Successive type deep tissue stitching instrument

A technology for deep tissue and suturing devices, applied in the field of medical devices, can solve problems such as poor stability, non-continuous operation, complex production process, etc., and achieve the effects of easy replacement, stable operation, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

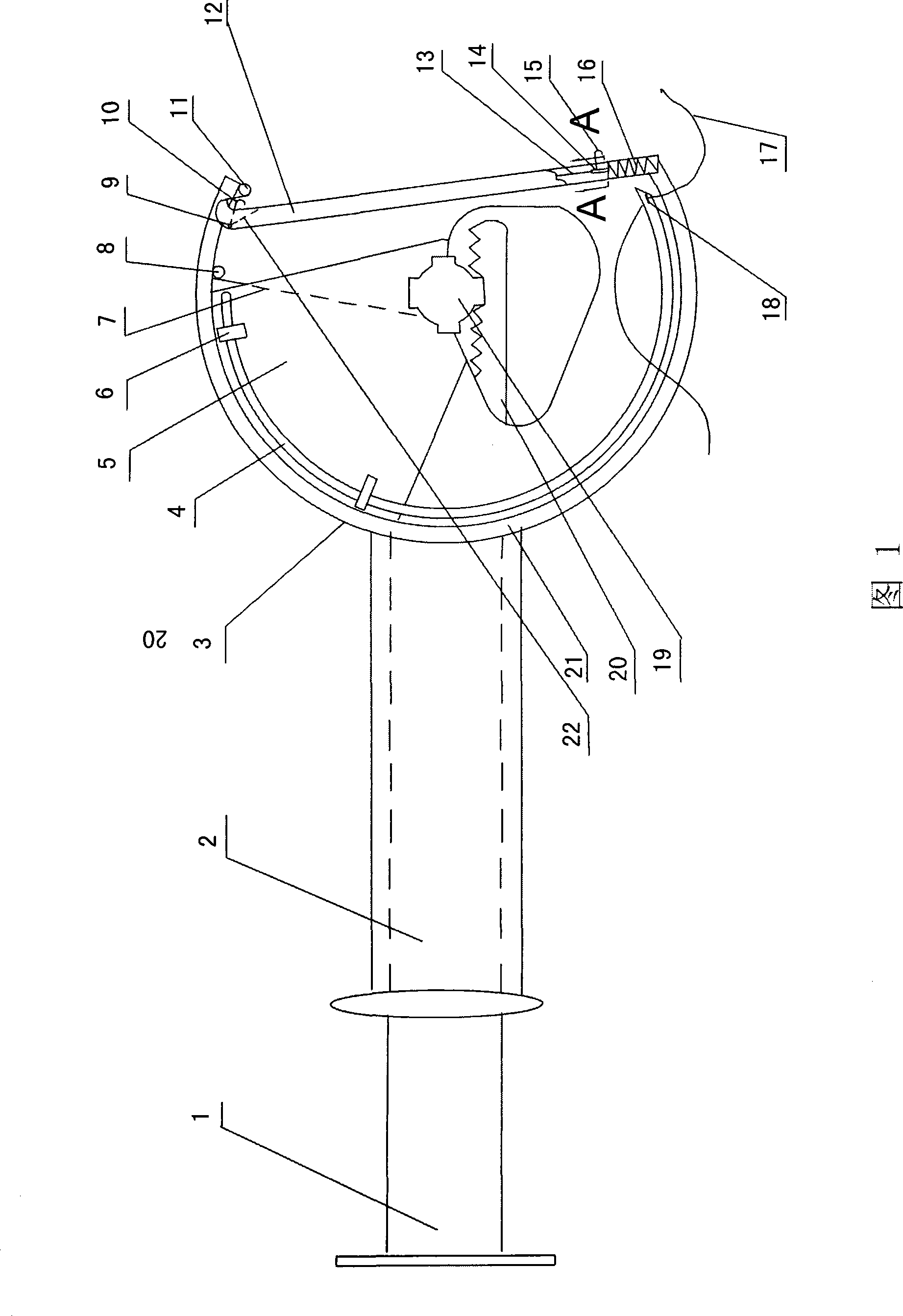

[0015] Figure 1, figure 2 Shown:

