Patents

Literature

37results about How to "Close in color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

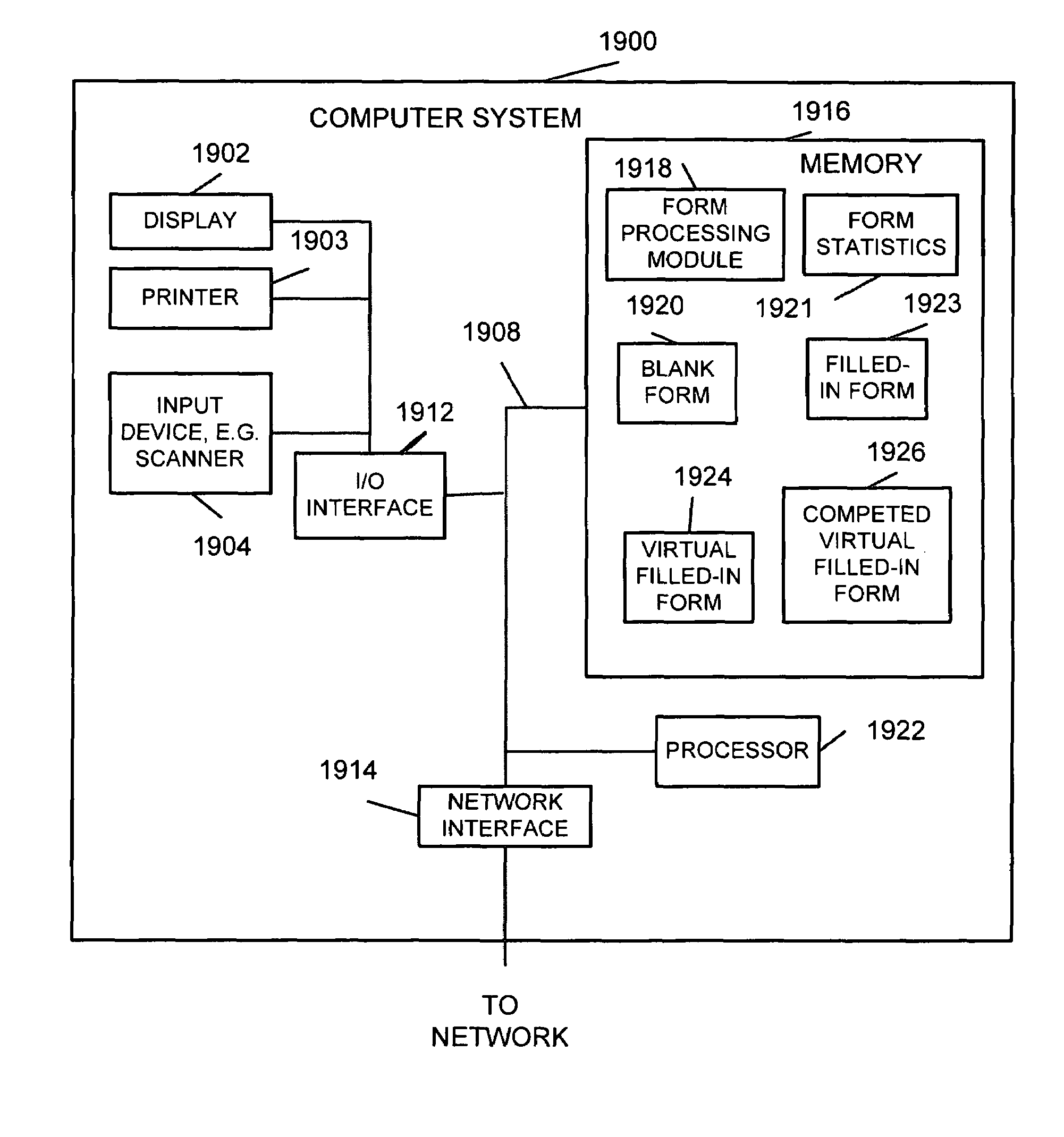

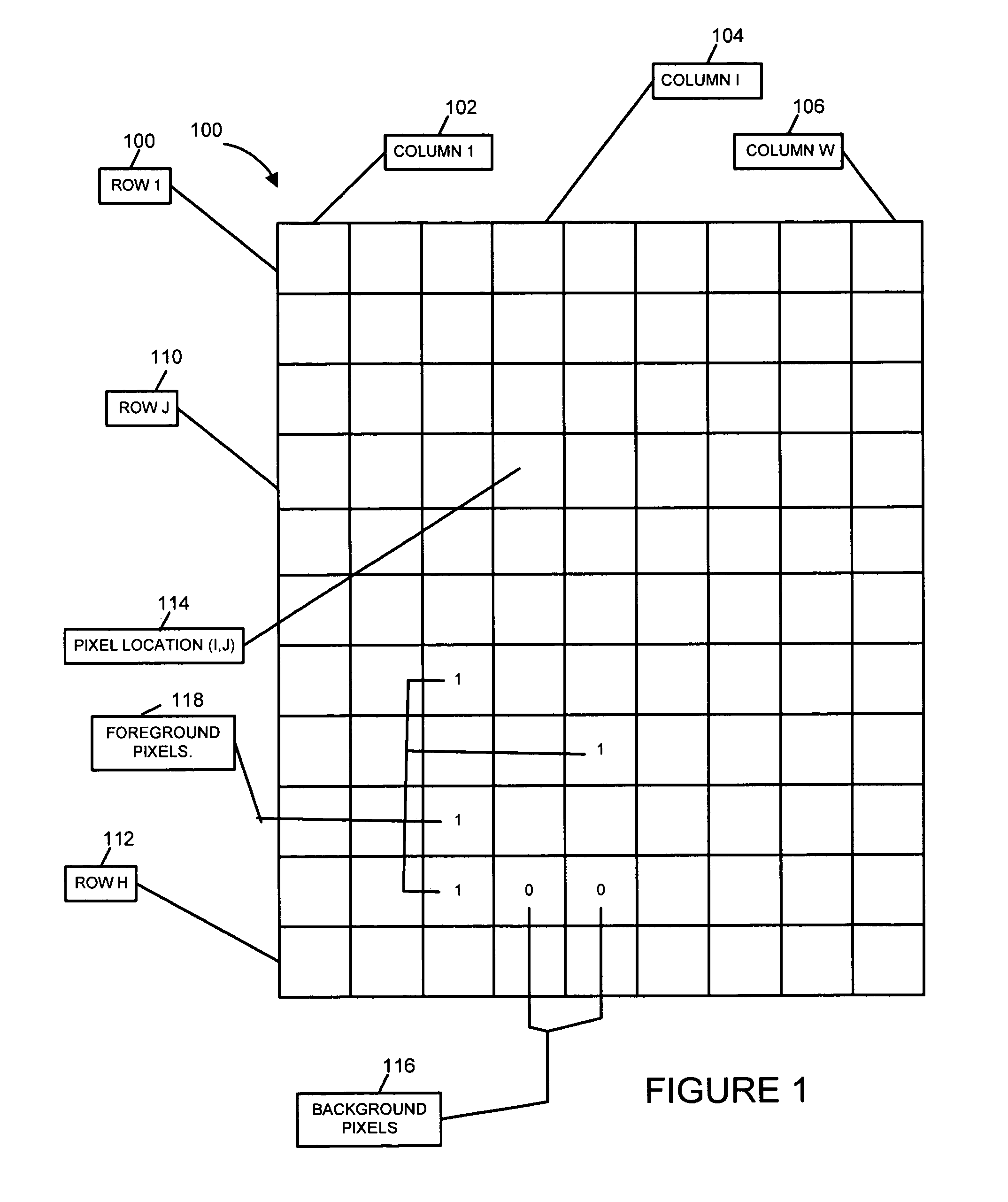

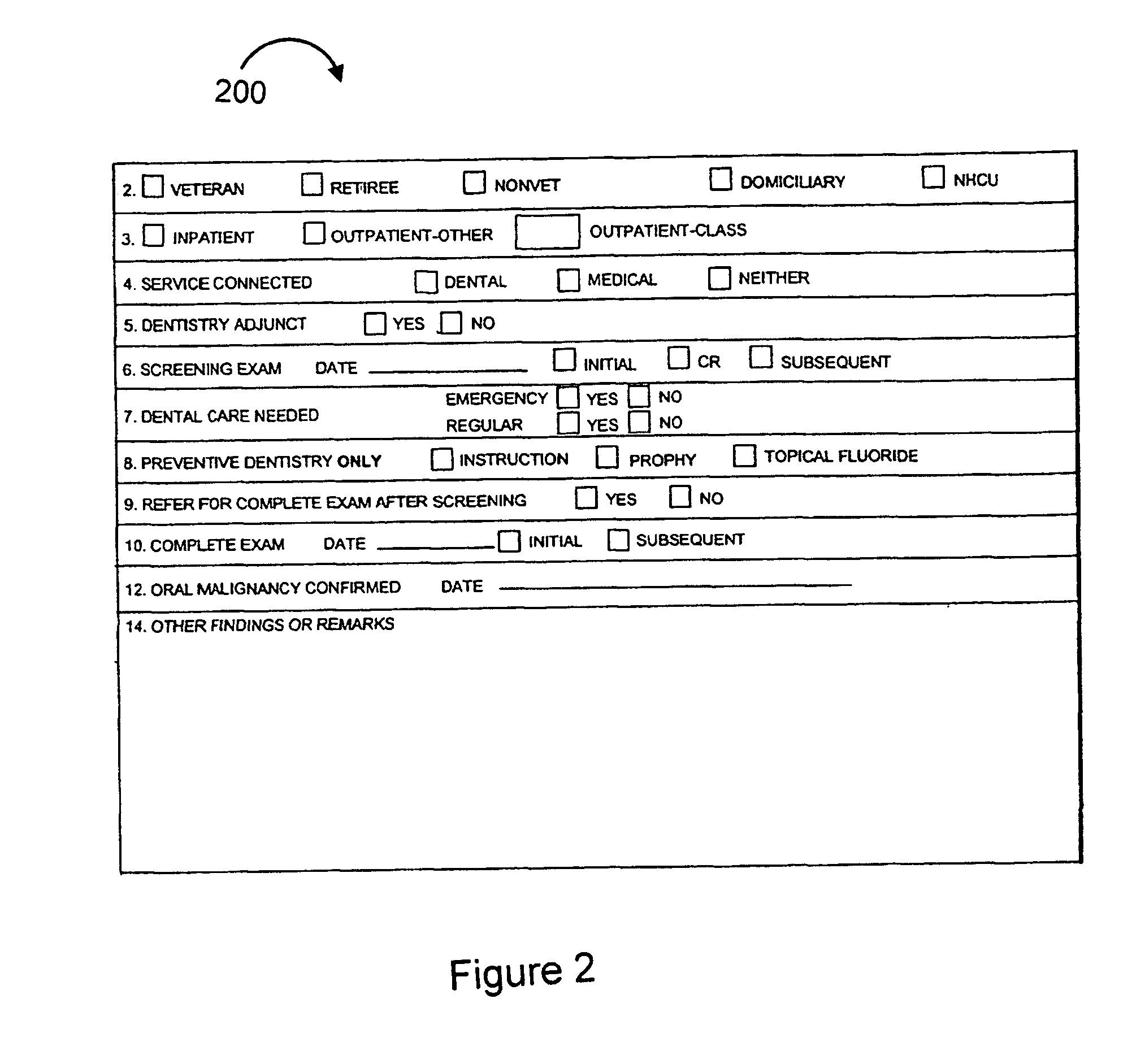

Method and apparatus for recognizing a digitized form, extracting information from a filled-in form, and generating a corrected filled-in form

ActiveUS7487438B1Close in colorCharacter and pattern recognitionSpecial data processing applicationsPattern recognitionComputer graphics (images)

Methods and apparatus for comparing blank forms represented in a digital format to digitized filled-in forms are described. Different errors are attributed different weights when attempting to correlate regions of blank and filled-in forms. Foreground pixels in the blank form which are not found in a corresponding portion of a filled-in form are attributed greater error significance than foreground pixels, e.g., pixels which may correspond to added text, found in the filled-in form which correspond to a background pixel value in the blank form. A virtual filled-in form including content, e.g., pixel values, from the filled-in form is generated from the content of the filled-in form and pixel value location mapping information determined from comparing the blank and filled-in forms. Various analysis is performed on a block basis, but in some embodiments the final pixel mapping to the virtual form is performed on a pixel by pixel rather than a block basis.

