Optimization modeling method for coupling of production and energy of continuous enterprises

A modeling method, continuous technology, applied in the field of information, can solve problems such as failure to integrate modeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

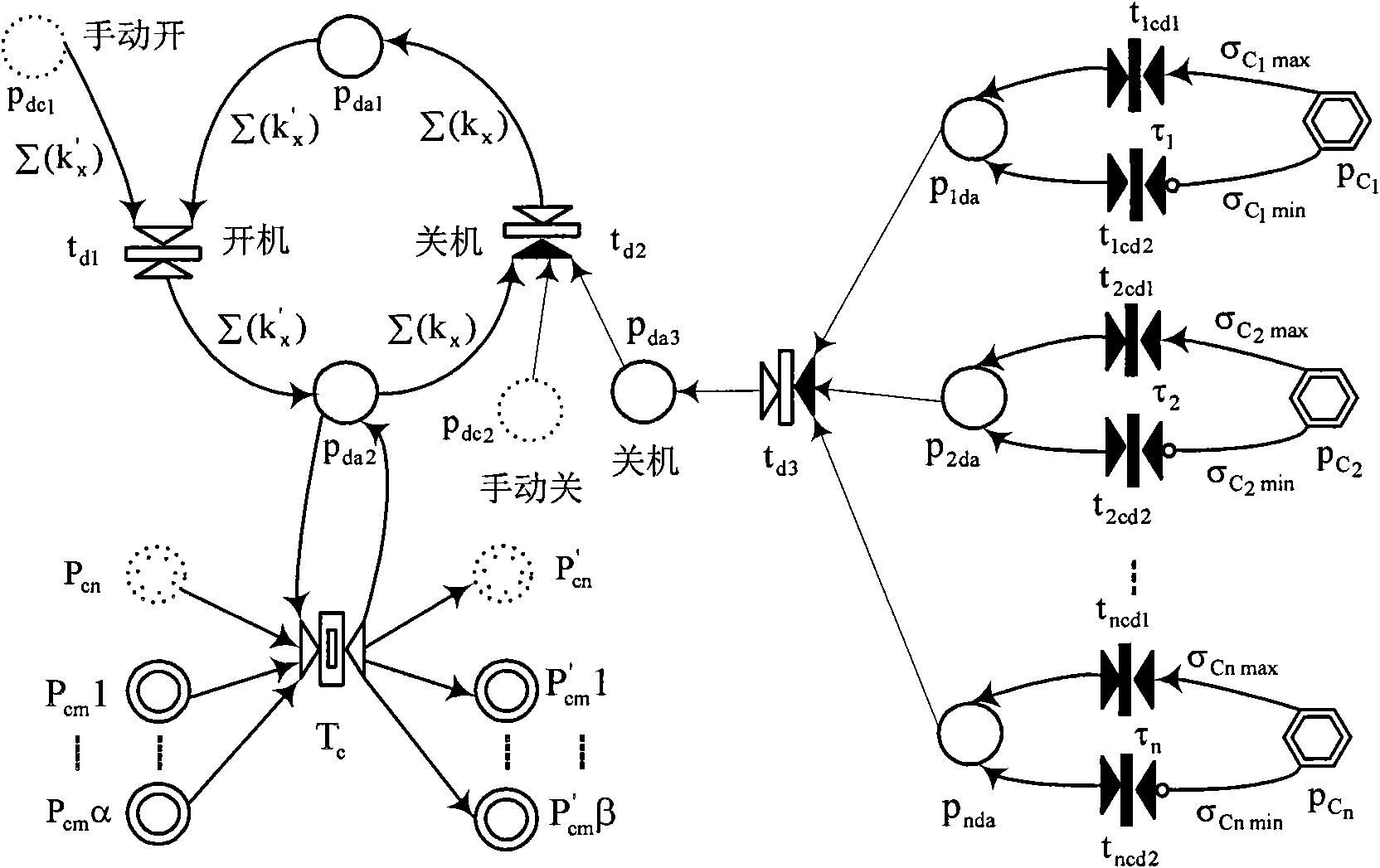

Method used

Image

Examples

Embodiment example

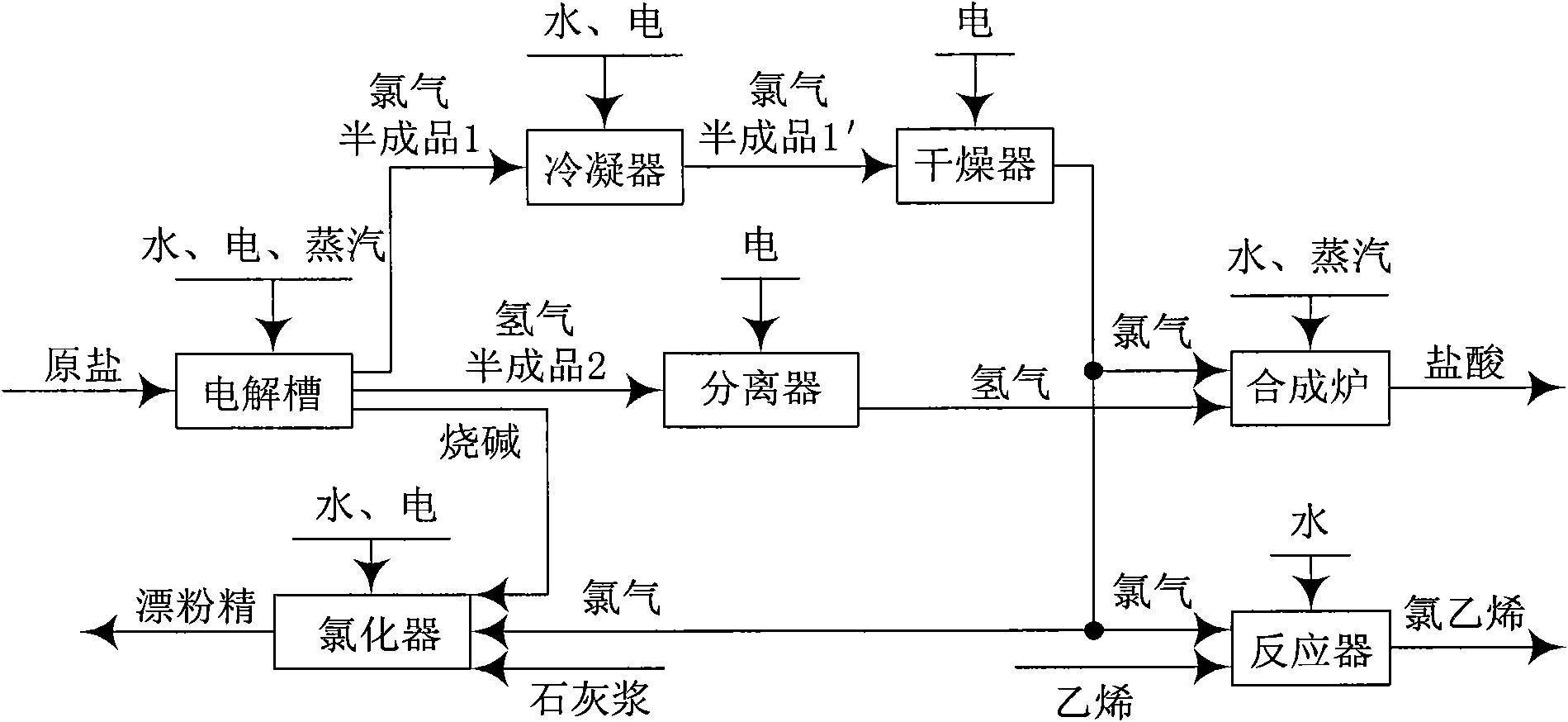

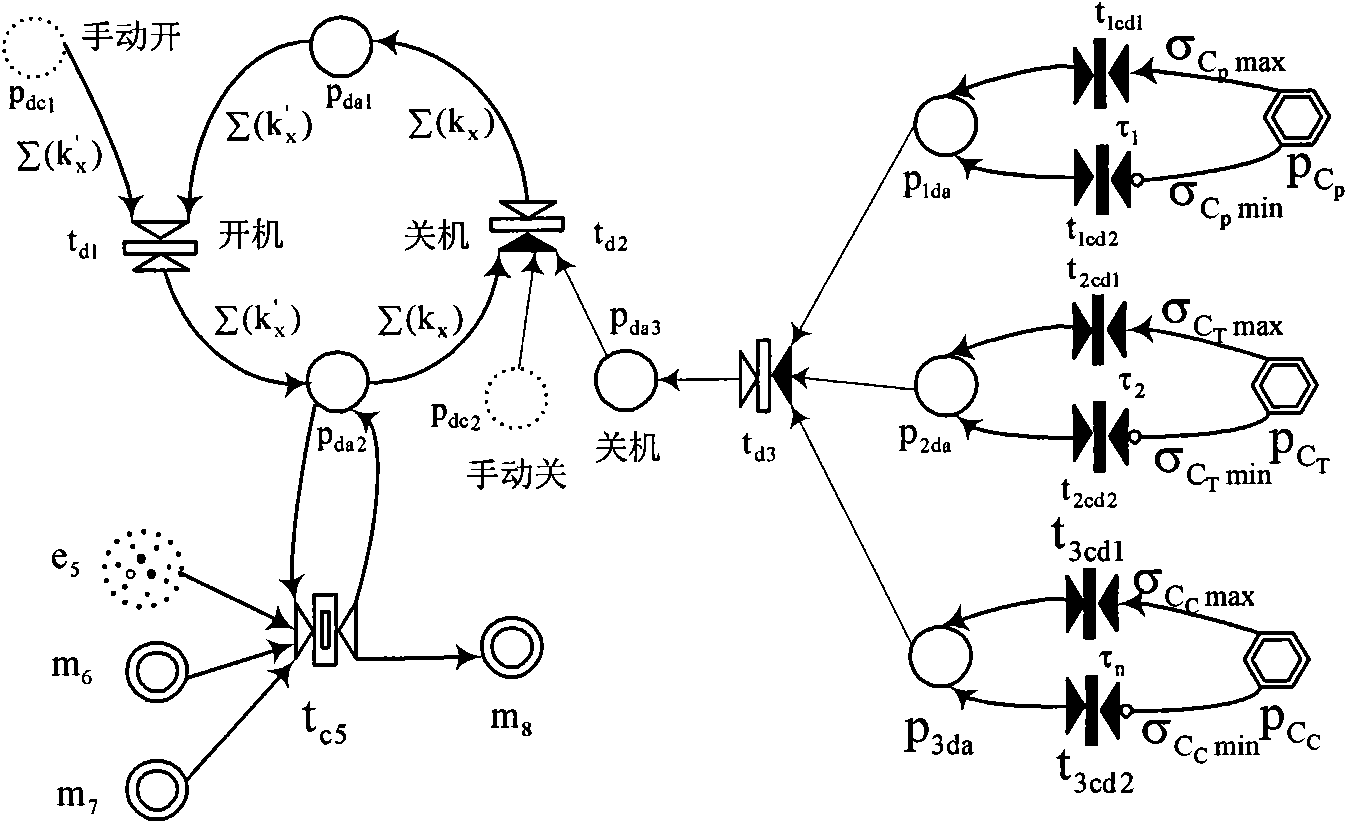

[0038] Implementation case: The production optimization link of the modeling system includes diaphragm electrolysis of salt water, the combination of chlorine and hydrogen to produce hydrochloric acid, the sodium method to produce bleaching powder and the ethylene oxychlorination method to produce vinyl chloride. There are three main raw materials: raw salt, lime slurry, and ethylene. Six products are produced, namely chlorine, hydrogen, caustic soda, hydrochloric acid, bleaching powder and vinyl chloride. Among them, chlorine is used as the raw material for the production of vinyl chloride, hydrogen and chlorine are used as the raw materials for the production of hydrochloric acid, and chlorine and caustic soda are the products of bleaching powder. Raw materials. Mainly consume three kinds of energy: water, electricity, steam, see figure 2 . Scheduling period T P =120 hours, see Table 1 for the scheduling plan. See the water consumption of the electrolyzer Figure 5 .

[0039...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com