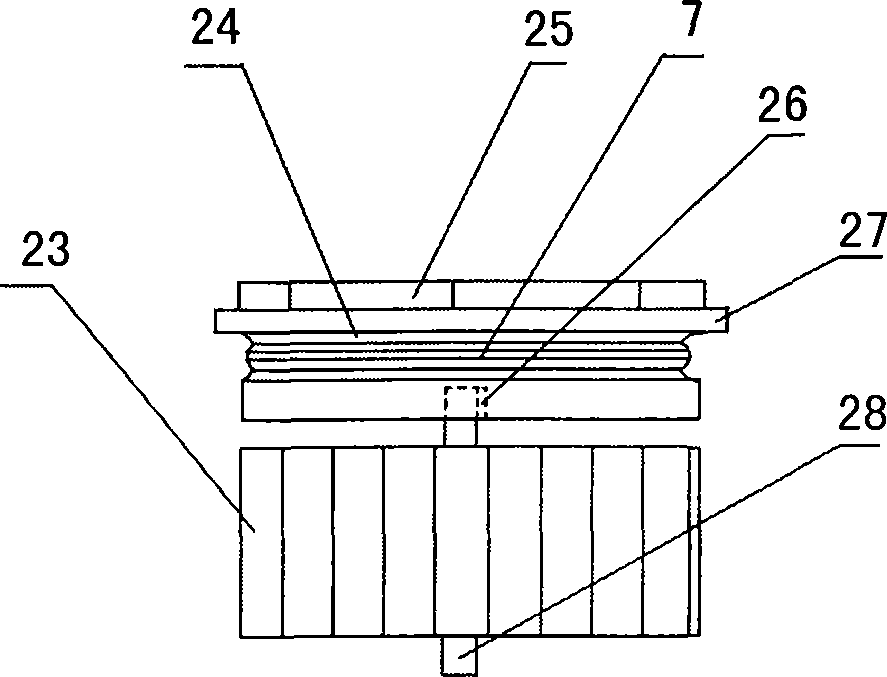

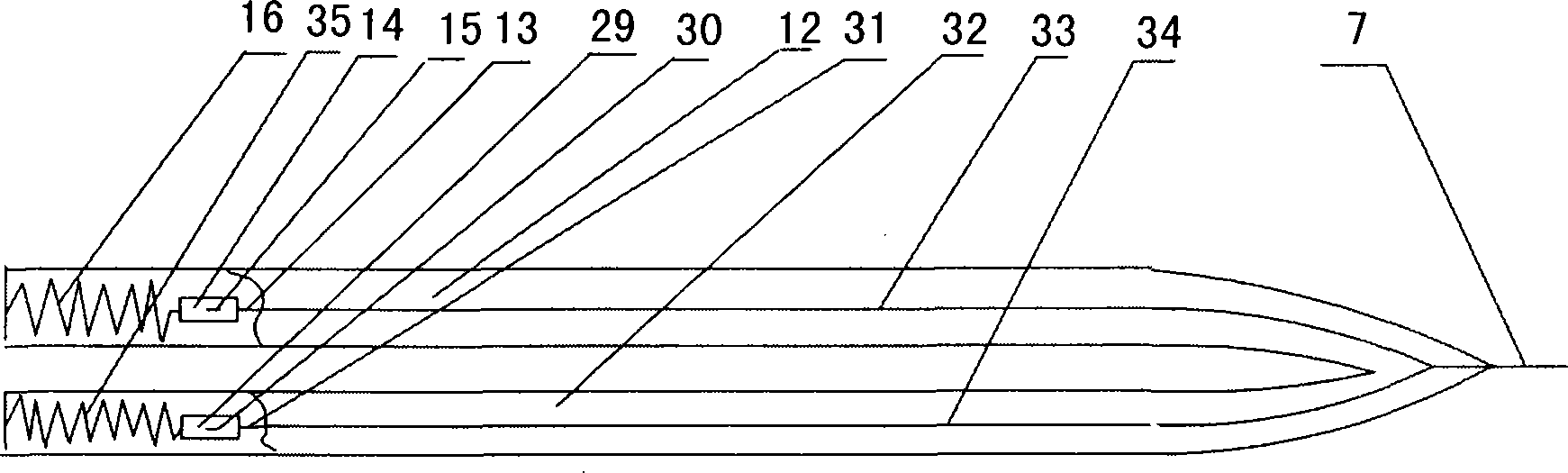

[0016] The continuous deep tissue suturing device proposed by the present invention includes an inner rod, an outer cylinder, and a suturing needle, and is characterized in that: there is a casing 3, a driving mechanism and a thread locking device, and the casing 3 is closed by the upper and lower parts to form a closed type. One side of the arc has an outer edge 21 that is higher than the plane. The driving mechanism has an inner rod 1, a rack 19, a central shaft 19, and a needle spinner 5. 19 traverses the center of the upper plane of the shell 3, the upper and lower ends of the shaft core 28 of the central shaft 19 are respectively embedded in the bearings fixed on the upper and lower parts of the shell 3, the bottom part of the central shaft 19 is provided with a gear 23, and the gear 23 is fixed to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com