Owner:ACCUSOFT CORP

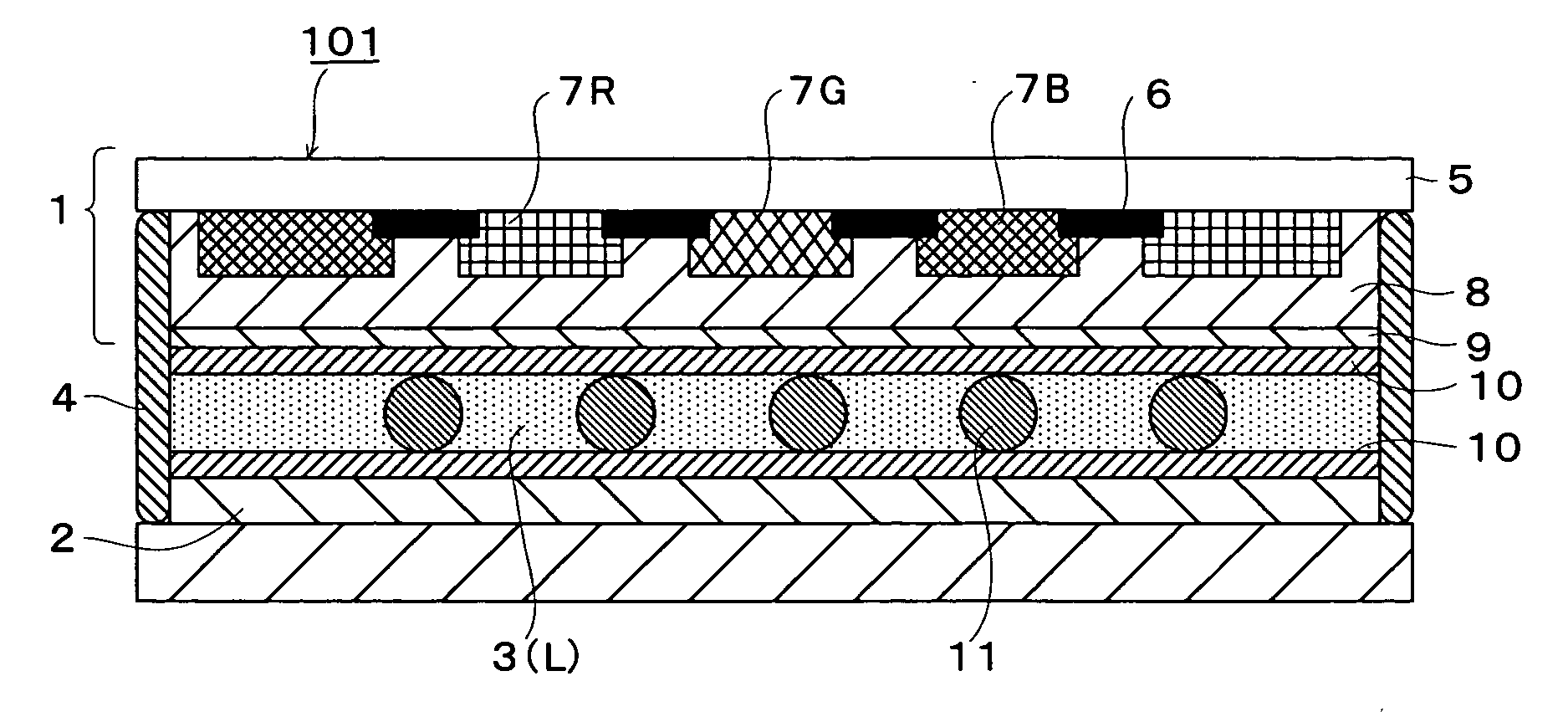

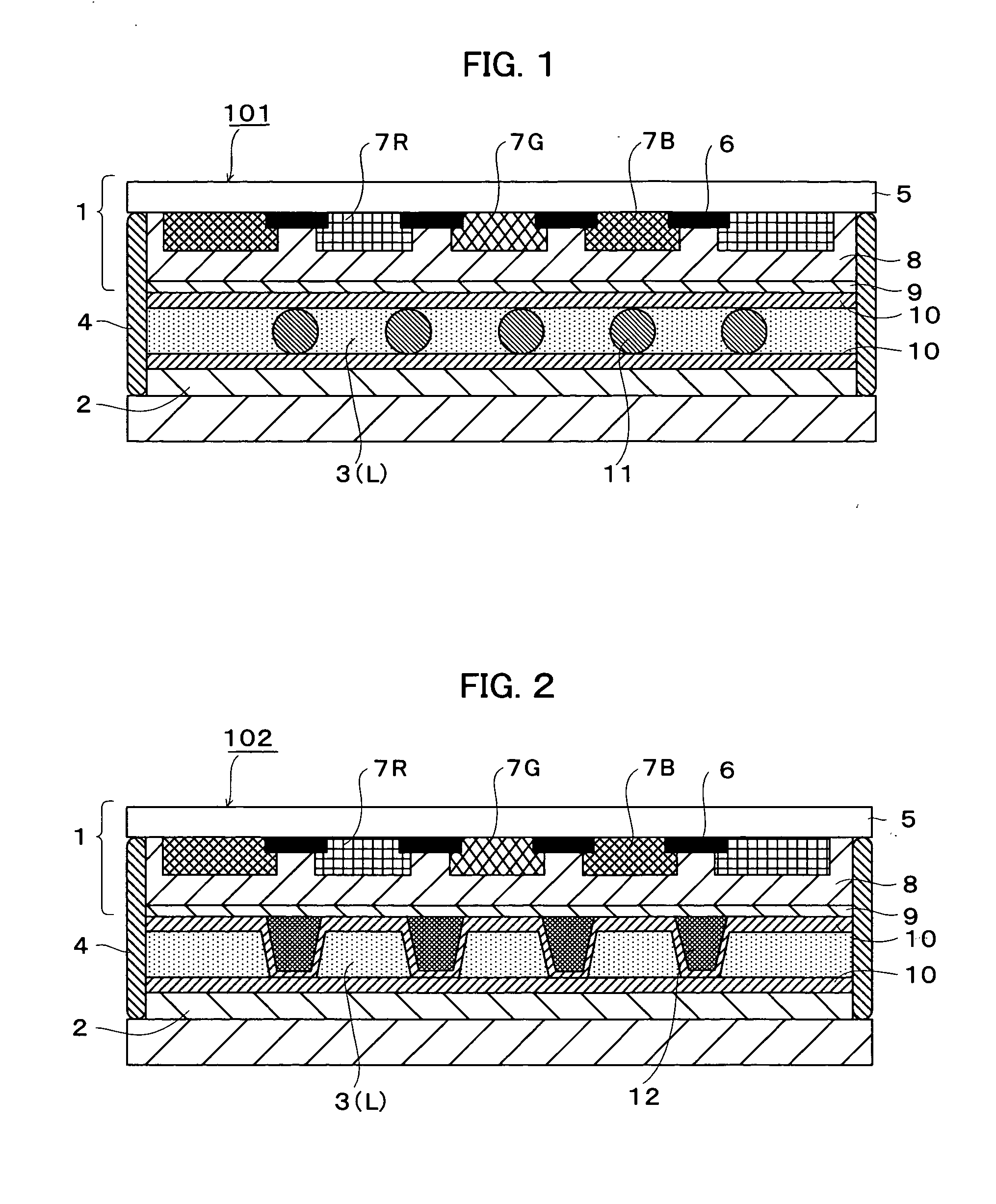

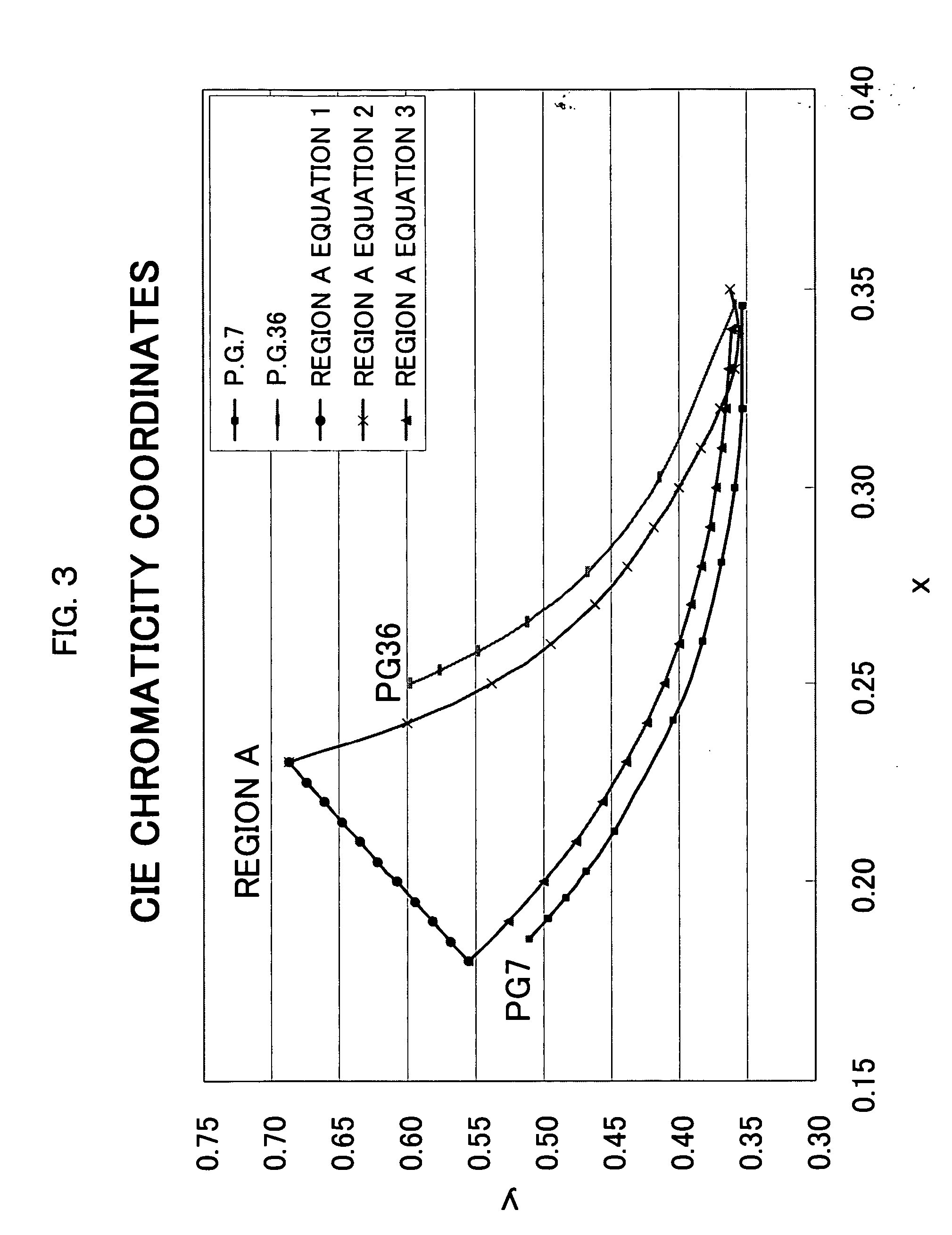

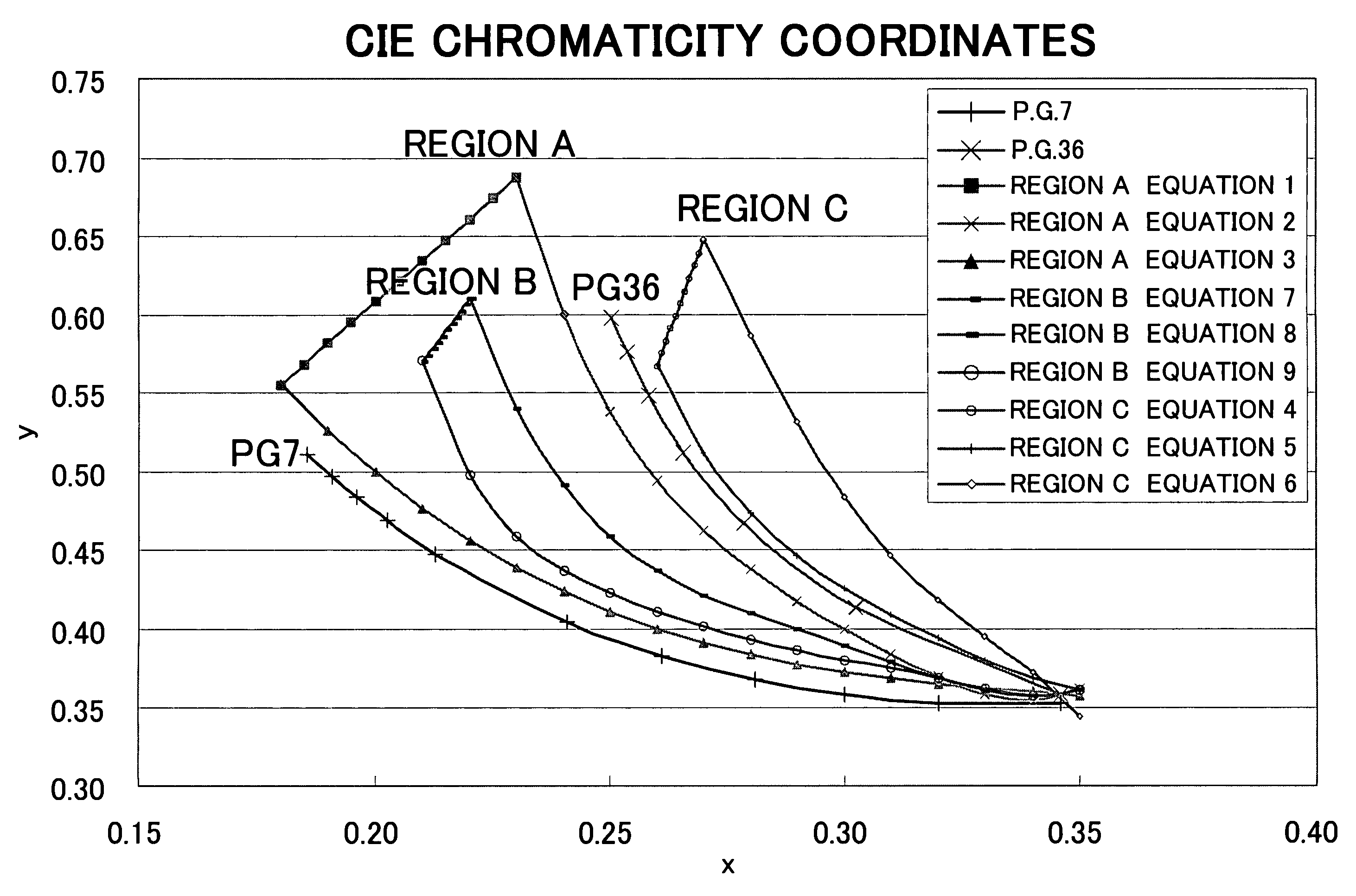

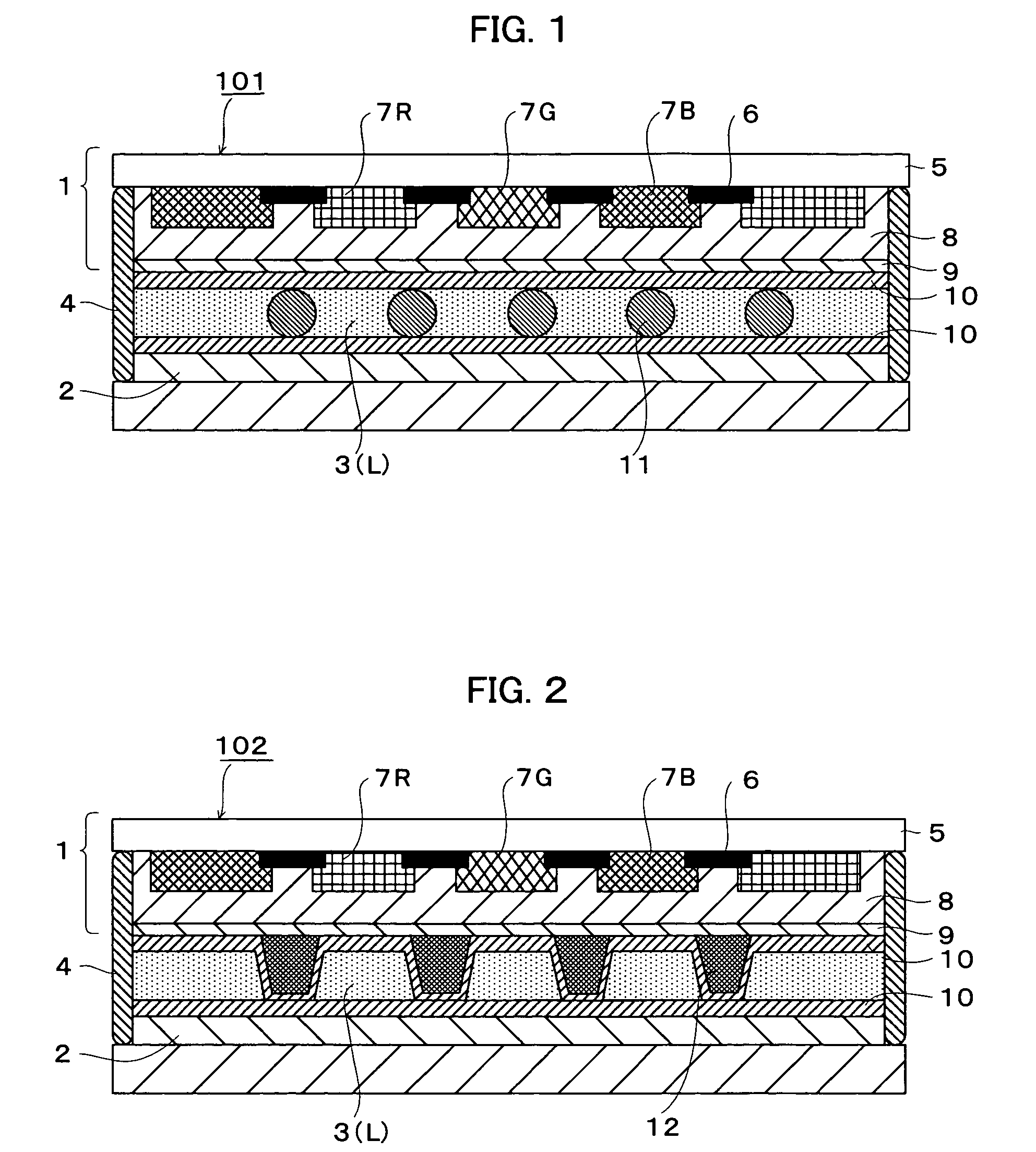

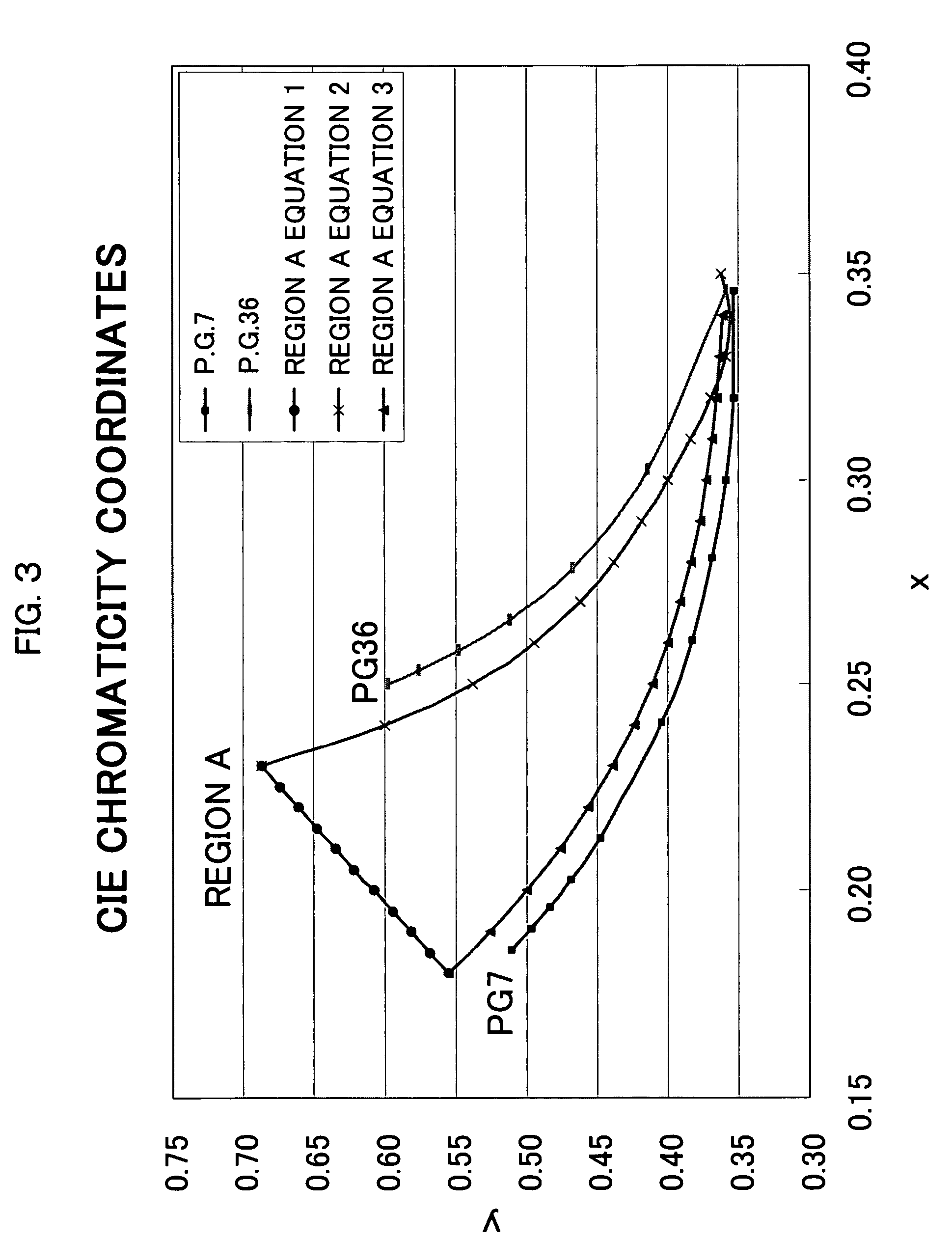

Green pigment for color filter, green pigment dispersion, photosensitive color composition, color filter, and liquid crystal panel

ActiveUS20060098316A1High strengthPromote formationPhotosensitive materialsPhotomechanical apparatusPhotopigmentPigment dispersion

An object of the present invention is to provide a green pigment for a color filter, capable of displaying the chromaticity coordinates not to be displayed by the conventional green pigments, having the excellent color strength as a green color which is not excessively strong in a blue tinge, and a high transmittance, and moreover, to provide a photosensitive color composition, a pigment dispersion, a color filter and a liquid crystal panel, using the above-mentioned green pigment. In order to achieve the above-mentioned object, the present invention provides a green pigment for a color filter comprised of a phthalocyanine green pigment and capable of expressing a region of xy-chromaticity coordinate enclosed by predetermined equations 1, 2 and 3 defined by the XYZ color system of the CIE when the green pigment is solely subjected to colorimetry. Moreover, using the above-mentioned green pigment, it provides a photosensitive color composition capable of forming a color filter having a wide color reproduction range and a high transmittance. Furthermore, it provides a color filter having a wide color reproduction range and a high transmittance with a green pixel formed using the above-mentioned photosensitive color composition, and a liquid crystal panel using the color filter.

Owner:DAI NIPPON PRINTING CO LTD +1

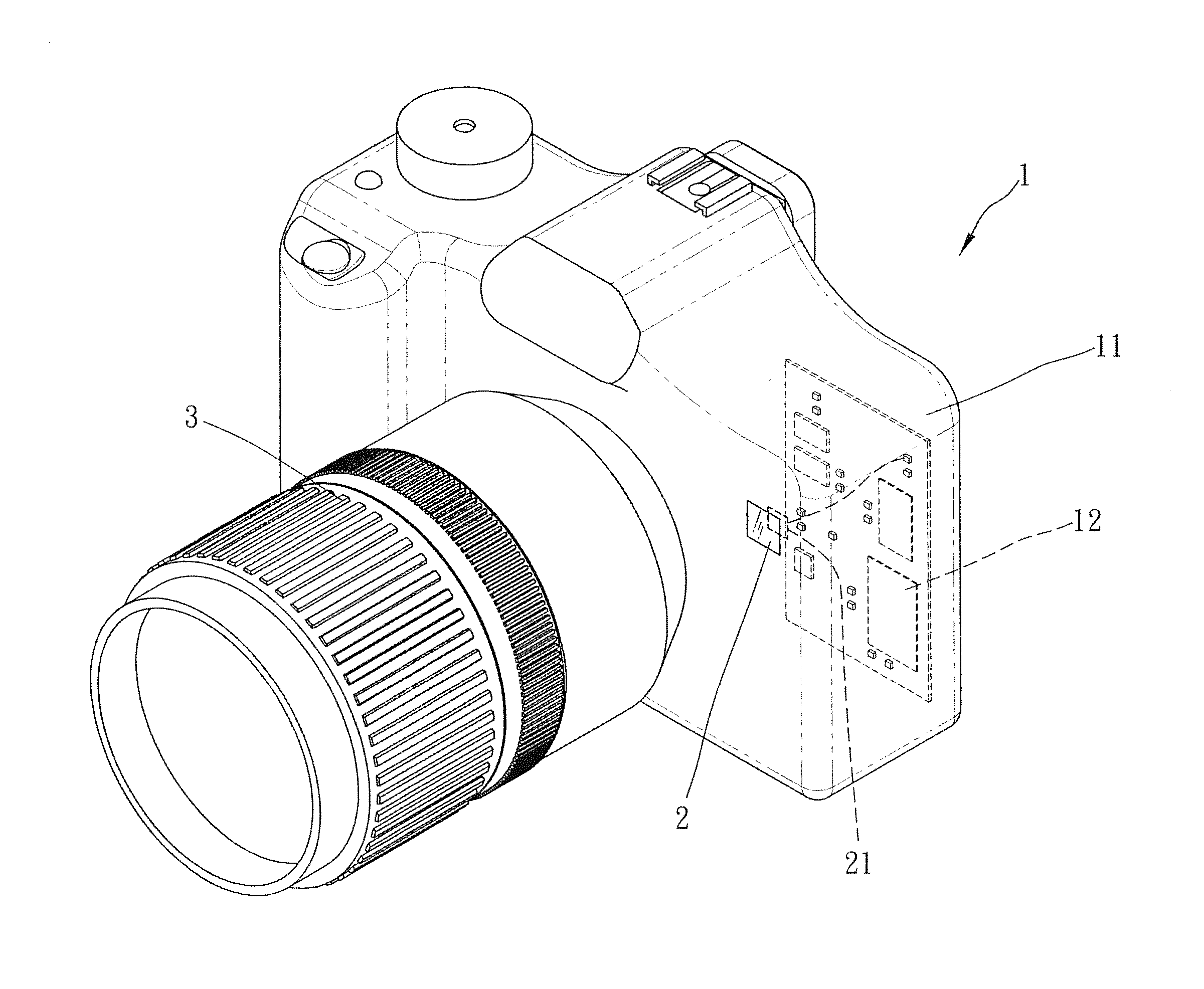

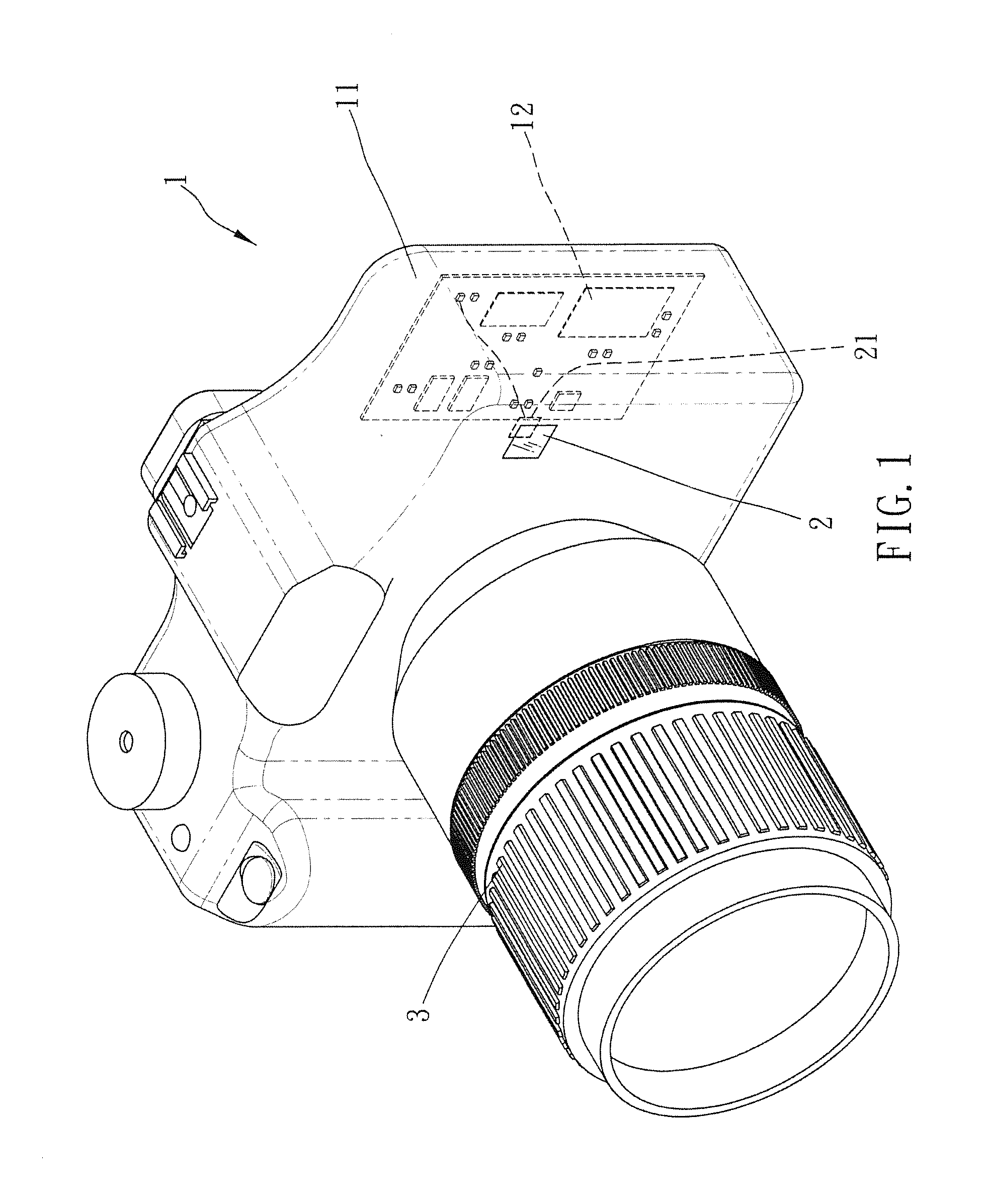

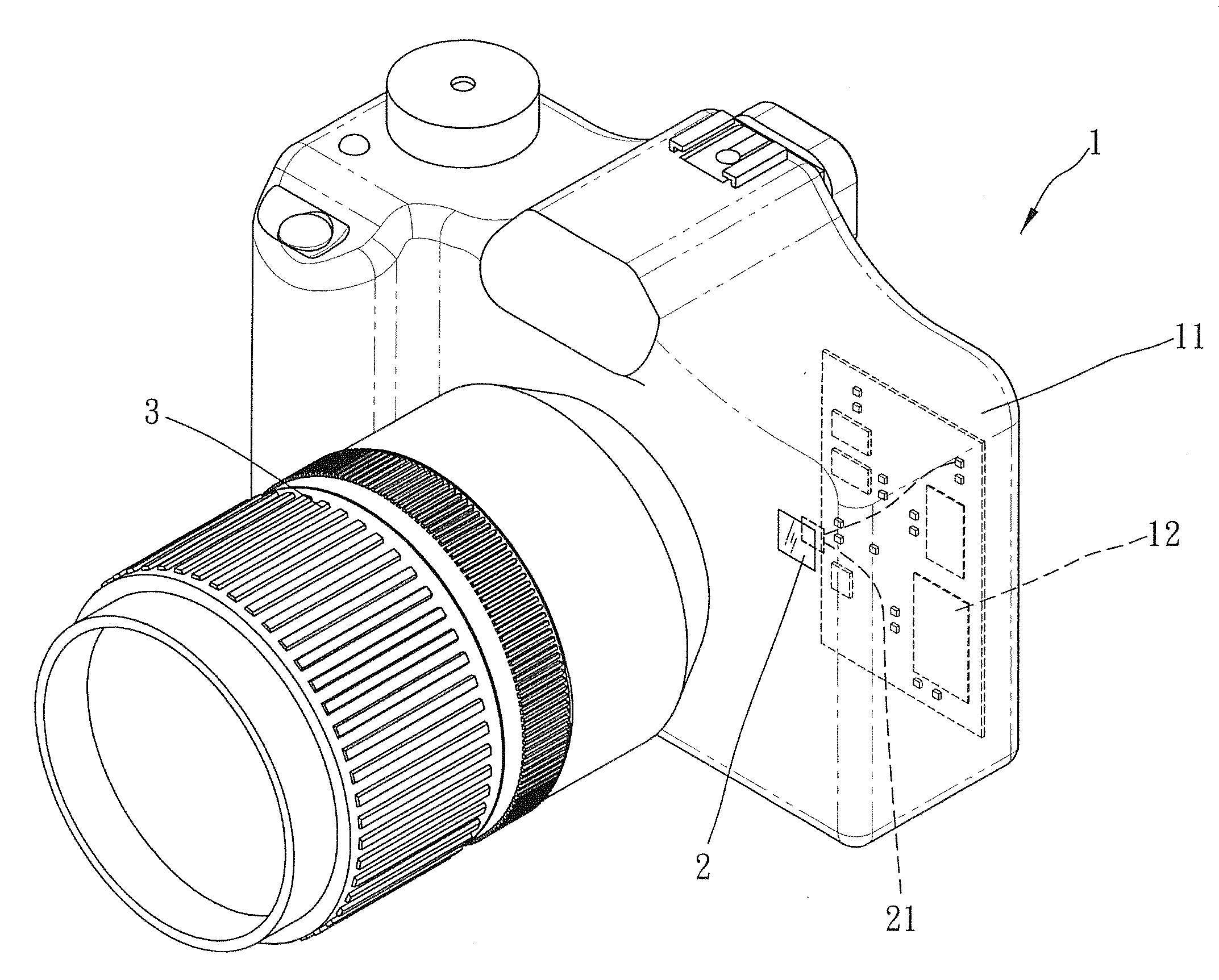

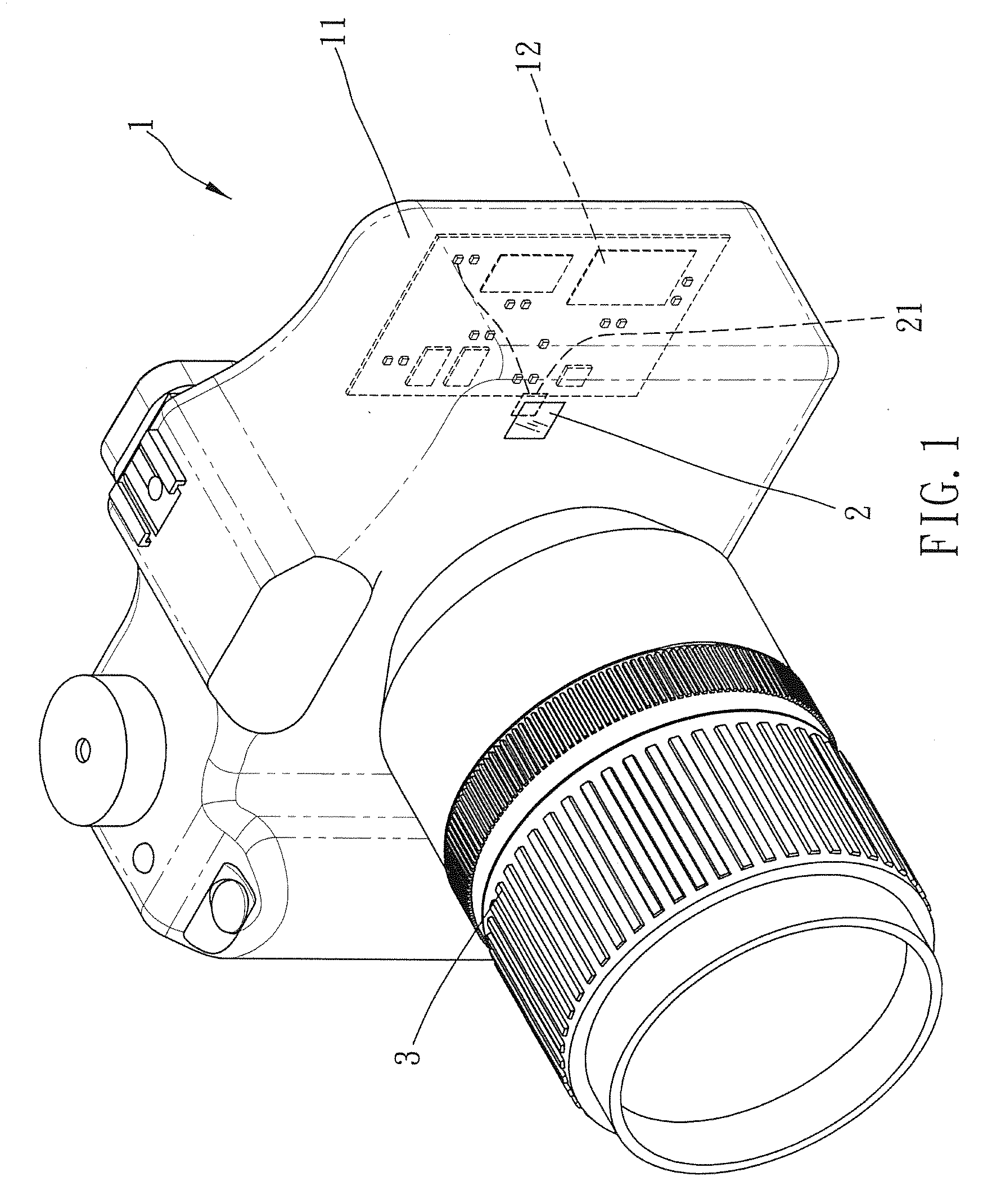

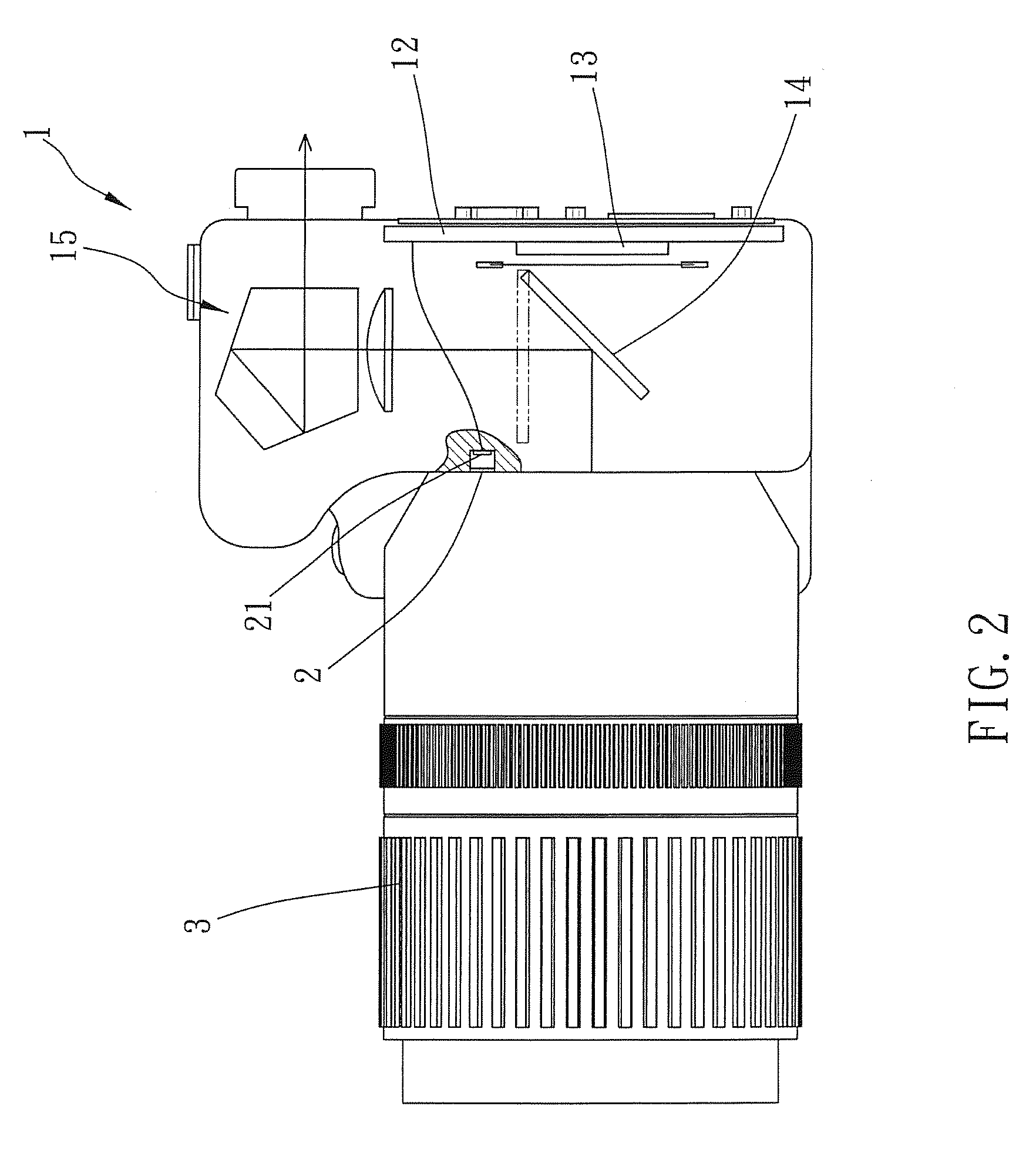

White-balance color temperature measuring device for image pick-up device

InactiveUS20150116535A1Close in colorRadiation pyrometryColor signal processing circuitsCamera phoneMeasurement device

A white-balance color temperature measuring device for image pick-up device includes a white or gray light transmitting sheet and a color temperature sensing element and installed in a camera body of a camera, camera phone, video camera or any other image pick-up device such that when focusing or pressing the shutter, incident light is changed by white or gray light transmitting sheet into a neutral light that falls upon the color temperature sensing element, causing the color temperature sensing element to induce a spot color temperature signal and to provide the signal to a CPU for processing, and thus, the color of the captured photos or images can be close to the natural colors of the shooting scene.

