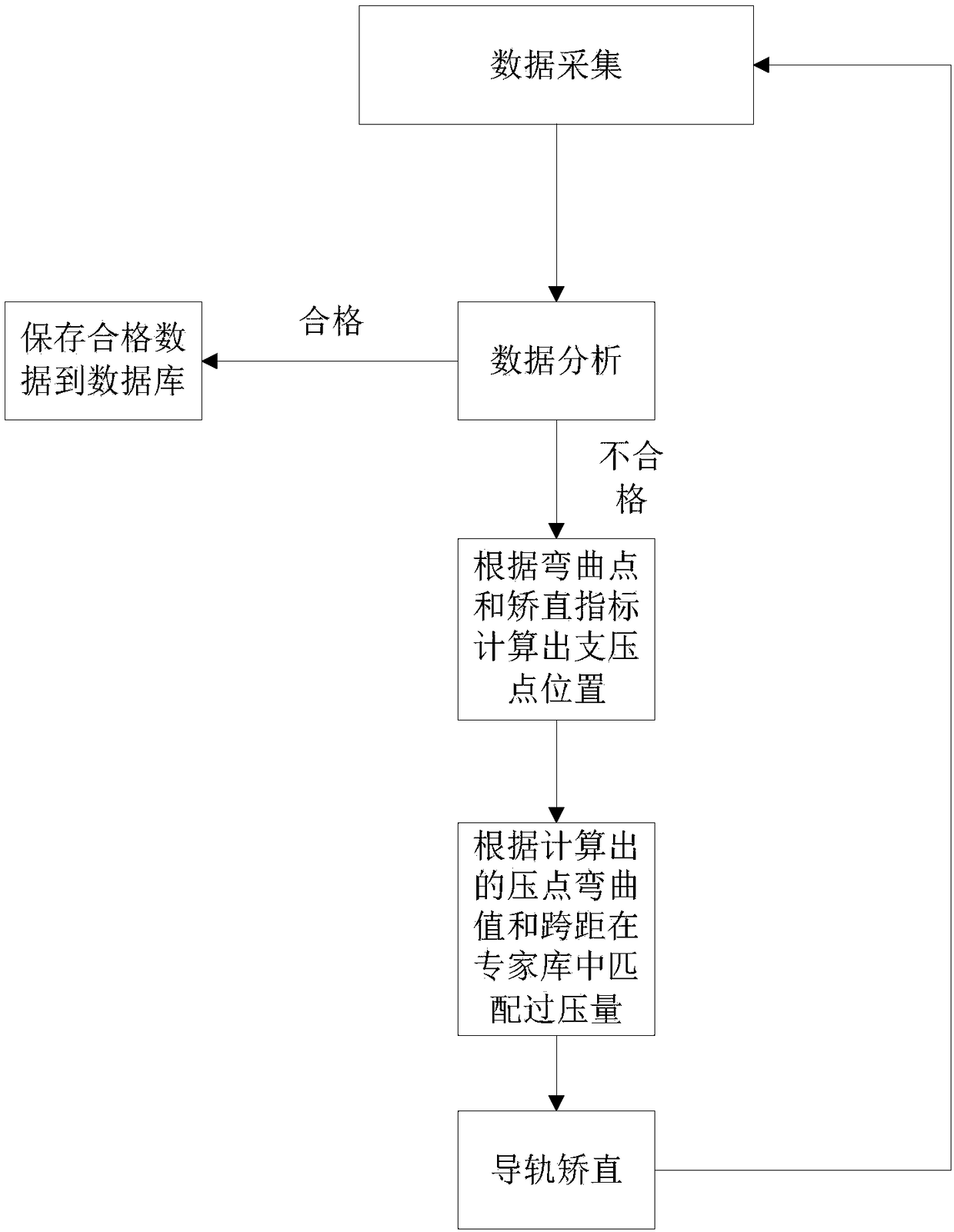

[0021] A method for automatic straightening of elevator guide rails based on expert library technology, comprising the steps of:

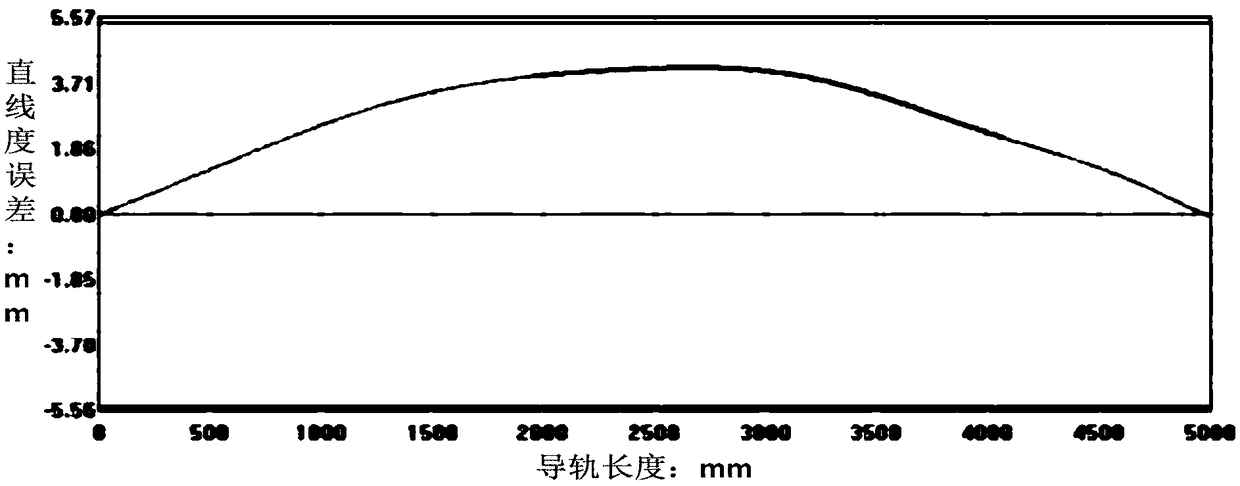

[0022] Step 1: Use the empirical data of successful manual straightening in the early stage to normalize the span and the bending value of the pressure point, determine the span, the bending value of the pressure point and the corresponding downward pressure, and form an expert database; The specific method of normalization processing is as follows: the unified span of the span greater than 1000mm is set to 1000mm, the span between 800mm and 1000mm is normalized to 800mm, and the span between 600mm and 800mm is normalized to 600mm, the span between 0mm and 600mm is normalized to 400mm. The specific method of normalizing the bending value of the pressure point is: in the case of 1000mm span and 800mm span, the bending value greater than or equal to 2mm is uniformly normalized to 2mm, and the bending value greater than or equal to 1.5mm is less than ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com