Automatic cleaning and disinfecting system for floating seedling-raising disks

A floating seedling raising and automatic cleaning technology, applied in cleaning methods and utensils, cleaning methods using liquids, cleaning methods using tools, etc., can solve the problems of lack of mechanized cleaning equipment, difficulty in meeting production needs, and difficulty in improving cleaning speed , to achieve good disinfection effect, good social and economic benefits, and low damage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

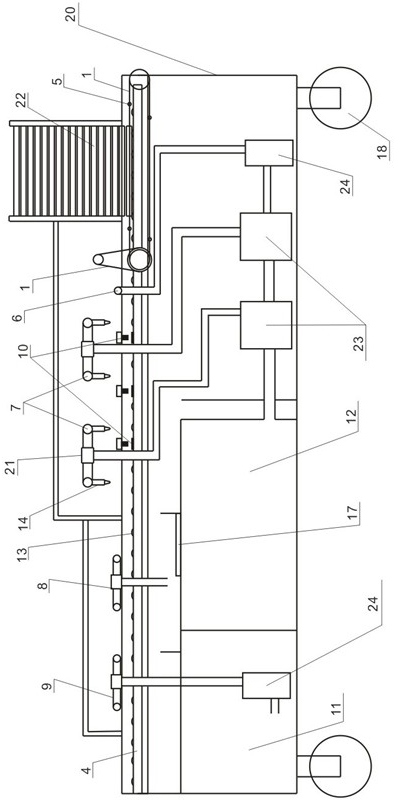

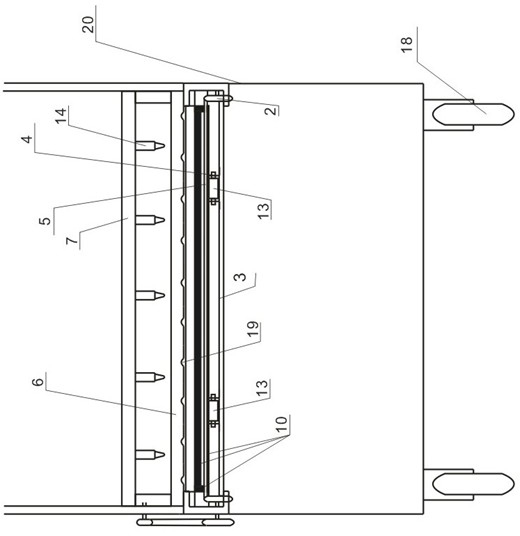

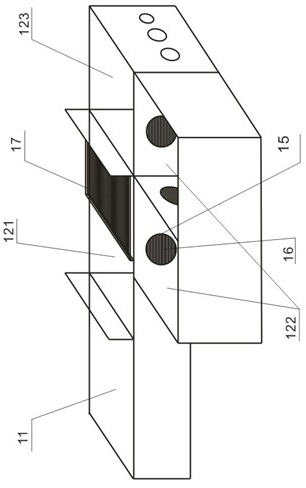

[0017] Embodiment: the automatic cleaning and disinfection system of the floating seedling raising tray of the present invention, the frame 20 is made of metal materials such as iron or steel, the crossbeam is welded on the frame, the support rail 4 is fixed on the crossbeam in parallel, and the small rollers 13 in the support rail 4 Adopt plastic small wheel and get final product, when floating seedling raising dish 22 runs on support rail, the setting of small roller is arranged, can reduce the frictional resistance between floating seedling raising dish and support rail, run smoothly, reduce damage; Circular steel pipes are welded on the chains 1 on both sides, and are used to push the floating seedling tray to run on the support rail. The pusher 5 can also use steel plate or iron plate, as long as its upper edge is not higher than the thickness of the floating seedling tray. ; A plurality of water outlet holes 19 are evenly opened on the bottom surface of the pre-wet pipe 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com