Owner:WU NA +1

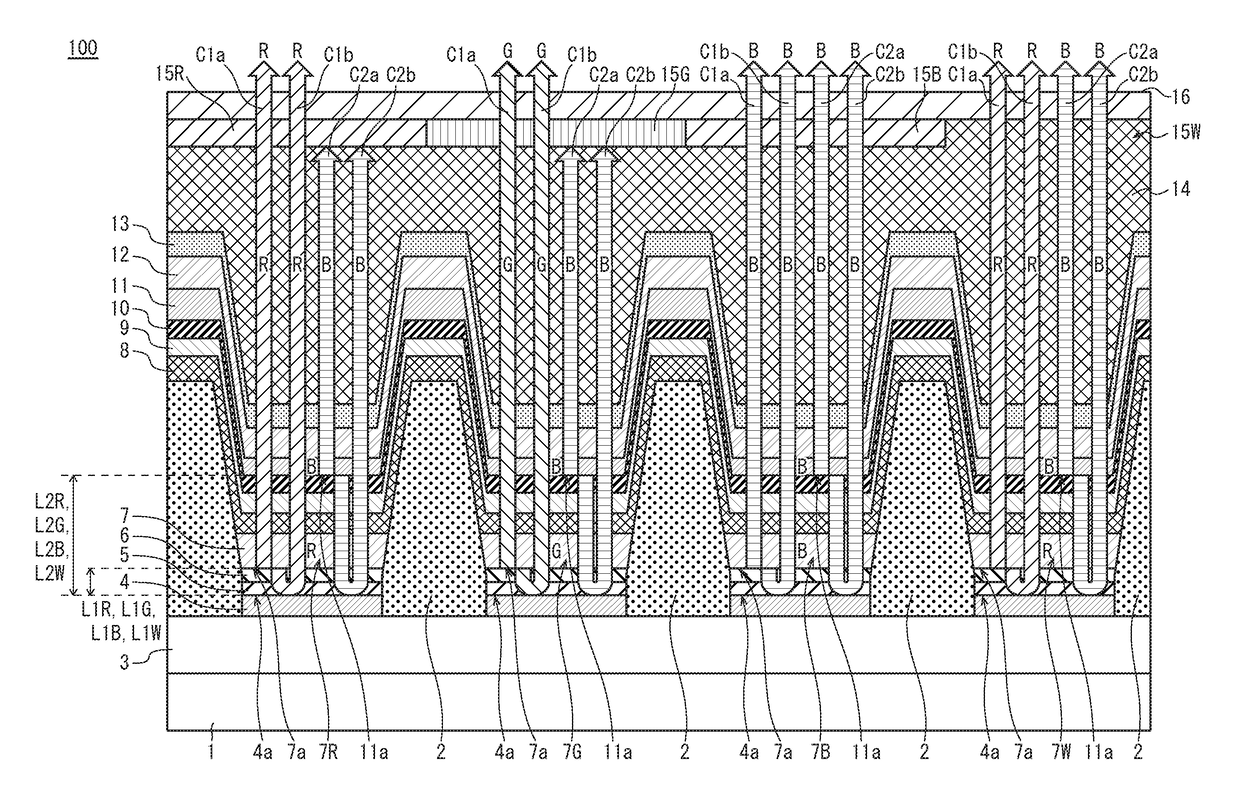

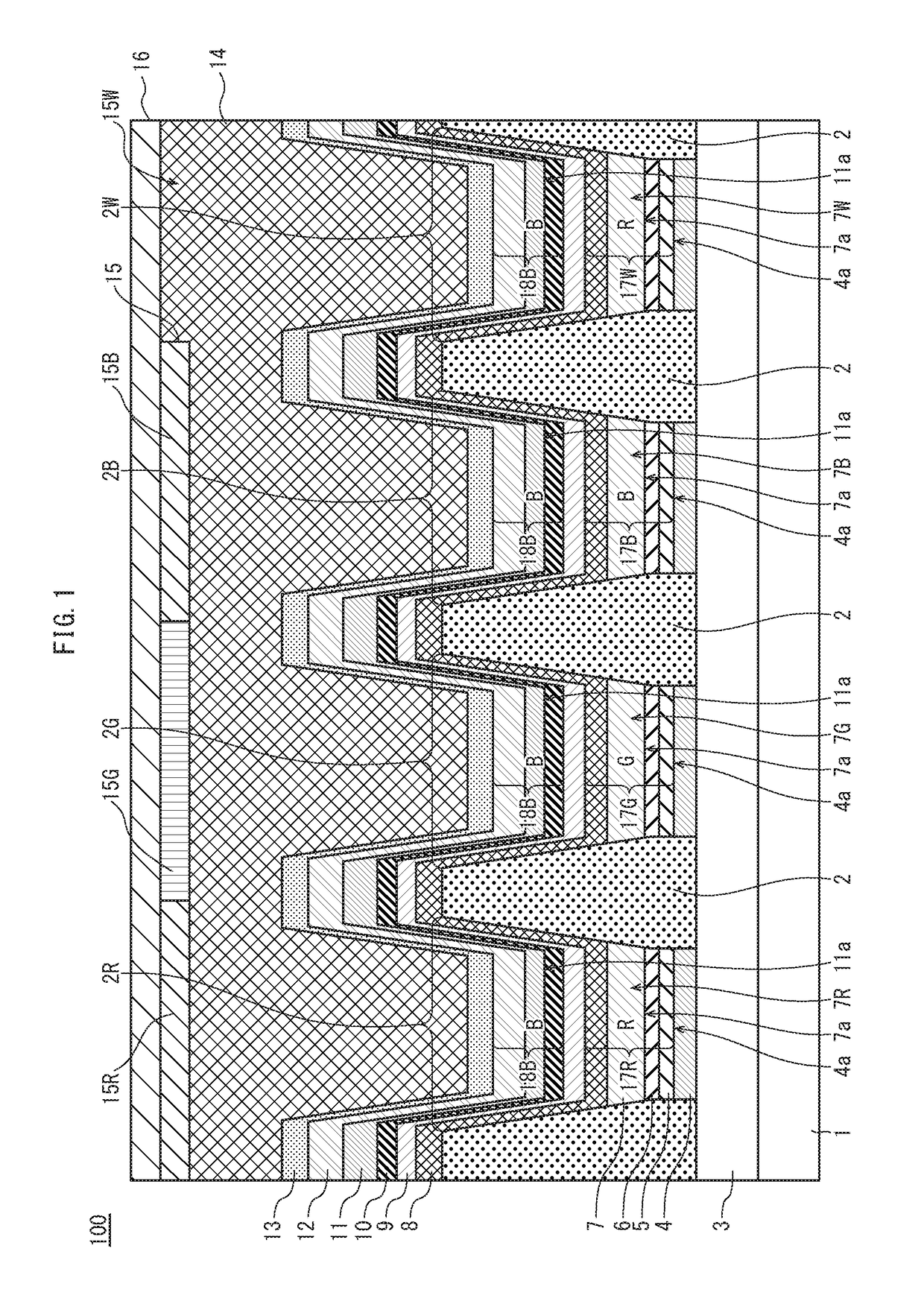

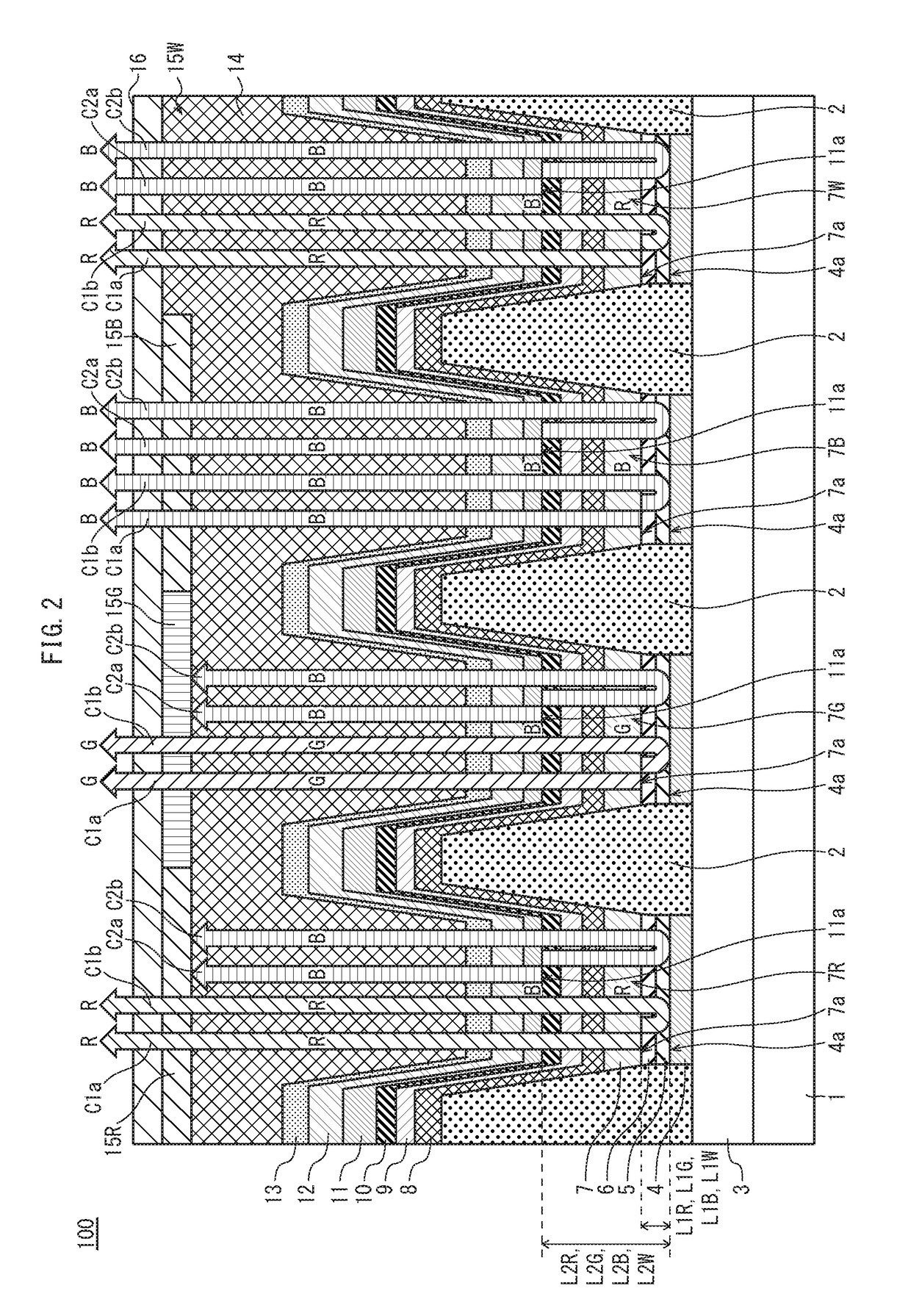

Organic el display panel, display device incorporating same, and organic el display panel manufacturing method

ActiveUS20170222173A1Increase manufacturing costIncrease productivitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceGreen-light

An organic EL display panel includes light-reflective electrodes, a first red light-emitting layer, a green light-emitting layer, a first blue light-emitting layer, a second red light-emitting layer, a charge generating layer, a second blue light-emitting layer, and a light-transmissive electrode. In a red and a white sub-pixel region, a first optical length is from 20 nm to 50 nm, and a second optical length is from 210 nm to 230 nm. In a green sub-pixel region, the first optical length is from 20 nm to 50 nm, and the second optical length is from 240 nm to 295 nm. In a blue sub-pixel region, the first optical length is from 20 nm to 60 nm, and the second optical length is from 195 nm to 205 nm.

Owner:JOLED INC

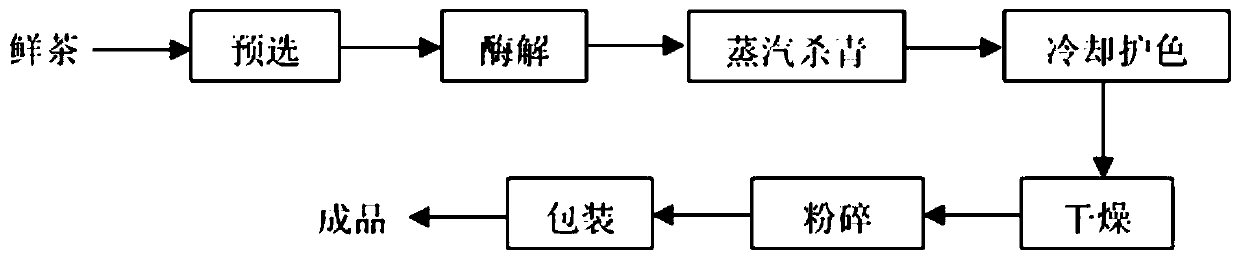

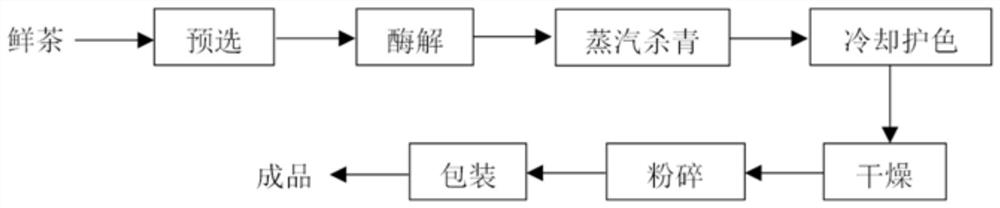

Ultrafinely pulverized green tea powder preparation method

The invention relates to the technical field of tea processing. A method comprises the steps of first washing and draining fresh tea, then pulverizing to large particles, spraying 1 / 10 enzymatic hydrolyzate on the surfaces of tea leaves, and turning the tea during enzymolysis; after the enzymolysis technology, performing enzyme deactivation by an enzyme deactivation machine until the fresh leavesare evenly and thoroughly evaporated to be free of grassy taste, then immersing the fresh leaves in a color protection solution at 20-25 DEC, repeatedly soaking in ice water for cooling, draining water, and then performing liquid nitrogen freezing treatment and vacuum freeze-drying treatment; after that, performing air jet pulverization at 15 DEC by an air flow ultrafine pulverizer to form ultrafinely pulverized green tea powder with an average particle diameter smaller than 20 microns. The ultrafinely pulverized green tea powder prepared by a preparation process provided by the invention usesconventional green tea as a raw material, thereby reducing production cost and labor cost; the final finished product is low in bitterness, moreover the green tea powder is more emerald green in color and better in solid fragrance and solubility, and can effectively maintain the original color and flavor quality of the tea, increase the quality of tea soup, and make the overall quality of the green tea powder closer to the quality of matcha.

Owner:SICHUAN UNIV

Clonal tea tree breeding method

The invention mainly aims to provide a clonal tea tree breeding method comprising the following steps: a, selecting a garden; b, trenching and grooving; c, cutting and seedling growing; d, nursery garden management; tea seedling using the seedling growing method is high in cutting survival rate, and breeding inherent characteristics can be well kept, so progeny properties are consistent, breeding period and growth vigor are tidy, and new shoot size, shoot tenderness0keeping ability and colors are close; subsequent mechanical tea harvesting is convenient, and primary processing technology can be standardized; the breeding method is simple, and easy to operate.

Owner:安徽省屯溪实验茶场

Dental Zirconia Restoration Material With Uniform Transition Of Strength And Color, And Preparation Method Thereof

InactiveUS20180327319A1Reduce harmHigh strengthImpression capsCeramic shaping apparatusHigh intensityCam

The application discloses a dental zirconia restoration material with uniform transition of strength and color, and a preparation method thereof. The preparation method includes the following steps: (1) pouring colored zirconia powder into a dry pressing mould in accordance with a sequence of the strength from high to low and the color from dark to light for each layer, and performing dry pressing; (2) performing isostatic cool pressing after the dry pressing; (3) performing pre-sintering after the isostatic cool pressing to obtain a greenware; and (4) performing CAD / CAM cutting on the greenware, and finally performing final sintering to obtain the dental zirconia restoration material. In the present application, the strength of a restoration can gradually increase from a cut end to the neck, the wear to adjacent teeth and jaw teeth is reduced, and long-bridge restoration can be realized due to the high strength of the neck.

