Static sensitization device and its cutting body

A technology of static sensitization device and cutting edge body, which is applied to explosives processing equipment, offensive equipment, explosives, etc., can solve the problems of low production efficiency, explosion, and the agitator cannot work continuously, and achieve the effect of avoiding explosion accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

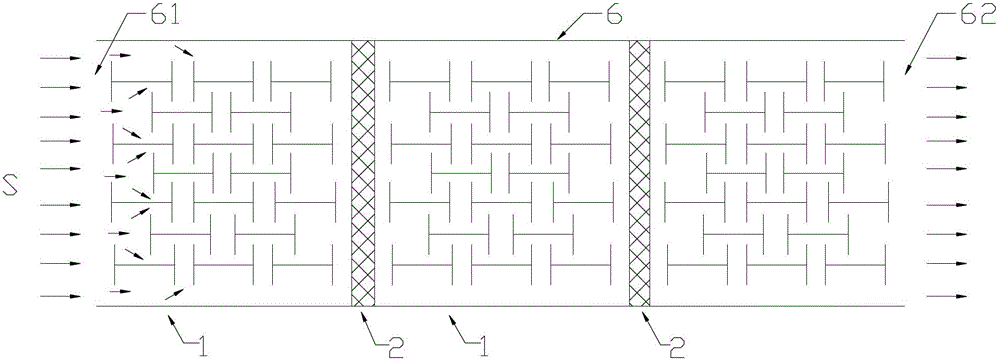

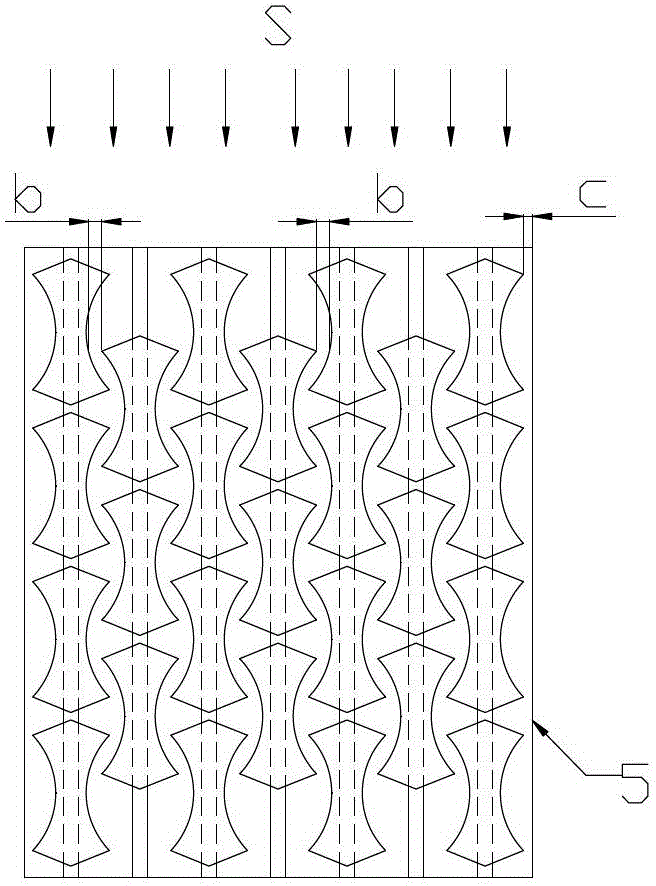

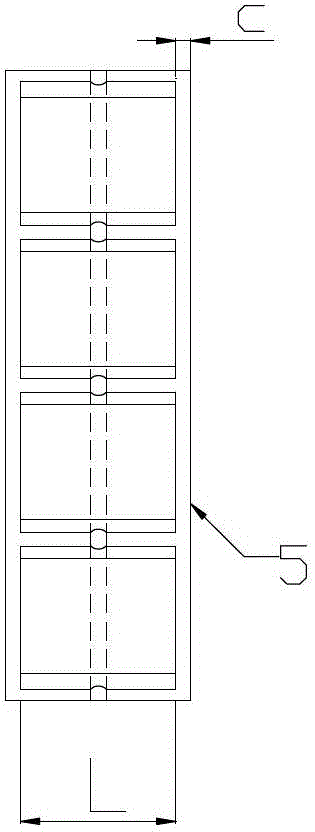

[0038] The static sensitization device adopts an "I"-shaped cutting edge body, and the cutting edge body string 8 in the first unit 1 has only one row.

[0039] In Examples 1 to 12 listed in Table 1 below, the number of cutting blade bodies, the number of cutting blade body strings, the size of cutting blade bodies and the relevant gaps in the static sensitization device are different, that is, the arrangement of cutting blades The cloth density is different, and the inlet pressure and the mesh body used are also different, and the following test results are obtained. The results show that the application of the invention can meet the emulsification requirement, and can produce the emulsified explosive meeting the requirement.

[0040] Explanation: In the column of the series number of cutting blade bodies in Table 1, "2; 1" indicates that in a row of cutting blade body strings, two I-shaped cutting blade bodies are connected in series on the odd-numbered cutting blade body st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com