Continuous type high-temperature and high-speed gas-solid two-phase flow erosion abrasion test device

A wear test, high-speed technology, used in measuring devices, testing wear resistance, instruments, etc., can solve the problems of effective research of test devices and unclear erosion mechanism, and achieve environmental protection and energy, reduce temperature, and effectively use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with drawings and embodiments.

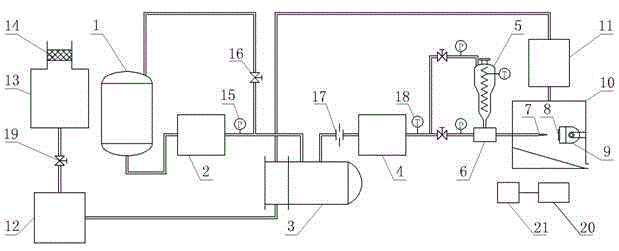

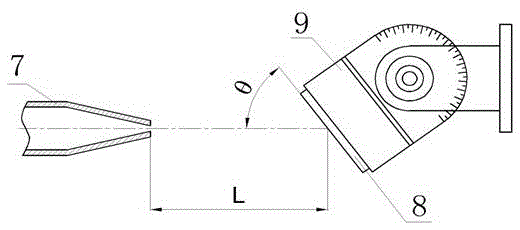

[0018] Such as figure 1 As shown, the present invention comprises a dehumidifier 1, an air compressor 2, an air heat exchanger 3, a heater 4, a storage tank 5, a mixing chamber 6, a nozzle 7, a test bench 9, a test box 10, and a cyclone separator 11 , air cooler 12, pool 13, foam breaking net 14, three pressure gauges 15, three ball valves 16, flowmeter 17, two thermometers 18, check valve 19, high-speed camera 20 and computer 21.

[0019] The bottom of the dehumidifier 1 is divided into two paths after the air compressor 2 and the first pressure gauge 15. One path is connected to the heater 4 through the air heat exchanger 3 and the flow meter 17, and the other path is connected to the top of the dehumidifier 1 through the first ball valve 16. Connected, the heater 4 outlet is connected to the first thermometer 18 and then divided into two paths, one path is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com