Polymer emulsion and preparation method thereof

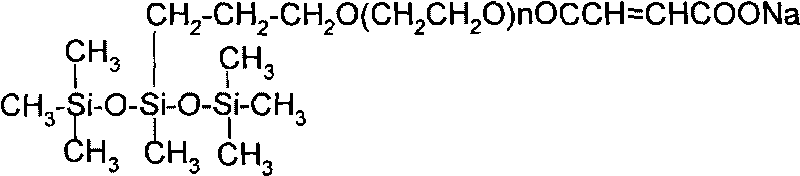

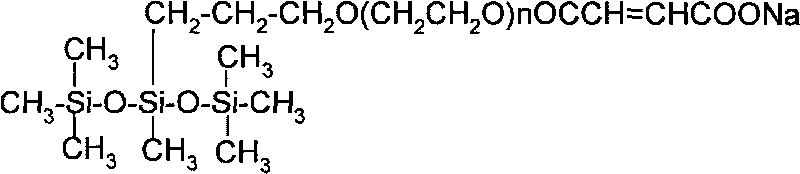

A technology of polymer emulsion and emulsifier, applied in the field of polymer emulsion and its preparation, can solve the problems of little research on polymerizable emulsifier, affecting water resistance of membrane, etc., to avoid potential safety and health risks, improve water resistance, and simple reaction process easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Put 50g of styrene, 18g of butyl acrylate, 3.6g of acrylic acid and 24g of deionized water into a 250ml four-necked flask and stir, add 2g of polymerizable silicone emulsifier PMSC (n=5~6), heat up to 25°C and add 0.32 g ammonium persulfate, stirred for 30 minutes to adjust pH=7 for subsequent use. Add 50g of deionized water, 0.16g of ammonium persulfate, 0.24g of sodium bicarbonate, and 0.24g of emulsifier PMSC into a 250ml four-neck flask. Under nitrogen protection, stir and heat up to 70°C, add 20g of pre-emulsion, and continue to heat up to At 82°C, the inside of the flask began to turn blue, and the pre-emulsion was added dropwise. The temperature was controlled at about 85°C, and the dropping speed was controlled so that the monomer pre-emulsion was dripped for 2.5 hours. After the dropwise addition, 0.14 g of ammonium persulfate was added, kept for 1.5 h, cooled to 40°C at room temperature, and adjusted to PH=7 to obtain the product. The latex film of the produc...

Embodiment 2

[0022] Put 48g of methyl methacrylate, 12g of methyl acrylate, 1g of octadecyl acrylate, 4g of acrylic acid and 23g of deionized water into a 250ml four-necked flask and stir, then add 2.2g of polymerizable silicone emulsifier PMSC (n=3~ 4), heat up to 30°C, add 0.3g ammonium persulfate, stir for 1 hour, adjust pH=6.9 for later use. Add 50g of deionized water, 0.15g of ammonium persulfate, 0.22g of sodium bicarbonate, and 0.28g of emulsifier PMSC into a 250ml four-neck flask. Under nitrogen protection, stir and heat up to 73°C, add 15g of pre-emulsion, and continue to heat up to At 80°C, the inside of the flask began to turn blue, and the pre-emulsion was added dropwise. The temperature was controlled at 85°C, the dropping speed was controlled, and the monomer pre-emulsion was dripped in 2 hours. After the dropwise addition, 0.15 g of ammonium persulfate was added, kept for 1 h, cooled to 30° C. at room temperature, and adjusted to PH=8 to obtain the product. The latex film o...

Embodiment 3

[0024] Put 60g of butyl methacrylate, 20g of butyl acrylate, 1.4g of octadecyl acrylate, 4g of acrylic acid and 35g of deionized water into a 250ml four-necked flask and stir, add 3g of polymerizable silicone emulsifier PMSC (n=7~ 8), heat up to 25°C, add 0.4g of ammonium persulfate, stir for 30 minutes to adjust pH=7.3 for later use. Add 45g of deionized water, 0.2g of potassium persulfate, 0.28g of sodium bicarbonate, and 0.3g of emulsifier PMSC into a 250ml four-neck flask. Under nitrogen protection, stir and heat up to 70°C, add 30g of pre-emulsion, and continue to heat up to At 80°C, the inside of the flask began to turn blue, and the pre-emulsion was added dropwise. The temperature was controlled at 84°C, and the dropping speed was controlled. The monomer pre-emulsion was dripped in 2.2 hours. After the dropwise addition, 0.14 g of potassium persulfate was added, kept at temperature for 1.5 h, cooled at room temperature to 35° C., and adjusted to pH = 7.5 to obtain the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal decomposition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com