Owner:AIDITE (QINHUANGDAO) TECH CO LTD

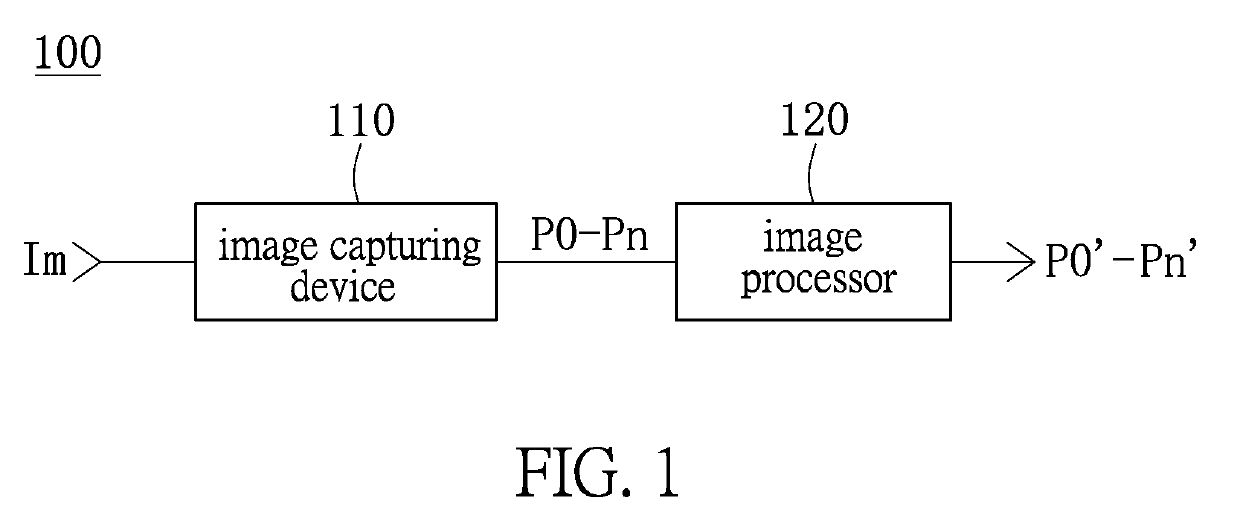

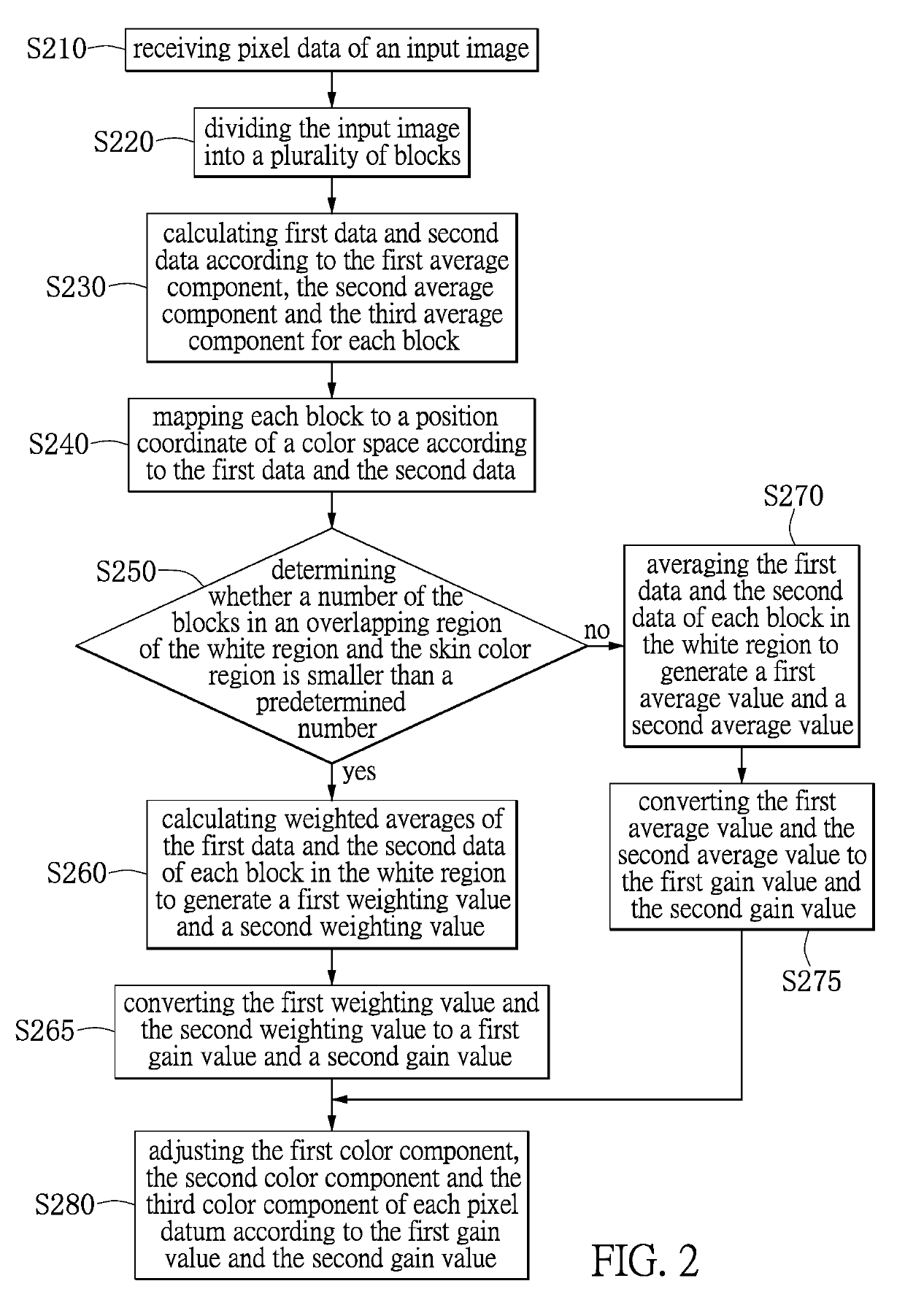

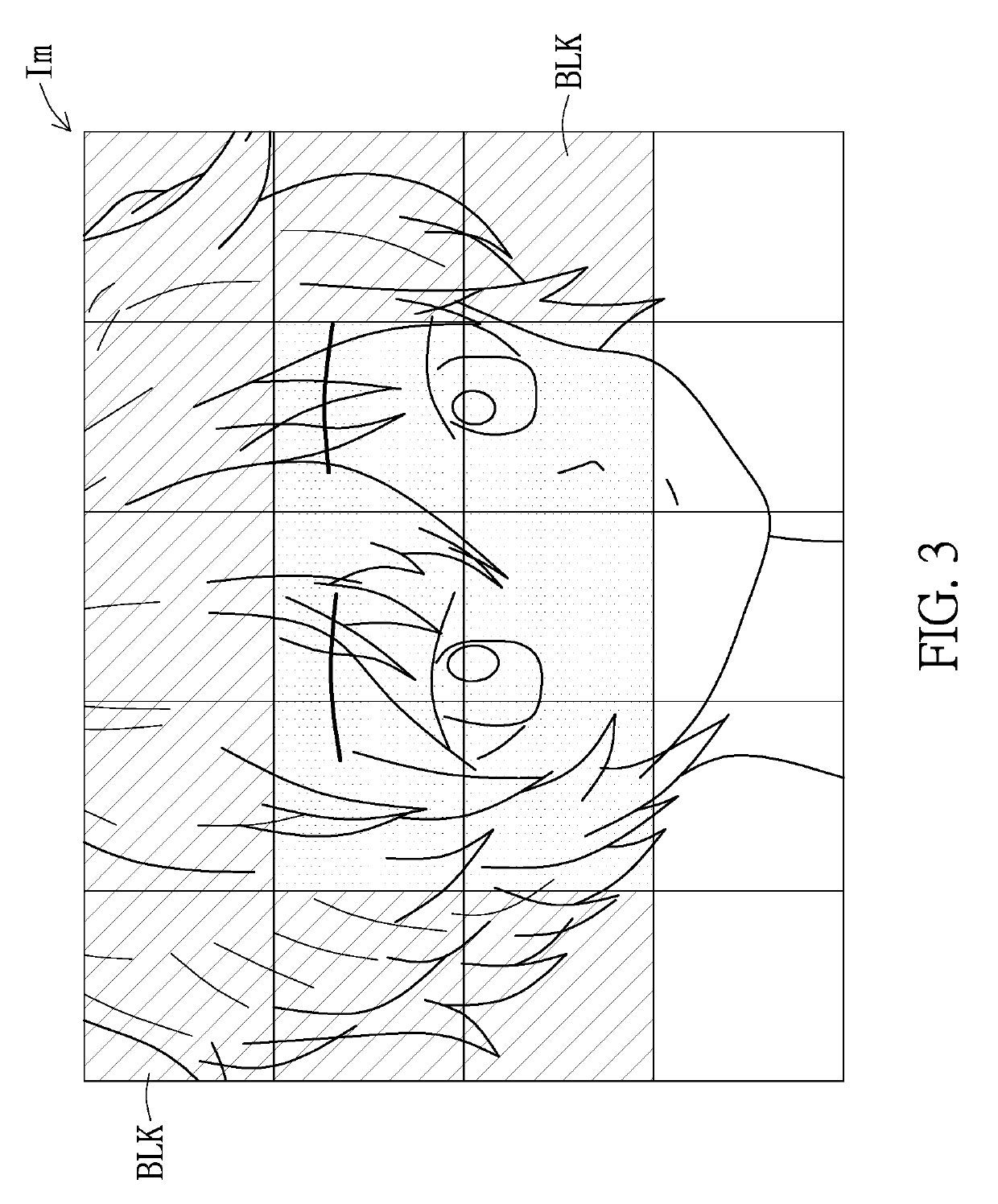

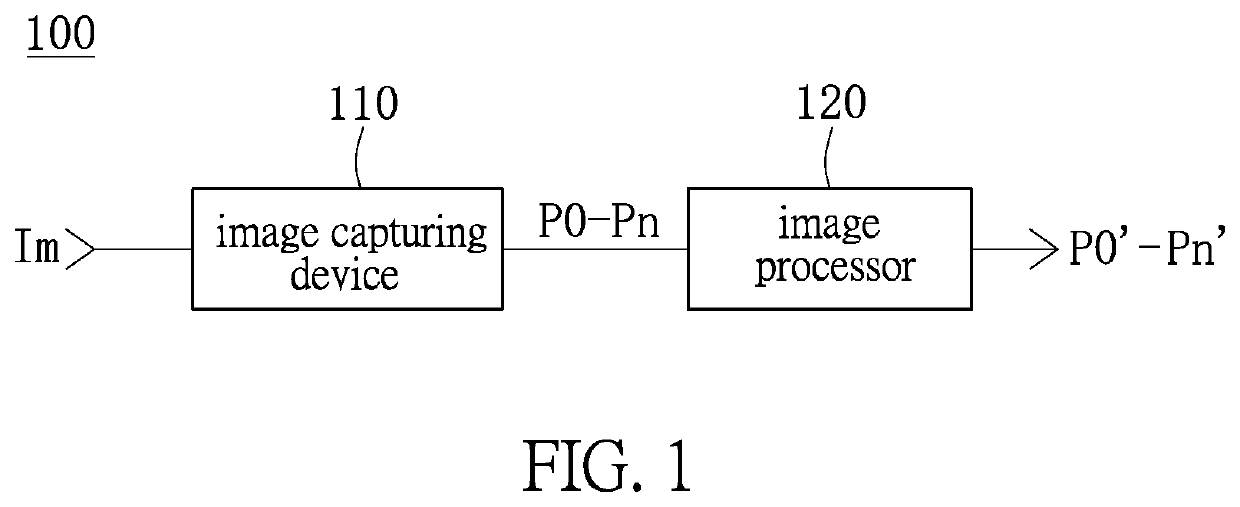

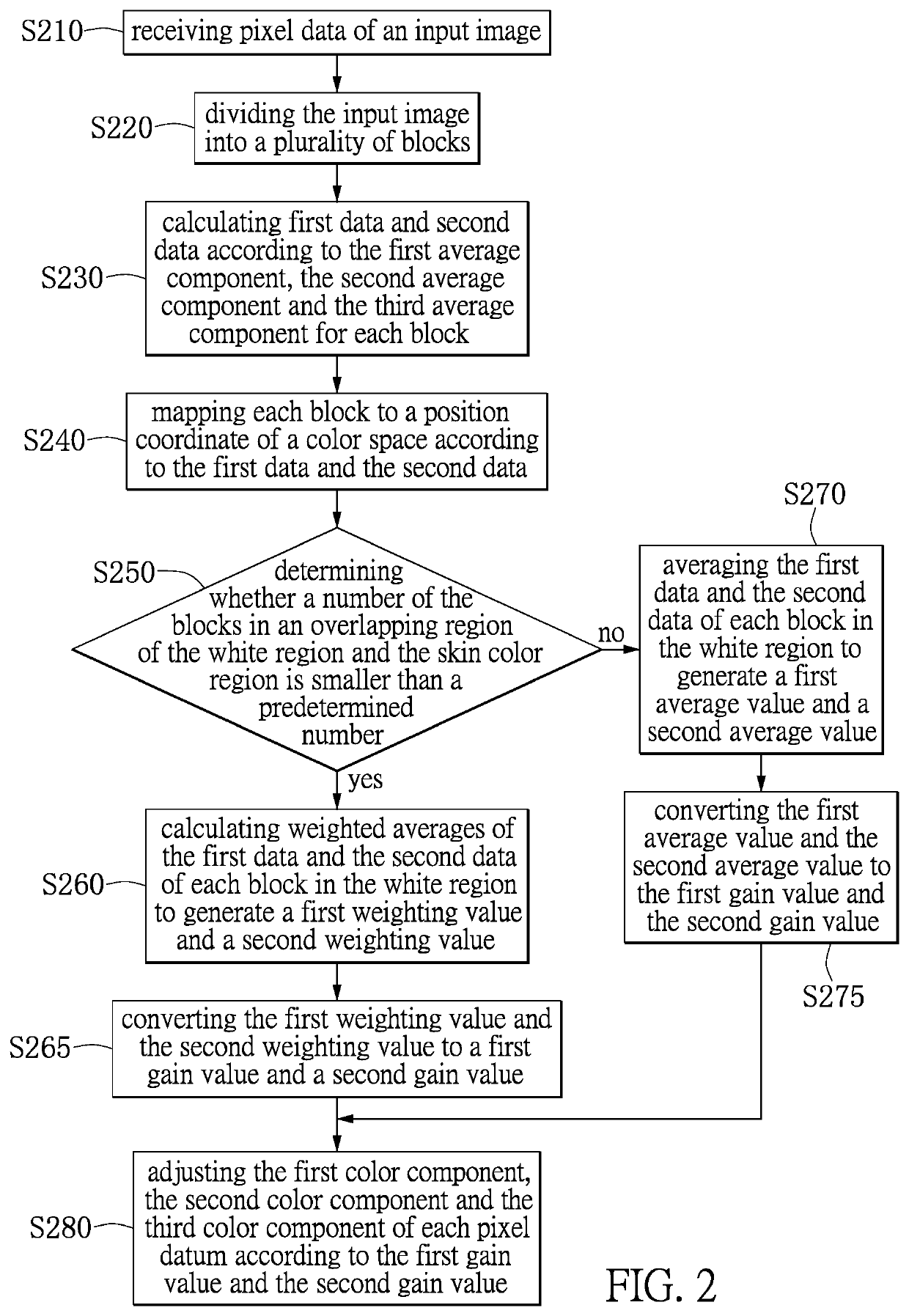

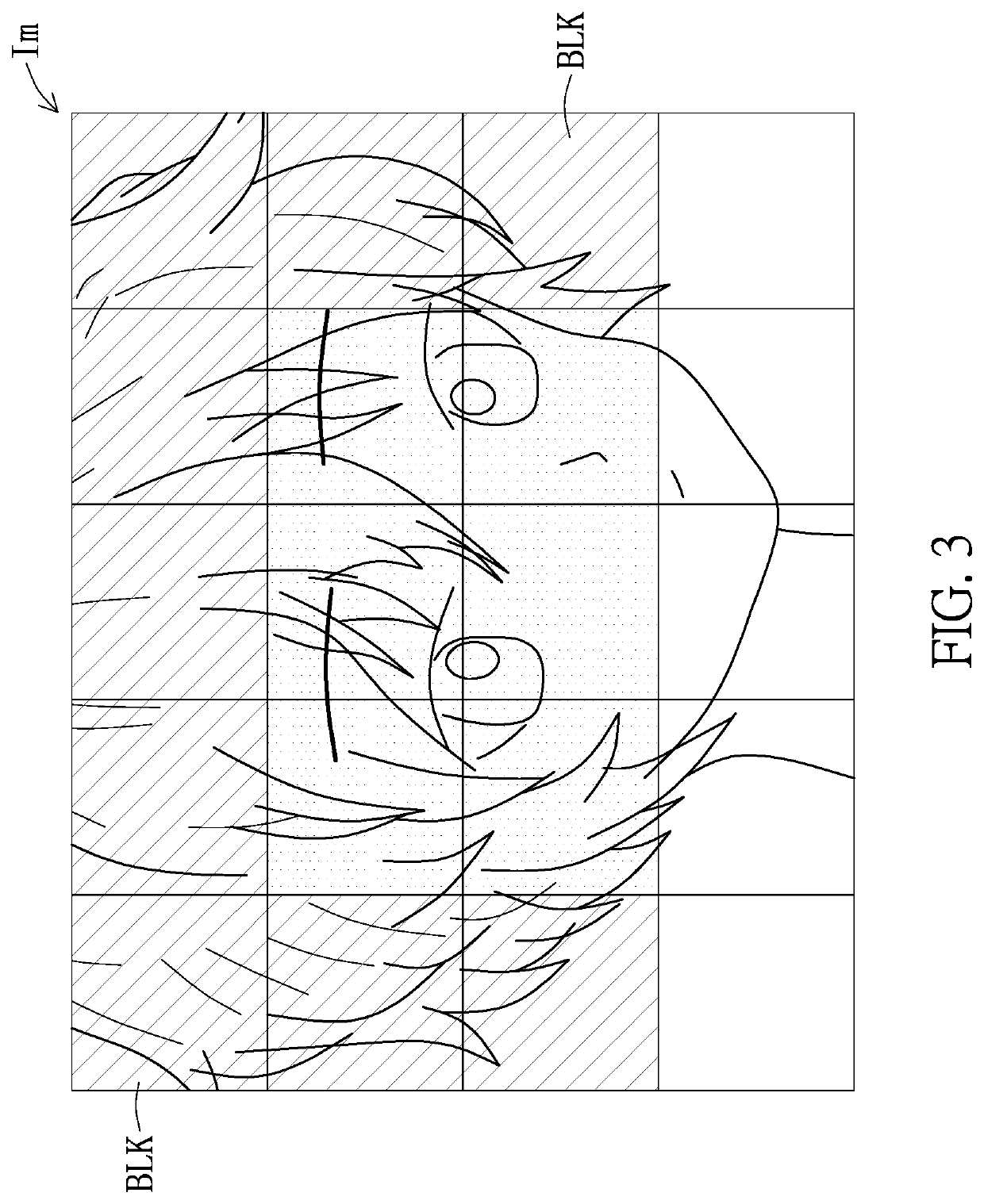

White balance calibration method based on skin color data and image processing apparatus using the same

ActiveUS20190320152A1Avoid mistakesEasy to interfereImage enhancementImage analysisPattern recognitionImaging processing

Disclosed are a white balance calibration method based on skin color data and an image processing apparatus using the same. By using the method and the image processing apparatus, weight allocation of the skin color data in an input image may be adaptively performed to avoid white balance calibration errors due to excessive skin color data. Therefore, the present disclosure can further solve an issue that in video applications, the white balance calibration is easily interfered by a large amount of the skin color data. Moreover, the present disclosure may be adapted to different color temperatures and may output images having colors closer to actual colors.

Owner:REALTEK SEMICON CORP

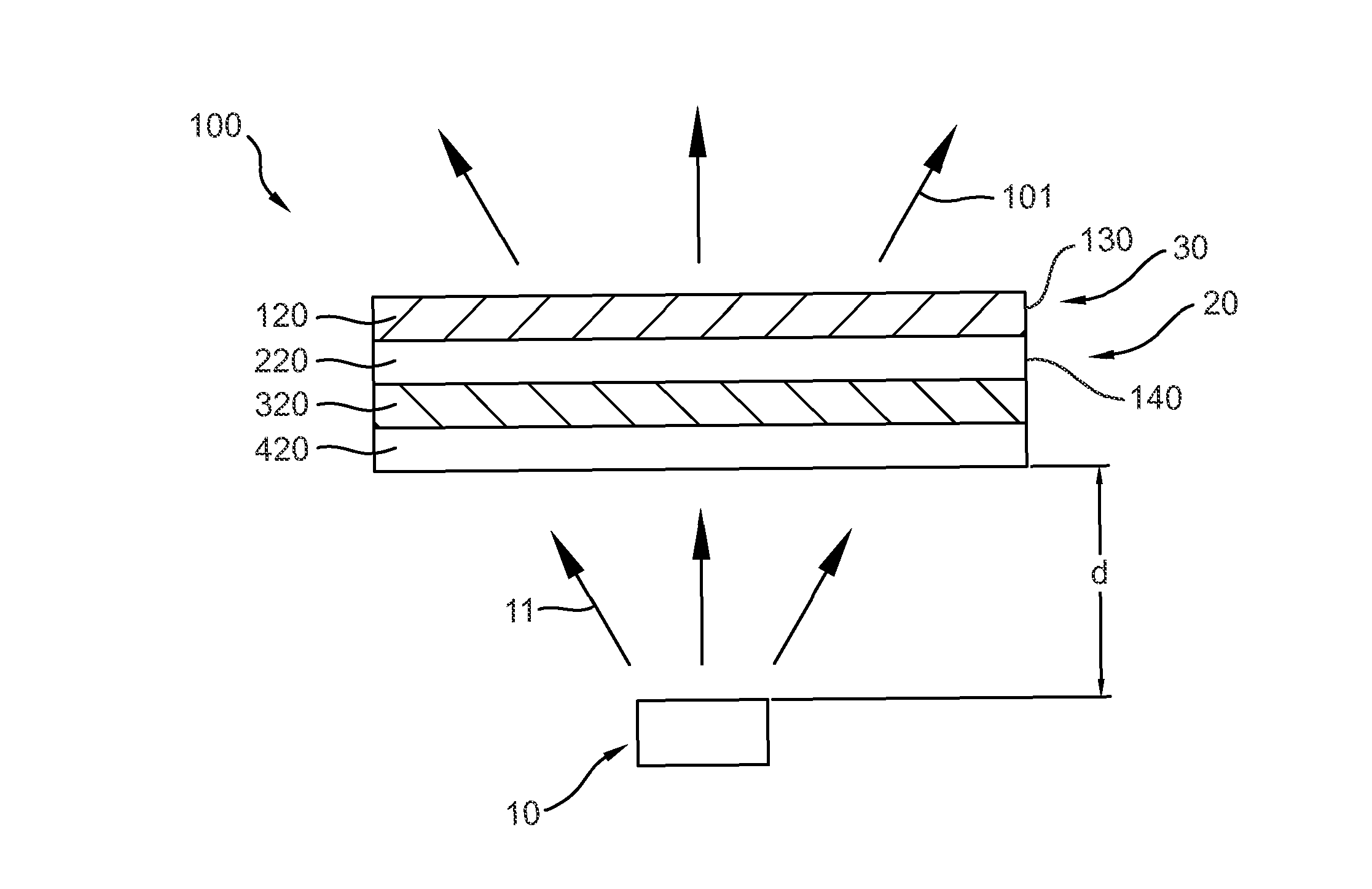

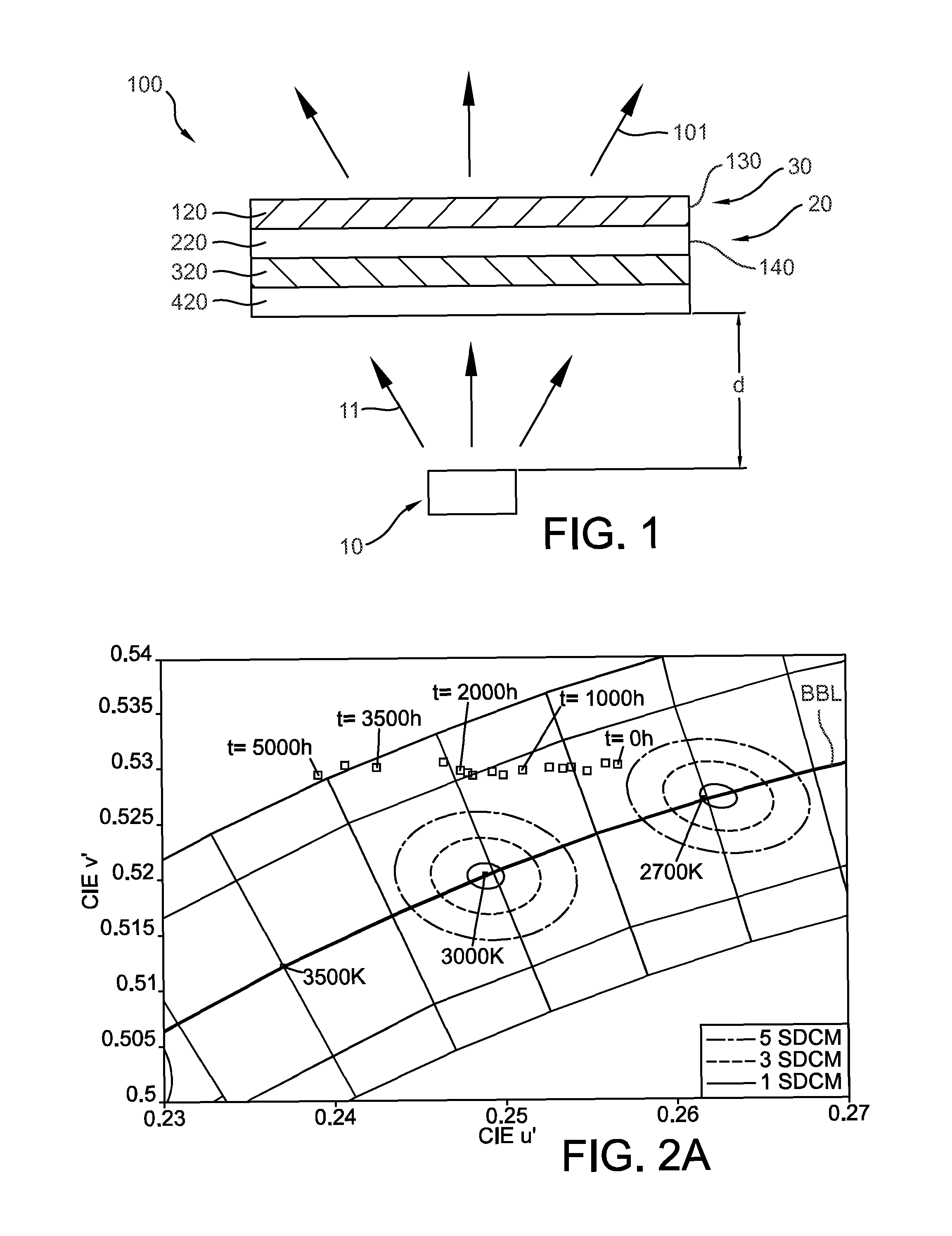

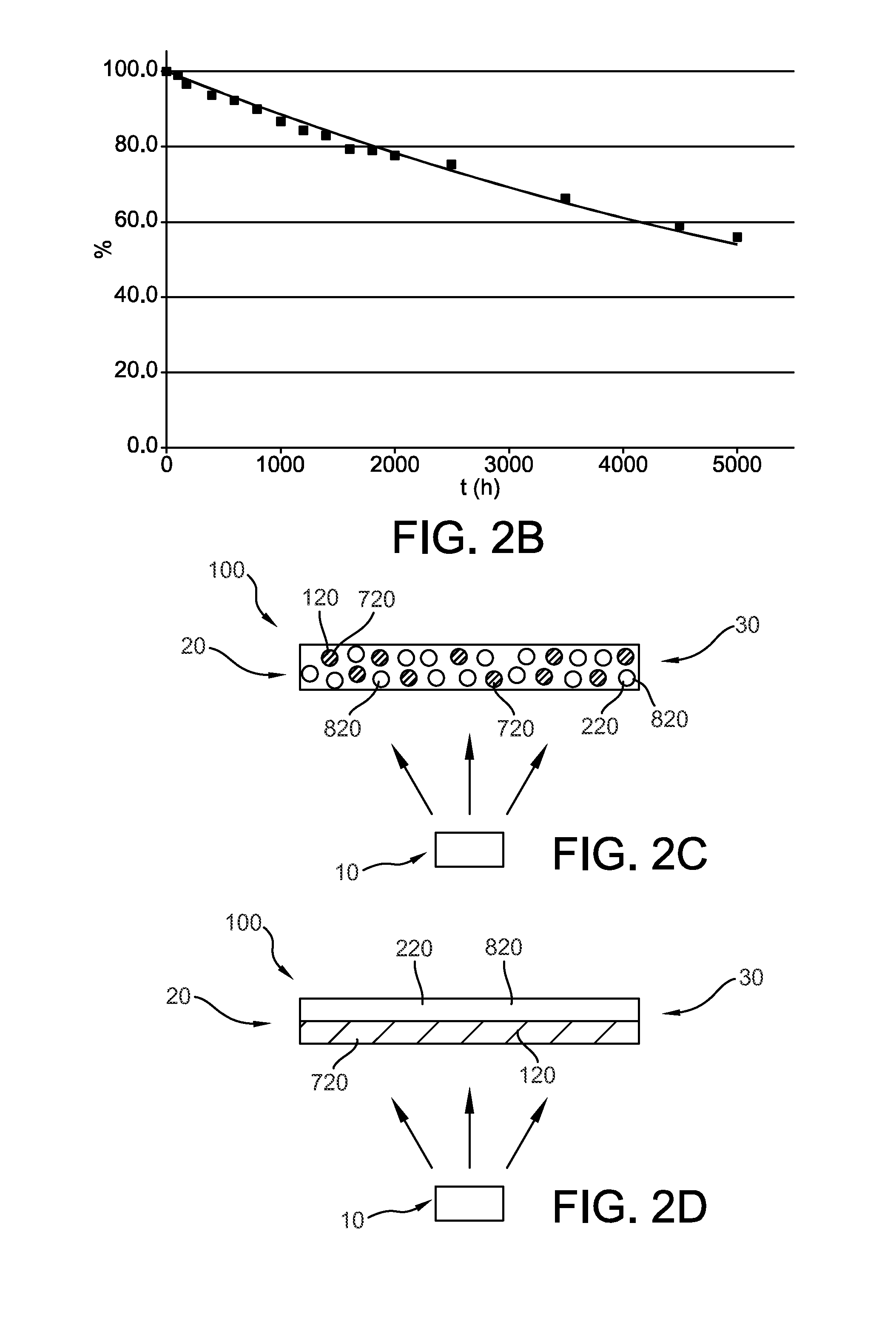

Lighting device comprising at least two organic luminescent materials

InactiveUS20150054401A1Improve efficacySimplify the design processDischarge tube luminescnet screensElectroluminescent light sourcesSecondary layerLight source

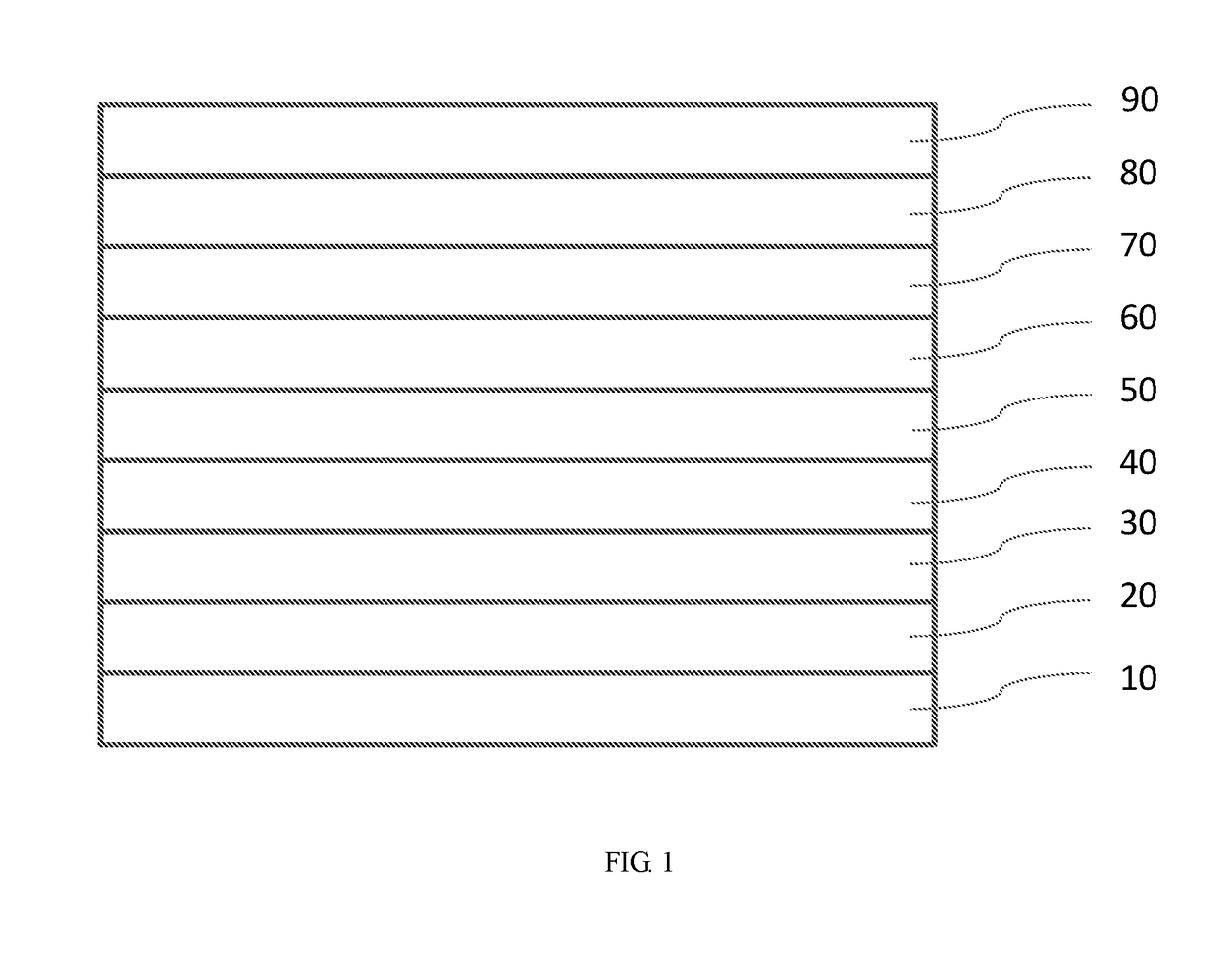

The invention provides a lighting device (100) comprising a light source (10) and luminescent materials (20). The luminescent materials (20) comprise a first organic luminescent material (120) and a second organic luminescent material (220), the light source (10) together with the luminescent materials (20) being configured to generate white lighting device light (101) during operation. The first organic luminescent material (120) degrades with time at a first degradation rate and the second organic luminescent material (220) degrades with time at a second degradation rate, wherein the first degradation rate is larger than the second degradation rate. The first organic luminescent material is configured in a first layer (130, 1020) and the second organic luminescent material is configured in a second layer (140, 1220). The first layer and / or the second layer is further configured to at least partly compensate for the difference in the first degradation rate and the second degradation rate in order to maintain the lighting device light (101) substantially white during operation time of the lighting device (100).

