Fully-automatic film laminator

A film laminating machine, fully automatic technology, applied in packaging and other directions, can solve the problems of inability to achieve large-scale automated assembly operations, inability to guarantee lamination accuracy, and inability to guarantee lamination accuracy, etc., to achieve automated assembly operations, Simple structure and enhanced fit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

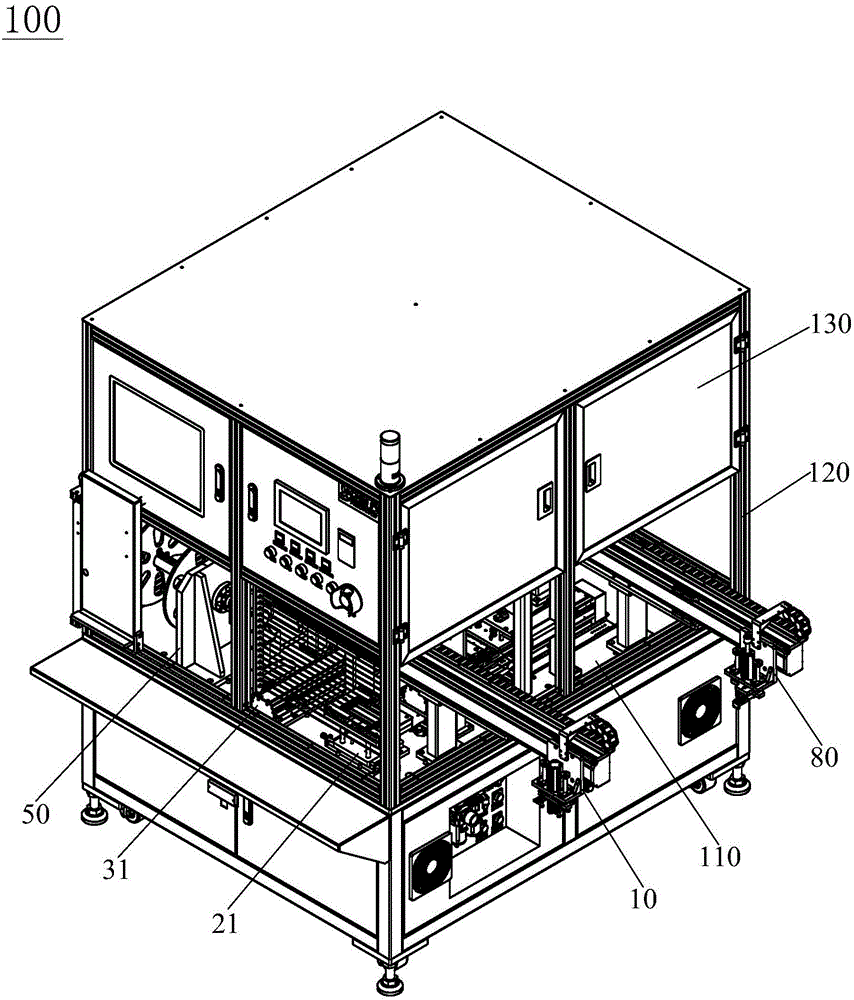

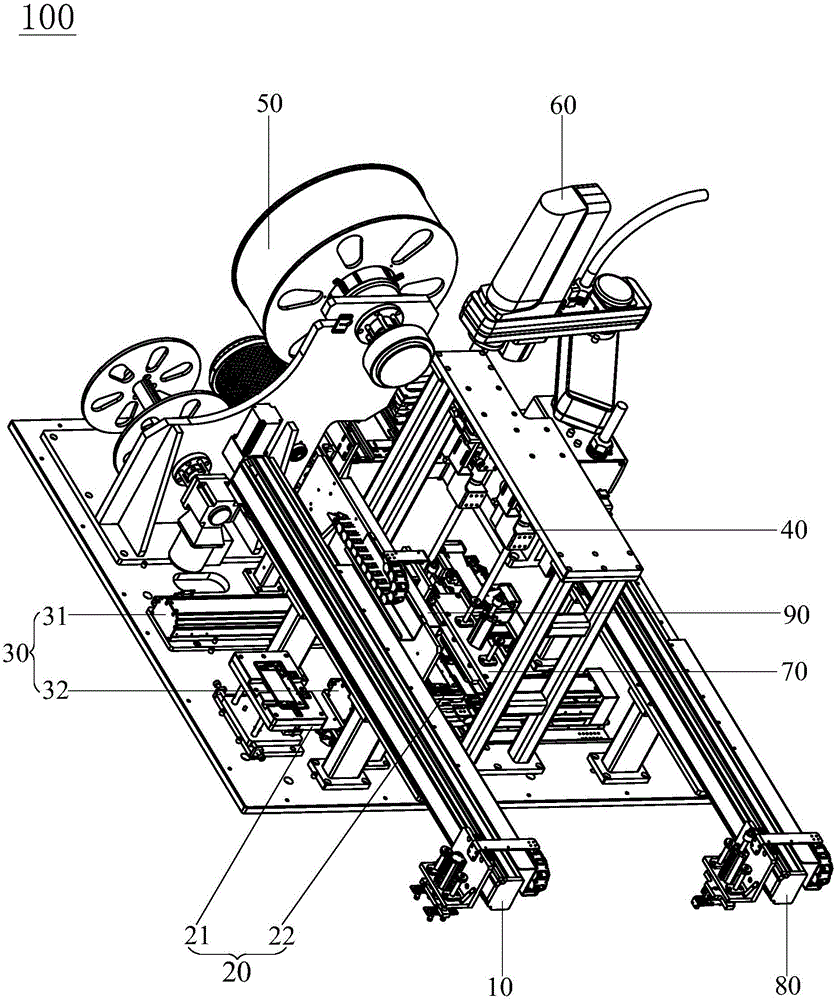

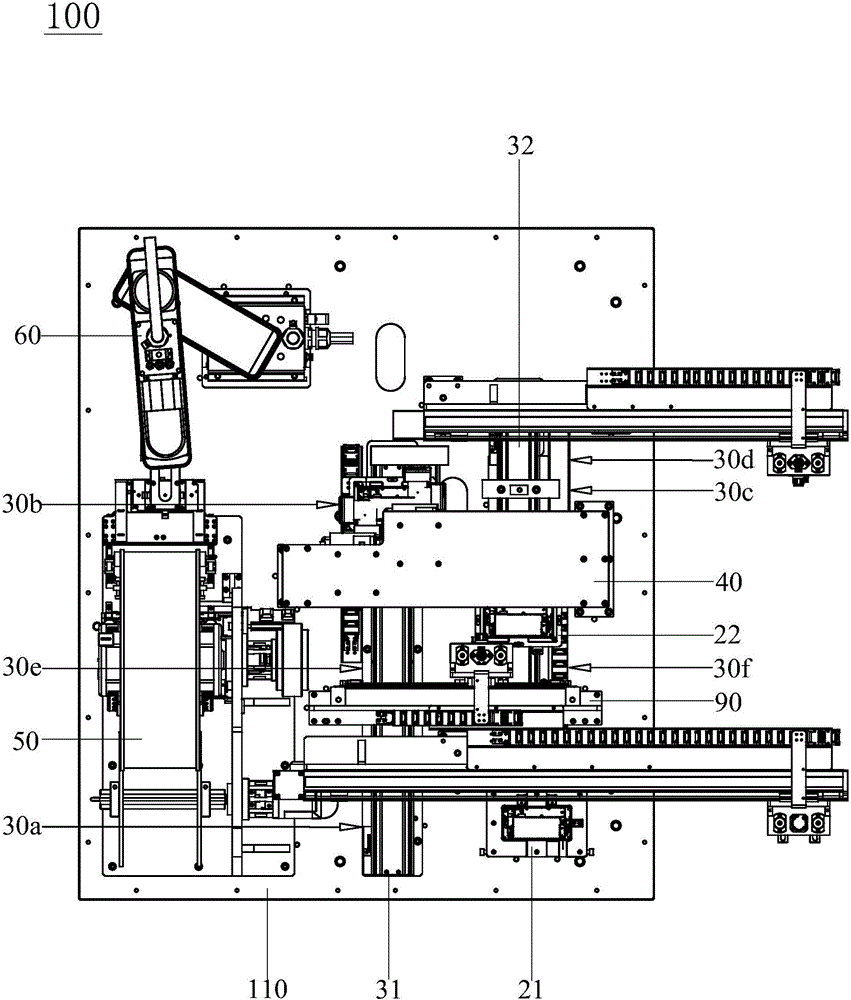

[0033] see Figure 1 to Figure 15 , the present invention discloses a fully automatic film laminating machine 100, which is used for laminating a film 200 and a mobile phone case 300. The film 200 is specifically a reflective film, a lower light-enhancing film or an upper light-enhancing film, etc. of a mobile phone display screen. There are multiple diaphragms 200, and the plurality of diaphragms 200 are equidistantly pasted on the tape 400, and the tape 400 pasted with the diaphragms 200 is coiled. The mobile phone case 300 is specifically the front case of the mobile phone. The fully automatic film laminating machine 100 of the present invention is suitable to be electrically connected with a controller (not shown in the figure), and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com