Processing technology of green tea

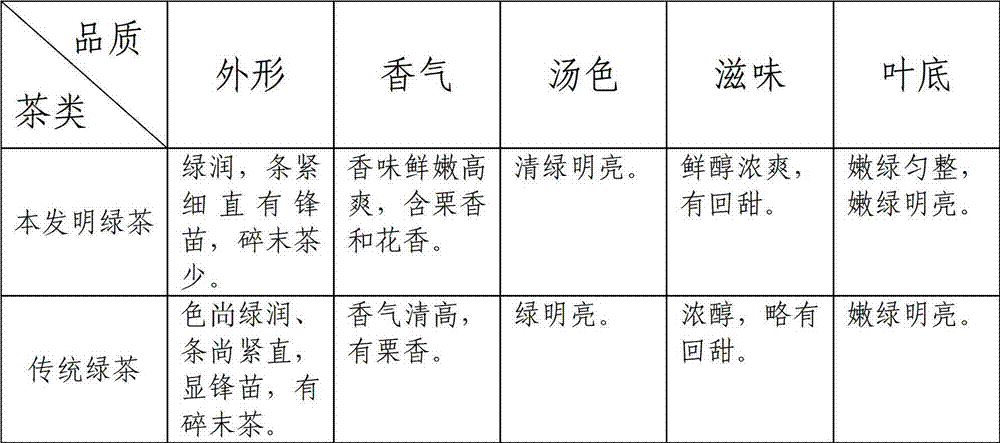

A processing technology, green tea technology, applied in the field of processing technology of fine new varieties of large leaf species in Yunnan, can solve the problems of excessive tea powder, loose strands, dull color, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1: The new shoots of the tea tree of the variety Foxiang No. 3 can be exploited when one bud and one leaf are first developed, and the fresh leaves should be packed in a clean bamboo basket. Centimeters, time 45 minutes, lightly turn once every 20 minutes; choose 6CH-70 fresh leaf classifier, classify according to large and small leaves, and classify and finish; use 6CH-70 type drum fixer, temperature 220 ° C, time 2 Minutes, the green leaves are immediately placed on the air-drying cloth and spread out for 20 minutes and blown to cool down; use the 6CH-65 type kneading machine to knead. Pressing method: light pressure for 8 minutes, heavy pressure for 20 minutes, loose pressure for 10 minutes, and time for 35 minutes; the green leaves are immediately spread on the air-drying cloth for 25 minutes, and the air is blown to cool down and then deblock; use 6CH-16 automatic drying Drying machine for initial drying, temperature 140 ℃, time 15 minutes, after the ini...

Embodiment 2

[0020] Embodiment 2: pick from the buds and leaves of Foxiang No. 3 tea garden, pick the standard one bud and one leaf or one bud and two leaves, put fresh leaves in a ventilated bamboo basket, do not squeeze, after sending to the factory for processing, the thickness of the spread leaves is 4 cm, The time is 50 minutes, and it is turned lightly once every 20 minutes; the 6CH-70 fresh leaf classifier is selected, classified according to the large and small leaves, and the classification is carried out; the 6CH-70 roller degreening machine is used to complete the greening, the temperature is 230 ° C, and the time is 3 minutes. The green leaves are immediately placed on the drying cloth and spread out for 20 minutes and blown to cool down; use the 6CH-65 type kneading machine to knead. Pressurization method: light pressure for 10 minutes, heavy pressure for 15 minutes, loose pressure for 10 minutes, and time for 35 minutes; the green leaves are immediately spread on the air cloth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com