Owner:SIGNIFY HLDG BV +1

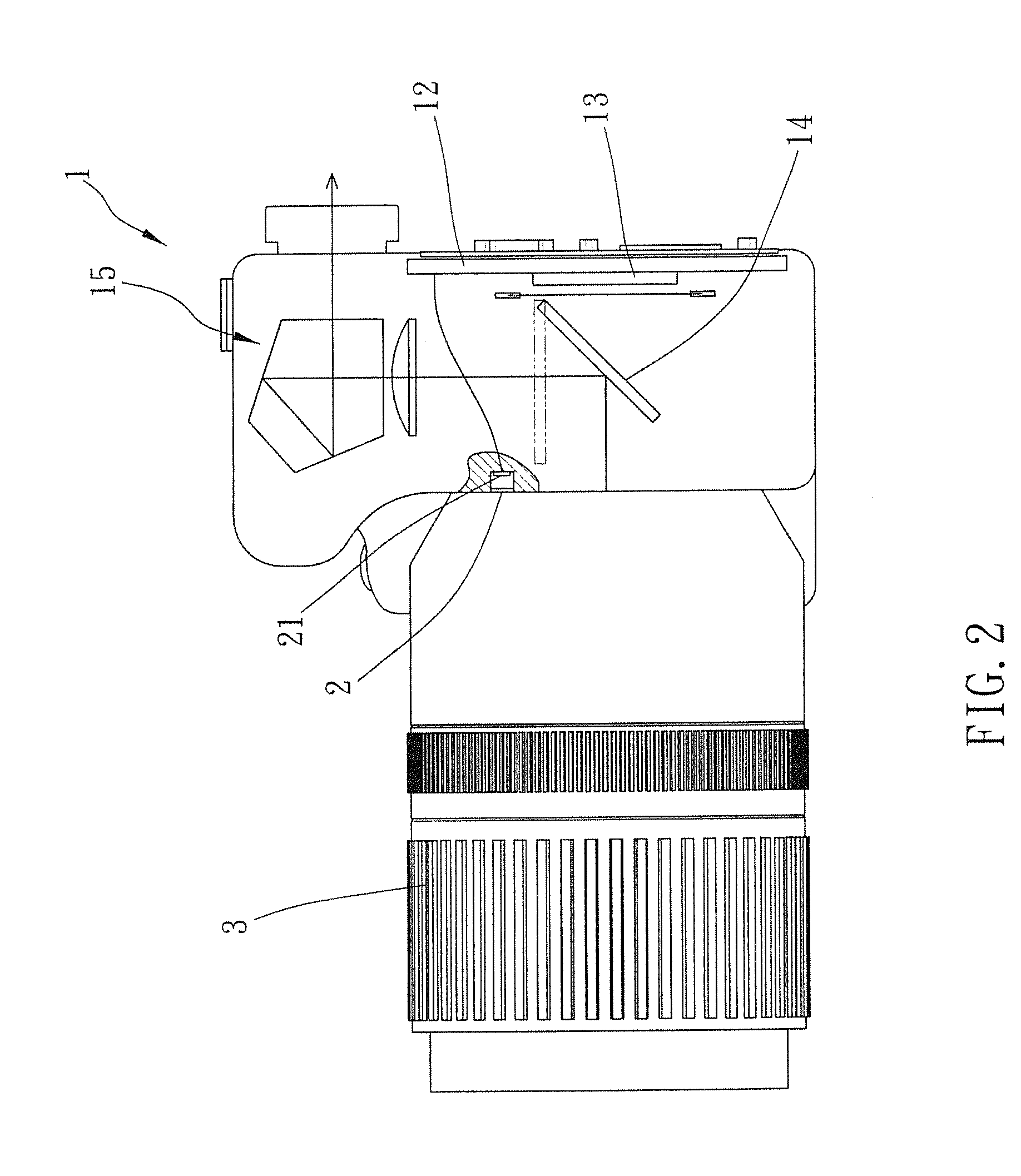

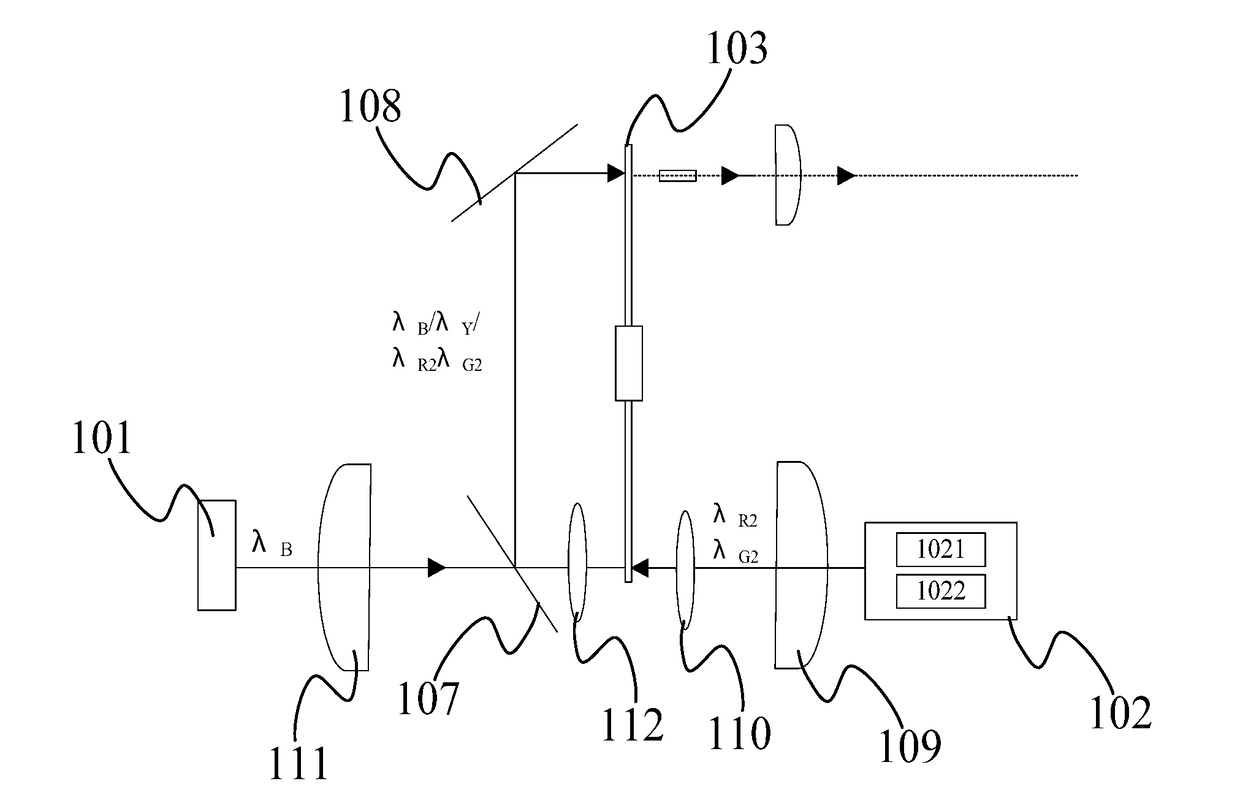

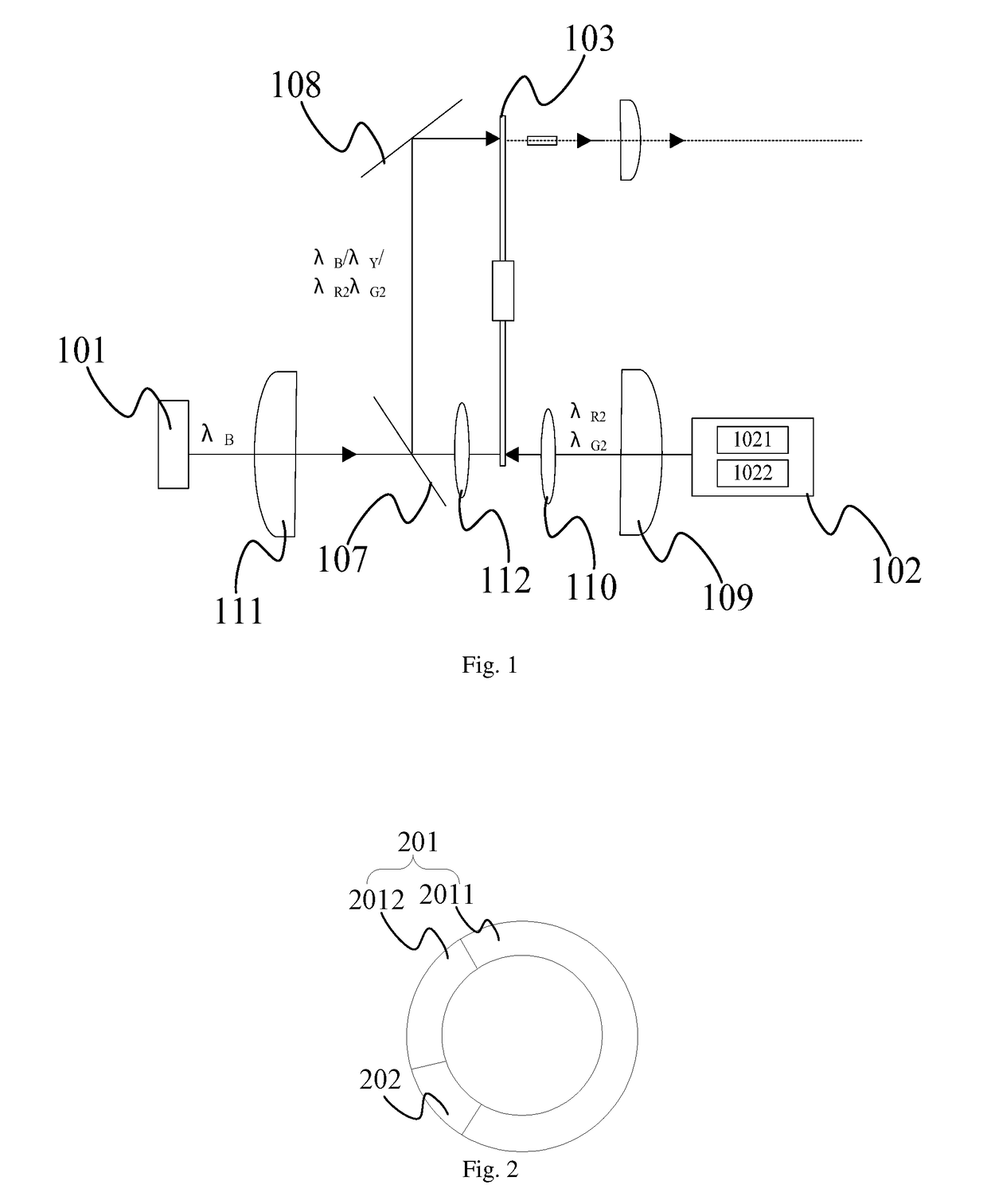

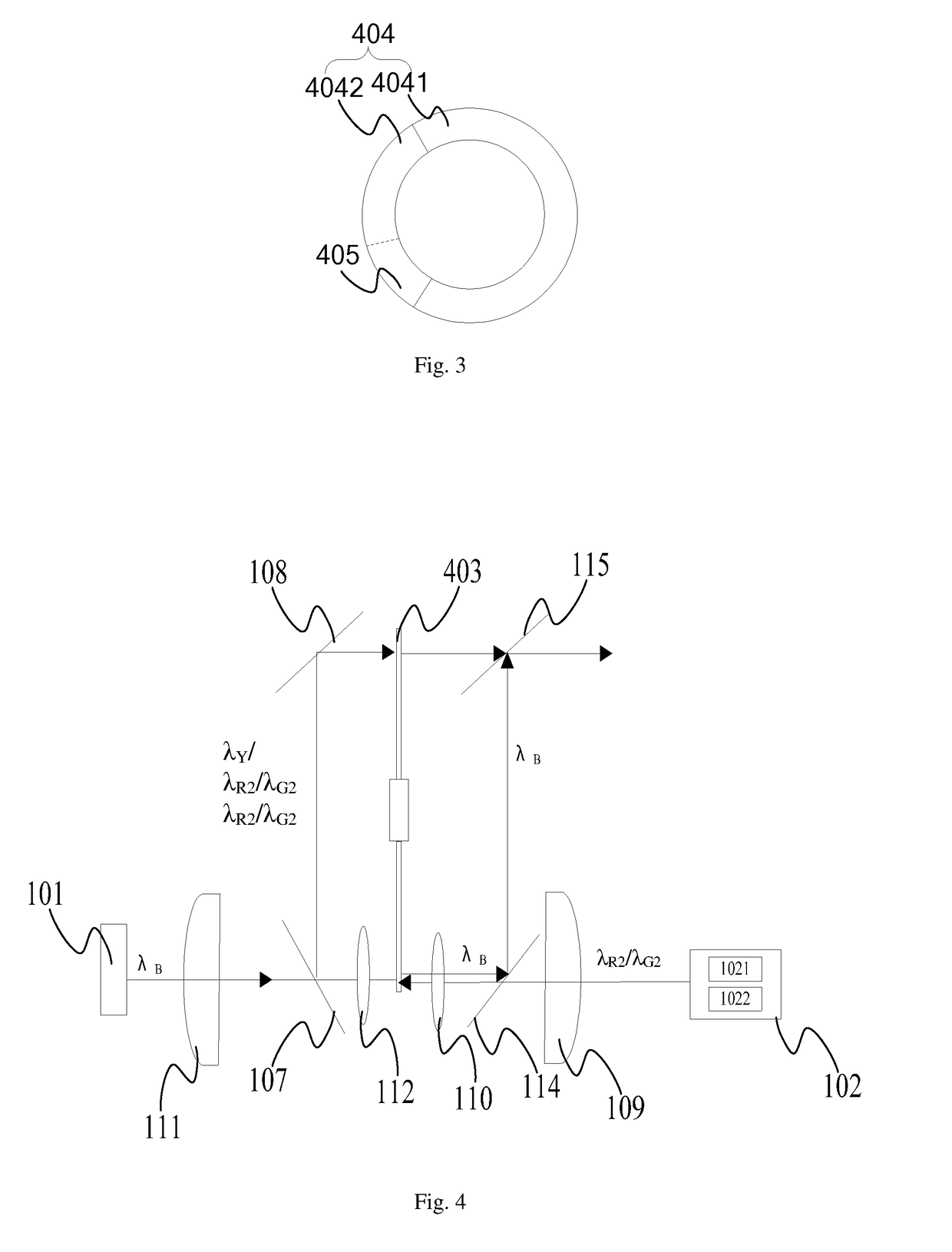

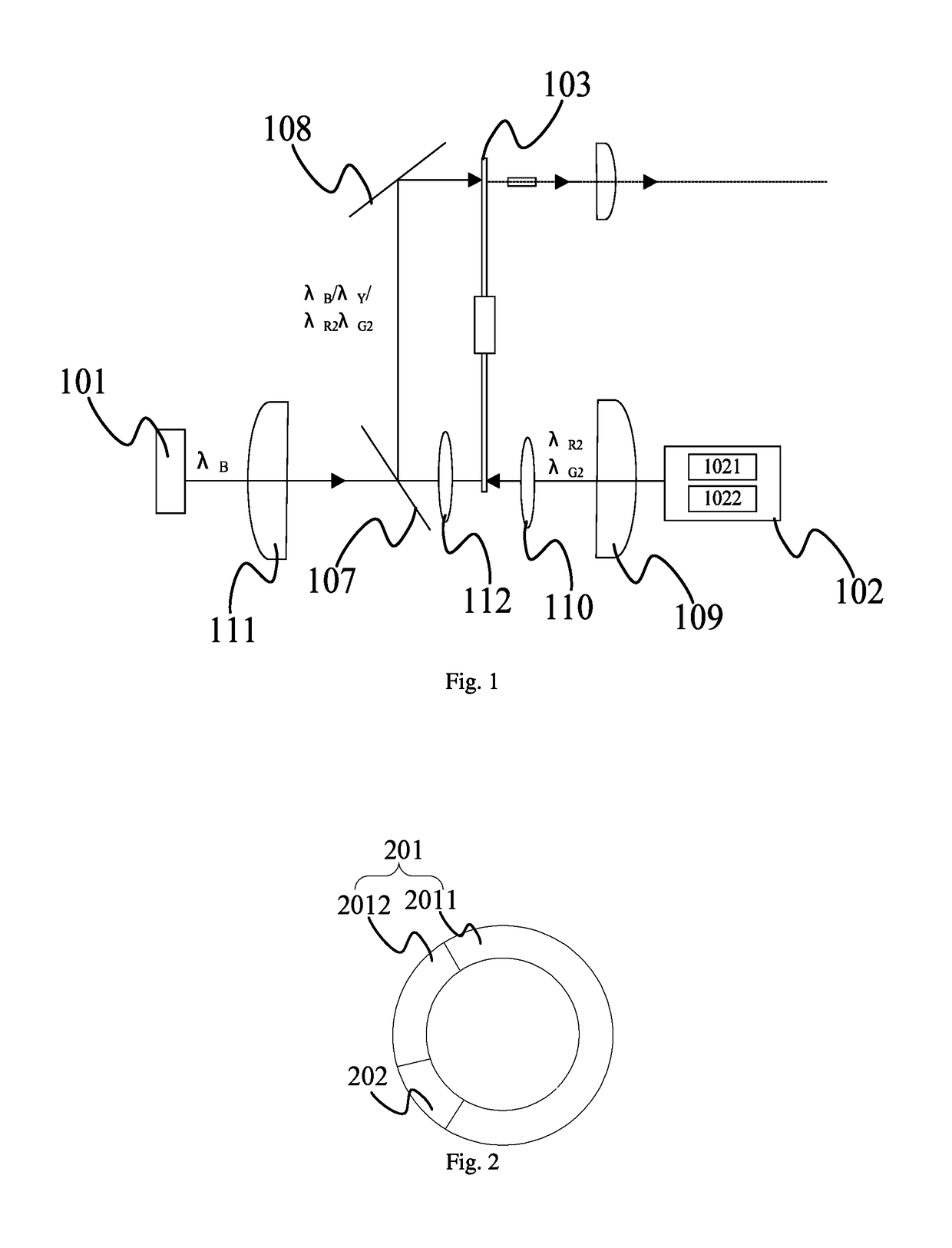

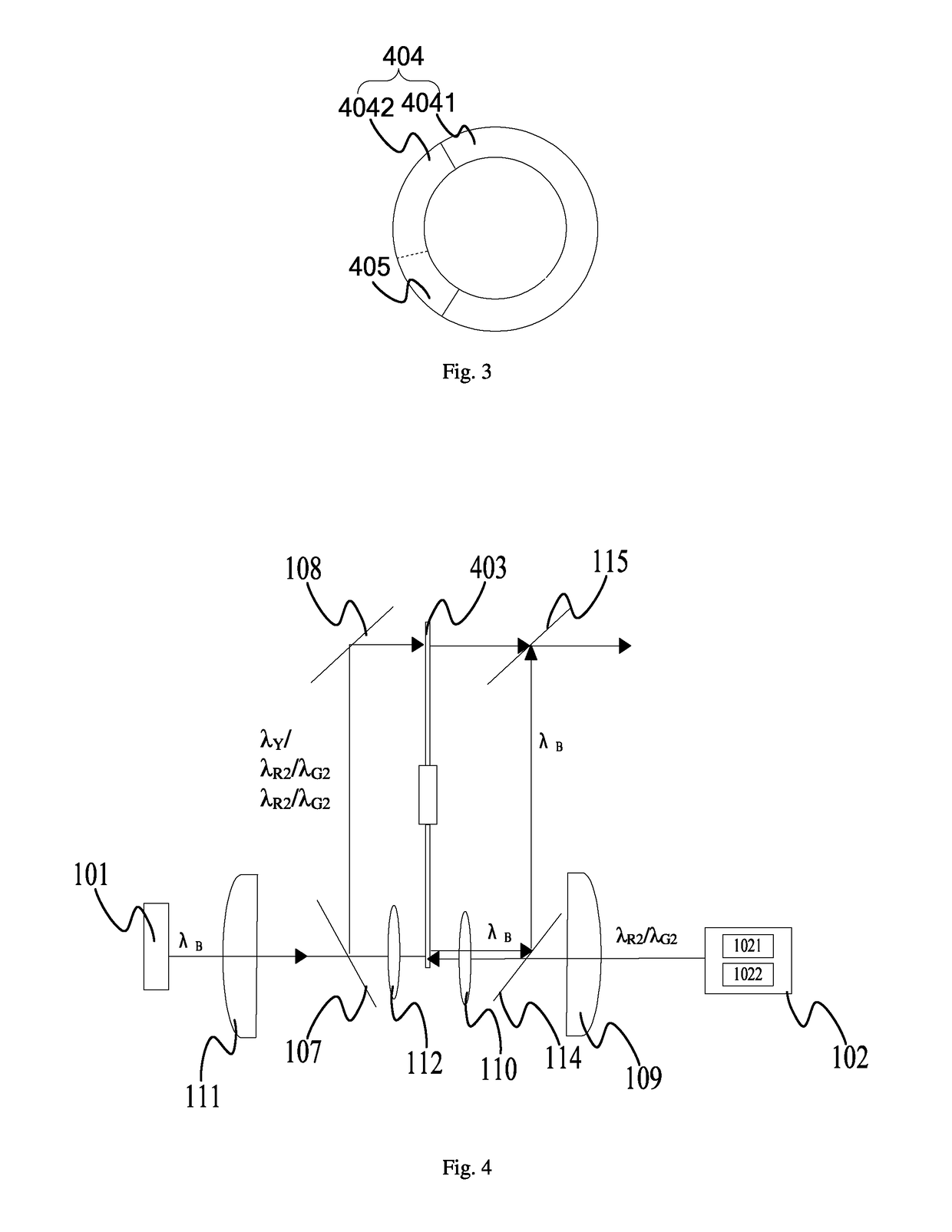

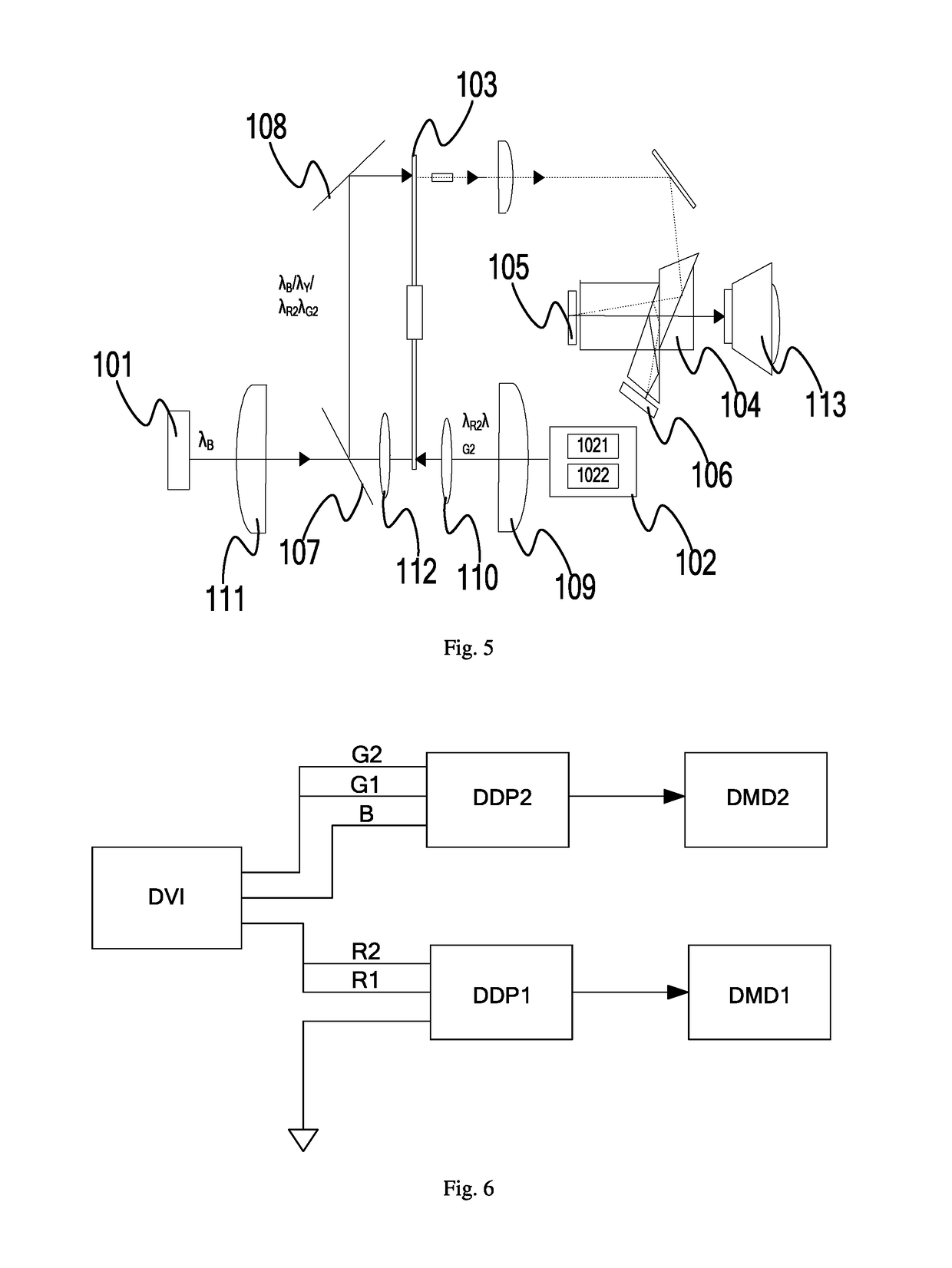

Light source system and projection system

ActiveUS20180129123A1Light lossEffective lightingProjectorsColor photographyFluorescenceScattering loss

A light source system and a projection system. The light source system comprises: an excitation light source (101) for emitting excitation light in at least a first time sequence and a second time sequence; a compensation light source (102) for emitting compensation light in at least a third time sequence, the compensation light emitted by the compensation light source (102) comprising laser of at least one color; and a rotating color wheel (103), comprising at least a first region (201) and a second region (202), wherein the first region (201) generates light of at least two different colors in time sequence under the irradiation of the excitation light in the first time sequence and the second time sequence, and the second region (202) is used for transmitting the compensation light in at least the third time sequence. The light of the at least two different colors comprises at least one type of wide-spectrum fluorescence, and the laser of the at least one color is used for compensating for the fluorescence or light split from the fluorescence. In this way, the compensation light is directly transmitted without being irradiated upon fluorescent powder, scattering loss of the compensation light is reduced, and utilization rate of the compensation light is increased.

