A split sliding heating oven for a battery production line

A production line, split-type technology, applied to the surface coating liquid device, pre-treatment surface, coating, etc., can solve the problems of wearing and connecting poles, etc., to achieve convenient operation, ensure safety, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

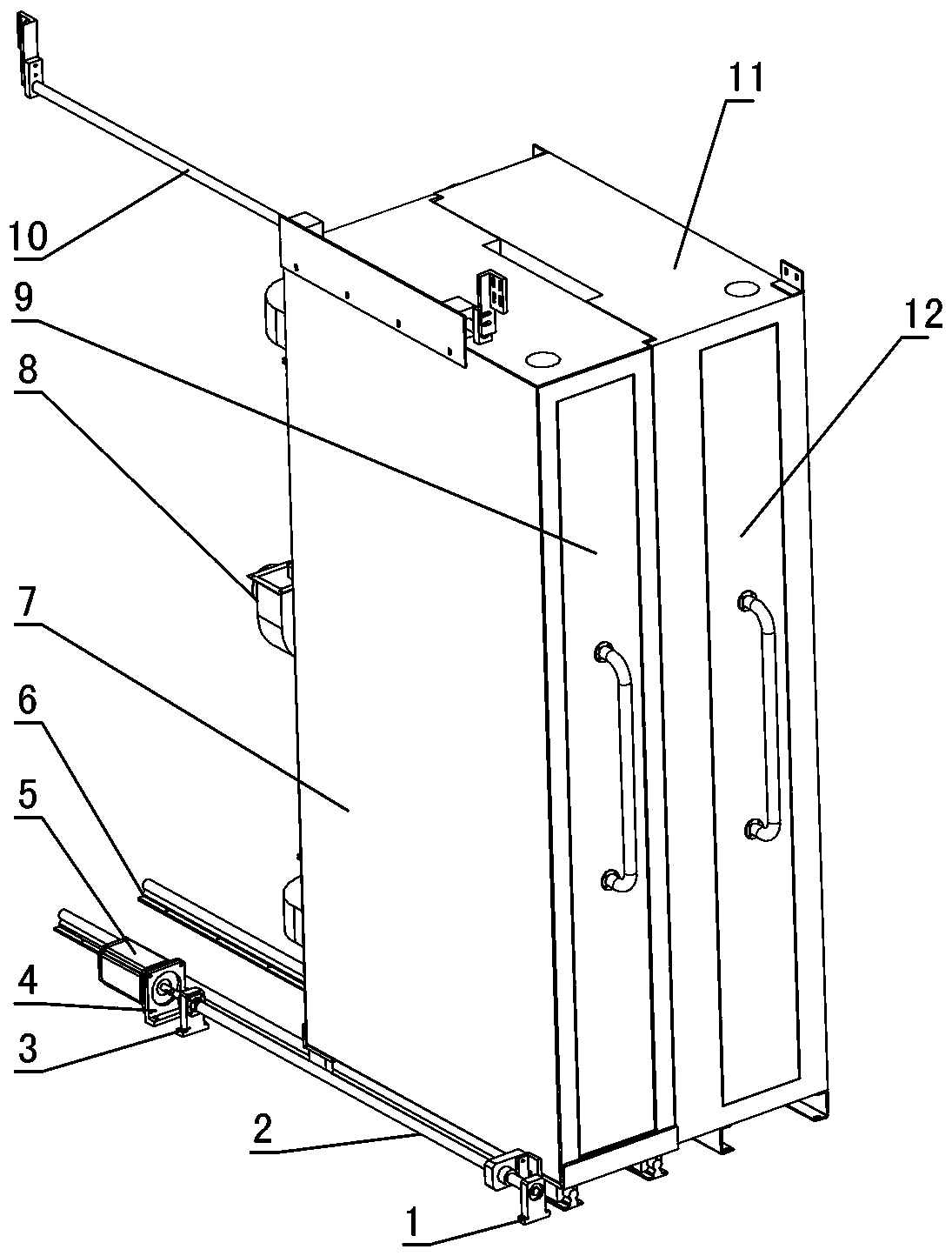

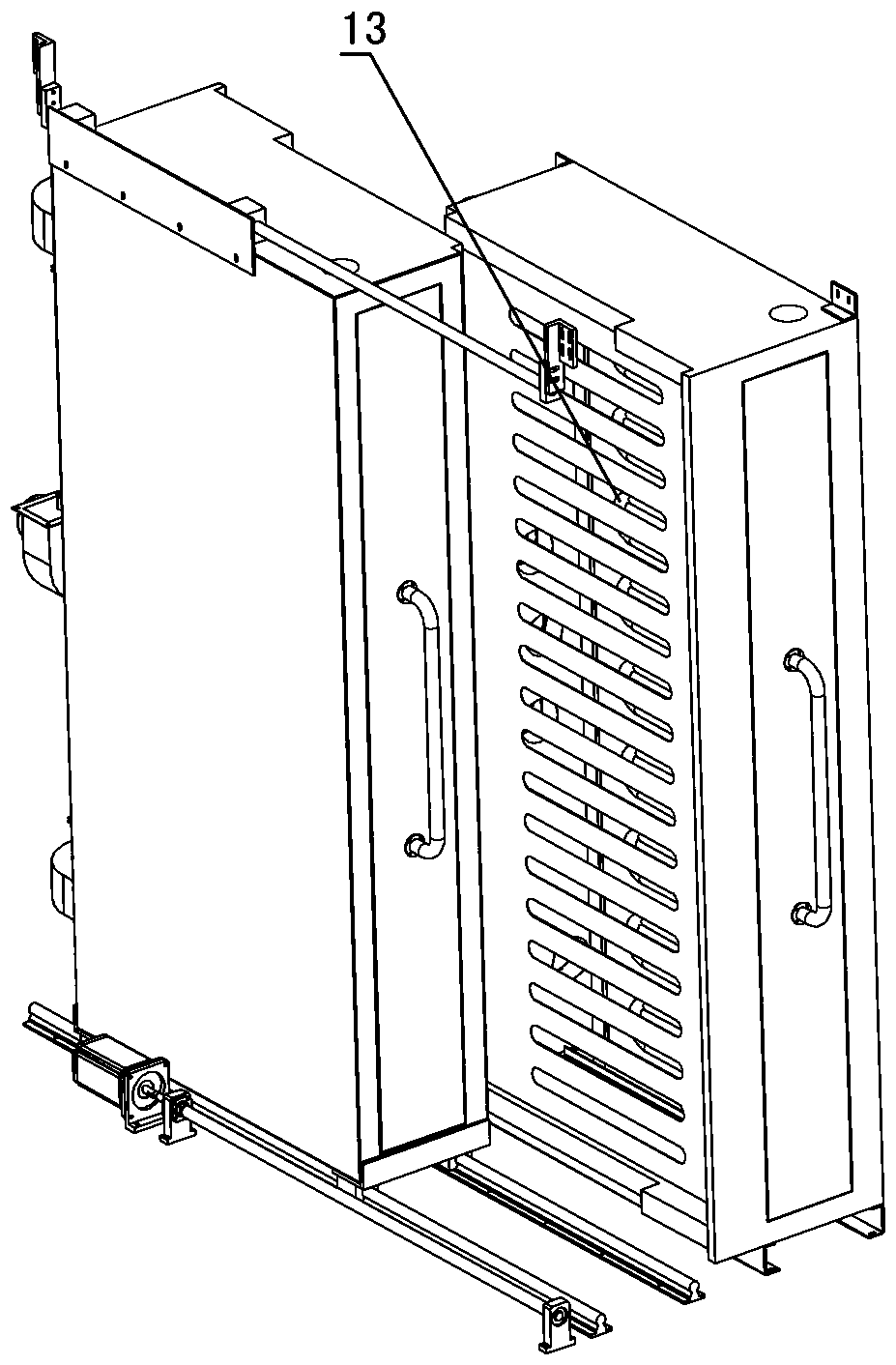

