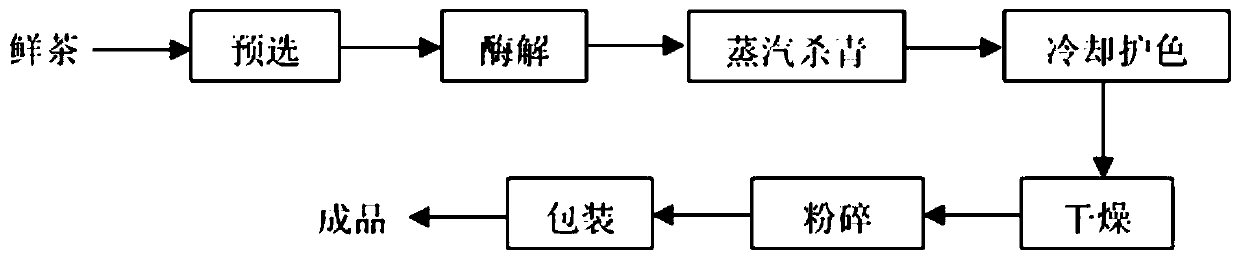

Ultrafinely pulverized green tea powder preparation method

A technology of ultrafine pulverization and green tea powder, which is applied in tea treatment before extraction, etc., which can solve the problems of loss of tea nutrients and improvement of bitterness of tea powder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] (1) Pre-selection: remove the impurities in the fresh leaves, old leaves and yellow leaves, wash and drain, and spread to dry until the fresh leaves are squeezed by hand until there is no moisture on the surface, and crush the fresh leaves to large particles for use;

[0122] (2) Enzymolysis: Take 100kg of large-grained tea and spread it out, spray the liquid according to the ratio of 10:1 between the tea leaves and the enzymatic solution, turn the tea leaves and spray the enzymatic solution evenly on the surface of the tea leaves, and the enzymatic hydrolysis time is 1.5 hours. Turn the tea leaves 6 times during the process, and the enzymolysis solution is made by mixing 95kg of water, 0.8kg of tannase, 0.2kg of lipase, and 0.5kg of cellulase;

[0123] (3) Steam greening: use a steam greening machine for greening, put the enzymatically hydrolyzed large-grain tea into the steam greening machine, steam temperature 110°C, steam greening time 150s, steam the fresh leaves ev...

Embodiment 2

[0129] (1) Pre-selection: remove the impurities in the fresh leaves, old leaves and yellow leaves, wash and drain, and spread to dry until the fresh leaves are squeezed by hand until there is no moisture on the surface, and crush the fresh leaves to large particles for use;

[0130] (2) Enzymolysis: Take 100kg of large-grain tea and spread it out, spray the liquid according to the ratio of 10:1 between the tea leaves and the enzymatic solution, turn the tea leaves and spray the enzymatic solution evenly on the surface of the tea leaves, and the enzymatic hydrolysis time is 1 hour. Turn the tea leaves 5 times in the middle, and the enzymolysis solution is made by mixing 90kg of water, 0.5kg of tannase, 0.1kg of lipase, and 0.4kg of cellulase;

[0131] (3) Steam fixation: use a steam fixer for fixation, put the enzymatically hydrolyzed large-grained tea into the steam fixer, steam temperature 105°C, steaming time 120s. Steam the fresh leaves evenly and thoroughly to ensure that ...

Embodiment 3

[0137] (1) Pre-selection: remove the impurities in the fresh leaves, old leaves and yellow leaves, wash and drain, and spread to dry until the fresh leaves are squeezed by hand until there is no moisture on the surface, and crush the fresh leaves to large particles for use;

[0138] (2) Enzymolysis: Take 100kg of large-grained tea and spread it out, spray the liquid according to the ratio of 10:1 between the tea leaves and the enzymatic solution, turn the tea leaves and spray the enzymatic solution evenly on the surface of the tea leaves, and the enzymatic hydrolysis time is 2 hours. Turn the tea leaves 8 times in the middle, and the enzymolysis solution is made by mixing 100kg of water, 1kg of tannase, 0.3kg of lipase, and 0.6kg of cellulase;

[0139] (3) Steam fixation: use a steam fixer for fixation, put the enzymatically hydrolyzed large-grained tea into the steam fixer, steam temperature 115°C, steaming time 180s. Steam the fresh leaves evenly and thoroughly to ensure tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com