Owner:APPOTRONICS CORP LTD

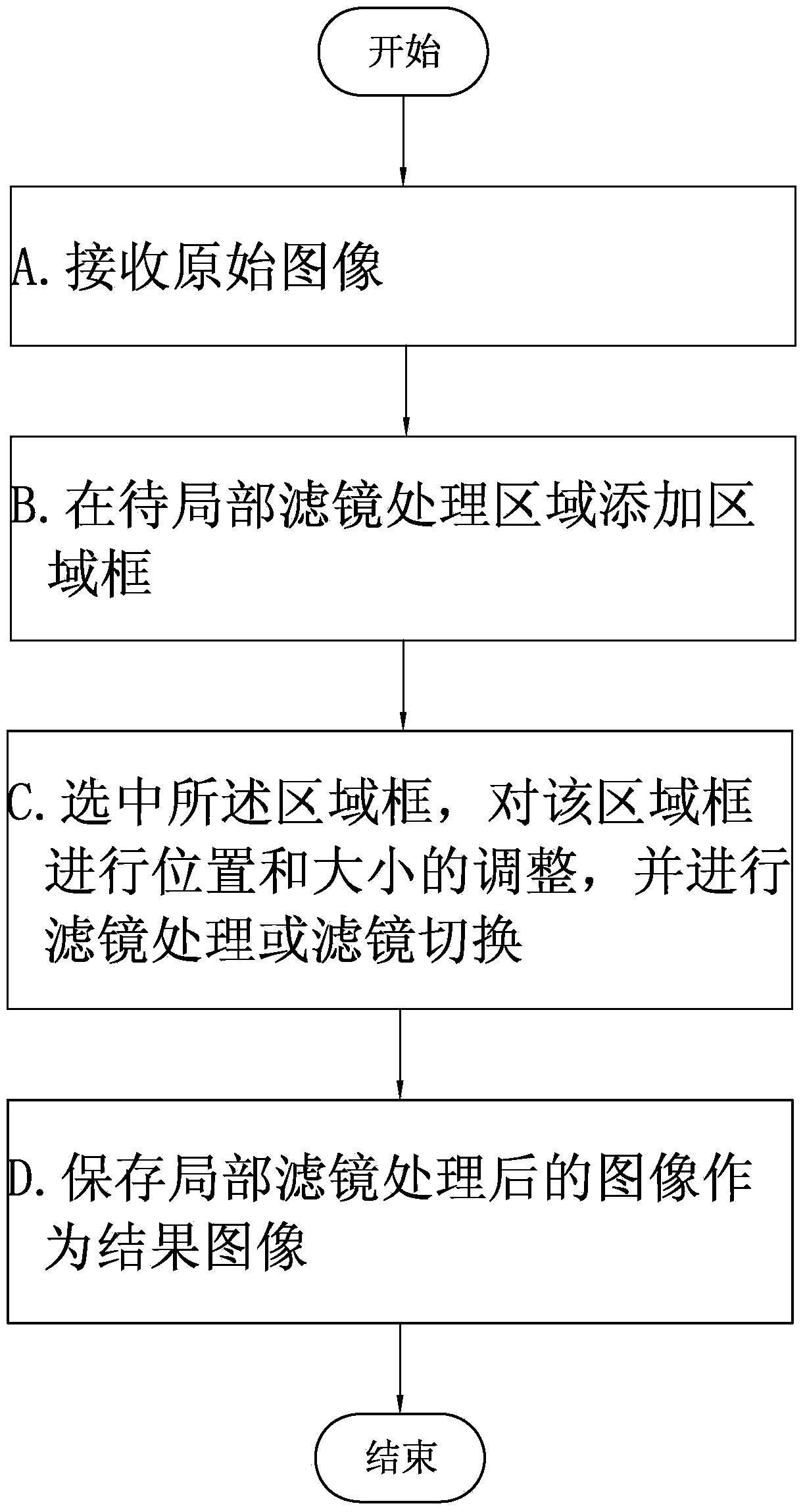

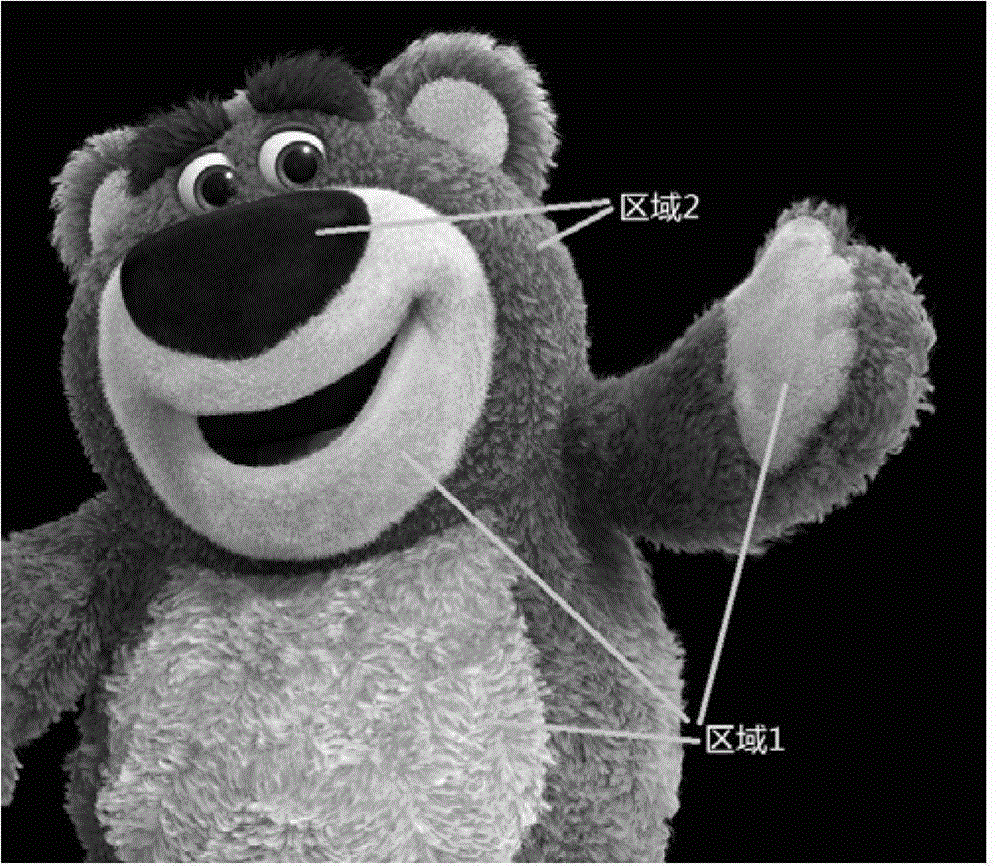

Image processing method capable of carrying out partial filter adding

The invention discloses an image processing method capable of carrying out partial filter adding. An area frame is added into an original image area on which the partial filter processing needs to be carried out, the position and size adjustment and the filter processing or filter switchover are carried out on the selected area frame, and the image obtained after the partial filter processing is carried out is stored as a result image. Compared with partial filter processing steps of existing software, the image processing method is faster and more convenient to operate, visual and capable of finishing the partial filter processing without professionals; the number of area frames can be multiple, the area frames can be mutually overlapped, or the sequence of the area frames can be adjusted, the position and size adjustment and the filter switchover can be carried out on the area frames obtained after the filter processing is carried out, a user can carry out operation more easily, and the filter effect is better.

Owner:MEITU

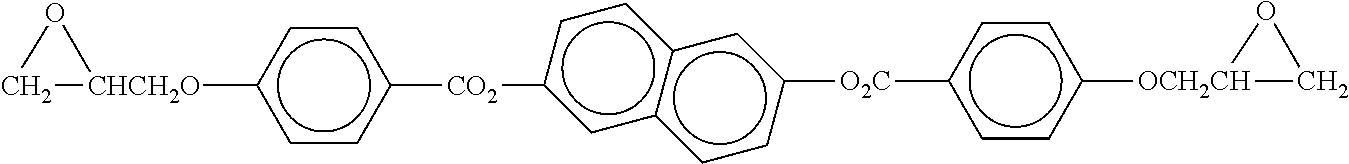

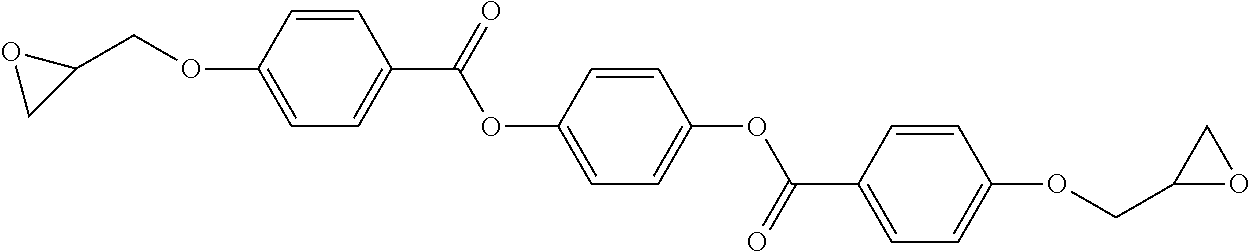

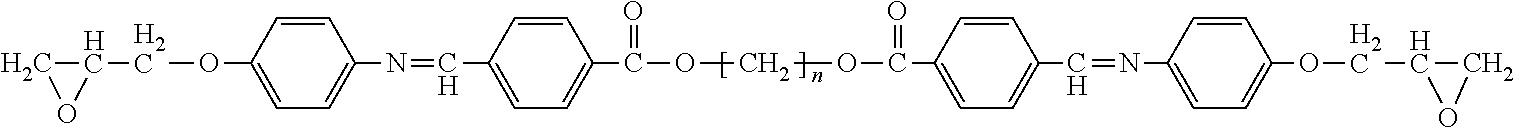

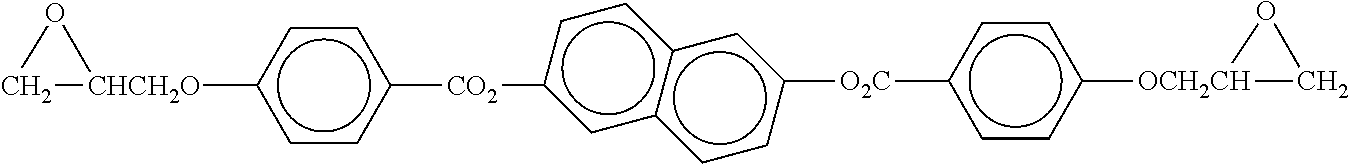

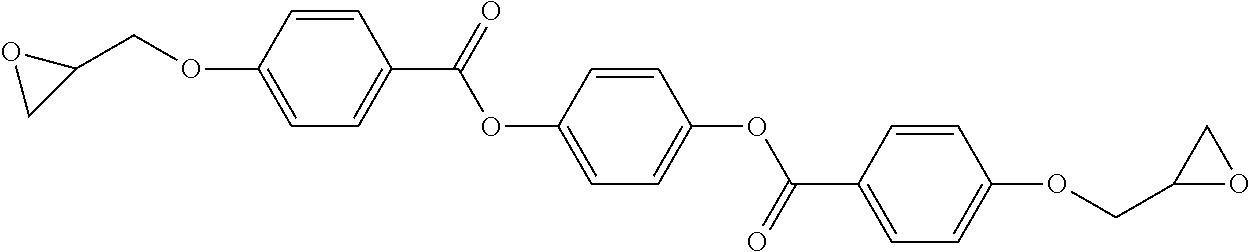

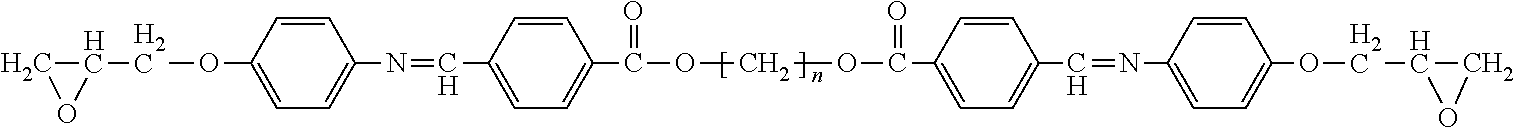

Liquid crystalline epoxy nanicomposite material and application thereof

ActiveUS20110009521A1Good integrityReduce consumptionImpression capsSurgical adhesivesFilling materialsOrthodontic Brace

The invention provides an epoxy nanocomposite material for dental therapy, which can be applied to direct or indirect clinical restoration, dental core-post system, and dental brace etc. The epoxy nanocomposite filling material provided by the invention can be polymerized with various curing agents to form the polymer with low shrinkage.

Owner:NAT TAIWAN UNIV

Green pigment for color filter, green pigment dispersion, photosensitive color composition, color filter, and liquid crystal panel

ActiveUS7781129B2High strengthPromote formationPhotosensitive materialsOptical filtersPhotopigmentPigment dispersion

Owner:DAI NIPPON PRINTING CO LTD +1

Preparation method of peeled and deodorized green bean whole powder

InactiveCN111280396AReduce churnRetain flavor substancesFood thermal treatmentFood dryingBiotechnologyNutrients substances

The invention relates to a preparation method of peeled and deodorized green bean whole powder. The preparation method comprises the following steps of: (1) pretreating raw materials; (2) peeling green beans; (3) protecting color and deodorizing; (4) conducting primary drying; (5) crushing and sieving; and (6) conducting secondary drying. According to the tomato blanching and peeling combined method, tomato skin is effectively removed, the taste of the product is improved, and a good color protection effect on tomatoes is achieved through blanching. Compared with a traditional method for preparing the green bean powder, the method disclosed by the invention saves energy without the processes of precooking, cooking and the like. And the drying temperature and the like are low, so that the color of the green bean powder is slightly damaged in the product drying process, the loss of nutrient substances is less, and the original taste and nutrient substances of the green beans are maintained to the maximum extent. And the operation process is simple and suitable for industrial large-scale production.

Owner:ANHUI DONGTAI AGRI SCI & TECH DEV CO LTD

Method for coloring magnesium-aluminum alloy surface

The invention provides a method for coloring a magnesium-aluminum alloy surface. The conditions for coloring a yellow color through electroplating are as follows: a KMnO4 solution with a concentration of 30 g / L is adopted, the temperature is 20 to 25 DEG C, the voltage is 15 V, and the time is 5 to 8 minutes. The conditions for coloring a red color through electroplating are as follows: a CuSO4 solution with a concentration of 30 g / L is adopted, the temperature is 20 to 25 DEG C, the voltage is 15 V, and the time is 5 to 8 minutes. The conditions for coloring a purple color through electroplating are as follows: a mixed solution, which is prepared by mixing a CuSO4 solution with a concentration of 40 g / L and a H2SO4 solution according to a volume ratio of 1:1, with a concentration of 30 g / L is adopted, the temperature is 20 to 25 DEG C, the voltage is 15 V, and the time is 3 to 6 minutes. The provided method is simple, the colors electroplated on the alloy surface are more next to the standard colors, and the coloring quality is improved.

Owner:WUXI HONGSHENG ALUMINUM IND

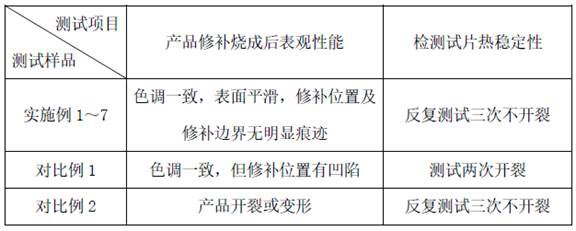

Sanitary ware repairing glaze and preparation method thereof

The invention discloses sanitary ware repairing glaze and a preparation method thereof, the sanitary ware repairing glaze comprises the following raw materials by weight percentage: 10-20% of low-melting-point glass powder, 15-30% of spodumene, 50-74% of surface glaze and 0.3-0.8% of nano La2O3, wherein the initial melting temperature of the low-melting-point glass powder is 400-530 DEG C. The sanitary ware repairing glaze has the advantages of high color consistency before and after repair, good thermal stability of the repair position, improvement of the repair superior rate, low re-burningtemperature, and solving of the problems of mismatching of the repair position and the main body color, and high proportion of burnt and deformed products after re-burning. According to the preparation method of the sanitary ware repairing glaze, the prepared sanitary ware repairing glaze mud and sanitary ware repairing glaze slip cannot crack due to rapid drying, the bonding property with a sanitary ware main body is good, no crack exists at the bonding boundary, and the problems that the repairing position or boundary is prone to drying and cracking, and the repairing effect is poor are solved.

Owner:江门市东鹏智能家居有限公司 +1

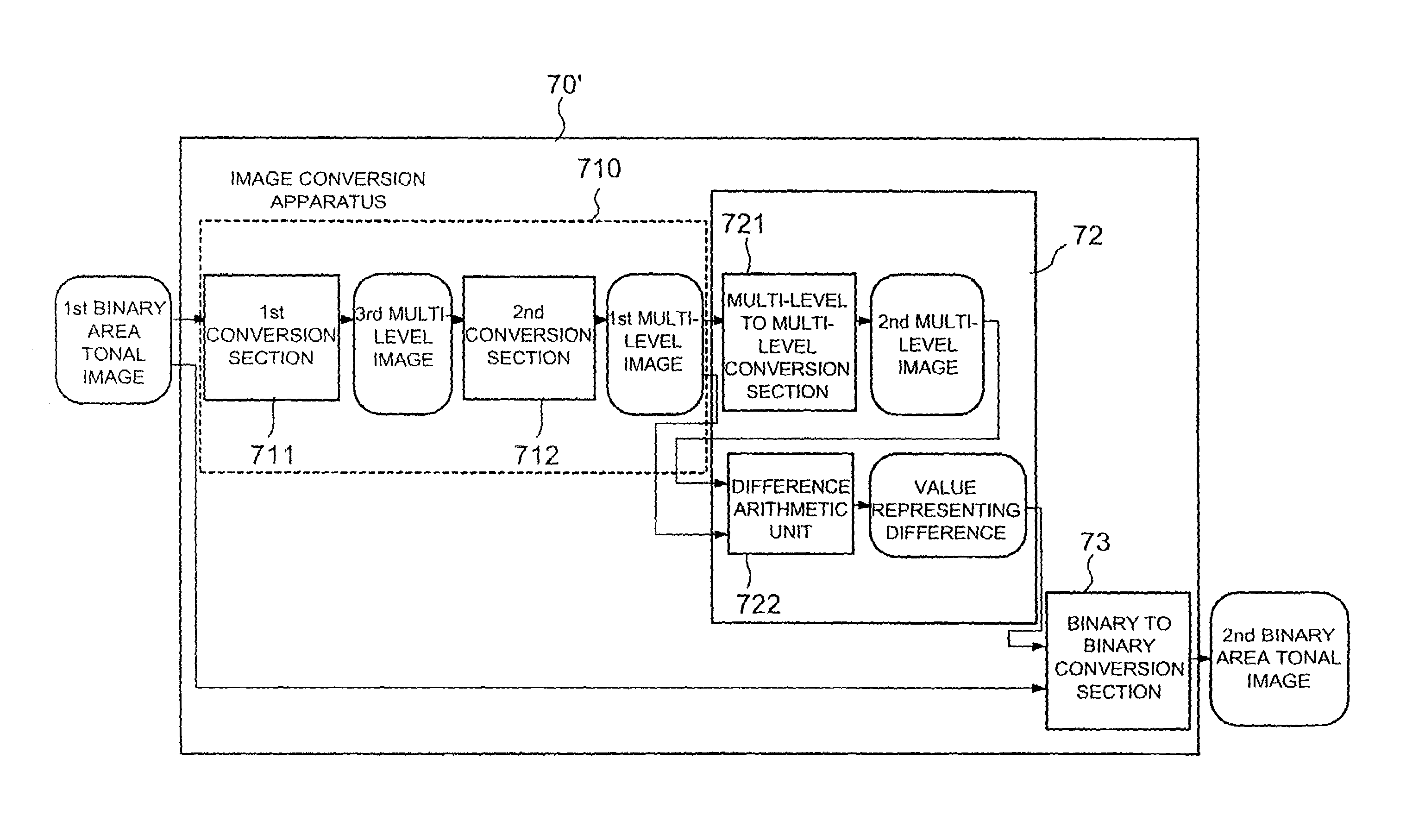

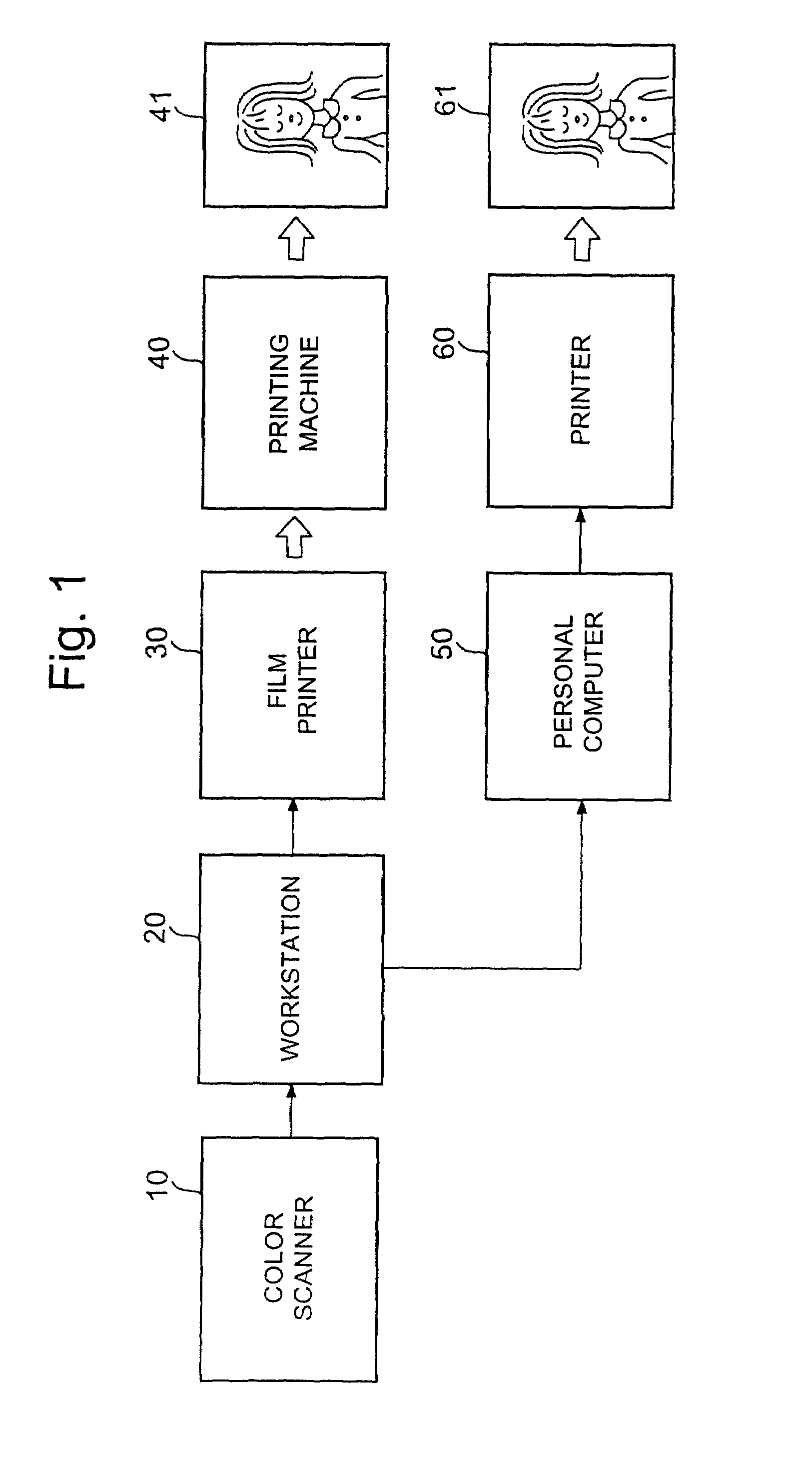

Image conversion method, image conversion apparatus, and image conversion program storage medium

InactiveUS7224486B2Increase and decrease areal ratioClose in colorDigitally marking record carriersDigital computer detailsComputer graphics (images)Image conversion

In an image conversion method of performing an image conversion between binary area tonal image-to-binary area tonal image, an image conversion apparatus, and an image conversion program storage medium storing an image conversion program which causes a computer to operate as such an image conversion apparatus, a binary area tonal image is once converted into a multi-level image, and pixel values of the multi-level image are converted. An areal ration of each divided area corresponding to the associated pixel of the multi-value image, of the original binary area tonal image is increased or decreased in accordance with the difference value between the pixel values of the associated pixels between the multi-value image after conversion of the pixel value and the multi-value image before conversion of the pixel value.

Owner:FUJIFILM HLDG CORP +1

Liquid crystalline epoxy nanocomposite material and application thereof

ActiveUS8309632B2Low shrinkageImprove wear resistanceImpression capsSurgical adhesivesEpoxyLiquid crystalline

The invention provides an epoxy nanocomposite material for dental therapy, which can be applied to direct or indirect clinical restoration, dental core-post system, and dental brace etc. The epoxy nanocomposite filling material provided by the invention can be polymerized with various curing agents to form the polymer with low shrinkage.

Owner:NAT TAIWAN UNIV

Light source system and projection system

ActiveUS10139713B2Low utilization efficiencyClose in colorProjectorsColor photographyFluorescenceScattering loss

A light source system includes an excitation light source emitting excitation light in at least first and second time intervals; a compensation light source emitting compensation light in at least third time intervals, the compensation light including laser light of at least one color; and a rotating color wheel, including at least first and second regions, the first region generating light of at least two different colors in time sequence under irradiation of the excitation light in the first and second time sequences, and the second region transmitting the compensation light in at least the third time sequence. The light of the at least two different colors includes at least one type of wide-spectrum fluorescence, and the laser compensates for the fluorescence or light split from the fluorescence. The compensation light is directly transmitted without being irradiated upon fluorescent powder, so scattering loss of the compensation light is reduced.

