Coffee machine with frothing device and method for cleaning milk suction line

A technology for coffee machines and bubblers, applied in beverage preparation devices, household appliances, applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

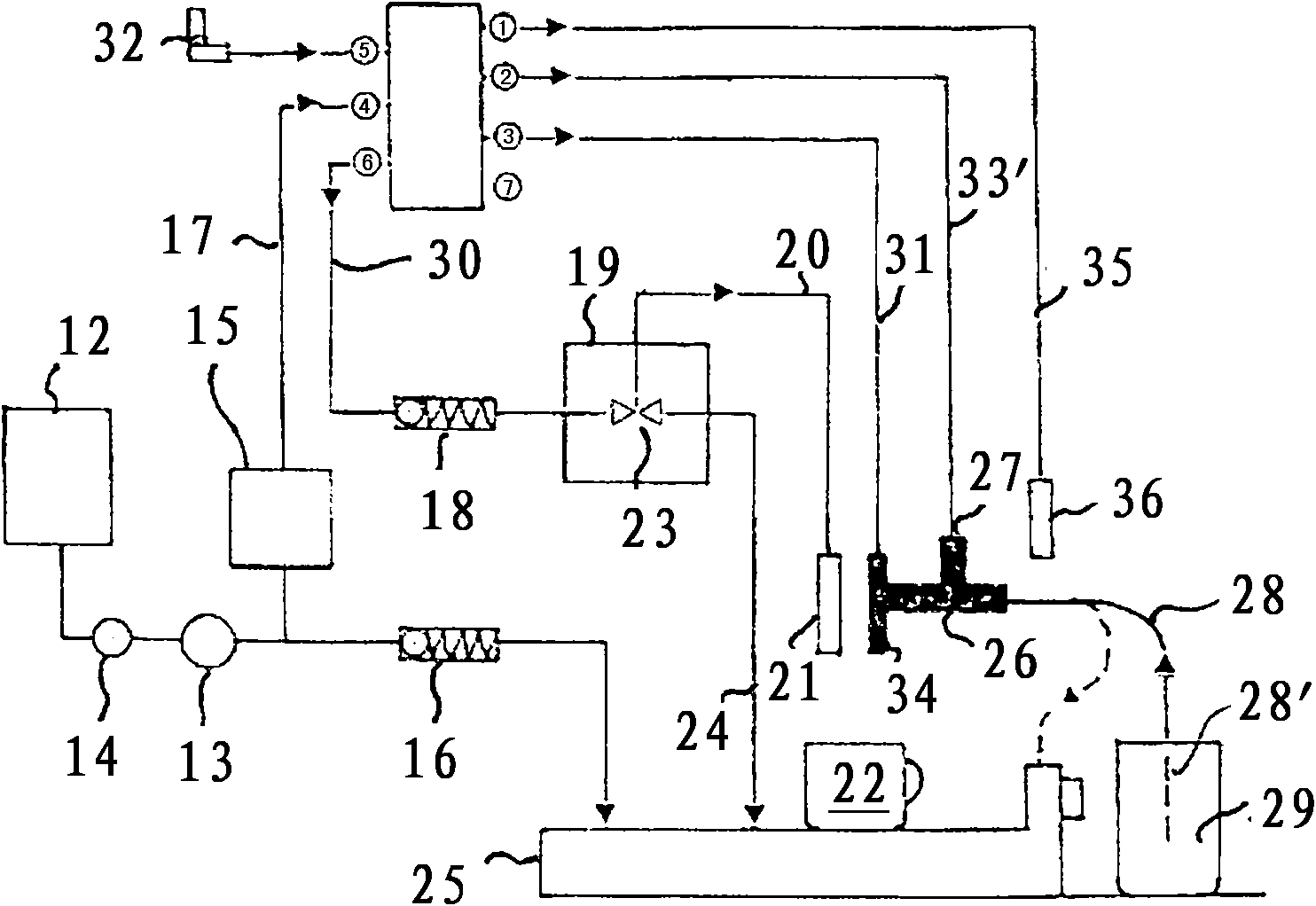

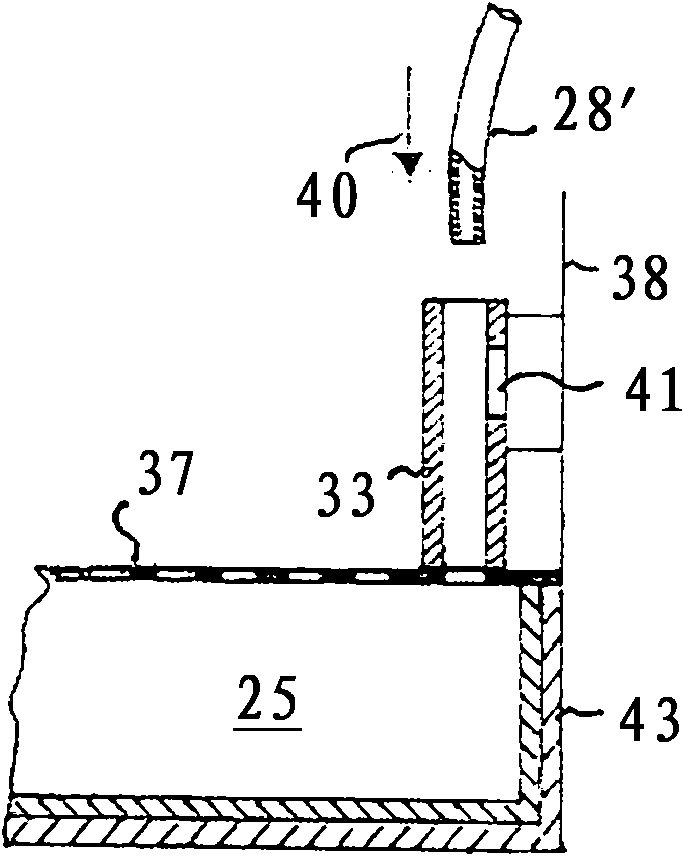

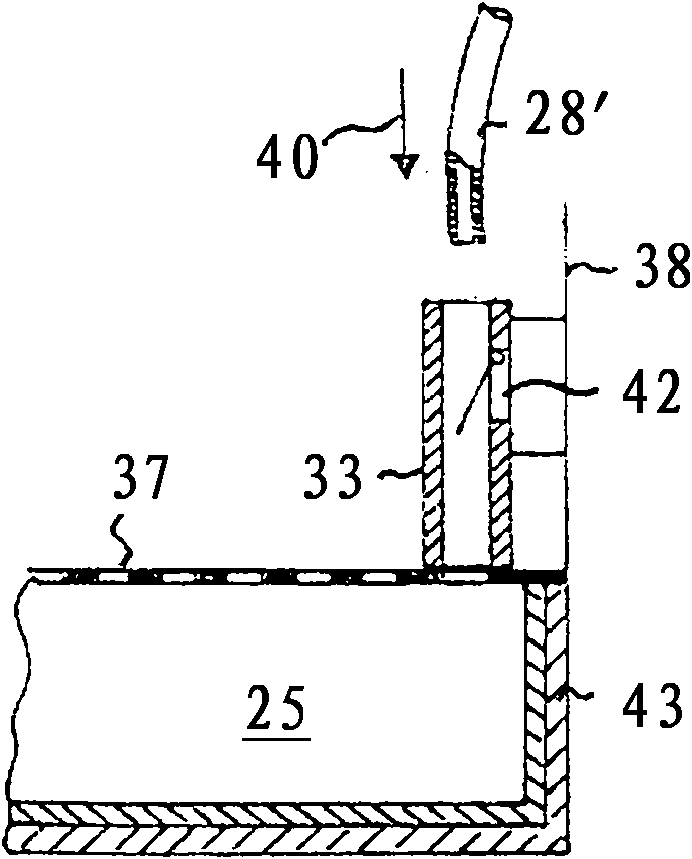

[0026] in the drawings, especially figure 1 , 3 The coffee machine shown in and 4 includes components for the normal preparation of coffee and milk froth, which are described together with their functions:

[0027] The coffee machine comprises a ceramic valve 10 with extended functions or positions relative to the ceramic valves of conventional coffee machines, wherein all adjustable positions are in image 3 shown in . The ceramic valve 10 includes ceramic valve inlets / outlets 1-7, which are described in detail further below. exist image 3 The upper row shows the connection diagrams a, b, c, d, e, which belong to the ceramic valve 10 according to the image 3 Five different positions in the lower row of middle. The position of the ceramic valve 10 is adjusted by a selector switch 11 on the front of the coffee machine, see Figure 4 .

[0028] For normal coffee preparation, the ceramic valve 10 is in the Figure 4 The position a, as further elaborated below.

[0029]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com