Sanitary ware repairing glaze and preparation method thereof

A sanitary ware and repair glaze technology, which is applied in the field of sanitary ware repair glaze and its preparation, can solve the problems of color mismatch at the repair position, low burnback temperature, poor repair effect, etc., and achieve high color consistency and low burnback temperature , The effect of reducing the ratio of burning and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

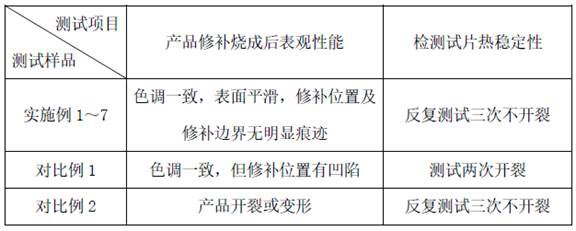

Examples

preparation example Construction

[0042] A preparation method of sanitary ware repair glaze for preparing the sanitary ware repair glaze includes the following steps:

[0043] The preparation step of the repair glaze slurry is to mix the raw materials of the repair glaze with water according to the formula amount, and calculate according to the weight percentage of the dry weight of the repair glaze. Add 0.25~0.35% of carboxymethyl cellulose, 0.5~1.5% of glycerin and 33 ~38% water, continue ball milling to obtain slurry, and then use plaster mold to absorb the water in the slurry to prepare a sanitary ware repair glaze;

[0044] And the repair glaze slurry preparation step, the repair glaze raw materials are mixed with water according to the formula amount, and calculated according to the weight percentage of the dry weight of the repair glaze raw materials, add 0.25-0.35% carboxymethyl cellulose and 33-38% water, Continue ball milling to obtain slurry, and then add water to adjust the specific gravity of the slurr...

Embodiment 1~5

[0058] A sanitary ware repair glaze is calculated according to weight percentage, and its raw material formula is shown in the following table.

[0059]

[0060] Among them, calculated by weight percentage, the chemical composition of low melting point glass powder is 55% SiO 2 , 23%B 2 O 3 , 2% Al 2 O 3 , 10%CaO, 1%MgO, 4%ZnO, 3%K 2 O and 2%Na 2 O, the initial melting temperature is 450℃;

[0061] Calculated by weight percentage, the chemical composition of spodumene is 7.5% Li 2 O, 1%K 2 O, 0.2%Na 2 O, 25% Al 2 O 3 , 65% SiO 2 , 0.5% CaO, 0.3% MgO and 0.5% ignition loss;

[0062] Calculated by weight percentage, the raw material components of the surface glaze are 25.5% of potash feldspar, 27.5% of quartz, 5.2% of kaolin, 3.5% of alumina, 10.8% of wollastonite, 3.8% of dolomite, 9.9% of calcium carbonate, Zirconium silicate 9.2% (average particle size <0.9µm), calcined zinc oxide 2.1%, frit 2.467%, and pigment 0.033% (the pigment is 0.011% cobalt blue and 0.022% zirconium iron red)...

Embodiment 6

[0073] The raw material formula is the same as in Example 2. The preparation method of sanitary ware repair glaze includes the following steps:

[0074] The preparation step of the repair glaze mud is to mix the raw materials of the repair glaze with water according to the formula amount, and calculate according to the weight percentage of the dry weight of the repair glaze. Add 0.35% carboxymethyl cellulose, 1.5% glycerin and 38% water. Continue ball milling to obtain the slurry, and then use a plaster mold to absorb the moisture in the slurry to prepare a sanitary ware repair glaze with a moisture content of 23%;

[0075] And the repair glaze slurry preparation step, the repair glaze raw materials are mixed with water according to the formula amount, calculated according to the weight percentage of the dry weight of the repair glaze raw materials, 0.35% carboxymethyl cellulose and 38% water are added, and the ball mill is continued to obtain the slurry And then add water to adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com