Double light path optical-fiber laser bonding machine for plate-type solar thermal absorber

A technology of solar heat absorber and fiber laser, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of increasing product cost, labor and time-consuming welding, and difficult welding, so as to improve efficiency and reduce production The effect of low cost and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples are used to illustrate the present invention and uses thereof, but are not intended to limit the protection scope of the present invention.

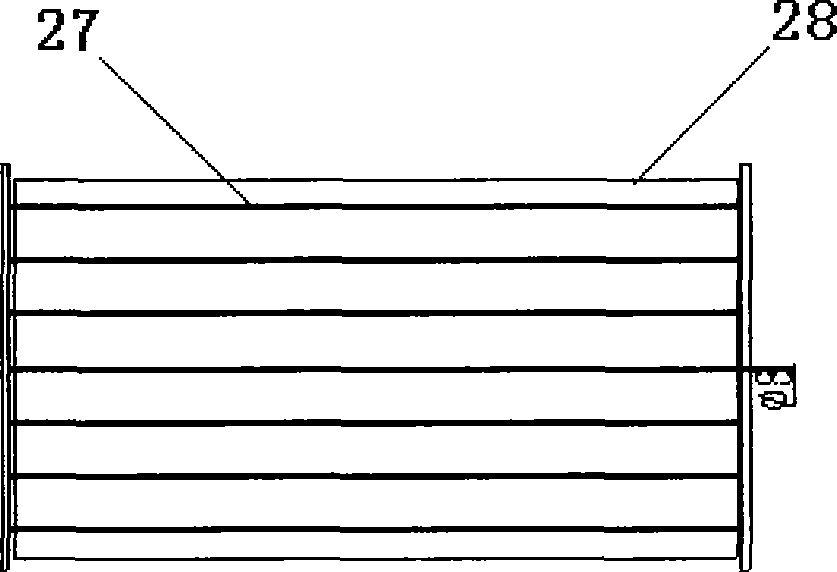

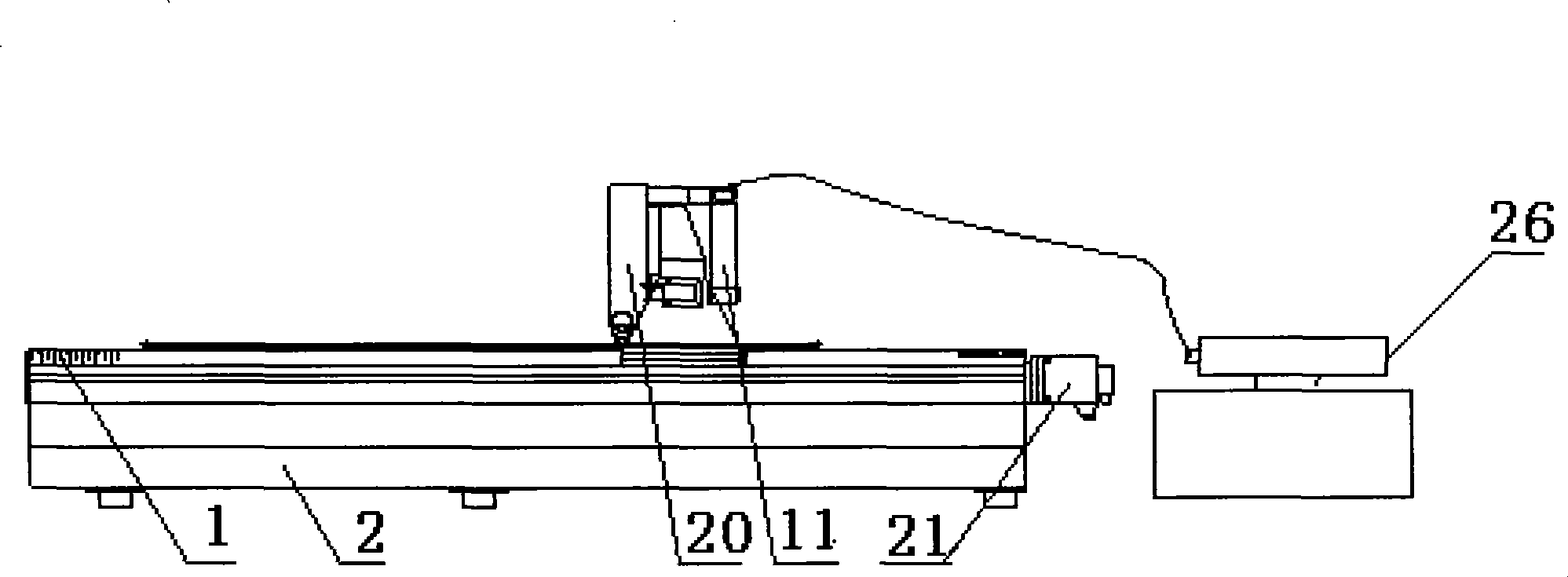

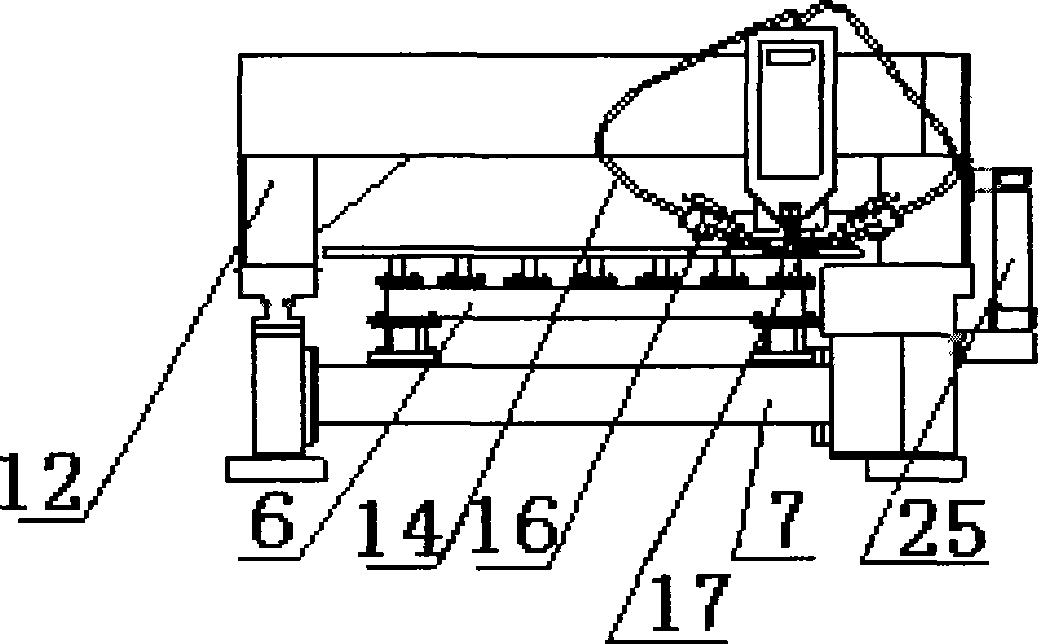

[0026] see figure 2 , image 3 A kind of dual optical path fiber laser welding machine for plate solar heat absorber of the present invention is made up of laser 26, two optical fibers 14, two cover focusing systems 16, base unit, gantry unit. in:

[0027] see Figure 4 , Figure 5 , The base device is made up of base 2, connecting seat 8, two pairs of X-direction guide rail slider pair 3, X-direction screw nut pair 9, X-direction motor 4, and positioning bed 6. Among them, the left column 5 and the right column 10 of the base 2 are connected into a whole by four connecting rods 7, two pairs of X-direction guide rail slider pairs 3 are installed on the base 2, and the X-direction screw nut pair 9 and the X-direction motor 4 Connections are also made on base 2. Six connecting seats 8 are connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com