Shoulder injecting device and related shoulder injecting method for hose upper part

A hose and shoulder injection technology, applied in the field of hoses, can solve the problems of low efficiency and slow speed, and achieve the effect of high efficiency, fast shoulder injection, and suitable for large-scale promotion and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

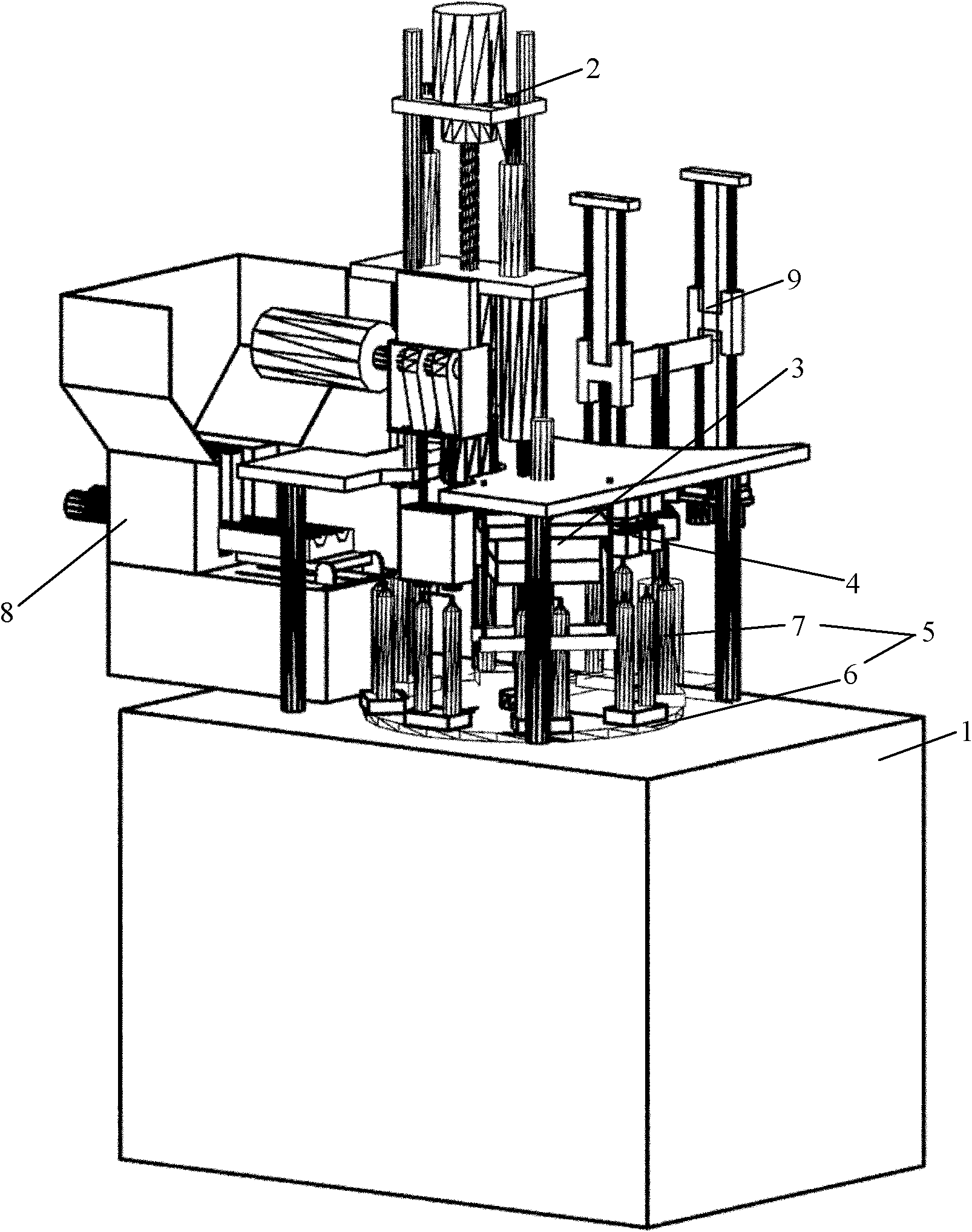

