Dewatering, drying and coating equipment for microwave waterborne wood paint furniture, and coating method

A technology of water-based wood lacquer and coating equipment, which is applied in the direction of liquid-coating devices, coatings, and pre-treated surfaces, etc. It can solve problems such as uneven heating temperature of the compartment, cracking of furniture, and difficulty in popularizing water-based wood lacquer. , to achieve the effect of uniform heating temperature and furniture moisture content, and stress relief

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

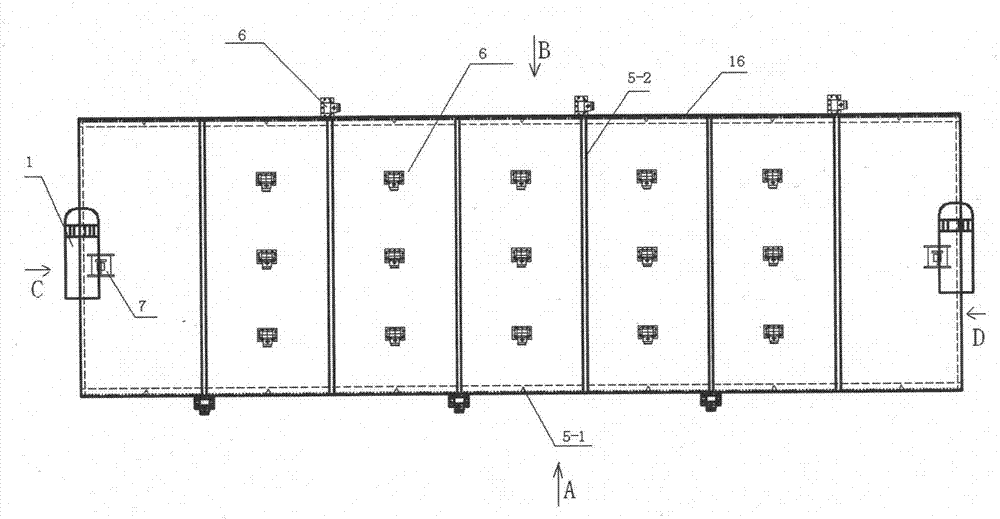

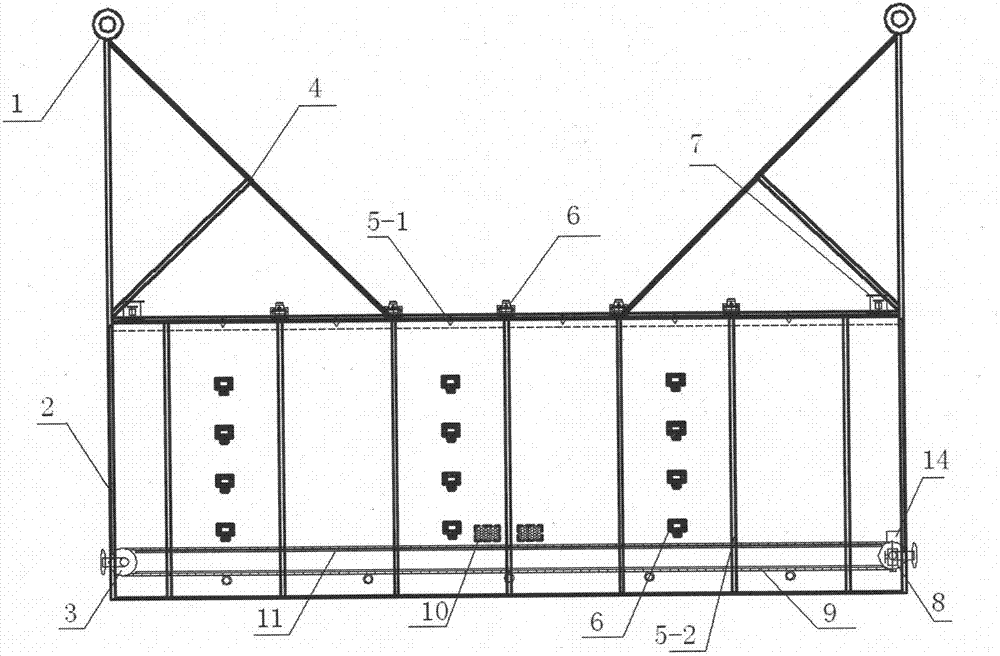

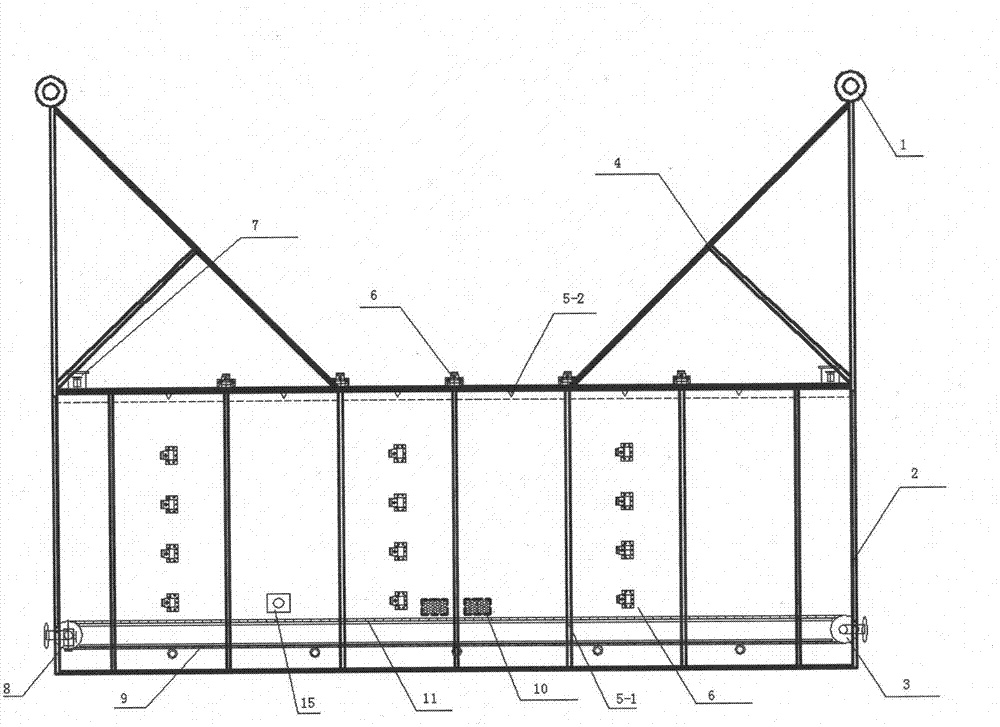

[0025] Such as Figure 1 to Figure 4 As shown, the present invention provides a microwave water-based wood paint furniture water-lifting and drying coating equipment, which includes a box body 16, and sliding doors 2 are respectively arranged at the inlet end and the outlet end of the box body 16. One end of steel wire rope 12 is fixedly connected with sliding door 2, and the other end is connected on the lifting motor 1. The lifting motor 1 is fixed on the support 4, and the support 4 is fixed on the top of the casing 16. The lifting motor 1 drives the movable door 2 to rise or fall through the wire rope 12 . After moving door 2 descends in place, moving door 2 is locked by locking cylinder 13. Inside the box 16 there is a conveyor belt 9 for transporting the furniture. The conveyor belt 9 is made of a material that does not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com