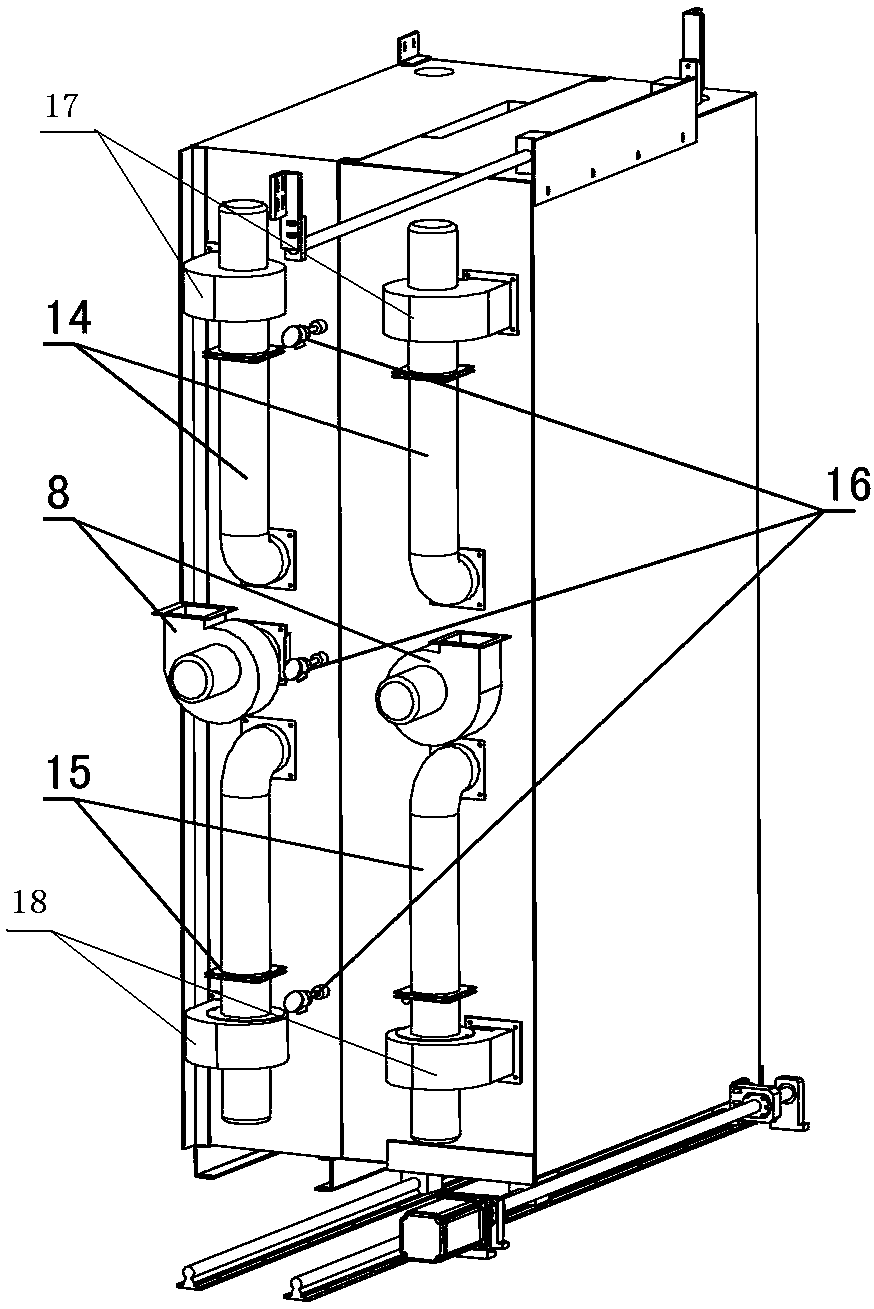

[0012] Such as Figure 1-4 As shown, a split-type sliding heating oven for a battery production line is composed of a fixed box part, a sliding box part and a driving mechanism. The fixed box 11 is fixed on the frame of the battery production line, the bottom of the sliding box 7 is placed on the lower linear guide rail 6, the upper end of the sliding box 7 is provided with an upper guide assembly 10, and the sliding box 7 is driven by a sliding drive mechanism. It can slide relative to the fixed box 11. The fixed box and the sliding box adopt a stepped structure to fit together. There is a sealing rubber strip 19 at the lap joint of the fixed box and the sliding box. This structure can ensure the sealing Good performance, no damage to the pole be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com