Owner:APPOTRONICS CORP LTD

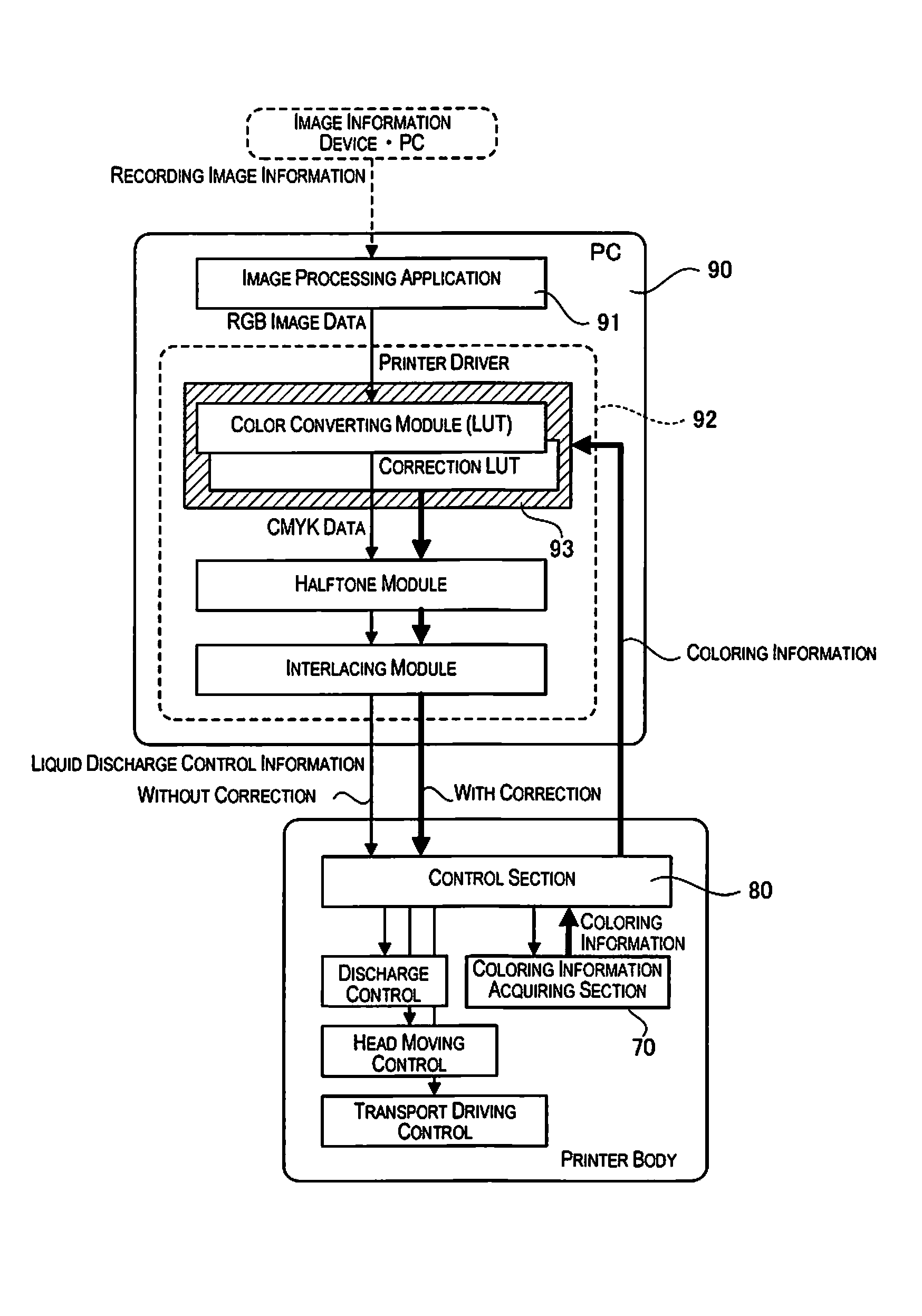

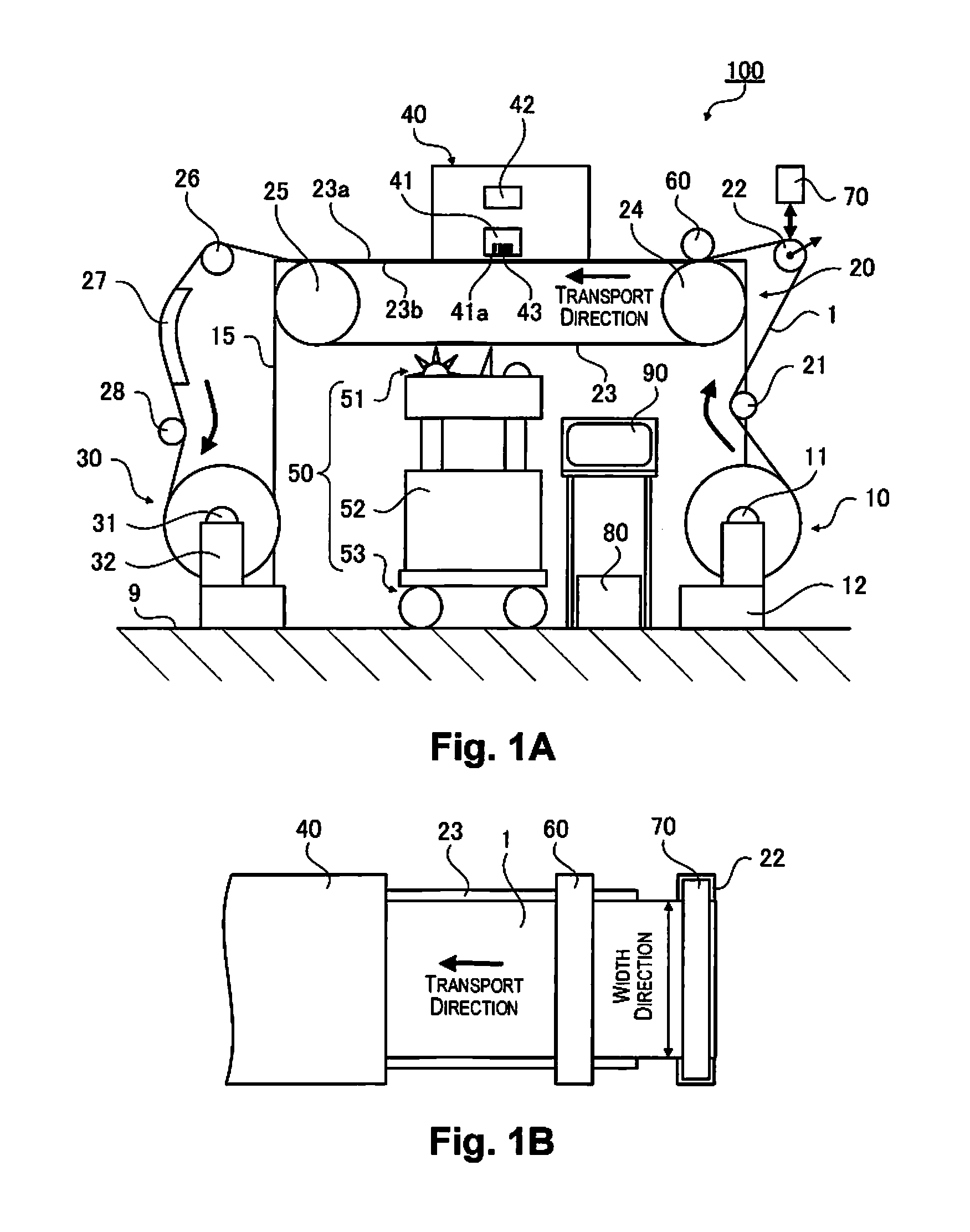

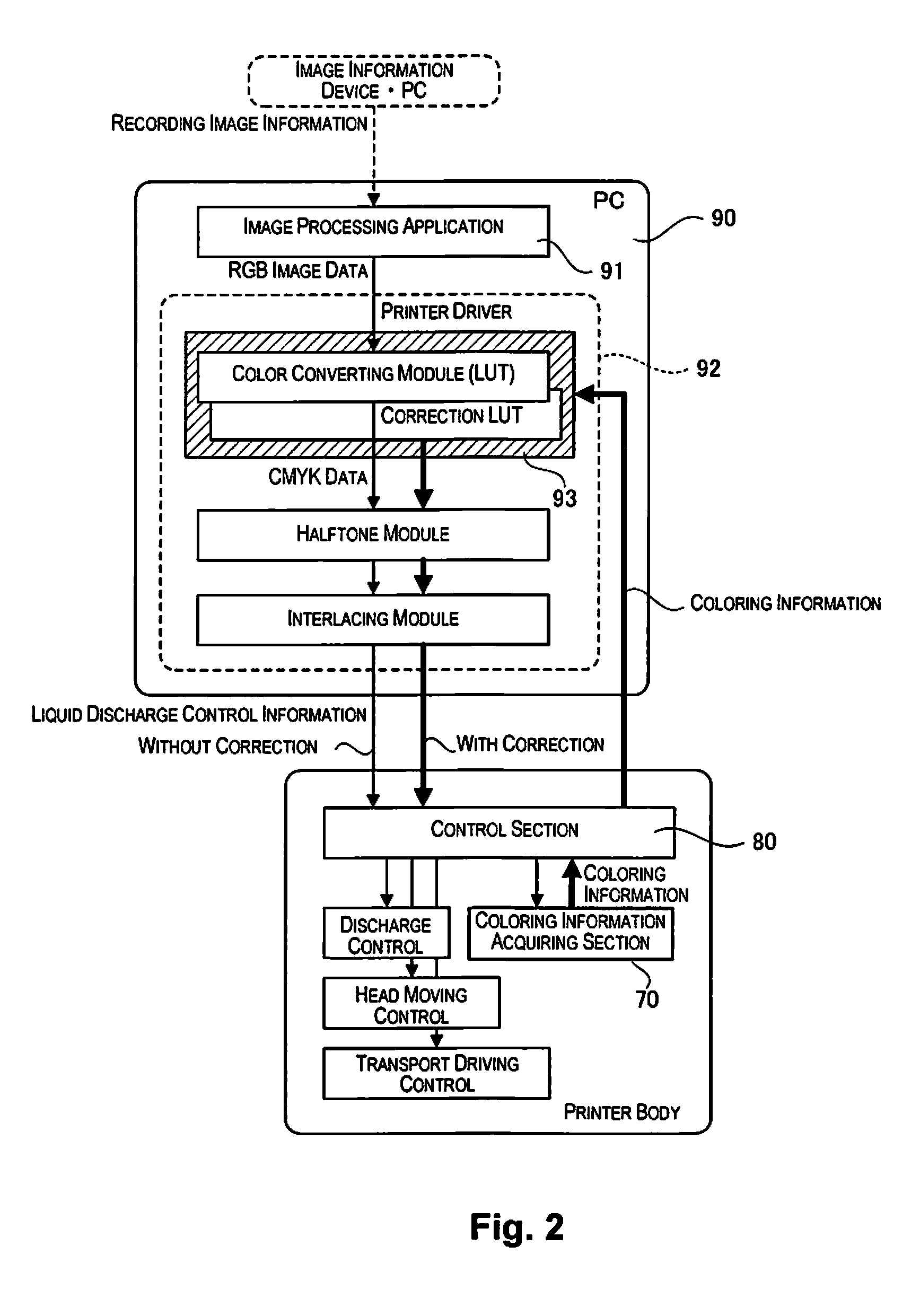

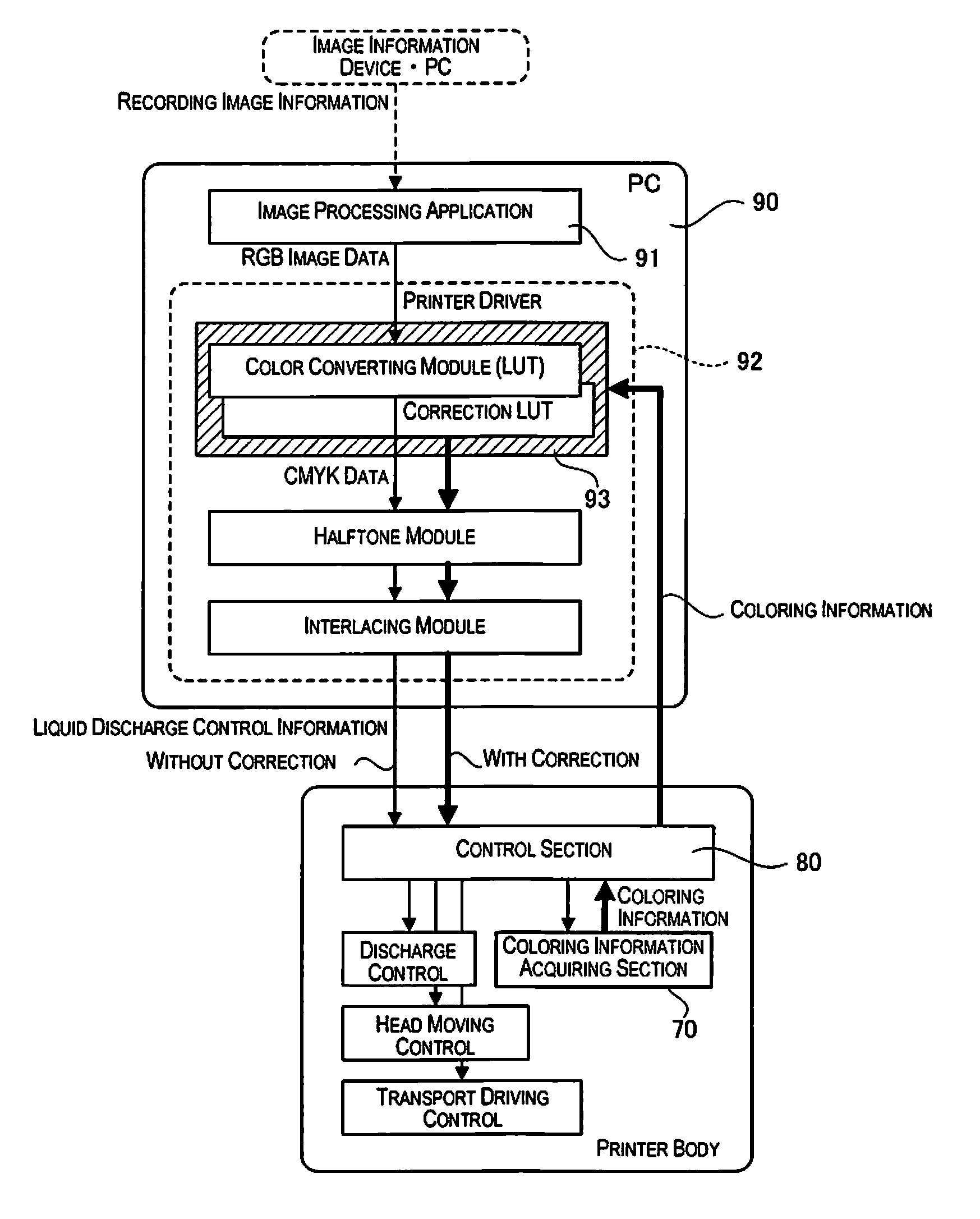

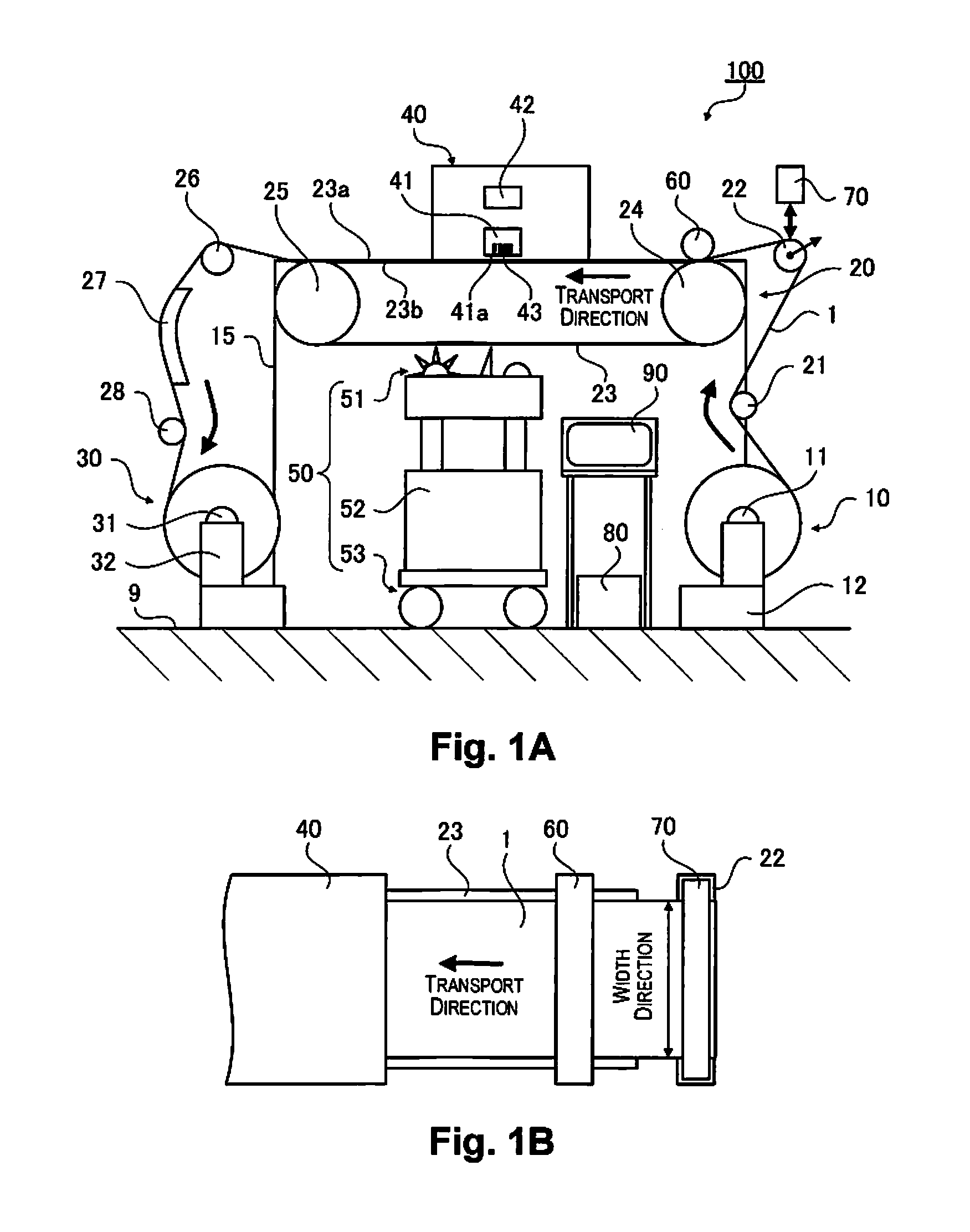

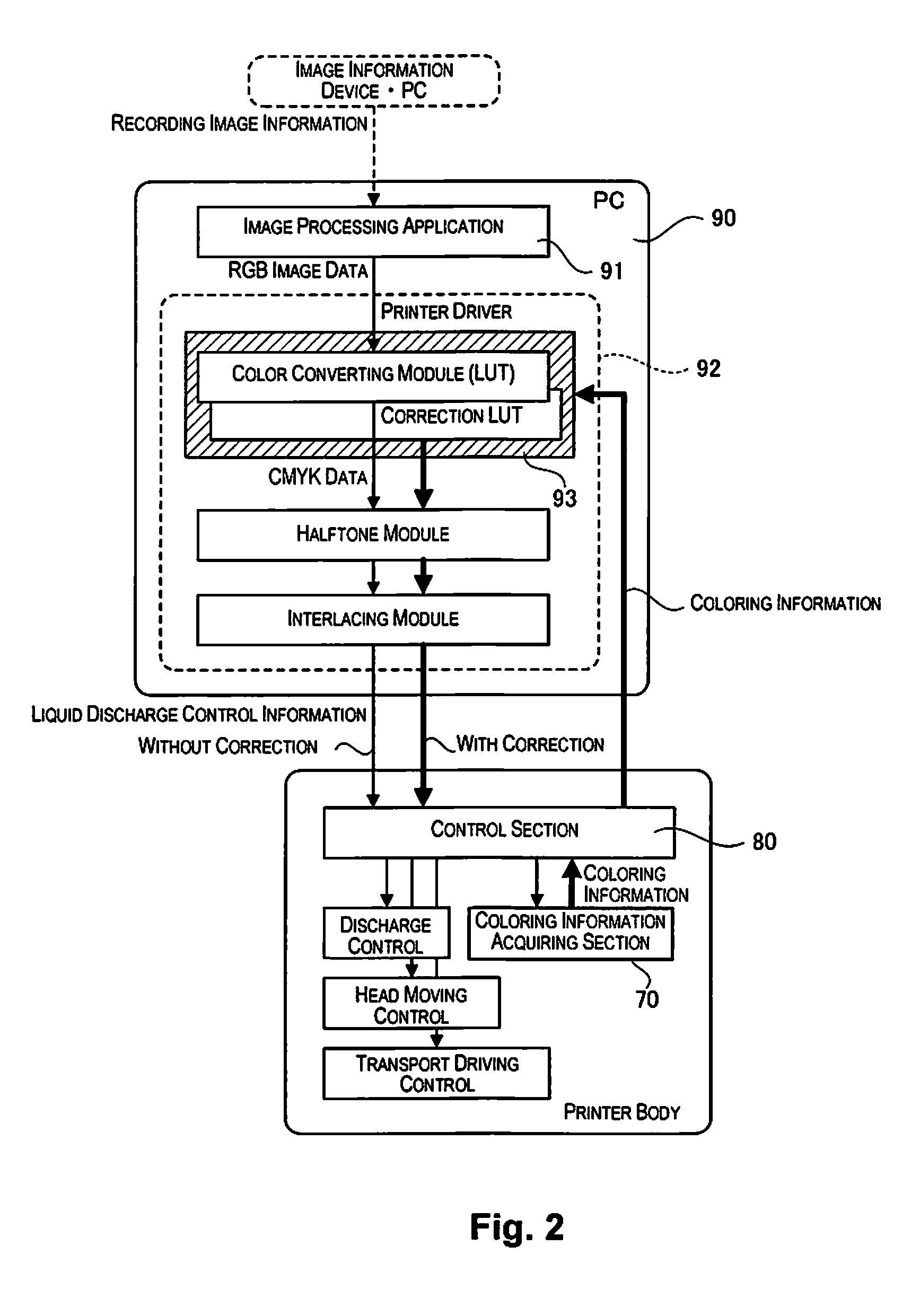

Liquid discharging apparatus and liquid discharging method

ActiveUS9278544B2Conveniently record (print)Improve productivityTypewritersDyeing processTextile printerMechanical engineering

A liquid discharging technique is provided that conveniently carries out recording (printing) with a desired coloring relative to media (fabric or the like) with various characteristics such as an ink color development property. A textile printing apparatus 100 is a liquid discharging apparatus which discharges a liquid (an ink) onto a recording medium (a fabric 1) and records an image and includes a liquid discharging section (a head 41) which discharges the ink onto the fabric 1 based on correction image information which is corrected according to coloring information for the fabric 1 which is obtained from the fabric 1 which is supplied to the textile printing apparatus 100.

Owner:SEIKO EPSON CORP

White-balance color temperature measuring device for image pick-up device

InactiveUS20150222868A1Close in colorTelevision system detailsRadiation pyrometryCamera phoneMeasurement device

A white-balance color temperature measuring device for image pick-up device includes a white or gray light transmitting sheet and a color temperature sensing element and installed in a camera body of a camera, camera phone, video camera or any other image pick-up device such that when focusing or pressing the shutter, incident light is changed by white or gray light transmitting sheet into a neutral light that falls upon the color temperature sensing element, causing the color temperature sensing element to induce a spot color temperature signal and to provide the signal to a CPU for processing, and thus, the color of the captured photos or images can be close to the natural colors of the shooting scene.

Owner:WU NA +1

White balance calibration method based on skin color data and image processing apparatus using the same

ActiveUS10757386B2Avoid mistakesEasy to interfereImage enhancementImage analysisPattern recognitionImaging processing

Disclosed are a white balance calibration method based on skin color data and an image processing apparatus using the same. By using the method and the image processing apparatus, weight allocation of the skin color data in an input image may be adaptively performed to avoid white balance calibration errors due to excessive skin color data. Therefore, the present disclosure can further solve an issue that in video applications, the white balance calibration is easily interfered by a large amount of the skin color data. Moreover, the present disclosure may be adapted to different color temperatures and may output images having colors closer to actual colors.

Owner:REALTEK SEMICON CORP

Liquid discharging apparatus and liquid discharging method

ActiveUS20150054875A1Reduce and eliminate effectConveniently record (print)TypewritersDyeing processTextile printerEngineering

A liquid discharging technique is provided that conveniently carries out recording (printing) with a desired coloring relative to media (fabric or the like) with various characteristics such as an ink color development property. A textile printing apparatus 100 is a liquid discharging apparatus which discharges a liquid (an ink) onto a recording medium (a fabric 1) and records an image and includes a liquid discharging section (a head 41) which discharges the ink onto the fabric 1 based on correction image information which is corrected according to coloring information for the fabric 1 which is obtained from the fabric 1 which is supplied to the textile printing apparatus 100.

Owner:SEIKO EPSON CORP

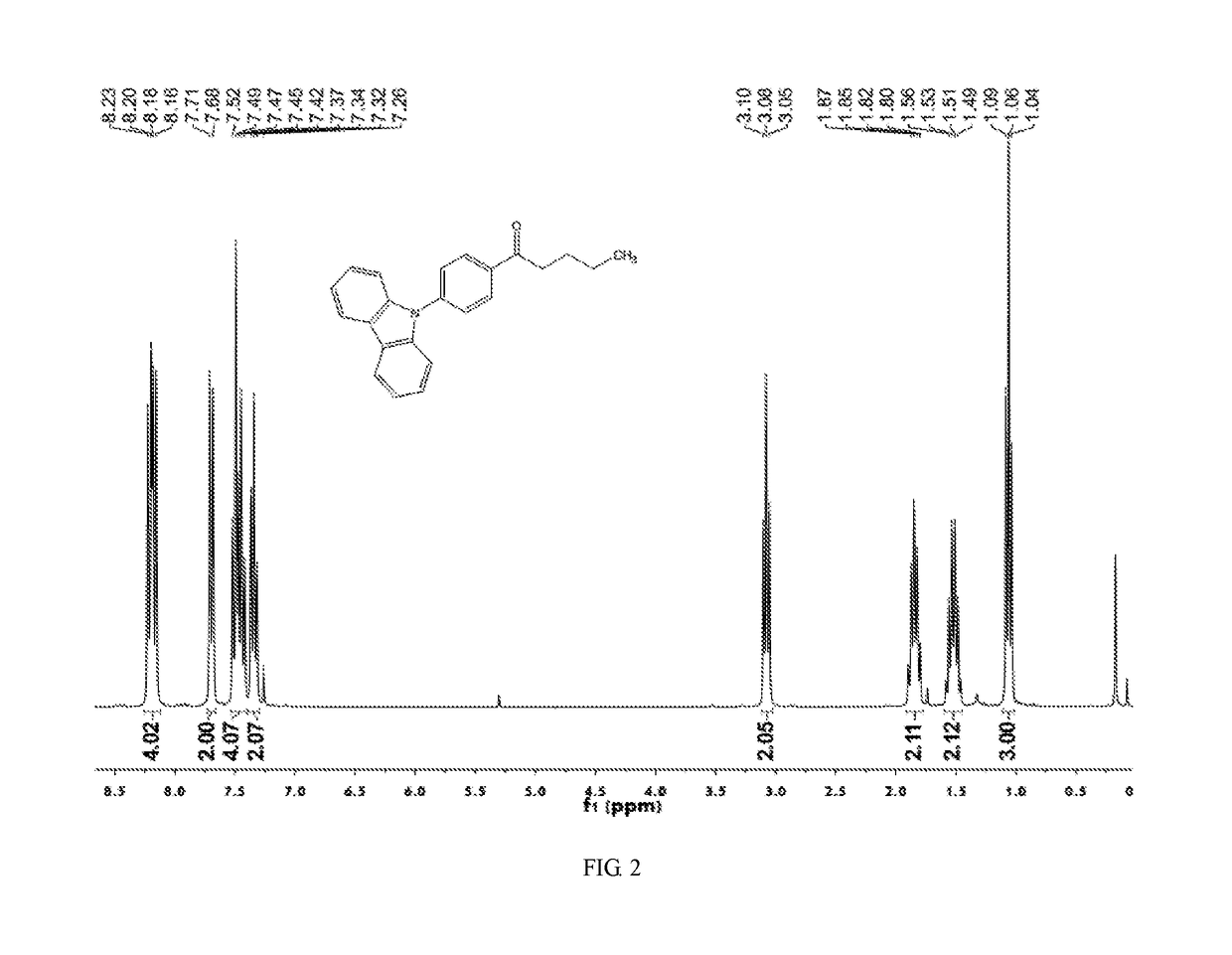

Organic electroluminescent material

InactiveUS20180297950A1High color purityHigh fluorescence quantum efficiencyOrganic chemistrySolid-state devicesFluorescenceElectron

The present invention discloses an organic electronic luminescent material, with the chemical formula (I). The compounds having the chemical formula (I) in the present invention have highly stable electron-withdrawing groups and electron-donating groups with stable chemical bonds between them but without a strong conjugation. With these features, the compounds with the formula (I) have high fluorescence quantum efficiency and excellent charge transport ability. These compounds are closer to the dark color of international standard, which is conducive to achieve full color displays with higher color purity.

