A special tool for replacing the 175t-rh sealing section air bag and its replacement method

A technology of special tools and replacement methods, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of low production efficiency, long replacement time, and high labor intensity, so as to improve the efficiency of maintenance operations, improve equipment utilization efficiency, and reduce labor costs. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

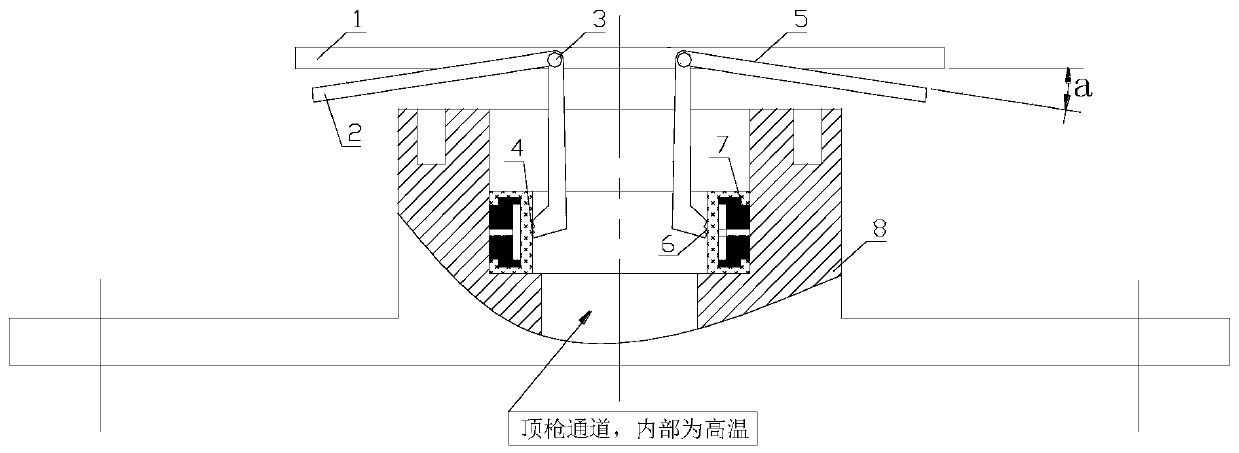

[0027] Such as figure 1 As shown, a special tool for replacing a 175T-RH sealing section airbag according to the present invention includes a fixed handle 1, a left movable handle 2, a pin shaft 3, a left clamping plate 4, a right movable handle 5, and a right clamping Plate 6, the left movable handle 2 and the right movable handle 5 are respectively hinged with the fixed handle 1 through the pin shaft 3, and the left clamping plate 4 and the right clamping plate 6 are respectively arranged on the left movable handle 2 and the right movable handle 5 the end of.

[0028] The left movable handle 2 and the right movable handle 5 are both "<" shaped two-bar linkages, which are symmetrically hinged along the midline of the fixed handle 1, and between the left movable handle 2 and the fixed handle 1 and between the right movable handle 5 and the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com