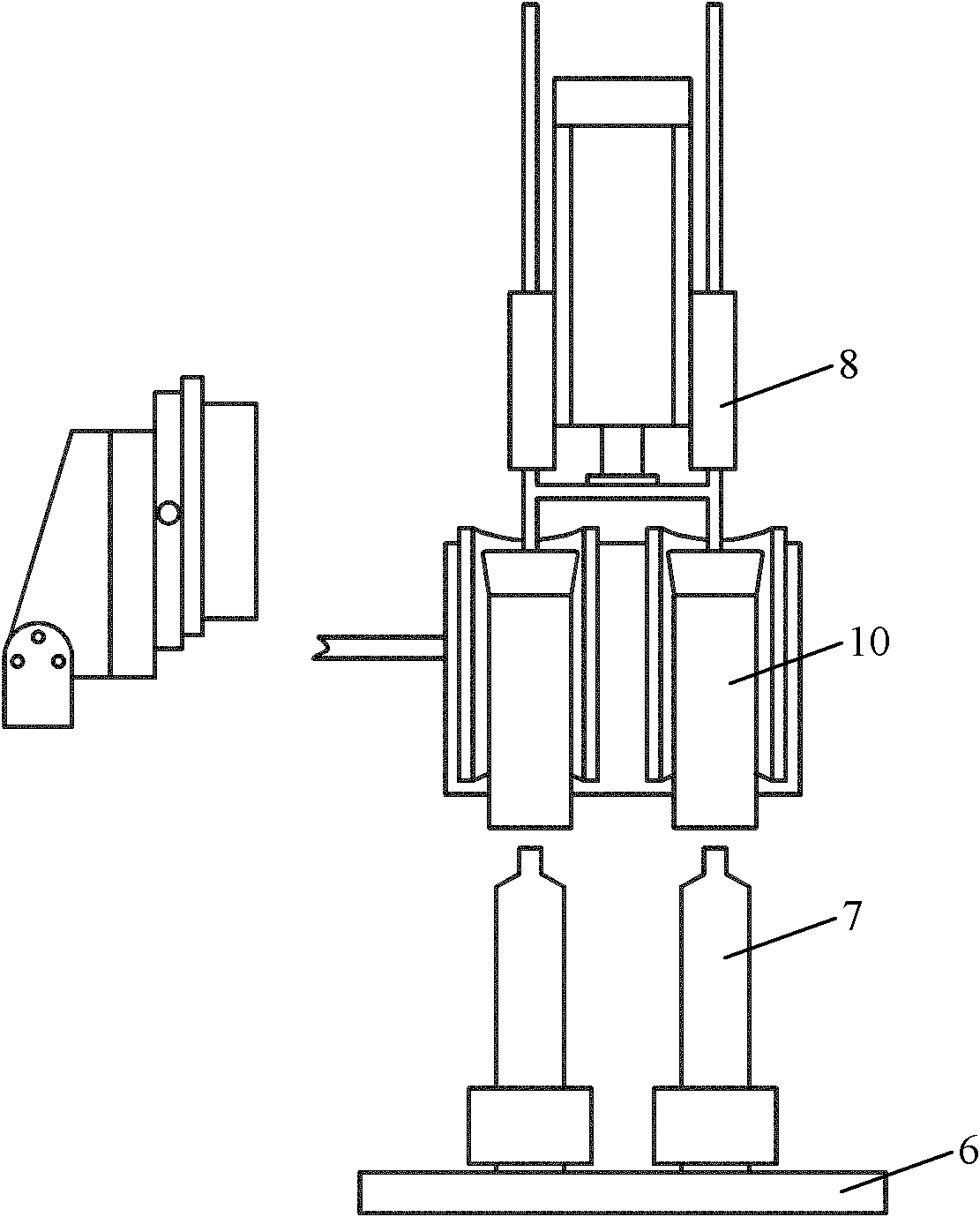

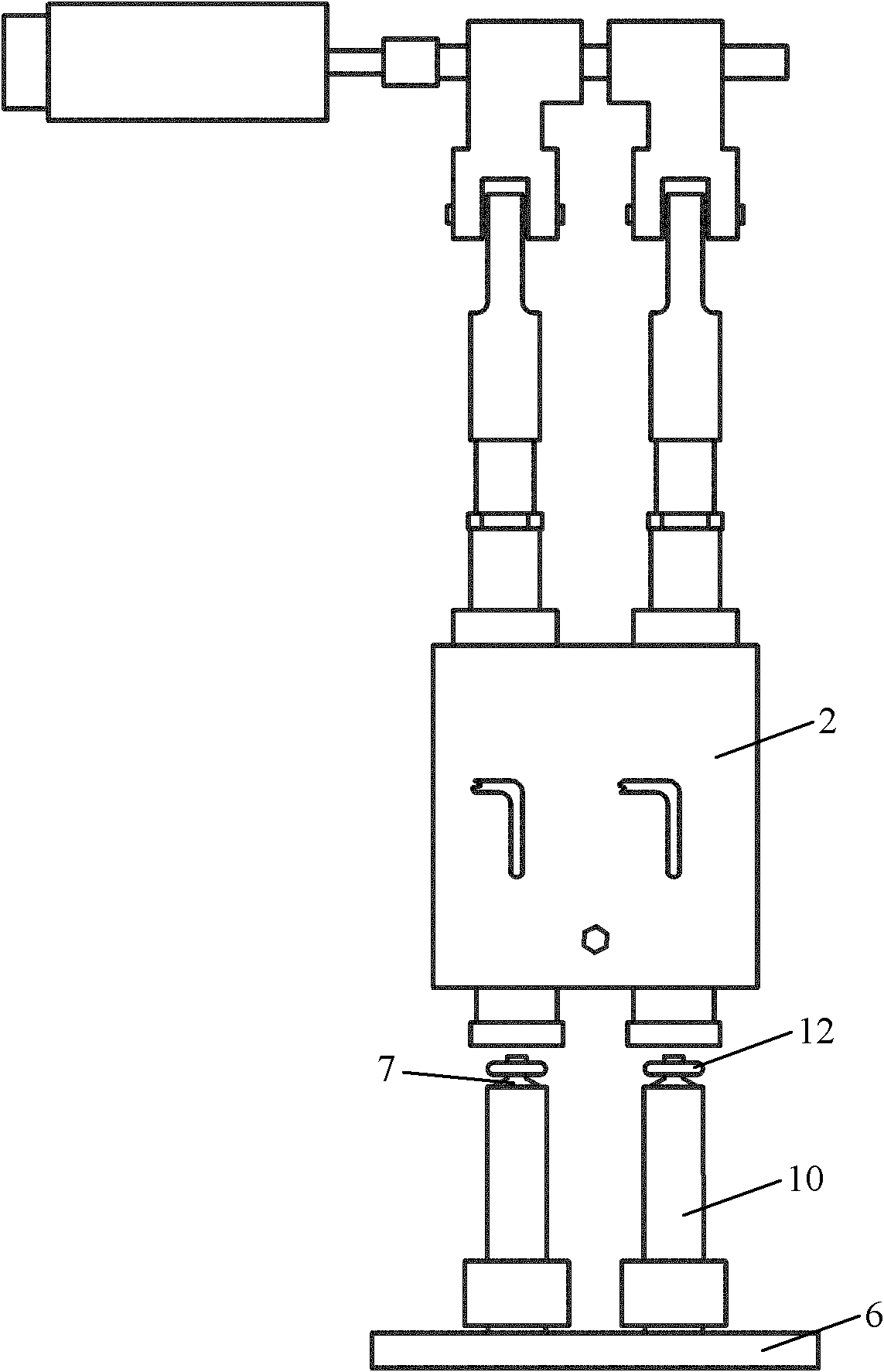

[0029] See Figure 1-7 As shown, the hose upper shoulder injection device of the present invention includes a control mechanism (not shown), a frame 1 and an injection molding mechanism 2 arranged on the frame 1, a tube shoulder molding mechanism 3, and a cooling molding mechanism 4. Turntable assembly 5 and driving parts (not shown), said turntable assembly 5 includes a turntable 6 and a number of mandrels 7, said mandrel 7 is arranged on said turntable 6 and is formed with respect to the center of said turntable 6 Arranged in a circle, the driving parts are connected to the turntable 6 to drive the turntable 6 to rotate, the injection molding mechanism 2, the shoulder molding mechanism 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com