Owner:GUANGDONG AGLAIA OPTOELECTRONICS MATERIALS +1

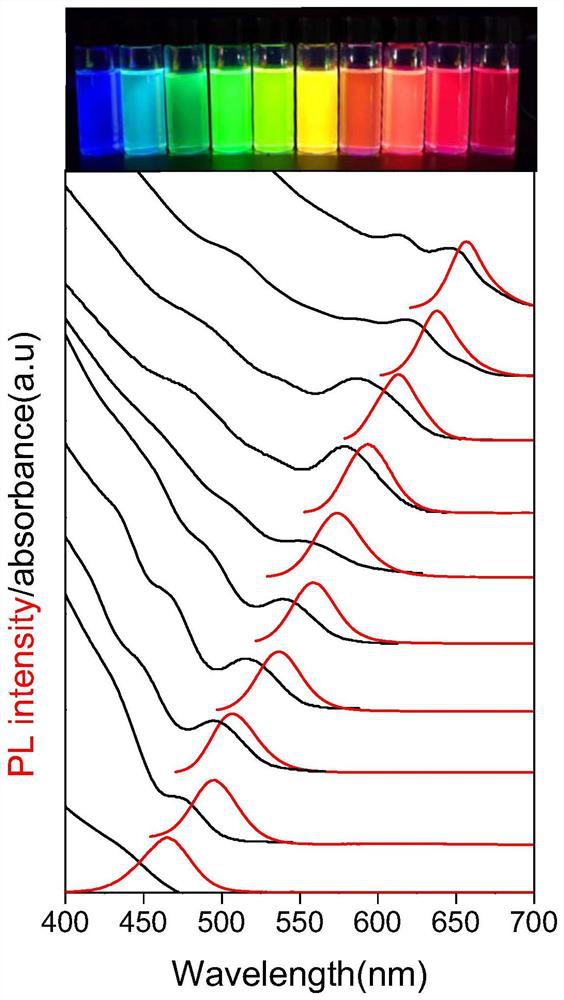

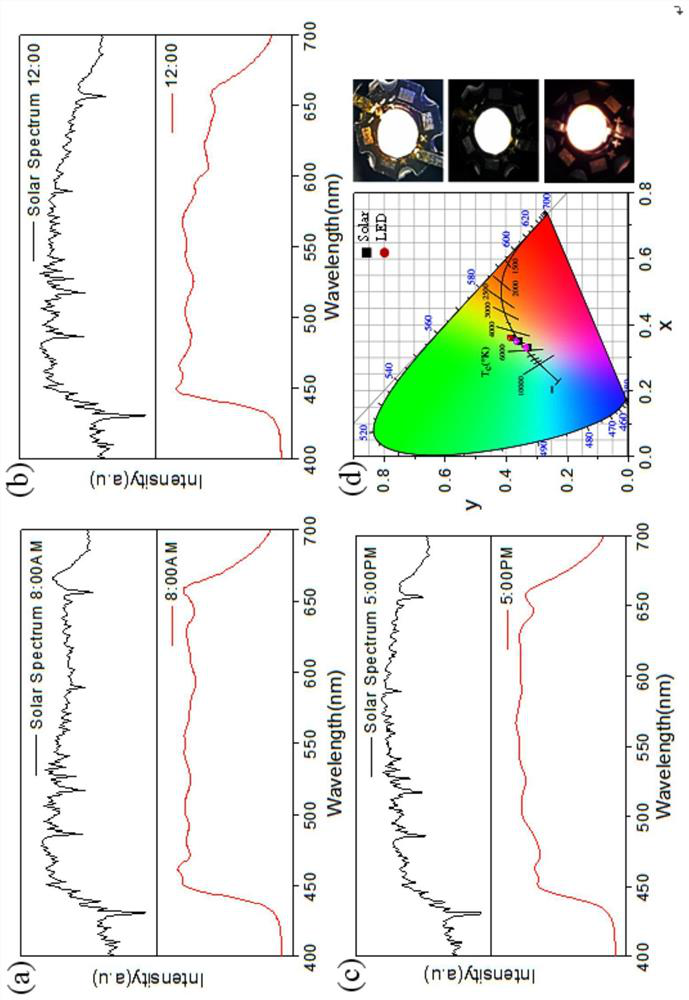

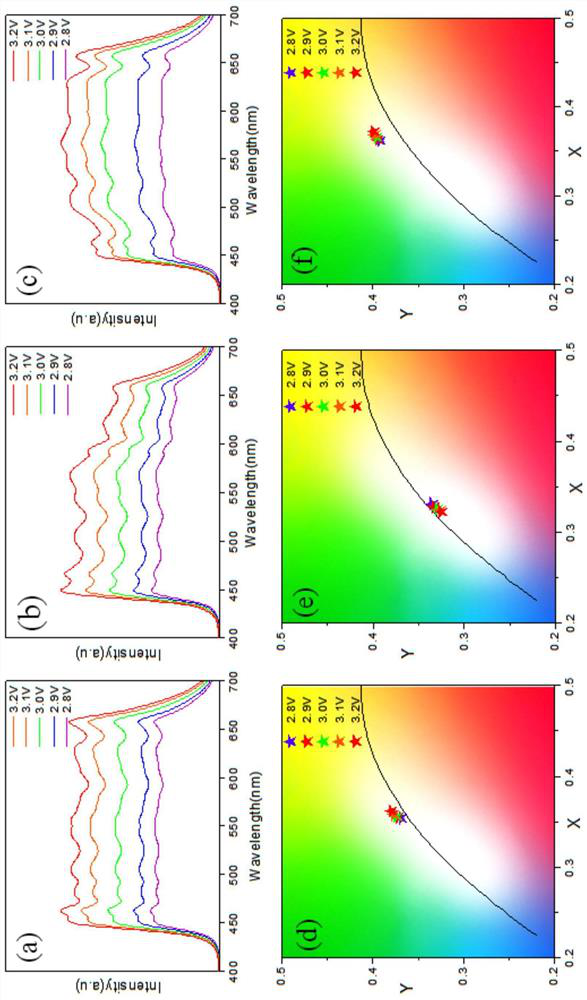

Quantum dot-based manufacturing method for simulating solar spectrum wled and smart light bulb

ActiveCN110718618BSymmetrical emission spectrumGood fluorescence stabilityMaterial nanotechnologyNanoopticsEpoxyQuantum yield

The invention relates to the technical field of bright lighting, in particular to a solar spectrum simulation WLED manufacturing method based on a quantum dot, and the method comprises the following steps: (A) synthesizing CdSe / ZnS core-shell quantum dot solvents in various sizes; (B) synthesizing CdSe / CdS core-shell quantum dot solvents in various sizes; (C) mixing the various solvents obtained at the steps A and B, mixing the mixture solvents with epoxy resin, and performing uniform stirring; (D) dropwise adding the mixture obtained at the step C onto the surface of a GaN chip, and performing heating in a vacuum oven to obtain a WLED. The invention further discloses a smart lamp bulb made of the WLED. Due to the quantum confinement effect of the quantum dots, the CdSe core-shell quantumdots have many advantages compared with traditional fluorescent materials, such as symmetrical emission spectrum, strong fluorescence stability, narrow full width at half maximum and high fluorescencequantum yield; by changing the size and chemical composition of the semiconductor quantum dots, the fluorescence emission wavelength can cover the whole visible region, and the method is very practical.

Owner:JILIN UNIV

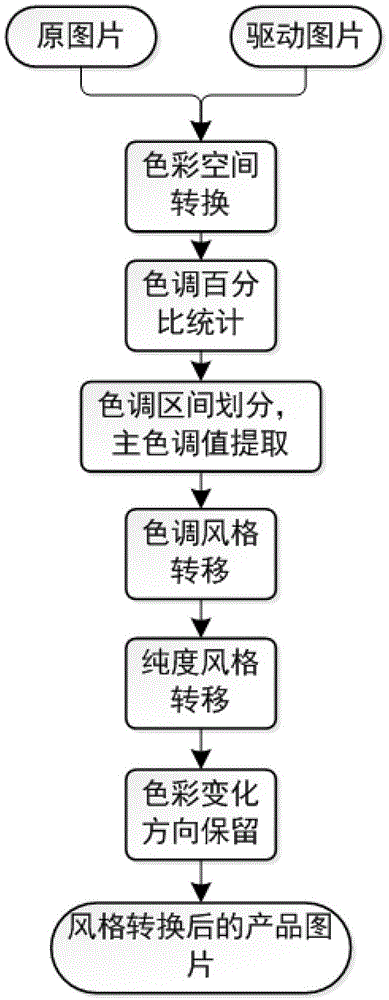

Method for rapidly rematching colors of product appearance based on color style transfer

The invention discloses a method for rapidly rematching colors of product appearance based on color style transfer, which comprises the following steps: extracting hue regions of main colors and dominant hue values in an original image and a drive image, completing transfer of hue transfer, revising colors for a transformed picture by utilizing value in an HVS (hue, saturation and value) color space and completing transfer of value style. The invention provides the method which can keep a same color shading trend of the drive image and transfer the trend to the original image to complete the transfer of the color shading style, can keep textural features when embodying the color style of the drive image to the greatest extent, and can realize fast conversion for designed color style of the product appearance.

Owner:ZHEJIANG UNIV

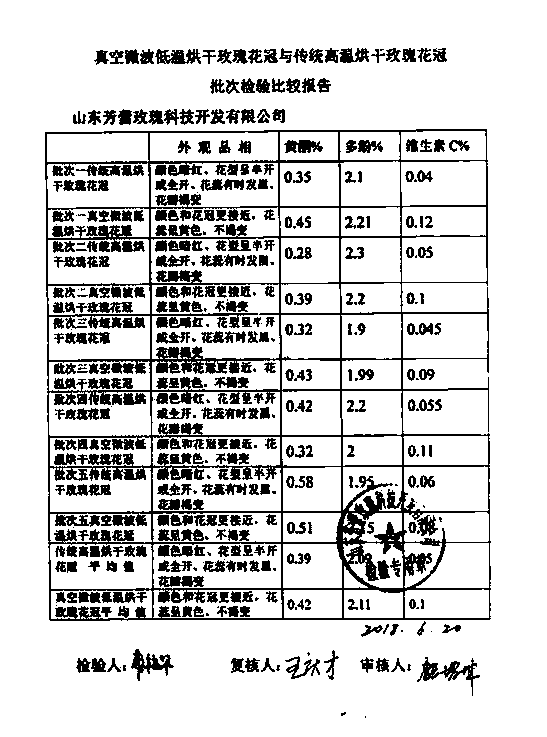

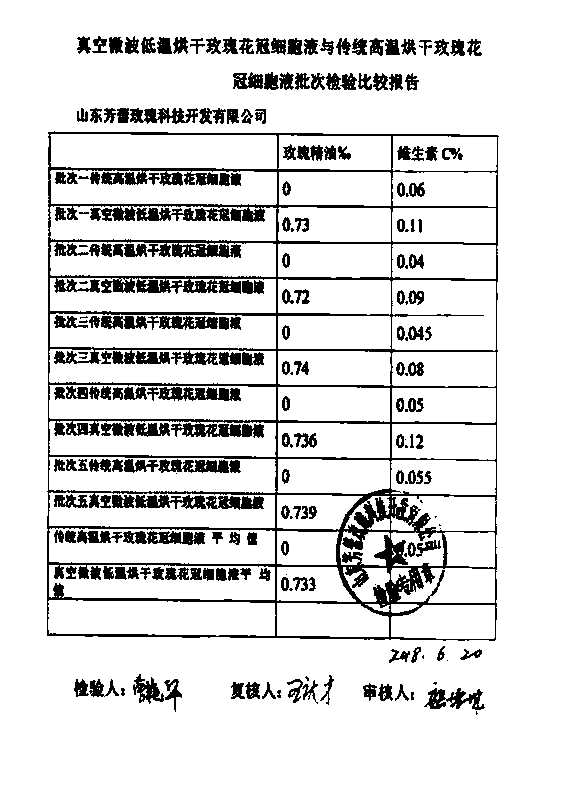

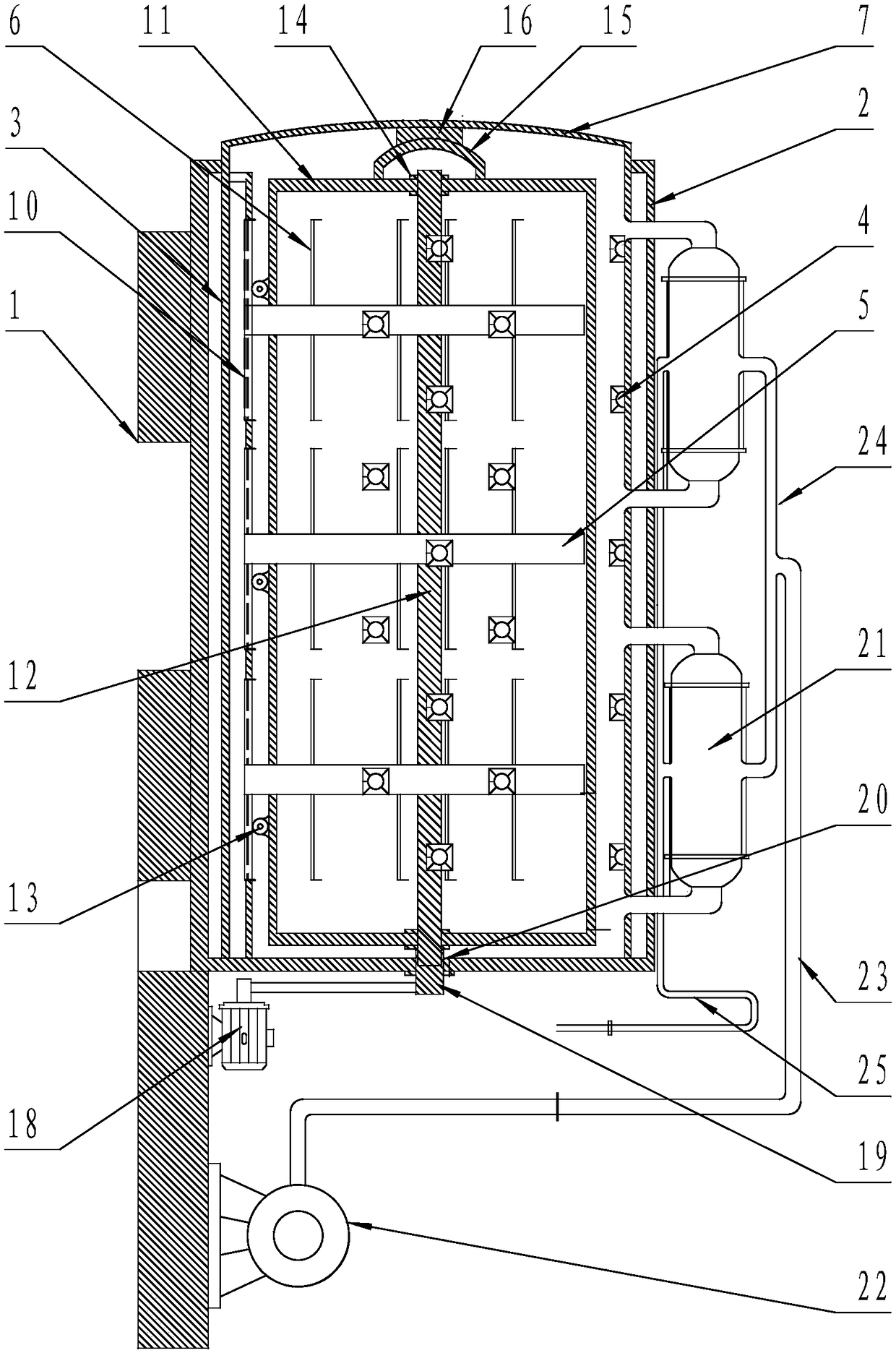

Vacuum microwave device for drying rose corolla and method thereof

PendingCN109489349AAchieve dryingReduce labor intensityDrying solid materials with heatDrying solid materials without heatMicrowaveAdditive ingredient

The invention discloses a vacuum microwave device for drying rose corolla and a method thereof. The vacuum microwave device comprises a frame, a box body, a cylindrical vacuum tank body and microwavegenerators, and further comprises a rose corolla drying material vehicle, a cylindrical vacuum tank vacuumizing and rose corolla cell solution collecting and condensing device, and a rose corolla shaping device; the rose corolla drying material vehicle can enter into or exits from a circular opening in the front end of the cylindrical vacuum tank body and can be pushed in the vacuum tank body along guide rails mounted on two sides of the bottom of the inner surface of the cylindrical vacuum tank body and provided with grooves in the axial direction; and the rose corolla shaping device is arranged on the bottom of a rose corolla material frame. The quality and the efficiency of the dried rose corolla are improved, the labor intensity of operators for drying the rose corolla is reduced, thenatural nutritional ingredient and the fragrance of a cell solution of the rose corolla are improved, the quality of the cell solution of the rose corolla is improved, and the dried rose corolla is full in appearance, is unfolding, and is bright in color.

Owner:山东芳蕾玫瑰科技开发有限公司 +1

A kind of preparation method of ultrafine pulverized green tea powder

The invention relates to the technical field of tea processing. The fresh tea is firstly washed and drained for later use, and then crushed into large particles, and 1 / 10 of the enzymolysis solution is sprayed on the surface of the tea leaves, and the tea leaves are stirred during the enzymolysis. After the enzymatic hydrolysis technology, use a greening machine to kill the green leaves until the fresh leaves are evenly steamed until there is no grassy smell, and then put them into the color protection solution at 20-25°C for soaking, and repeatedly soak in ice water to cool down, and drain the water. Line liquid nitrogen freezing treatment, and carry out vacuum freeze-drying treatment. After the end, the airflow pulverizer is used to pulverize the green tea powder at 15° C. until the average particle diameter is less than 20 μm. The ultrafine pulverized green tea powder prepared by the preparation process of the present invention uses conventional green tea as a raw material, thereby reducing production costs and labor costs. The finished product not only has low bitterness and astringency, but also has greener green tea pink color, better aroma and solubility, and can effectively maintain the original color, fragrance and quality of tea, increase the quality of tea soup, and make the overall quality of green tea powder better. Close to matcha quality.

Owner:SICHUAN UNIV

Coating process of ceramic product and the ceramic product

The invention discloses a coating process of a ceramic product and the ceramic product. The coating process comprises the following steps: a, mixing semitransparent extinction powder and printing varnish according to a mass ratio of 10:11, and grinding the mixture into a painted mixture A by using a grinder; b, mixing semitransparent embossment powder, an embossment cooling agent and printing varnish according to a mass ratio of 5:5:11, and grinding the mixture into a painted mixture B by using a grinder; c, under the conditions that the environment temperature is 25-26 DEG C and the humidityis 50-60%, evenly spraying the paint-like mixture A to the surface of the porcelain in a fine mist mode through the spray gun, then airing the porcelain, and performing secondary spraying until the first spraying object is evenly covered with the secondary spraying material, and then airing the porcelain; d, under the conditions that the environment temperature ranges from 25 DEG C to 26 DEG C andthe humidity ranges from 50% to 60%, evenly spraying the paint-shaped mixture B is evenly on the paint-shaped mixture A through a spray gun until the paint-shaped mixture A is completely covered withthe paint-shaped mixture B, and then air-drying the porcelain; and e, firing the sprayed porcelain in a kiln. The coating process can be implemented on a glazed porcelain body and can also be implemented on an unglazed porcelain body, and the processed porcelain has an unglazed visual effect and has the advantages that a glazed porcelain product is not prone to water seepage and dirt seepage, notprone to scratching, easy to clean and the like.

Owner:唐山市琨窑陶瓷有限公司 +1

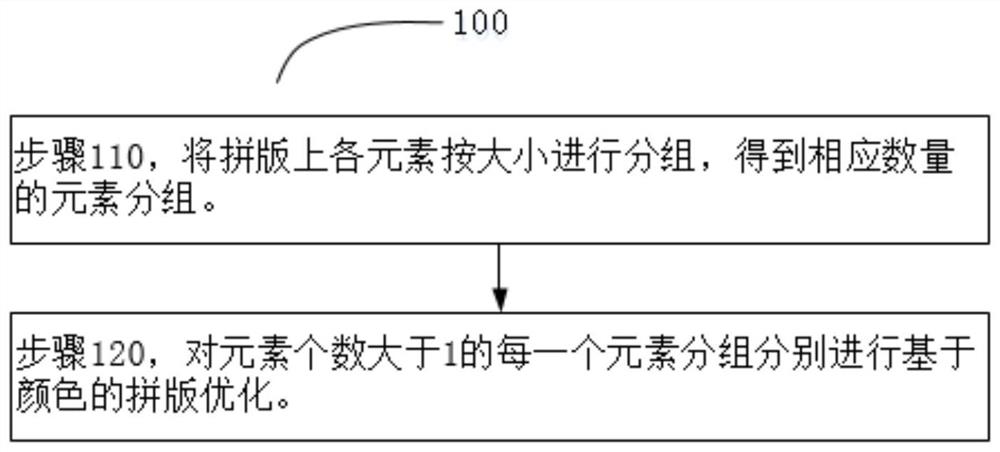

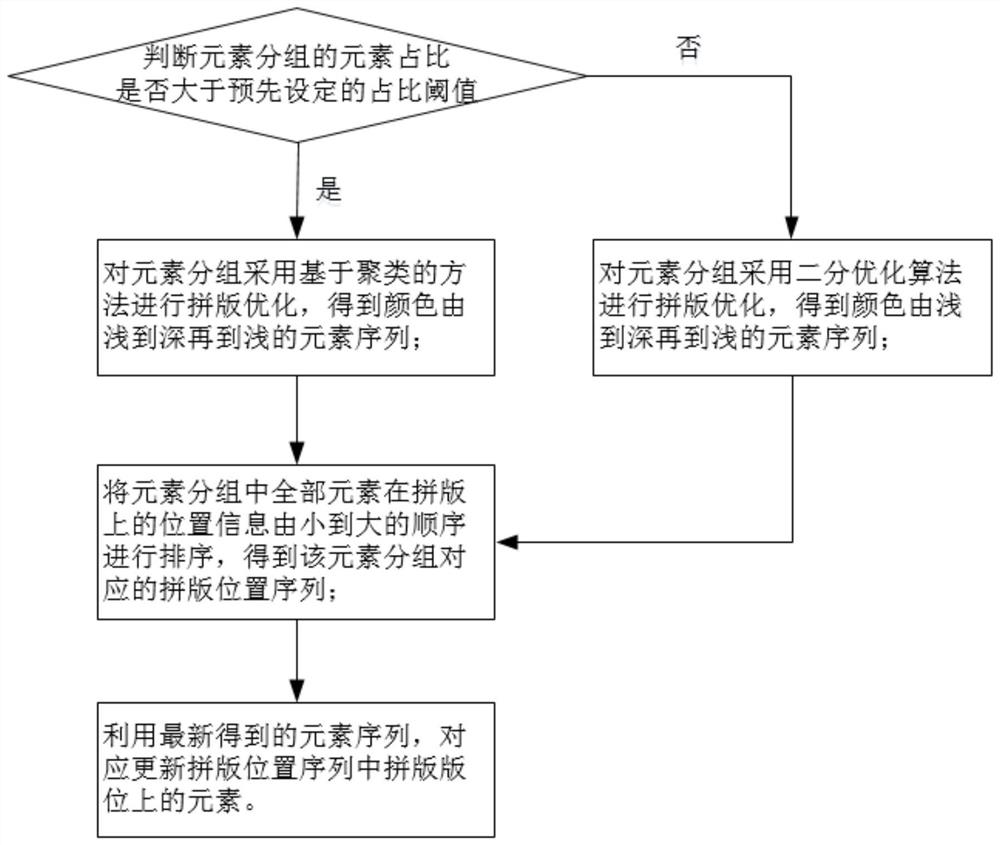

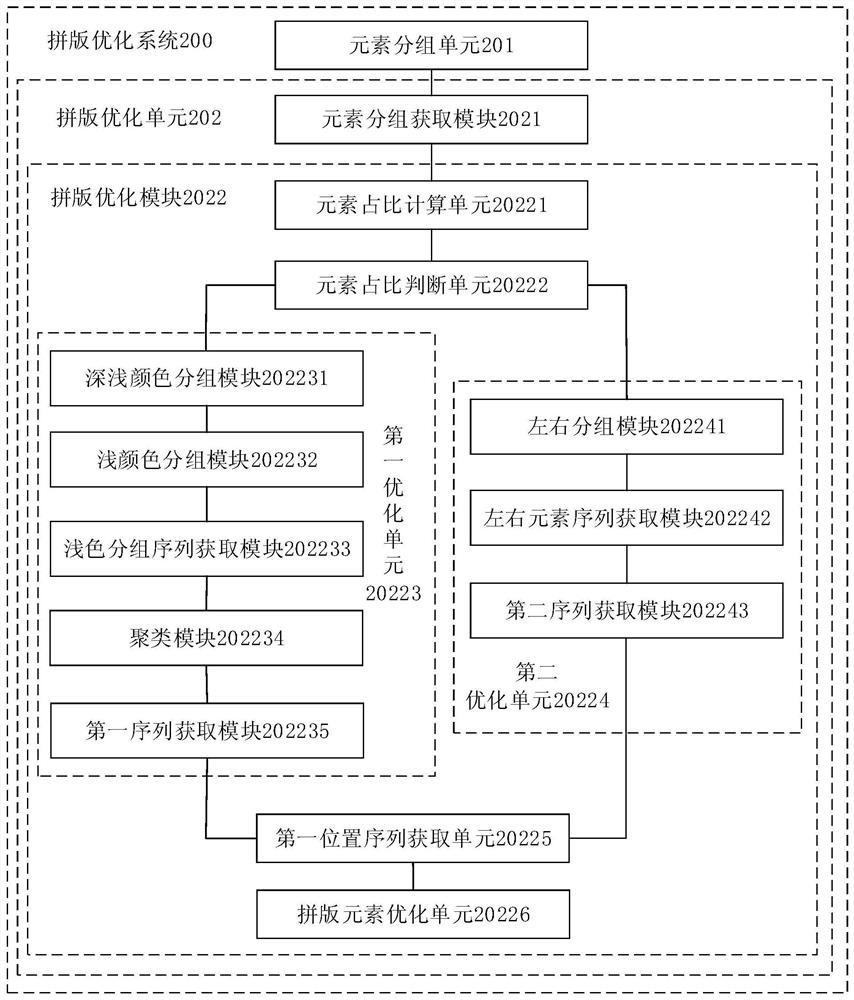

Makeup optimization method and system

ActiveCN112365047AReduce workloadAvoid influenceForecastingCharacter and pattern recognitionAlgorithmThresholding

The invention provides a makeup optimization method and system. The makeup optimization method and system can both comprise: grouping elements on a makeup to obtain a corresponding number of element groups; performing color-based makeup optimization on each element group of which the number of elements is greater than 1, wherein the color-based makeup optimization comprises the following steps: determining whether the element proportion of an element group is greater than a proportion threshold value or not, and if so, performing makeup optimization on the element group by a clustering-based method to obtain an element sequence of which the color is changed from light to deep and then to light, if not, performing makeup optimization on the element group by a binary optimization algorithm to obtain an element sequence of which the color is changed from light to deep and then to light, sorting the position information of all the elements in the element group on the makeup based on sizesin an ascending order to obtain a corresponding makeup position sequence; and correspondingly updating the elements on the makeup positions in the makeup position sequence by utilizing the latest obtained element sequence. The method is used for avoiding the influence of makeup item colors on the printing process and reducing the workload of printing personnel.

Owner:世纪开元智印互联科技集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com